The Nissan Juke has always been a polarizing vehicle. People either love its bold, unconventional design or find it off-putting. But design debates aside, the Juke has carved out a niche as a compact crossover with personality.

With its turbocharged engine options, nimble handling, and urban-friendly size, it’s a tempting choice for many looking for something different in the small SUV segment. That said, the Juke isn’t immune to wear and tear.

Like all vehicles, it needs care and attention to maintain long-term performance. Unfortunately, many owners ignore critical maintenance areas until it’s too late, which can lead to costly repairs and a shortened vehicle lifespan.

This article outlines ten simple but effective hacks that can dramatically improve the Nissan Juke’s reliability. These aren’t quick gimmicks or magical fixes; instead, they’re practical habits and mechanical checks that anyone can adopt. The good news is you don’t have to be a master mechanic to apply these principles.

Some require minor investments in parts or professional services, while others are about adjusting how you use the car day-to-day. The overall goal is to prevent common issues before they become serious problems and to keep the car running smoothly for years to come.

Some hacks focus on the engine and transmission, which are obviously central to any car’s longevity. Others deal with electronics, suspension, and overlooked components that often break down due to neglect. Think of this list as a framework for smart ownership.

If you’ve just purchased a Juke or have owned one for years, these strategies can help you get the most out of it. Reliability isn’t just about factory quality; it’s about how the vehicle is treated throughout its life. Many Nissan Juke models have surpassed 200,000 miles with consistent upkeep. The key is knowing what to look out for and acting before issues snowball into major headaches. Let’s get into the top ten hacks that can extend the reliability of your Nissan Juke.

Also Read: 7 Driving Habits That Destroy a Subaru Legacy Faster Than You Think

1. Change CVT Fluid More Frequently Than Suggested

The Juke’s continuously variable transmission (CVT) is both its blessing and its curse. When working correctly, it provides smooth, efficient power delivery. But when neglected, it can become the most expensive repair on the car.

Nissan’s official maintenance schedule for CVT fluid changes is conservative, often suggesting long intervals or even claiming the fluid is “lifetime.” That’s risky advice for a car intended to last beyond 100,000 miles. Changing the CVT fluid more often than recommended can significantly increase the transmission’s life.

A smart approach is to replace the CVT fluid every 30,000 to 40,000 miles, especially if the vehicle is driven in stop-and-go traffic or mountainous terrain. The Juke’s CVT generates a lot of heat during operation, which causes the fluid to degrade more rapidly than traditional automatic transmissions.

Fresh fluid helps the metal belts and pulleys inside the CVT stay lubricated and cool, reducing friction and wear over time. Dirty fluid, on the other hand, leads to rough shifting, overheating, and eventual component failure.

Another often-missed detail is using the correct type of CVT fluid. Not all CVT fluids are created equal. Nissan’s proprietary NS-2 or NS-3 fluid (depending on your Juke’s model year) is specifically engineered for their transmissions.

Generic fluids may be cheaper, but they can cause damage due to mismatched chemical compositions. It’s also wise to replace the CVT filter or screen when changing the fluid, although this step is more labor-intensive and may require a professional mechanic.

Regular CVT maintenance won’t make the transmission bulletproof, but it drastically reduces the chances of major failure. This simple fluid change can mean the difference between a Juke that dies at 120,000 miles and one that lasts past 200,000. If there’s only one reliability hack to commit to, this one is near the top of the list.

2. Install an Oil Catch Can

Turbocharged engines like the one in the Nissan Juke tend to suffer from oil vapor build-up inside the intake system. This is due to crankcase pressure forcing small amounts of oil through the PCV system, where it gets recirculated into the intake manifold. Over time, this leads to carbon deposits on the intake valves, especially in direct-injection engines like the Juke’s. An oil catch can is a simple device that traps this oil mist before it can enter the engine.

Installing an oil catch can helps reduce carbon build-up, which in turn maintains engine performance and fuel economy. Carbon deposits can cause misfires, rough idling, and even valve damage if left unchecked.

