The Dodge Nitro, introduced in the mid-2000s, aimed to combine the rugged appearance of an SUV with the practicality and functionality demanded by families and off-road enthusiasts alike. With its bold styling, square-jawed design, and aggressive presence, it quickly stood out among the more conservatively designed compact SUVs of the time.

It came with promises of solid performance, capable towing, and a more truck-like driving feel than many of its car-based rivals. However, despite its potential, the Dodge Nitro developed a reputation over time for being less than reliable.

Much of this came not from the vehicle’s inherent design flaws alone, but rather from consistent oversights in maintenance, misuse, or even neglect by owners and sometimes even technicians unfamiliar with the model’s specific needs.

A vehicle like the Dodge Nitro demands attention to detail. While it was never intended to be a luxury SUV with cutting-edge electronics, it was built to serve as a capable daily driver with some versatility. Unfortunately, many owners fell into the trap of treating it like a set-it-and-forget-it machine, expecting the vehicle to operate trouble-free regardless of driving habits or upkeep.

This attitude often led to premature mechanical failures, driveability issues, and expensive repairs that could have been avoided. For a model that was already fighting to gain long-term credibility, this only worsened its reputation and reduced its presence in the used car market over time.

It’s easy to blame a brand or model for problems, but just as often, the root cause lies in the way the vehicle is handled. With the Dodge Nitro, many common problems stem from user oversight rather than fundamental engineering disasters. From ignoring transmission service intervals to using the wrong type of fluids or neglecting suspension wear, seemingly small details can snowball into major issues.

This article outlines ten specific oversights that owners, mechanics, or dealers often make that directly impact the Nitro’s reliability. If addressed proactively, these issues can be managed or even avoided, helping extend the life and dependability of a vehicle that, with proper care, still has something to offer.

Also Read: Best Waterless Car Wash Sprays That Provide Convenient Cleaning

1. Ignoring Transmission Fluid Service

One of the most damaging oversights that affects the Dodge Nitro’s reliability is the neglect of timely transmission fluid maintenance. Unlike older vehicles that came with dipsticks for checking fluid levels easily, many modern automatics, including those in the Nitro, use sealed transmissions that require a technician to inspect and service them. This leads many owners to assume the fluid is a lifetime fill.

That assumption is dangerous. Over time, transmission fluid degrades due to heat and friction, which can result in harsh shifting, slipping, or even full transmission failure if left unchanged. Regular servicing, ideally around every 30,000 to 60,000 miles depending on driving habits, can greatly increase the transmission’s lifespan.

Another problem tied to the transmission is the use of incorrect fluid. Dodge designed the Nitro’s transmission to work with specific fluid types, and yet some quick lube shops or uninformed mechanics top it off with universal or incorrect fluids. This leads to compatibility issues, degraded performance, and eventually, component wear that could have been easily avoided.

Because the effects of using the wrong fluid may not show up immediately, it can be a hidden time bomb for the drivetrain. Over time, components inside the transmission such as the torque converter and valve body can suffer irreversible wear.

In some cases, people assume that transmission problems stem from more obvious issues like mechanical failure or computer malfunctions. While those are possible, the root cause is often just dirty, degraded, or incompatible fluid. Once damage is done, flushing the system or replacing parts becomes expensive and time-consuming.

This could be prevented by simply treating transmission service with the same level of importance as oil changes. Yet because it’s not always as visible or routine, it’s easily forgotten.

Treating the transmission as a sealed-for-life component is a costly misconception. Routine maintenance, done by someone familiar with the correct procedure and fluid specifications, is a relatively small investment compared to the cost of a full rebuild or replacement. Dodge Nitros, particularly older ones with higher mileage, rely heavily on this kind of upkeep to stay reliable, and ignoring it is one of the surest ways to shorten their lifespan.

2. Failure to Replace Worn Suspension Components

The Dodge Nitro’s heavy curb weight and somewhat truck-like ride put significant stress on its suspension system. This includes control arms, ball joints, bushings, shocks, and struts. Unfortunately, many owners wait until there’s a noticeable clunk or vibration before they consider suspension service.

By that time, wear has often advanced to the point where multiple components are compromised. Replacing one part while ignoring others creates an imbalance in the system and may only temporarily solve the issue. A worn-out suspension doesn’t just reduce ride comfort, it can also affect braking distance, tire wear, and alignment, which all impact reliability.

