The Jeep Compass Trailhawk is a compact SUV designed to handle both urban roads and rugged terrains. It offers off-road capabilities, all-wheel drive, and features tailored for those who want adventure combined with daily usability. While it is built tougher than a typical compact crossover, the Trailhawk is not indestructible.

Like any vehicle, it requires care, maintenance, and mindful driving practices. Many owners unintentionally shorten the life of their Jeep Compass Trailhawk by adopting bad habits that can lead to serious mechanical problems, cosmetic deterioration, or reduced performance.

Sometimes, it’s not the extreme use that does the damage but the repetitive misuse or neglect over time. A lot of drivers assume that because it’s a Trailhawk with off-road features, it can endure more abuse without consequence. This mindset often leads to a series of habits that gradually wear down the components that make this model special.

These habits aren’t always obvious either. They can range from driving behavior to maintenance routines, or the lack thereof. What might feel like minor oversights can snowball into significant repair bills or even total failure of key systems.

Understanding which habits are harmful can make the difference between a Trailhawk that lasts 5 years and one that runs well past the 200,000-mile mark. The idea is not to baby the vehicle or avoid using it to its full potential, but rather to know its limits, respect its design, and stick to proper practices. If you’re going to invest in a vehicle like the Trailhawk, it makes sense to protect that investment with a smart approach to ownership.

In this article, we’ll look at 8 specific habits that, if left unchecked, can quickly degrade or destroy your Jeep Compass Trailhawk. Whether you’re new to the brand or a long-time Jeep owner, avoiding these mistakes will help extend the life of your vehicle, save you money, and preserve its performance.

