The Jeep Cherokee XJ is one of the most iconic compact SUVs ever made. Produced between 1983 and 2001, it developed a reputation for being rugged, durable, and capable both on and off the road. Its simple design and reliable engineering helped it become a favorite among off-road enthusiasts, daily drivers, and people looking for a solid, affordable vehicle.

Yet, despite its reputation for toughness, many Jeep Cherokee XJs face reliability issues much earlier than expected. The key to keeping these vehicles running well often lies in understanding the common pitfalls that cause premature failures and damage.

There are several factors that can quickly deteriorate the reliability of a Jeep Cherokee XJ. Some of these factors are related to neglect or poor maintenance, while others come from inherent design weaknesses or typical usage patterns.

Owners who are unaware of these issues or who overlook important maintenance can experience costly repairs, frustrating breakdowns, and a shorter lifespan for their vehicles. From mechanical failures to electrical gremlins, these problems tend to build up quietly over time, often caught only after major damage has already occurred.

Understanding what specifically affects the Cherokee XJ’s reliability is crucial for any current or prospective owner. It helps identify red flags early and allows for preventative measures to be taken before problems escalate.

Moreover, knowing the history of common failures enables owners to make informed decisions when buying used models or customizing their Jeep for off-road use. Each of the nine issues listed here plays a significant role in how the Cherokee XJ performs over the long haul, and recognizing them can save both money and headaches.

In the following sections, each problem is explained in detail, highlighting how it develops, why it matters, and what can be done to avoid or fix it. Whether you own a Cherokee XJ now or are considering purchasing one, this guide will give you a clearer picture of the potential reliability pitfalls and how to keep your Jeep running strong.

Also Read: 5 SUVs with Seats Comfortable for 8-Hour Drives and 5 That Cause Back Pain

1. Neglected Rust and Frame Corrosion

One of the biggest enemies to the Jeep Cherokee XJ’s reliability is rust, particularly on the frame and underbody. Due to the vehicle’s age, many XJs are already past the 20- to 30-year mark, making them susceptible to serious corrosion issues.

While the body panels might suffer cosmetic rust, it’s the structural rust on the frame and suspension components that can cause catastrophic failures. The frame is the backbone of the vehicle, and when it weakens or breaks due to rust, it compromises safety and drivability.

Rust tends to form early in areas with high exposure to road salt, moisture, or mud. In northern climates or coastal areas, corrosion can progress rapidly if not addressed. Water can accumulate in the frame rails and other hidden cavities, accelerating decay.

Over time, rust can cause suspension mounts to deteriorate, brake lines to weaken, and even fuel tanks to leak. These issues don’t just affect performance, they are safety hazards.

Many owners neglect rust because it often starts out invisible or hidden under dirt and grime. By the time visible rust shows up on the exterior, the frame might already have extensive damage.

Repairs on heavily corroded frames are expensive and sometimes not worth it, leading many to scrap or replace the vehicle. Preventative measures such as regular undercarriage washing, applying rustproof coatings, and inspecting vulnerable areas can dramatically slow the rusting process and extend the Jeep’s life.

Addressing rust early requires vigilance and consistent maintenance. For example, regularly cleaning the undercarriage after exposure to salt or mud, applying rust inhibitors annually, and inspecting weld points and suspension mounts can catch problems before they worsen.

Ignoring rust often leads to expensive structural repairs or unsafe driving conditions, both of which reduce the Cherokee XJ’s reliability far sooner than it should.

2. Weak Head Gaskets and Engine Overheating

The Jeep Cherokee XJ, especially the models with the 4.0-liter inline-six engine, is generally praised for its durability, but weak head gaskets remain a known Achilles heel. These gaskets seal the connection between the cylinder head and the engine block, keeping coolant and combustion gases separate. Failure of this gasket can cause overheating, coolant leaks, loss of compression, and eventually severe engine damage.

Overheating is a common symptom of a failing head gasket, and it can develop slowly. Some owners overlook early signs like slight coolant loss or occasional temperature spikes.