Front-end components like upper and lower control arms tend to wear prematurely, especially in regions with poor road conditions or extreme temperatures. These parts don’t always fail catastrophically. Instead, they gradually degrade until the driver starts noticing poor steering response or excessive play in the steering wheel.

Once these symptoms appear, it’s often a sign that the damage has been present for a long time. At this point, continuing to drive the vehicle without repair can cause stress on the steering rack and additional systems, multiplying the cost and severity of the repair.

Another issue is with aftermarket suspension parts. Some owners looking to save money or lift their Nitro slightly opt for cheaper components that don’t meet original equipment specifications. While the initial cost might seem attractive, the long-term impact on performance and durability is usually negative.

Cheap bushings may squeak or fail quickly, while off-brand shocks might not properly support the vehicle’s weight or provide adequate rebound. The result is a compromised ride and handling experience that can lead to more frequent breakdowns or handling issues.

Maintaining the Nitro’s suspension isn’t just about keeping it smooth and quiet. It’s about preventing cascading failures. If one ball joint fails, it can cause uneven tire wear or even lead to a wheel detachment in extreme cases. Staying ahead of these issues with inspections and timely replacements is essential for ensuring the vehicle’s reliability. Skipping or delaying suspension service is one of the biggest mistakes Nitro owners make.

3. Overlooking Cooling System Maintenance

The cooling system is often taken for granted until it fails, and in a vehicle like the Dodge Nitro that operates with high engine temperatures, this is a dangerous oversight. The cooling system includes components like the radiator, water pump, thermostat, radiator fan, and hoses.

Any failure in this system can result in overheating, which is one of the fastest ways to destroy an engine. Unfortunately, many owners only notice a problem when the temperature gauge rises or the engine starts knocking. By then, the damage may already be extensive.

Radiators can become clogged with debris and mineral deposits, especially when low-quality or incorrect coolant is used. This leads to reduced cooling efficiency and higher operating temperatures, particularly under load or during long drives.

The Dodge Nitro’s radiator and thermostat are not known for early failure, but once wear sets in, symptoms appear rapidly. An engine that’s running hot, even slightly above normal levels for extended periods, can warp heads, damage gaskets, and stress internal components.

Another common oversight is ignoring coolant flush intervals. Coolant isn’t just antifreeze—it also contains corrosion inhibitors and lubricants that protect the engine and cooling system components. Over time, these additives break down, and the fluid becomes more corrosive than protective.

Continuing to run with old coolant can eat away at internal parts like the water pump or lead to buildup that clogs narrow passages in the heater core or block. This can result in poor heat in the cabin, engine overheating, and system leaks.

Ignoring signs like coolant smell, visible leaks, or fluctuating temperature readings is a major misstep. Even something as minor as a loose clamp or aging hose can rupture under pressure, leaving the driver stranded or causing overheating. Staying on top of coolant health, monitoring temperatures, and replacing parts proactively is not just good maintenance; it’s a key factor in keeping the Dodge Nitro on the road long-term.

4. Using the Wrong Engine Oil

Engine oil choice is more critical than some owners assume. The Dodge Nitro came with different engines across its model years, including the 3.7L V6 and the 4.0L V6. Each engine has specific oil viscosity requirements that must be followed for optimal performance.

Using oil that’s too thick or too thin for the engine’s temperature range and tolerance can result in poor lubrication, increased friction, and eventual wear. Yet this is one area where shortcuts are often made, either by the owner during a DIY oil change or by shops trying to standardize their bulk oil inventory.

Thicker oil may seem like a better option for high-mileage engines, but in the Nitro’s case, it can reduce oil flow during cold starts. This delay in oil circulation creates a brief but damaging period where engine parts operate with less protection.

On the other hand, thinner oil may not provide enough film strength under heavy load or high-heat conditions, which are both common when towing or driving in summer. Both conditions contribute to long-term wear that isn’t immediately visible but significantly reduces the engine’s usable life.

Another issue is infrequent oil changes. The Dodge Nitro’s engines are not particularly forgiving when it comes to sludge buildup. Going far beyond recommended intervals, especially with lower-quality oil, leads to deposits in vital areas like the oil pickup tube, valve covers, and lifters. This

Another often overlooked issue is the role oil plays beyond just lubrication. In modern engines, oil also assists with cooling, cleaning internal surfaces, and even supporting variable valve timing systems when equipped. The 4.0L engine in particular, which appeared in some Nitro trims, is more sensitive to oil quality because of the tighter clearances and higher operating temperatures.