Also Read: 10 Tricks That Keep a Toyota Crown Reliable Past 200k

1. Ignoring Regular Oil Changes

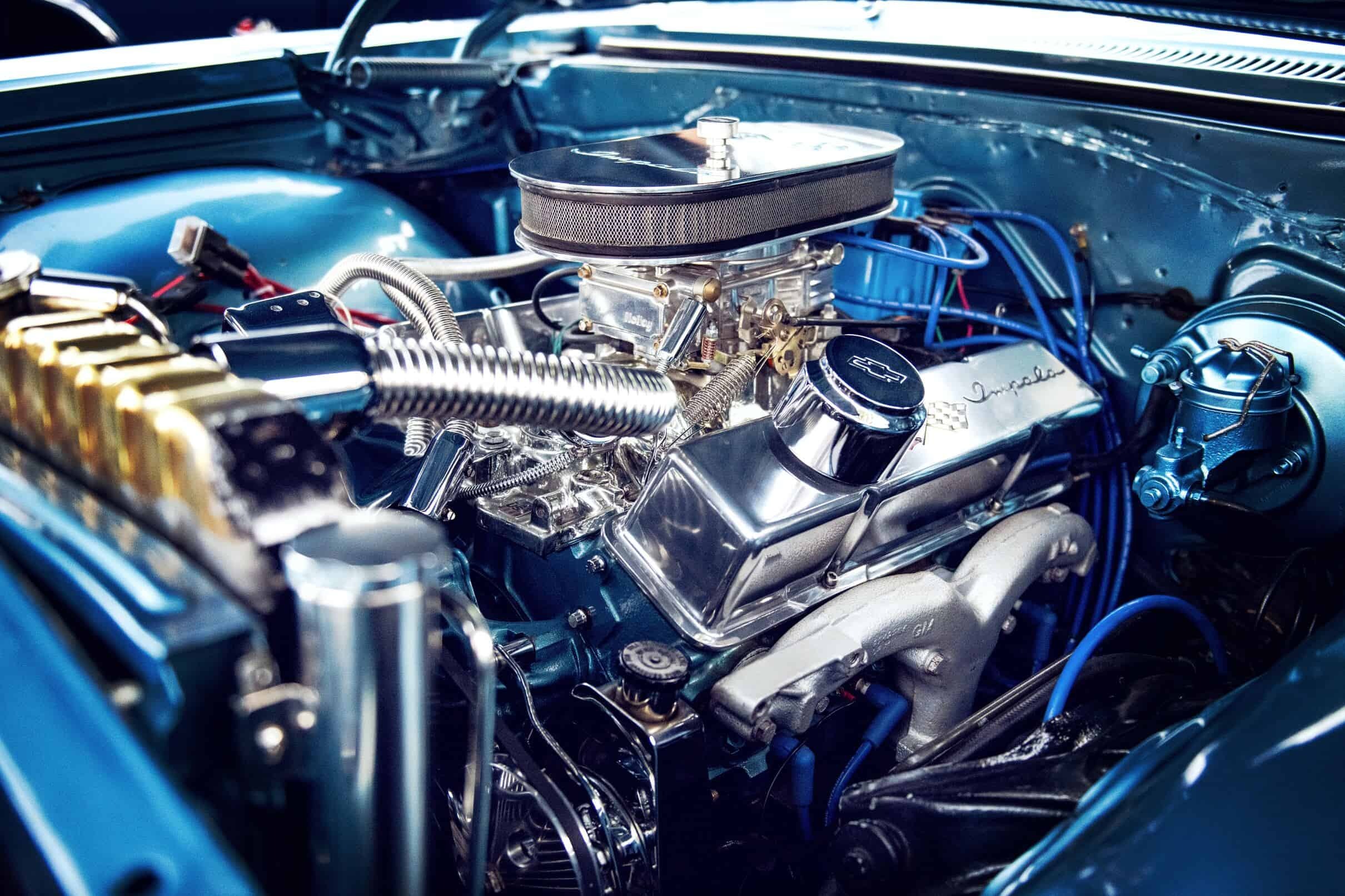

One of the most common and damaging habits is neglecting timely oil changes. The Jeep Compass Trailhawk, like any modern engine, relies heavily on clean, high-quality oil to keep all internal components properly lubricated. Oil not only reduces friction but also helps regulate temperature and remove debris.

When oil breaks down or becomes dirty, it can no longer do its job effectively. Running the engine on old or low-quality oil can result in premature wear of pistons, valves, and the turbocharger, if equipped.

Many people stretch the interval between oil changes far beyond the manufacturer’s recommendations. Some assume synthetic oil lasts forever, or that mostly short trips don’t warrant frequent maintenance. The Trailhawk’s engine isn’t particularly forgiving in this area.

Short trips, especially in cold weather, can create moisture in the crankcase that contaminates the oil faster than expected. Pushing oil past its usable life can lead to sludge buildup, reduced fuel efficiency, and potential failure of key components like the timing chain or camshaft.

Another related issue is using the wrong type of oil. Jeep specifies oil types based on viscosity, temperature range, and additives. Using a cheaper or incorrect oil might save a few bucks upfront, but it can cost thousands down the road. Engine damage caused by improper lubrication often starts subtly, with odd noises or reduced performance, and escalates quickly if not addressed.

Finally, many owners underestimate the importance of checking oil levels between changes. Even if oil is replaced on schedule, running low between services can cause the same damage as never changing it at all. Trailhawks driven off-road or under heavy loads may burn oil at a faster rate. A simple check once every few weeks can prevent catastrophic engine failure.

2. Overloading the Vehicle Beyond Its Limits

While the Trailhawk is built with off-road strength, it’s still a compact SUV and has clear limitations when it comes to payload and towing. Many owners treat it like a full-size truck, loading it with gear, equipment, or trailers far beyond what it was designed to handle. Overloading puts excessive strain on the suspension, brakes, engine, and transmission. Even short trips with a heavy load can cause long-term damage.

One major risk of overloading is overheating the powertrain. The engine and transmission have to work harder to move the extra weight, especially when climbing hills or navigating rough terrain. This can result in elevated temperatures, leading to fluid breakdown, faster wear on internal parts, and eventually complete failure. Transmission overheating, in particular, is a silent killer and can occur without warning until the damage is already done.