The catch can collects oil vapors in a reservoir, which can then be emptied periodically. This setup ensures the intake system stays cleaner for longer, especially in vehicles that are frequently driven in urban environments where stop-and-go driving is common.

It’s important to install the oil catch can correctly. Most units are installed between the PCV valve and the intake manifold, but configurations may vary. The can should have a filter or baffle system inside to separate the oil from the air. Cheap, unfiltered cans will not be effective. While this is not a factory-approved modification, it’s widely used by enthusiasts and mechanics alike as a preventive measure.

Routine cleaning of the catch can is necessary, but it’s a small task compared to engine repairs caused by heavy carbon build-up. Even if you only gain modest performance improvements, the real benefit is in preserving the internal cleanliness of the engine, especially over high-mileage usage. This is one of those small tweaks that pay dividends long-term.

3. Clean the MAF Sensor Every 15,000 Miles

The Mass Air Flow (MAF) sensor plays a vital role in determining how much air enters the engine, which affects fuel injection and ignition timing. When it gets dirty, the sensor gives incorrect readings, leading to poor fuel economy, sluggish throttle response, and sometimes triggering the check engine light. Cleaning the MAF sensor regularly helps ensure optimal combustion and engine health.

Using a dedicated MAF sensor cleaner is essential. Never use carburetor cleaner or other strong solvents, as these can damage the sensor’s delicate components. The process is simple: remove the sensor, spray it thoroughly, allow it to air dry completely, and reinstall. This should be done every 15,000 miles or sooner if driving in dusty environments.

Neglecting the MAF sensor leads to a rich or lean fuel mixture, which can eventually damage spark plugs and catalytic converters. For turbocharged engines, incorrect air-fuel ratios can increase the risk of detonation under load, further stressing internal components. A well-maintained MAF sensor helps the engine operate efficiently and reduces emissions.

One bonus is improved throttle response and smoother acceleration after cleaning. It’s a subtle improvement, but over time it contributes to a more consistent driving experience. Given how cheap and easy this maintenance step is, it’s surprising how many owners skip it. Consistent air metering is critical for reliability, and this little step helps ensure just that.

4. Use OEM Spark Plugs and Change Them on Time

Spark plugs are responsible for igniting the air-fuel mixture in the engine’s combustion chamber. When they degrade or wear out, the engine misfires, runs inefficiently, and eventually develops more serious issues. The Nissan Juke’s turbocharged engine is particularly sensitive to spark plug condition, and using aftermarket plugs can introduce problems that don’t show up immediately.

Original Equipment Manufacturer (OEM) spark plugs are designed with the correct heat range and electrode design for your engine. Using the wrong spark plugs can result in incomplete combustion, pre-ignition, or fouling. All of these lead to long-term damage if left unchecked. The recommended replacement interval for spark plugs in the Juke is around 60,000 miles, but if you drive aggressively or frequently use boost, earlier replacement is better.

Changing spark plugs also gives you a chance to inspect coil packs and check for oil leaks around the valve cover. Many reliability problems are first discovered during basic service jobs like this. If you find oil on a spark plug, that could indicate a leaking gasket or a more serious issue with the head.

Sticking to OEM parts is especially important for ignition components. While high-performance plugs might promise better power or efficiency, they rarely work as well in the long run as factory-spec units. The Juke’s ignition system is tuned to specific tolerances, and deviating from that introduces unnecessary risk.

5. Flush and Bleed the Brake System Every Two Years

Brake fluid is one of the most overlooked components in vehicle maintenance, and the Nissan Juke is no exception. Most drivers assume brake fluid lasts forever, but in reality, it’s hygroscopic, meaning it absorbs moisture from the air over time.

That moisture drastically reduces braking performance and can corrode sensitive components inside the braking system. Flushing the brake system every two years is an excellent preventive measure to protect calipers, lines, the ABS module, and the master cylinder.

When brake fluid absorbs water, its boiling point lowers, which can lead to brake fade during hard stops or mountain driving. In a compact crossover like the Juke, especially when carrying passengers or cargo, brake performance becomes critical.