When low-quality or incorrect oil is used, it can break down under heat and leave behind varnish or carbon deposits. These residues may clog oil passages and cause ticking noises, poor performance, or even cause the timing chain tensioner to malfunction. Such problems often creep up slowly, so owners don’t notice until it’s too late.

Oil filter choice is also part of this oversight. A poor-quality oil filter may allow debris to circulate through the engine or may clog prematurely, triggering low oil pressure warnings. In some cases, aftermarket filters have been found to lack proper anti-drain back valves or bypass valves that meet OEM standards.

These small differences can cause long-term issues, especially during cold starts when the engine needs immediate pressure. While a high-mileage Nitro may seem to tolerate cheap oil and filters in the short term, the internal damage accumulates gradually and eventually shows itself through lifter noise, camshaft wear, and reduced compression.

To make things worse, many Nitro owners adopt the belief that as long as the engine has oil in it, everything is fine. They skip oil changes by thousands of miles, assuming the vehicle can “handle it.” Unfortunately, this lazy approach leads directly to sludge buildup and ring sticking, both of which significantly reduce engine reliability.

Once rings are stuck, oil consumption rises, blow-by increases, and compression drops. From that point forward, the engine is on borrowed time unless a costly rebuild is performed. This kind of damage is entirely avoidable with consistent oil changes and attention to specifications.

5. Neglecting Electrical System Checks

The Dodge Nitro has an electrical system that is fairly simple compared to today’s ultra-connected vehicles, but that doesn’t mean it’s immune to problems. Many reliability complaints stem not from major system failures, but rather from small, annoying issues that accumulate over time, flickering lights, power window malfunctions, radio resets, and intermittent sensor failures.

Often, these problems are brushed off by owners or attributed to age. But more often than not, they point to overlooked maintenance or poor electrical connections that could have been fixed with basic care.

Battery maintenance is one of the most fundamental aspects of electrical reliability, yet it’s also the one most often skipped. A failing or weak battery can cause a cascade of electrical issues, particularly in a vehicle that uses electronic throttle control and body control modules to manage lighting, locks, and other systems.

As batteries age, their voltage stability drops, and this can cause systems to behave unpredictably. The Nitro’s control modules are not particularly tolerant of voltage drops or spikes. For example, a weak battery can trigger false warnings on the dashboard or cause stored codes in the ECU that make diagnosis difficult and misleading.

Corrosion on battery terminals, poor grounding points, or damaged wiring harnesses can also wreak havoc on reliability. In many cases, especially in colder or more humid climates, ground straps become corroded or loose over time.

These are often missed during routine inspections because they’re out of sight. But a poor ground connection can cause sensors to read incorrectly, starters to engage slowly, or charging systems to fail under load. As frustrating as these issues are, they’re usually the result of basic neglect, not complex electronic faults. A simple voltage drop test during maintenance could catch many of these before they lead to problems.

Lastly, the habit of installing aftermarket electronics without professional help introduces another layer of risk. From poorly installed stereo systems to alarm kits with questionable wiring, these modifications often bypass or interfere with factory wiring in ways that strain the system.

This results in blown fuses, drained batteries, or fried circuits. Owners may not realize the full impact until something critical, like the ignition system or powertrain control module, starts acting up. Electrical reliability in the Nitro is more fragile than many assume, and it requires consistent attention to detail, clean grounds, quality connections, and avoidance of wiring shortcuts.