The suspension system also takes a serious hit when weight limits are ignored. The struts, shocks, and control arms are not designed to carry oversized cargo or passengers indefinitely. Over time, this leads to sagging, uneven tire wear, and poor handling.

A worn suspension not only makes the ride less comfortable but also reduces control in emergency maneuvers, increasing the risk of accidents.

Tires are another component that suffers from overloading. The extra weight increases tire pressure and heat buildup, which can lead to blowouts or premature tread wear. Even if you don’t exceed the listed payload or towing capacity, consistently running close to the limit can slowly degrade performance and shorten the vehicle’s lifespan. It’s essential to understand the limits set by Jeep and to stay well within them for daily use.

3. Abusing the 4WD System

The Compass Trailhawk is equipped with a capable four-wheel-drive system, including low-range gearing and terrain modes. While this system is designed to handle tough conditions, it’s not invincible. One of the most damaging habits is using 4WD improperly or leaving it engaged when it’s not needed.

For example, using 4WD Lock or low-range gears on dry pavement creates unnecessary stress on the drivetrain. This can lead to binding, overheating, and accelerated wear of components like the transfer case and differentials.

Some owners believe that having 4WD means they can power through any terrain without consequence. This mindset leads to reckless driving in mud, snow, or rocky trails, often resulting in mechanical failure.

The 4WD system is a tool, not a failsafe. Using it without understanding its limits can lead to broken axles, torn CV boots, or even a cracked transfer case housing. Replacing these parts is not cheap, and frequent misuse guarantees a visit to the repair shop sooner than expected.

Another issue is neglecting to use the 4WD system periodically. Ironically, not using it at all can be just as harmful as overusing it. Components can seize up if not engaged regularly, especially the transfer case. It’s a good practice to activate 4WD every few weeks, even on dry roads, just to keep the internal parts moving and lubricated. This simple habit can prevent costly repairs and ensure the system functions when you actually need it.

Owners also make the mistake of switching between drive modes at inappropriate times. Switching from auto to low-range mode while moving at speed, or engaging hill descent control incorrectly, can throw off the electronic systems and damage internal gears.

Always follow the recommended procedures in the owner’s manual to avoid unnecessary strain. Understanding when and how to use each mode is crucial to keeping the 4WD system in good health.

4. Skipping Tire Rotations and Alignment

Tires are one of the most important parts of any vehicle, and for the Jeep Compass Trailhawk, they do more than just support the ride. They affect traction, stability, braking, and fuel economy.

Skipping tire rotations is a habit that leads to uneven wear, reduced lifespan of the tires, and poor handling. Since the Trailhawk is often used in off-road or variable road conditions, its tires experience more stress than those on a typical sedan.

Tire rotation helps distribute wear evenly across all four tires. On an all-wheel-drive system like the one in the Trailhawk, uneven tire wear can cause issues with the drivetrain. The system expects all four tires to be the same size and rotate at similar speeds.

When one or more tires wear down faster, it confuses the sensors and puts strain on the differential and transfer case. Ignoring this can lead to expensive repairs and reduced system performance.

Alignment is another crucial factor often overlooked. Bumping a curb, hitting a pothole, or rough off-road use can knock the wheels out of alignment. This not only causes the vehicle to pull to one side but also accelerates tire wear and affects steering response.

A misaligned Jeep may also consume more fuel due to increased rolling resistance. Getting alignment checked regularly helps ensure the vehicle tracks straight and handles as it should.

Finally, keeping tires at the correct pressure is essential. Underinflated or overinflated tires can affect traction, comfort, and safety. Off-road driving often requires adjusting pressure for traction, but failing to reinflate them after the trip is a common mistake.

Driving long distances on underinflated tires damages sidewalls and reduces their load-bearing capacity. Regular checks and maintenance of tires can prevent many of these issues and extend the life of both tires and drivetrain components.