Spongy pedal feel or extended stopping distances are often signs that moisture has compromised the brake fluid. A full flush ensures that the entire system is purged of old, contaminated fluid, restoring braking effectiveness and reliability.

Additionally, modern vehicles with ABS and electronic brake force distribution systems rely on clean hydraulic fluid to function properly. Dirty fluid can cause internal valves in these systems to stick or malfunction.

Replacing a failed ABS pump or actuator due to neglected brake fluid is an expensive fix that can be avoided with timely maintenance. A properly bled system also helps maintain a firm, consistent pedal feel, which enhances driver confidence and safety.

Finally, doing a brake flush also presents an opportunity to inspect pads, rotors, calipers, and brake hoses for wear or leaks. Even if your Juke isn’t showing obvious braking problems, periodic flushing acts as insurance against corrosion-related failures and internal damage.

A brake system that receives regular care can remain dependable well into high mileage, whereas neglect can result in reduced performance and expensive repair bills.

6. Protect Suspension Components with Regular Undercarriage Cleaning

The Nissan Juke’s compact design makes it agile and easy to maneuver, but its suspension and undercarriage components are often exposed to the elements. Salt, mud, road debris, and even standing water can lead to premature rust and wear.

Regular undercarriage cleaning, especially in winter months or after off-road use, plays a crucial role in preserving your Juke’s suspension reliability. This simple habit can add years to the lifespan of key parts like control arms, bushings, sway bars, and struts.

Road salt is one of the most damaging substances to a vehicle’s chassis. It corrodes metal quickly and can penetrate into mounting points, bolts, and welds. Once rust begins forming, it tends to spread unless treated.

In climates with heavy snowfall or near coastal areas, undercarriage corrosion can be severe within just a few years. By spraying off the underbody with fresh water after snowstorms or salt exposure, you significantly reduce the chances of this damage taking hold.

Another important aspect is checking rubber bushings and suspension joints for signs of cracking or deterioration. While under the car, pay attention to worn bushings that can affect ride quality and steering precision.

Rubber components naturally degrade over time, but keeping them clean and free from oil and debris can extend their usable life. A clean underbody also makes it easier to spot early signs of leakage from shocks, struts, or brake lines.

Lastly, rust-proofing sprays or coatings can add a protective layer to exposed parts. While this may seem excessive, it’s a worthwhile investment for owners planning to keep their Juke beyond 100,000 miles. Suspension repairs are not only expensive but also complex due to labor costs. Preventing damage in the first place is far cheaper than dealing with rusted bolts or seized components later down the road.

Also Read: 7 Pro Tips That Keep a Subaru Outback Winter-Ready for Life

7. Check and Replace Engine Mounts Proactively

Engine mounts are often ignored until they fail, but by then, they’ve already caused other issues like vibrations, misalignment, or even damage to nearby components. In the Nissan Juke, the engine mounts support a turbocharged powertrain that produces more power and torque than a naturally aspirated engine.

Over time, these mounts break down due to stress and heat, leading to drivetrain instability. Inspecting and replacing them proactively, especially around the 80,000–100,000-mile mark, helps keep your car running smoothly.

A worn engine mount doesn’t always show up as a check engine light. Instead, it may present as increased engine vibration at idle, clunking sounds during acceleration, or a sudden jolt when shifting from Park to Drive.

These symptoms can often be mistaken for transmission or suspension issues. Ignoring them puts extra stress on the CV joints, axles, and even the transmission housing. Replacing faulty mounts early prevents this ripple effect of damage.

Quality of replacement matters too. OEM or high-quality aftermarket mounts are essential. Cheaper mounts may use softer rubber or inferior materials, which don’t absorb engine vibration as effectively and wear out faster.

Performance-oriented mounts can sometimes stiffen up the feel, but unless you’re tracking your Juke, factory-tuned mounts strike the best balance between comfort and durability.

In some cases, the mounts don’t need immediate replacement but benefit from reinforcement or support brackets, especially if you’ve modified your Juke for extra power.

Even without modifications, getting the mounts checked during routine service gives you a chance to spot early failure before it becomes severe. Paying attention to engine mounts might not feel urgent, but it’s one of those invisible upgrades that improve daily driving and long-term reliability alike.