When the head gasket fails, coolant can leak internally into the cylinders or externally onto the ground. This leads to poor engine performance, rough idling, white smoke from the exhaust, and a strong smell of coolant. If left unchecked, it can warp the cylinder head or cause cracks, leading to very costly repairs or engine replacement.

The problem is often exacerbated by poor maintenance habits such as neglecting coolant changes, using the wrong type of coolant, or ignoring cooling system issues like failing radiators or water pumps. Overheating caused by these problems puts additional strain on the head gasket, hastening its failure. Replacing a head gasket can be labor-intensive and expensive, but it’s crucial for preserving the engine’s longevity.

Preventing head gasket failure involves maintaining the cooling system meticulously. This includes regular coolant flushes with the correct antifreeze mixture, ensuring the radiator and hoses are in good condition, replacing the thermostat as needed, and monitoring the temperature gauge closely. Addressing small cooling issues early can prevent overheating and protect the head gasket, keeping the engine reliable for many miles.

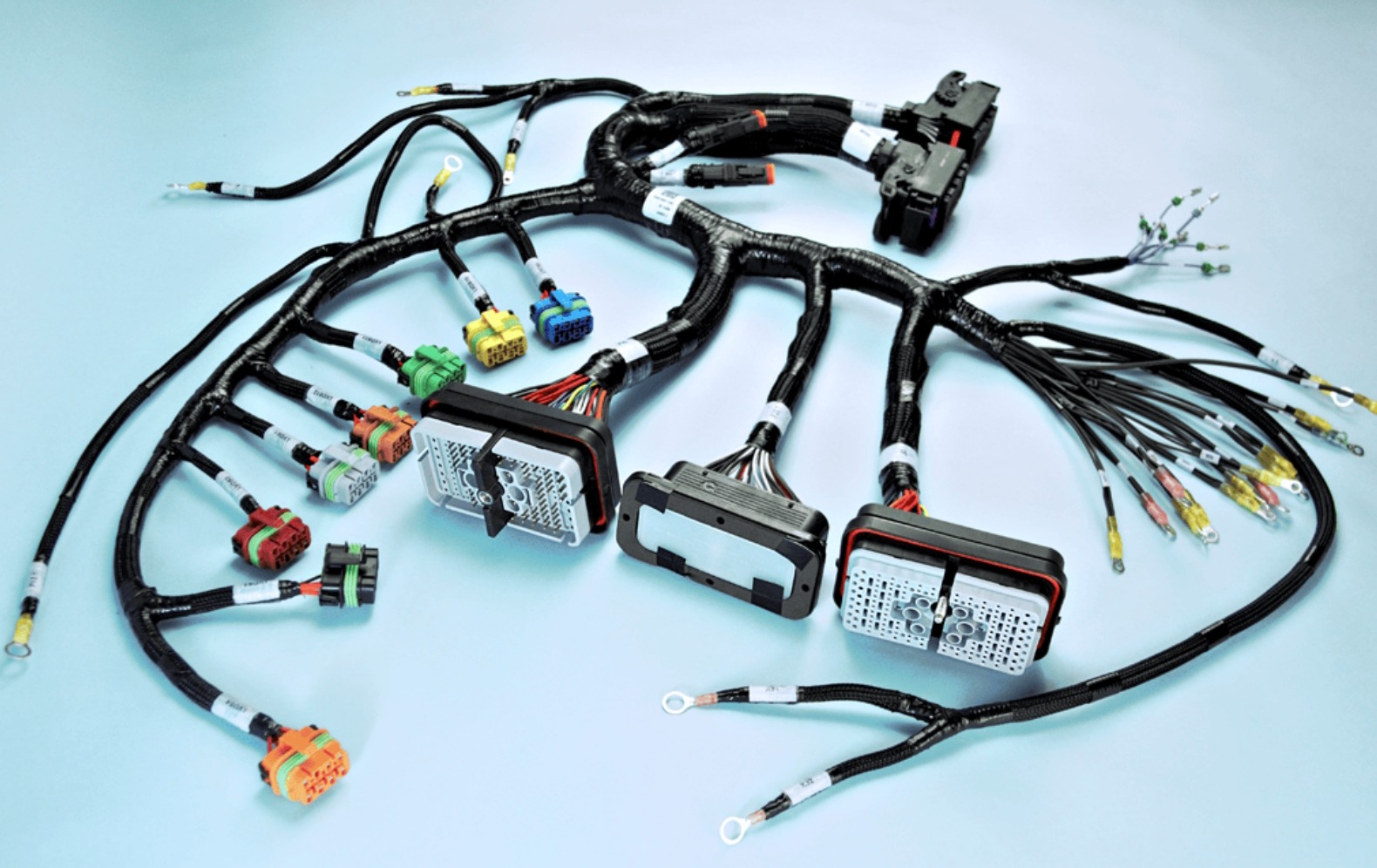

3. Faulty Electrical Grounds and Wiring Issues

Electrical problems are another common source of reliability headaches on the Jeep Cherokee XJ. Over time, the wiring harnesses and electrical grounds can degrade due to heat, moisture, and vibration. Faulty grounds and corroded connections cause intermittent electrical failures, dashboard warning lights, starting problems, and malfunctions in critical systems such as fuel injection and ignition.

The XJ’s wiring is often subjected to harsh environments, especially for those used off-road or in wet climates. Exposure to water, dirt, and oil can cause connectors to corrode or short circuits to develop.

Poor grounding is a frequent culprit, as the vehicle’s grounding points can rust or loosen, interrupting the electrical flow. When the electrical ground is compromised, it can affect multiple systems at once, making troubleshooting difficult.