5. Neglecting Fluid Checks and Changes

One of the more damaging oversights Jeep Compass Trailhawk owners make is forgetting to monitor and replace essential fluids beyond just the engine oil. The vehicle relies on a complex network of mechanical systems that require specific fluids to operate correctly, and allowing those to deteriorate over time leads to serious issues.

Transmission fluid, coolant, brake fluid, power steering fluid, and differential oil all degrade with use, heat, and exposure to contaminants. Ignoring these can quietly wear down expensive components until they reach a point of failure. For example, old transmission fluid can result in hard shifting, slipping, or overheating that may destroy the transmission, which is one of the most costly repairs on the vehicle.

Many drivers believe that unless there’s a visible leak or a dashboard warning light, fluid levels are fine. This assumption is risky, especially with systems that don’t show immediate signs of trouble. Brake fluid, for instance, absorbs moisture over time, which reduces its effectiveness and can cause corrosion inside the brake lines.

Similarly, coolant that’s left unchanged beyond its recommended interval can lose its ability to regulate temperature and protect engine parts from rust. These aren’t always noticeable until the damage has become expensive to fix. Regular fluid checks during routine maintenance, or even a monthly once-over with a flashlight and dipstick, can reveal small problems before they become large ones.

Off-road use accelerates the degradation of fluids even more. Water crossings, dusty trails, and steep climbs push the drivetrain harder and introduce more contaminants into places like the differentials or transfer case. If water or dirt infiltrates these systems and goes unnoticed, it will drastically reduce the lubricating and protective quality of the fluids.

This may eventually result in gear failure or seizure, both of which could leave you stranded in the worst conditions. Jeep specifically recommends more frequent fluid changes for vehicles used off-road, but many Trailhawk owners still follow city-driving schedules instead.

Even if the fluids aren’t visibly dirty, time alone is a factor. Chemical breakdown occurs gradually, even if the vehicle is driven infrequently. A Trailhawk sitting idle for months is not immune to fluid degradation. Some fluids, like brake or coolant, can become acidic and corrode internal parts.

Therefore, following time-based service intervals is just as important as mileage-based ones. Taking the time to understand your vehicle’s maintenance schedule and being proactive with fluid changes can add years to your Trailhawk’s life and reduce repair costs significantly.

6. Driving Aggressively on Pavement

Despite its off-road capabilities, the Jeep Compass Trailhawk is not a high-performance sports car, nor is it designed for aggressive on-road driving. However, many owners develop habits such as rapid acceleration, hard braking, and taking turns too quickly, especially when transitioning from city traffic to open roads.

These driving behaviors don’t just affect fuel efficiency; they actively reduce the longevity of multiple components, including the transmission, suspension, brakes, and tires. The drivetrain is designed to provide balanced torque and traction, not to handle excessive wear from sharp starts and sudden stops.

Hard acceleration stresses the engine, transmission, and axles far more than most drivers realize. The constant strain on internal parts like pistons, rods, and transmission clutches leads to faster wear and increased heat, which in turn shortens the life of these components.

The Trailhawk may offer a solid balance of power and control, but pushing it beyond its design limits repeatedly causes small, often irreversible damage. Even the CV joints and driveshaft can suffer from constant jerking motions, especially when combined with uneven terrain or sudden speed changes.

Braking aggressively wears down rotors and pads much faster than necessary. Overheated brakes don’t perform well, and repeated hard braking can even lead to warped rotors. Once brake components begin to wear unevenly, the performance of the entire system declines.

This creates a chain reaction: the brakes have to work harder to compensate, which generates more heat and leads to more wear. The result is a braking system that loses responsiveness and reliability, especially in emergencies or when driving on steep grades.

Cornering too fast or taking tight turns at higher speeds also stresses the suspension and tires. The weight of the vehicle shifts abruptly, putting more pressure on one side and wearing out bushings, control arms, and shocks unevenly. Tires may develop bald spots, and the added lateral force increases the risk of blowouts or sidewall damage.

These issues may not show up immediately, but they accumulate over time. Even though the Trailhawk can handle rough conditions, it’s still best driven with respect for its design. Smooth, moderate driving habits are not only safer but will preserve the core systems that make this SUV dependable.