Also Read: 5 Hyundais That Rarely Fail Brakes vs 5 That Burn Pads Monthly

6. Ignoring Transfer Case and Differential Service

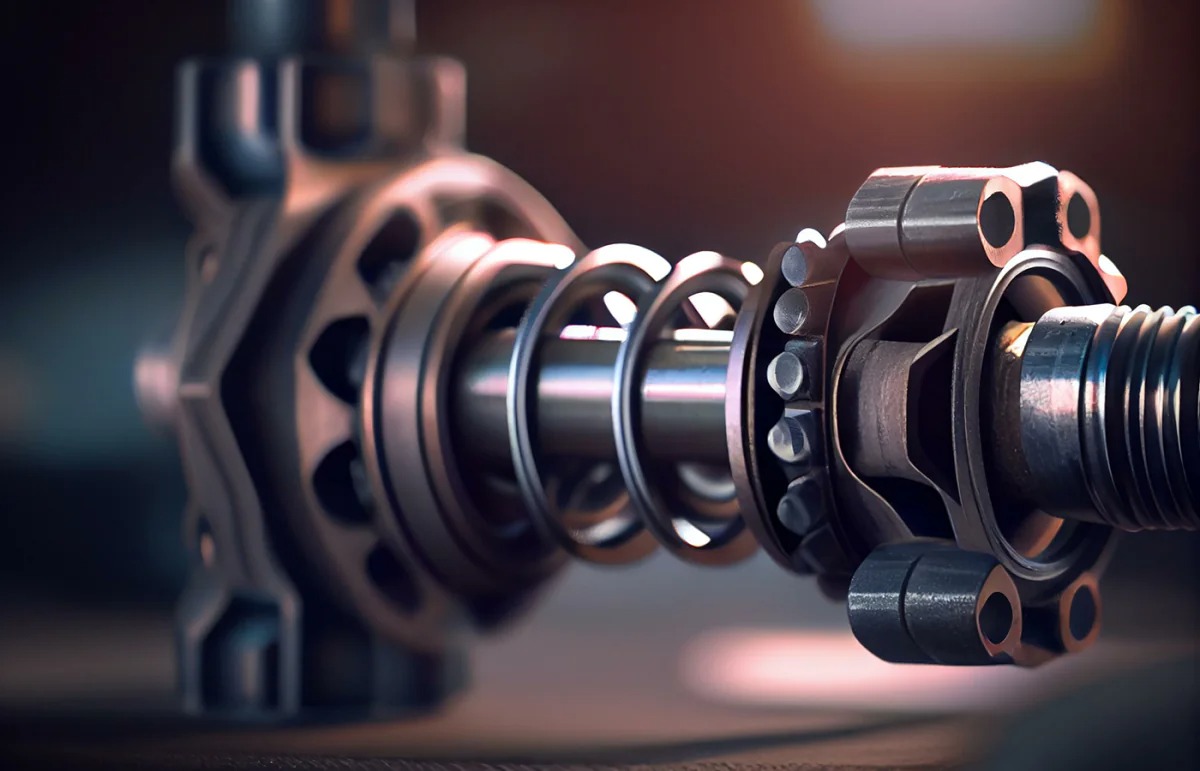

Many Dodge Nitro models came equipped with part-time four-wheel drive or all-wheel drive systems, which means they rely on transfer cases and differentials to function properly. These components, while rugged by design, require periodic maintenance that is often ignored.

One of the biggest oversights affecting the Nitro’s reliability is the failure to service the transfer case and differentials at the recommended intervals. These systems operate under heavy load and extreme pressure, particularly during towing or off-road use, and the fluid inside them breaks down over time, losing its ability to properly lubricate and protect gears.

Failure to change the transfer case fluid can lead to premature wear on internal chains, gears, and bearings. Once this happens, drivers may hear whining noises, feel vibrations at certain speeds, or notice that the vehicle no longer shifts properly into 4WD.

In some cases, fluid leaks develop slowly over time, particularly around the seals, and the transfer case runs dry before the problem is even noticed. When this happens, internal components can seize or strip, turning a preventable issue into a full replacement that costs thousands. Keeping up with this fluid is especially important for those who drive in snow, mud, or mountainous regions where the system gets more use.

Differential service is equally important and just as frequently forgotten. The front and rear differentials, particularly in AWD Nitro models, require gear oil that meets specific viscosity and additive requirements. Over time, this oil becomes contaminated with metal particles and moisture, especially if water has made its way into the housing during off-road use.

Dirty gear oil fails to protect the ring and pinion gear properly, leading to pitting, scoring, or even catastrophic failure under load. Symptoms like grinding noises during turns or humming at highway speeds often indicate neglected differential service.

Some drivers mistakenly believe that because they rarely use 4WD, the system doesn’t need attention. This is incorrect. Even occasional use of these systems requires regular fluid changes to keep everything working as intended.

Transfer case and differential failures are among the most expensive drivetrain repairs a Dodge Nitro can face, yet they are easily preventable with scheduled servicing. Choosing the right gear oil, inspecting for leaks, and checking fluid levels periodically can dramatically improve the vehicle’s long-term reliability.

7. Disregarding the Importance of Spark Plug Replacement

Spark plugs are easy to forget about, especially when a vehicle seems to be running smoothly. But for the Dodge Nitro, neglecting spark plug replacement is a common oversight that leads to performance and reliability issues. Depending on the engine, Dodge recommended replacement intervals ranging from 30,000 to 100,000 miles.

Owners who assume they can wait until the engine misfires or hesitates before replacing them are asking for trouble. The longer spark plugs are left in place, the more difficult they become to remove, sometimes requiring cylinder head work if they seize or break.