Owners who do not inspect and maintain electrical connections often experience random electrical glitches that can be frustrating and dangerous. Problems like flickering lights, erratic gauges, or failure of the cooling fans can all be traced back to wiring or grounding issues. In some cases, these electrical faults can even prevent the vehicle from starting or cause it to stall while driving.

Fixing these problems requires systematic inspection and repair. Cleaning or replacing corroded connectors, tightening or replacing grounding straps, and protecting wiring harnesses from moisture are all essential.

Some owners opt to rewire key sections or add additional grounds to improve reliability. Paying close attention to the electrical system during regular maintenance can prevent small faults from turning into major failures.

4. Transmission and Transfer Case Wear

The Jeep Cherokee XJ was available with several transmission options, including manual and automatic units paired with either a part-time or full-time four-wheel-drive transfer case. While these components are generally robust, early wear or failure of the transmission or transfer case can quickly reduce the vehicle’s reliability.

Many XJs accumulate high mileage, often in off-road or tough driving conditions. This usage puts additional strain on transmissions and transfer cases. Neglected fluid changes, heavy towing, or aggressive off-road use can lead to premature wear of gears, bearings, and seals. Symptoms such as slipping gears, delayed engagement, whining noises, or leaking fluid often indicate internal damage.

The transfer case, which distributes power between front and rear axles, is particularly vulnerable if fluid is not changed regularly. Old or contaminated fluid causes bearings to wear faster and can lead to chain stretch in chain-driven models. This results in sloppy engagement and eventual failure. Similarly, the automatic transmissions require fluid changes and proper cooling to avoid overheating and internal damage.

Proper maintenance is key to avoiding these issues. Regular transmission and transfer case fluid changes, inspecting for leaks, and servicing seals and linkages can greatly extend the life of these components. For owners using their Jeep for heavy-duty off-roading or towing, additional cooling or upgrades might be necessary to maintain reliability. Ignoring transmission or transfer case issues typically leads to costly repairs or complete replacement.