8. Keep the Cooling System in Top Shape

The cooling system often determines how well an engine ages. In the Juke’s case, its turbocharged engine runs hotter than most naturally aspirated motors, meaning the radiator, hoses, thermostat, and water pump all work harder to regulate temperature.

A single point of failure in this system can quickly lead to overheating and potentially catastrophic engine damage. Keeping the cooling system well-maintained is not just recommended, it’s essential for long-term reliability.

Start by checking coolant levels monthly and always use the correct type. Nissan recommends specific formulations that protect against corrosion while maintaining the right boiling and freezing points. Using the wrong coolant or mixing different types can result in internal gelling and blockages.

Changing the coolant every 60,000 miles, or sooner if the color darkens or loses transparency, is a wise move, especially in turbocharged engines where temperature fluctuations are more aggressive.

The radiator and coolant hoses should also be inspected regularly for cracks, swelling, or brittleness. These rubber parts naturally degrade with time and heat cycles. A small leak can turn into a blown hose in minutes under pressure.

Likewise, the thermostat should be replaced preventively around 100,000 miles. A stuck thermostat won’t always trigger a warning light until it’s too late and the engine is already overheating.

Finally, pay attention to the radiator fan and temperature sensors. The electric fan must kick on at the right temperature, especially when idling in traffic. If it fails, coolant temperatures can spike fast, putting stress on head gaskets and other engine internals.

Replacing sensors and relays before failure can save the engine from being cooked. The entire cooling system functions as a team, and one weak link can compromise everything. Maintaining it ensures the engine stays at the right temperature, which is critical for reliability.

9. Avoid Aggressive Driving on a Cold Engine

Turbocharged engines need to be warmed up properly before being subjected to high loads. The Juke’s small-displacement engine relies heavily on oil pressure and lubrication to protect its turbocharger and internal components.

Accelerating hard before the engine reaches operating temperature increases wear, not just on the engine, but on the turbo and transmission as well. One of the easiest habits to build for long-term reliability is simply driving gently for the first 5 to 10 minutes.

When an engine is cold, oil is thicker and doesn’t circulate as effectively. During those first few minutes, internal friction is at its highest. Revving high or accelerating aggressively before the oil has thinned out and reached every part of the engine leads to metal-on-metal contact in the worst cases.

This kind of wear isn’t immediately obvious, but over years of repeated abuse, it adds up. Pistons, bearings, and turbo components wear faster, eventually resulting in a noisy engine or loss of compression.

Additionally, the CVT transmission also benefits from a warm-up period. Cold transmission fluid is more viscous and doesn’t lubricate moving parts as effectively.

Launching the car aggressively from a cold start stresses the belt and pulleys inside the CVT, increasing the chance of early failure. Letting both the engine and transmission warm up by driving moderately allows all fluids to reach ideal operating conditions.

This habit costs nothing and requires no tools or parts. It’s just mindful driving. Even on short trips, waiting for engine temperature to normalize before accelerating hard helps reduce internal wear. Many reliability issues stem not from defective parts but from poor habits. Giving your Juke a proper warm-up period every time you start it is one of the simplest and most effective ways to extend its life.

10. Perform a Full Inspection Every 12 Months

Most car owners stick to oil changes and tire rotations, but once a year, your Nissan Juke deserves a deeper look. A full annual inspection covers all the small systems that can fail without warning, belts, hoses, seals, electronics, gaskets, and more.

This isn’t just about safety; it’s about catching problems before they become expensive or disabling. Making a full-vehicle inspection part of your maintenance routine is a powerful way to stay ahead of mechanical surprises.

Start with the drive belts and pulleys. These parts are easy to overlook but critical to engine operation. A frayed or slipping belt can lead to charging issues or engine overheating.

Check the serpentine belt for cracks and glazing. Also, inspect tensioners and idler pulleys for smooth rotation. Replacing a $40 belt every few years is a lot cheaper than replacing a seized alternator or overheating due to a failed water pump.