7. Poor Off-Roading Practices

Using a Trailhawk off-road is one of the reasons people buy it, but doing so without proper technique and understanding can shorten the vehicle’s lifespan dramatically. Many drivers underestimate how precise and careful off-roading needs to be.

Speeding over uneven surfaces, for example, can lead to severe damage to the suspension, undercarriage, and even body panels. While the Trailhawk has skid plates and raised clearance, these features are not substitutes for smart driving. Repeated impacts to the underside can warp frame components or crack protective armor, leaving vital systems vulnerable.

Using the wrong tire pressure while off-roading is another mistake that causes long-term harm. Some drivers forget to deflate for better grip on sand or rocks and end up spinning out, causing unnecessary tire and drivetrain wear. On the flip side, those who lower pressure too much and drive aggressively may suffer tire de-beading or rim damage.

The balance is delicate, and misuse either way affects not just the tires but the axles and suspension. Every jolt sends force through the entire drivetrain, which adds up quickly over time.

Attempting trails that exceed your skill level or the capabilities of the vehicle also results in more than just a stuck Jeep. Getting bogged down in deep mud, for instance, might tempt the use of excessive throttle or wheel spinning, which destroys traction systems and stresses the differentials.

Overheating or damaging the transmission during recoveries is a common consequence. Many off-roaders don’t realize how much harm they’re causing because the problems don’t appear right away. However, a single poorly executed trail run can shave years off your Trailhawk’s mechanical health.

Failing to clean the vehicle thoroughly after off-road use is another harmful habit. Mud, salt, and sand trapped in crevices can corrode metal, eat through paint, and damage suspension joints. Undercarriage rinsing is often skipped, yet it’s critical. Electrical connectors and exhaust components are also vulnerable.

If you regularly take your Trailhawk off-road and don’t follow up with careful cleaning and inspection, you’re allowing damage to accumulate unnoticed. Off-roading should be enjoyable and rewarding, not an activity that ruins your investment. Responsible technique and consistent maintenance are what make the difference.

8. Delaying Small Repairs Until They Become Big Problems

The final and perhaps most underestimated habit is ignoring small issues when they first appear. Whether it’s a strange noise, a warning light, or a minor leak, putting off a repair often leads to far more expensive consequences. For example, a loose exhaust clamp might just rattle at first, but if left unchecked, it could lead to a broken exhaust pipe or catalytic converter failure.

Likewise, a slow coolant leak could eventually turn into overheating and a blown head gasket. Many Trailhawk owners assume that if the car still drives, it’s not urgent. That kind of thinking shortens a vehicle’s lifespan more than most realize.

Even something as small as a cracked boot on a CV joint can snowball. That crack allows dirt and moisture to enter the joint, wearing down the grease and leading to metal-on-metal contact. Over time, this destroys the joint and causes clunking, vibration, or even full axle failure.

If that part breaks while driving at speed or while off-road, the result is both dangerous and costly. A $30 boot replacement becomes a $700 repair because of the time wasted. Small fixes are usually affordable and quick, but once the issue spreads to connected systems, it gets much worse.

Modern vehicles like the Compass Trailhawk rely on interconnected systems. One failing sensor might seem minor, but it can throw off the entire powertrain or fuel efficiency.

For instance, a faulty O2 sensor may not stop the car from running, but it can lead to poor air-fuel ratios that reduce performance, increase emissions, and eventually damage the catalytic converter. Dash lights, especially check engine warnings, should never be ignored. Using a basic scan tool or visiting a mechanic when these lights appear can prevent long-term complications and costly repairs.

Postponing small repairs is also a psychological habit. Owners put things off until “next week,” and before they know it, the vehicle has accumulated several issues. At that point, the cost and inconvenience feel overwhelming, which often results in selling the vehicle or trading it in prematurely.

Taking action early keeps your Trailhawk running reliably, preserves its resale value, and gives you more confidence in its long-term performance. A well-maintained vehicle is more than just functional, it becomes something you can rely on no matter the road ahead.