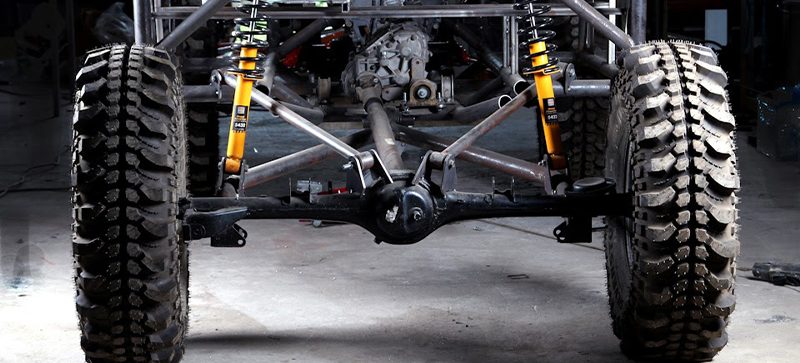

5. Worn Suspension and Steering Components

The Jeep Cherokee XJ’s suspension and steering systems play a crucial role in its performance, safety, and ride quality. These components take a heavy beating, especially if the vehicle has been used extensively for off-roading, rough terrain driving, or heavy-duty daily commuting. Over time, critical parts like ball joints, control arm bushings, tie rod ends, and shocks naturally wear out, causing the vehicle to handle poorly and increasing the risk of accidents.

One of the first signs of suspension wear is a loose or vague steering feel. When ball joints or tie rods degrade, the steering can develop excessive play, making the Jeep feel unstable or difficult to control, especially at higher speeds.

This can lead to uneven tire wear and reduced precision in handling. Worn shocks and struts fail to absorb road impacts effectively, resulting in a harsh and uncomfortable ride, and can also cause the vehicle to bounce excessively after hitting bumps.

Furthermore, the XJ’s suspension geometry can be affected by worn bushings and mounts. Control arm bushings deteriorate over time, especially when exposed to mud, water, and road salt, leading to misalignment and vibrations through the steering wheel. These problems not only reduce driving comfort but also accelerate wear on other drivetrain components. It’s common to find cracked or dried-out rubber bushings during inspections of older XJs.

Many Jeep Cherokee XJ owners modify their suspensions by lifting the vehicle or adding oversized tires to improve off-road capabilities or appearance. While these modifications can enhance certain aspects of the vehicle, they also place additional strain on factory suspension and steering components

. Without upgrading to heavy-duty parts designed for the added stresses, owners risk early failure, compromising reliability and safety. Proper maintenance, including frequent inspections and timely replacement of worn parts, is essential to prevent suspension-related failures.

6. Fuel System Problems and Clogged Injectors

The fuel system in the Jeep Cherokee XJ is vital for delivering the right amount of fuel to the engine, and when it fails, it immediately affects the vehicle’s drivability and reliability. Components such as the fuel pump, fuel filter, and fuel injectors are prone to wear or clogging due to age, fuel quality, and maintenance habits. Failure in any of these parts can cause hesitation, misfires, stalling, or failure to start.

One of the most common problems is fuel pump failure. The pump works continuously to supply pressurized fuel to the injectors, and over time, its internal parts wear out.

Many Cherokee XJ owners have experienced pump failures, especially if the vehicle has been run with low fuel levels frequently. Running on near-empty tanks causes the fuel pump to overheat and wear prematurely since the pump relies on fuel for cooling and lubrication.

Fuel filters also play a key role in protecting the injectors and engine from contaminants. When filters are neglected and allowed to become clogged, fuel flow decreases, leading to lean running conditions and poor engine performance.

Over time, contaminants and varnish deposits accumulate inside the fuel injectors, causing partial blockages or poor spray patterns. This results in rough idling, loss of power, poor fuel economy, and increased emissions.

Cleaning or replacing fuel injectors is often necessary to restore smooth engine operation. Many owners overlook regular fuel system maintenance, which allows deposits to build up and degrade performance. Preventative steps include changing fuel filters at manufacturer-recommended intervals, using high-quality fuel, and applying fuel system cleaners periodically. Proper attention to the fuel system can avoid costly repairs and maintain engine reliability over time.

Also Read: 8 Worst Mistakes That Ruin a Honda Fit in Under 10 Years

7. Cooling System Failures

Maintaining a healthy cooling system is crucial to the Jeep Cherokee XJ’s long-term reliability. The system keeps the engine operating within a safe temperature range, preventing overheating and subsequent engine damage. The cooling system is made up of several components, including the radiator, water pump, thermostat, hoses, and coolant, each of which can cause problems if not properly maintained.

Radiator failures are common in older XJs due to corrosion, leaks, and physical damage from debris or road hazards. Corroded radiators lose efficiency, restricting coolant flow and heat dissipation.