The inspection should also include a scan for stored error codes. Even if no warning lights are on, modern vehicles store “pending” codes that could point to future issues. A basic OBD-II scanner can read these, and you can take corrective action early. Look at the battery’s health, check for small oil or coolant leaks, and review the state of electrical connectors, which often corrode or loosen with time.

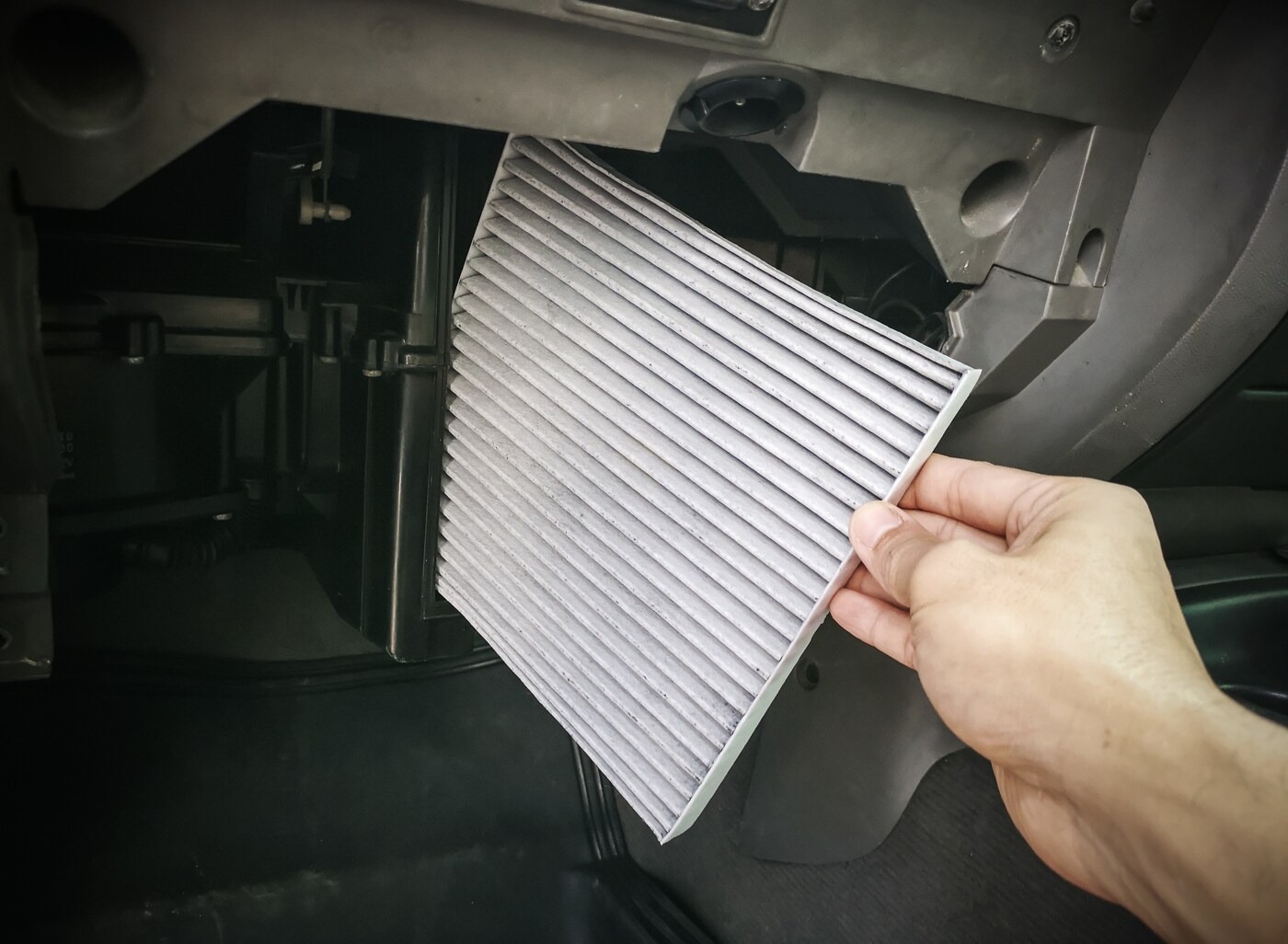

Finally, inspect tires for uneven wear, which could indicate alignment problems or suspension wear. Look under the car for signs of fluid drips or rust. Even minor details like cabin air filter cleanliness or headlight lens clarity can affect your daily experience.