Old or worn spark plugs reduce combustion efficiency, which can lead to poor fuel economy, hard starts, or reduced throttle response. In more severe cases, they cause engine misfires, which in turn damage the catalytic converter due to unburned fuel. This is not just a performance issue, it becomes a very expensive emissions problem. A failed converter can cost well over a thousand dollars to replace, especially on models with dual exhaust. All of this can be traced back to a simple decision to skip a basic tune-up.

Another issue with overdue spark plug changes is coil-on-plug damage. Each cylinder in the Nitro uses its own ignition coil. When spark plugs wear out, they force the coils to work harder, creating excess heat and electrical resistance.

Eventually, this causes coils to fail one by one, leading to rough idling and check engine lights. It’s not uncommon to see Nitros with multiple failed coils because the plugs were left in far too long. These failures often occur just outside warranty coverage, making them even more frustrating for the owner.

The type of spark plug matters as well. Using a plug that doesn’t meet the OEM heat range can cause pre-ignition or fouling, both of which affect reliability. Cheap aftermarket plugs may look fine at first but fail early or cause subtle driveability issues that are difficult to trace.

Sticking with high-quality, manufacturer-recommended spark plugs and replacing them at the correct interval is a low-cost way to maintain engine health. Skipping or delaying this service undermines the long-term performance and reliability of the vehicle.

8. Underestimating the Impact of Tire Neglect

Tires are often treated as an afterthought by vehicle owners, but on a Dodge Nitro, a vehicle with a relatively firm ride, higher center of gravity, and SUV proportions, tire condition plays a critical role in both reliability and safety. The most common mistake Nitro owners make is running tires well past their prime.

This doesn’t just mean worn-out tread, but also old rubber that has hardened with age, reducing grip and increasing braking distance. Even if a tire still has visible tread, it may be dry-rotted, cupped, or unevenly worn, all of which affect how the vehicle handles. A Nitro with poor tires can easily develop strange suspension noises, poor fuel economy, and unpredictable steering feedback, often leading owners to suspect more serious issues when the root cause is right at the pavement.

Neglecting tire pressure checks is another serious oversight. The Nitro’s handling characteristics can feel sluggish or unstable if tires are underinflated, and when this happens, the vehicle places more stress on the power steering, suspension bushings, and shocks.

Not only that, but underinflated tires increase rolling resistance, which raises fuel consumption and puts added strain on the drivetrain. Overinflated tires, on the other hand, reduce the contact patch, leading to poor traction and a harsh ride, especially noticeable on the Nitro’s firm suspension setup. While tire pressure monitoring systems help catch extreme pressure drops, they aren’t always accurate enough to warn about gradual underinflation that can still cause damage.

Tire alignment and rotation are also areas where owners cut corners. When tires are not rotated regularly, uneven wear sets in quickly, particularly on a vehicle like the Nitro that has a slightly nose-heavy balance. Front tires wear faster, and if the alignment is even slightly off, this can lead to feathering, shoulder wear, or scalloping.

9. Skipping HVAC System Maintenance

The heating, ventilation, and air conditioning (HVAC) system is not just about comfort; it’s deeply tied to vehicle reliability, especially in climates that experience extreme temperatures. One of the most common oversights in Dodge Nitro maintenance is the complete neglect of the HVAC system until something fails.

Many owners assume that as long as the A/C blows cold or the heater feels warm, everything is fine. But over time, the blower motor, blend door actuators, cabin air filter, and A/C compressor all suffer wear, and if not maintained properly, they fail unexpectedly. These failures aren’t always cheap, and in the Nitro’s tightly packed dashboard layout, even minor component replacements can become labor-intensive.

One specific problem involves blend door actuators, which are known to be weak points in the Nitro. These small electric motors control airflow direction and temperature mix. When they fail, the vehicle might only blow hot air regardless of the setting or become stuck blowing through one set of vents.

Many owners ignore the clicking noise that blend door actuators make before they fully fail, assuming it’s not a big deal. But once the actuator fails, proper cabin temperature control becomes impossible. In colder climates, this can also impact visibility by limiting window defrosting, leading to unsafe driving conditions. Since accessing these actuators often requires dashboard disassembly, repairs are frequently delayed or skipped entirely.

Another often ignored part is the cabin air filter. When left unchanged for years, it becomes clogged with dust, leaves, and moisture, which leads to restricted airflow and extra strain on the blower motor. That strain can cause the motor to overheat and eventually fail, especially during the summer months when the A/C system is under the most load.