Additionally, radiator fins may become clogged with dirt, insects, and leaves, reducing airflow and cooling effectiveness. Without proper radiator function, the engine runs hotter, which puts more stress on other cooling system parts.

Water pumps and thermostats also have limited lifespans. The water pump circulates coolant through the engine and radiator; when its internal bearings or seals fail, it can leak or stop pumping coolant effectively, leading to overheating.

The thermostat regulates coolant flow based on temperature; a sticking thermostat may cause the engine to run too hot or too cold, both of which negatively affect performance and fuel economy.

Hoses connecting cooling system components degrade with age, exposure to heat, and chemical breakdown. Cracked or brittle hoses can burst or leak suddenly, causing rapid coolant loss and immediate overheating risks. Many Cherokee XJs have experienced unexpected breakdowns due to hose failure, which could have been avoided with timely inspection and replacement.

Routine maintenance of the cooling system, including flushing coolant, inspecting and replacing hoses, checking radiator condition, and testing thermostat and water pump function, is essential. Neglecting these steps often leads to overheating, head gasket failure, and engine damage, all of which reduce reliability dramatically.

8. Faulty Idle Air Control Valve (IACV) and Throttle Body Issues

The Idle Air Control Valve (IACV) and throttle body are critical for maintaining proper engine idle and throttle response in the Jeep Cherokee XJ. Problems with these components often lead to unstable idling, engine stalling, and decreased drivability, which in turn affect the vehicle’s reliability and user experience.

The IACV controls the amount of air bypassing the throttle plate when the throttle is closed, helping to stabilize engine RPMs during idle. Over time, carbon buildup, dirt, and grime can clog the IACV, limiting its movement or causing it to stick. When this happens, the engine may struggle to maintain a steady idle, particularly when cold or under load, such as when the air conditioner is running or electrical accessories are drawing power.

Similarly, the throttle body can accumulate deposits that restrict airflow and interfere with throttle plate operation. A dirty throttle body causes inconsistent throttle response, hesitation, and sometimes even stalling. This can be especially noticeable during acceleration or when coming to a stop. A malfunctioning IACV or throttle body disrupts the air-fuel mixture balance, leading to rough running conditions and increased fuel consumption.

Cleaning the throttle body and IACV during regular tune-ups can prevent many of these issues. In some cases, the IACV may need to be replaced if cleaning is insufficient. Ignoring these symptoms often results in worsened engine performance and increased stress on other components, reducing the reliability of the Cherokee XJ.

9. Poor Maintenance and Owner Neglect

The reliability of any vehicle depends on the care it receives, and this is especially true for older vehicles like the Jeep Cherokee XJ. One of the most significant factors contributing to early reliability problems is poor maintenance and neglect. Many of the XJ’s common failures are avoidable with consistent and proper upkeep.

Skipping oil changes or using poor-quality oil leads to sludge buildup, which damages engine bearings, pistons, and other critical components. Over time, this reduces engine efficiency and can cause catastrophic failures. Similarly, neglecting to replace or top off fluids such as transmission fluid, coolant, and brake fluid results in increased wear and overheating in those systems.

Ignoring warning signs such as strange noises, leaks, vibrations, or changes in performance allows small issues to escalate into major repairs. For example, delaying suspension repairs not only causes uncomfortable driving but can also damage tires and suspension geometry. Overlooking electrical issues may cause intermittent failures that become harder to diagnose and fix over time.

Owners who adhere to regular maintenance schedules, promptly address issues, and perform thorough inspections dramatically increase the longevity and reliability of their Jeep Cherokee XJ. The difference between a reliable, long-lasting vehicle and one plagued by frequent breakdowns often comes down to how well it has been cared for over the years.

10. Poorly Done Modifications and Aftermarket Add-Ons

Many Jeep Cherokee XJ owners love to modify their vehicles to enhance off-road capabilities, improve aesthetics, or increase performance. While some modifications are well-planned and executed with quality parts, others are rushed or done on a budget without proper knowledge or tools.

Poorly done modifications can severely compromise the Jeep’s reliability and safety, especially when they alter key systems like suspension, drivetrain, or electrical.