This full check-up helps the car feel solid and predictable rather than slowly deteriorating over time. Preventive maintenance always costs less than reactive repairs, and a yearly inspection is the cornerstone of keeping your Juke dependable long after the odometer hits six digits.

11. Replace the Cabin and Engine Air Filters on Schedule

Air filters may seem like small, inexpensive parts, but they play a critical role in how smoothly and efficiently your Nissan Juke runs. Both the engine air filter and the cabin air filter need to be replaced regularly, yet they are often forgotten.

A dirty engine air filter restricts airflow into the engine, causing it to work harder, run hotter, and burn more fuel. A clogged cabin filter, on the other hand, affects HVAC performance and even impacts electronics by increasing moisture and dirt inside the cabin.

The engine air filter should typically be replaced every 15,000 to 20,000 miles, depending on driving conditions. If you live in a dusty environment or frequently drive on unpaved roads, you’ll need to do this more often.

When the filter is dirty, the engine can’t “breathe” efficiently. This leads to reduced fuel economy, sluggish acceleration, and more carbon buildup in the intake and combustion chambers. Replacing it on time helps maintain consistent throttle response and combustion efficiency.

The cabin air filter is just as important, though it often gets overlooked because it doesn’t directly affect engine performance. Over time, dust, pollen, and pollutants clog the filter, reducing airflow into the cabin. This puts extra strain on the blower motor and can lead to foggy windows or musty odors.

Worse, a clogged filter can encourage mold growth inside the HVAC system, which becomes a health hazard. Replace the cabin filter at least once a year, or every 12,000 to 15,000 miles.

These filters are cheap and easy to replace, making them ideal for DIY maintenance. The benefits go beyond performance, your engine will last longer, your AC and heat will work better, and your driving environment will be cleaner and healthier.

These are low-effort, high-impact parts that play a big role in long-term reliability. Skipping them invites slow degradation of engine function and interior comfort, which eventually adds up to costly repairs and annoying issues that could have easily been prevented.

12. Use a Battery Tender If the Car Sits for Long Periods

Many Nissan Juke owners don’t drive their vehicles daily, especially those who live in urban areas or use public transportation during the week. When a car sits unused for extended periods, the battery slowly drains, even if everything appears off.

Modern vehicles have a constant electronic drain due to systems like the immobilizer, infotainment memory, and electronic key detection. If the battery drops below a certain voltage repeatedly, it weakens over time and eventually dies early. Using a battery tender keeps the battery in an ideal condition without overcharging it.

A battery tender (or maintainer) is different from a standard charger. It supplies a small, steady amount of current and automatically shuts off or switches to maintenance mode when the battery is full. This prevents overcharging, which can be just as harmful as undercharging.

If your Juke sits for more than a week at a time without driving, a battery tender is a smart investment. It’s especially useful during cold seasons when battery performance naturally declines.

Allowing the battery to die repeatedly shortens its lifespan and can cause deeper electrical issues. A weak battery strains the starter motor and forces the alternator to work harder than necessary, leading to early failure of those components as well.

Modern vehicles like the Juke rely heavily on stable voltage for everything from throttle control to sensor readings. Even a slightly low battery can lead to misfires, false warning lights, or erratic behavior in systems like the transmission or power steering.

Installation is simple, most battery tenders come with clips or permanent ring terminals for easy connection. They’re affordable and don’t take up much space in a garage. This is especially useful for owners who go on extended trips, store their car seasonally, or just don’t drive daily.

Keeping your battery topped off with a tender ensures your Juke starts reliably and avoids the hidden wear caused by repeated deep discharges. It’s a quiet way to protect one of the most essential systems in your car.