9. Using Low-Quality or Incorrect Replacement Parts

When it’s time for repairs or maintenance, many Jeep Compass Trailhawk owners look for ways to save money. While that’s understandable, choosing low-quality or incompatible replacement parts is a mistake that often leads to even higher costs down the line.

Whether it’s brake pads, air filters, spark plugs, or suspension components, every part of the Trailhawk is engineered to work together within specific tolerances. Cheap aftermarket parts may claim to “fit” but often lack the quality control or performance specifications required to maintain proper function over time.

For example, using discount brake pads may result in poor stopping power, excessive dust, or uneven wear on rotors. Some of these pads may not handle heat properly, especially on steep terrain or with heavier loads. Over time, you might notice vibrations during braking or hear grinding noises, which are signs that the inferior materials are failing.

What could have been a basic maintenance job turns into rotor replacement or caliper damage, both of which are much more expensive. The Trailhawk’s off-road potential and weight make braking performance even more critical, so quality should never be compromised.

Another common area where corners are cut is suspension parts. Off-brand struts or bushings may initially fit and function but wear out much faster under the weight and motion of a Trailhawk used off-pavement. They often provide a harsher ride or develop annoying squeaks and rattles.

Some may not handle sharp impacts well, leading to premature failure and risking damage to nearby components. Because suspension systems are interconnected, a weak or poorly fitting part often stresses other joints and mounts in the system, accelerating wear elsewhere.

Even using cheap fluids, filters, or spark plugs can lead to trouble. Filters that don’t meet OEM specs may let debris into the engine or transmission, while incompatible spark plugs may cause misfires and reduced fuel economy.

It’s not always about going with the most expensive brand, but it is about selecting components that meet or exceed the manufacturer’s standards. Investing in high-quality parts once is almost always cheaper than fixing the damage caused by poor replacements. The Trailhawk is a refined machine and should be treated accordingly when it comes to parts selection.

10. Leaving It Parked for Long Periods Without Preparation

It may seem harmless to leave a vehicle sitting for a few weeks or even months, but the reality is that long-term inactivity can severely impact the health of your Jeep Compass Trailhawk. Many owners don’t consider that a vehicle deteriorates differently when idle.

Fluids settle, seals dry out, the battery drains, and tires can develop flat spots. Suppose you let your Trailhawk sit for long periods without proper storage practices. In that case, you’re inviting a series of mechanical and electrical problems that will surface as soon as you start driving again.

One of the most immediate issues is battery drain. The Trailhawk’s modern systems, including keyless entry, infotainment, and security modules, all draw a small amount of power even when the car is off. If the vehicle isn’t driven regularly or hooked up to a trickle charger, the battery may die completely.

Repeated deep discharges also shorten battery life permanently. When this happens, the alternator is forced to work harder to recharge the battery, and that extra load can reduce its lifespan as well. A dead or weak battery can also cause system glitches and trigger warning lights.

Tires suffer too when the vehicle is parked in the same position for a long time. The weight of the Trailhawk pressing down on unmoving tires can cause flat spots, especially in colder weather or if the tires are slightly underinflated. These flat spots can make the ride feel bumpy or uneven, and in some cases, they may not go away after driving.

Over time, the rubber compounds also begin to degrade, particularly if exposed to sunlight and temperature fluctuations. This reduces traction, increases the risk of a blowout, and requires premature replacement.

Fluid issues are another concern. Engine oil, transmission fluid, and coolant don’t circulate when the vehicle is off, and they tend to settle or even separate over time. This can cause sludge buildup or allow moisture to collect in the system. Hoses and seals may dry out or crack, especially if the vehicle is stored in a dry or overly humid climate.

Suppose you know your Trailhawk will be sitting for more than a few weeks. In that case, it’s worth taking preventive steps: fill the tank, keep the battery charged, check tire pressure regularly, and run the engine periodically to circulate fluids and prevent buildup.