Lift kits, for example, are one of the most common upgrades for XJ owners. But lifting the vehicle without correcting geometry issues, such as track bar angle, driveshaft length, or caster alignment, can lead to premature wear on suspension and steering components.

Incorrect lift setups often cause issues like death wobble, increased driveline vibration, and reduced control on the road. Without additional upgrades such as adjustable control arms, upgraded shocks, or dropped pitman arms, the suspension may become unstable and dangerous.

Electrical add-ons like light bars, winches, and aftermarket stereos also present risks when installed incorrectly. Tapping into factory wiring without using proper relays or fuses can lead to electrical shorts, dead batteries, or even fires. Many electrical problems in XJs can be traced back to shoddy installations of aftermarket accessories. Adding unnecessary strain to the electrical system, especially in an older vehicle, is a fast track to reliability issues.

Performance modifications, such as altered fuel mapping, throttle body spacers, or cold air intakes, often promise gains but rarely deliver meaningful improvements unless paired with supporting upgrades.

Worse, some mods can throw off engine tuning or emissions systems, resulting in poor fuel economy, check engine lights, or erratic engine behavior. Before modifying an XJ, it’s essential to understand the long-term implications and ensure all supporting systems are accounted for. Otherwise, these changes might reduce reliability instead of enhancing it.

11. Rear Main Seal Leaks

One of the most infamous and persistent issues for the Jeep Cherokee XJ is the rear main seal leak. The rear main seal is located between the engine and the transmission, and it prevents oil from leaking out of the back of the crankshaft. As XJs age, this seal tends to harden and crack, resulting in oil leaks that can drip onto the ground or the exhaust, leading to burning smells and messy engine bays.

While a minor leak may not seem urgent, ignoring it can lead to bigger problems. Constant oil loss reduces lubrication, especially during long drives or under heavy loads.

Running the engine low on oil accelerates wear on internal components, including bearings and cylinder walls. Over time, this can lead to reduced compression, poor performance, or even a seized engine. A seemingly small leak, if left unchecked, can cause major engine failure.

The challenge with the rear main seal is that it’s difficult and labor-intensive to replace. It requires separating the transmission from the engine, making it a job that many owners delay due to cost or time. Unfortunately, the longer the leak goes on, the worse the potential damage. Some owners attempt to fix the problem with additives, but these are temporary at best and don’t address the root cause.

The best approach is to monitor oil levels regularly and address the seal when leakage becomes significant. Many experienced XJ owners choose to replace the rear main seal during other jobs that already require removing the transmission or oil pan, like clutch replacements or oil pan gasket service. Though time-consuming, tackling this issue properly can extend the engine’s lifespan and preserve the Cherokee’s long-term reliability.

12. Cracked Exhaust Manifold

The exhaust manifold on the Jeep Cherokee XJ, especially on the 4.0L inline-six engine, is prone to cracking over time. This is a well-known problem that affects many XJ models, particularly those exposed to frequent heat cycling or hard driving.

The manifold is made of cast iron and is located right next to the engine block, where it endures intense heat during operation and rapid cooling afterward. This constant expansion and contraction eventually leads to stress fractures.

A cracked exhaust manifold creates several reliability issues. First, it causes exhaust leaks, which lead to reduced engine efficiency and power. You may hear a ticking or tapping noise during cold starts that gradually quiets as the engine warms up. Second, these leaks can allow unburned fuel and hot gases to escape into the engine bay, which may damage nearby components, melt wiring, or, in rare cases, cause a fire risk.

In addition to the mechanical problems, a cracked manifold can introduce harmful exhaust gases like carbon monoxide into the cabin through the firewall or ventilation system. This poses a serious health hazard, especially if the vehicle is used for long commutes or family travel. Many drivers overlook this risk or attribute the symptoms to other causes, failing to catch the leak until it becomes severe.

Replacement manifolds are available and usually more durable than the original design. Some aftermarket headers are built with expansion joints or improved materials to handle the thermal stresses better. Regular inspection of the exhaust system, especially around the manifold and downpipe, is essential.

If caught early, a cracked manifold can be replaced without damaging other engine components. Left alone, however, it contributes to poor fuel economy, engine misfires, and reduced reliability.