When it comes to cars, few things frustrate owners more than an engine that fails prematurely. Engines are complex machines with hundreds of moving parts, and their lifespan depends on a combination of design quality, materials, usage, and maintenance.

While some engines reward their owners for meticulous care with long-lasting performance, others seem to have a predetermined fate, breaking down no matter how well they are maintained. This leads to a frustrating reality in the automotive world: not all engines are created equal, and not all of them respond to care in the same way.

There are engines out there known for their rugged longevity. These engines can clock hundreds of thousands of miles if you stay on top of basic service like oil changes, timing belt replacements, and proper cooling.

These are the types of engines found in vehicles that are passed down through generations or sold with confidence even after the odometer shows six figures. The reliability of such engines is not an accident. It often stems from conservative engineering choices, solid materials, and a lack of unnecessary complexity. Their strength lies in simplicity and a design philosophy that values durability over flash.

Then there are the engines that seem cursed from the start. These engines may come from prestigious brands, feature impressive horsepower figures, or use advanced technology, but beneath the surface, some flaws cannot be masked. No amount of careful maintenance can prevent their inevitable issues.

Some suffer from poor design, others from cost-cutting during manufacturing, and some are just too complex for their own good. The problems could be premature timing chain failure, weak internals, fragile cooling systems, or oil consumption that worsens with time regardless of how often the oil is changed.

This article will compare five engines that are known to thrive with proper maintenance and five that are known to break regardless of owner diligence. While individual experiences may vary, especially based on usage and climate, these engines have developed reputations over time in enthusiast forums, repair shops, and real-world owner feedback.

By examining these examples, we can better understand what makes an engine truly dependable and what makes one destined for failure. Whether you’re shopping for a used car or simply curious about engine reliability, this comparison helps illustrate why some engines stand the test of time, while others become cautionary tales.

Also Read: 5 Engines That Keep Their Power After 200K vs 5 That Lose It Early

5 Engines That Thrive on Regular Maintenance

1. Toyota 2UZ-FE (4.7L V8)

The 2UZ-FE is part of Toyota’s famous UZ engine family and has become a symbol of rugged dependability, especially in trucks and SUVs like the Land Cruiser, Sequoia, and Tundra. It’s an engine that does not try to impress with high-revving performance or groundbreaking technology. Instead, it is built with a focus on reliability and ease of maintenance. The cast iron block and aluminum heads are designed to withstand heavy use, making it an ideal choice for off-roaders and long-distance travelers alike.

Owners who follow a regular maintenance schedule with this engine are often rewarded with mileage that pushes well past the 300,000 mark. The key maintenance points are straightforward: regular oil changes with quality fluids, timely timing belt replacements, and checking for valve cover gasket leaks.

If these basics are handled, the engine runs smoothly year after year. Its tolerance for varying fuel qualities and simple emissions systems also makes it less prone to the types of failures seen in newer, more complicated engines.

Another reason for the 2UZ-FE’s long life is its relatively conservative power output for its displacement. Unlike smaller turbocharged engines that are often pushed to their limits, the 2UZ-FE never feels like it’s being overworked.

This margin of safety in its engineering allows it to handle towing, heat, and high mileage without complaint. It was designed with longevity in mind rather than squeezing out every bit of horsepower.

For those who own vehicles with this engine, the story is often the same: if you treat it right, it will last. Even neglected ones can be brought back to health with some work, but when well-maintained from the start, they are among the most reliable V8s ever built. Whether in harsh climates or city driving, this engine remains a benchmark of reliability when given basic, consistent care.

2. Honda K24 (2.4L Inline-4)

The K24 is widely considered one of Honda’s best engineering achievements, balancing power, fuel economy, and longevity. Found in vehicles like the Accord, CR-V, and Element, as well as performance variants in the Acura TSX and Honda Civic Si, the K24 is a versatile engine that can take abuse and keep going, as long as you take care of it. What makes the K24 special is its robust design paired with VTEC efficiency, delivering both reliability and decent performance.

Owners who stick to regular oil changes and timing chain inspections often see these engines running well into the 200,000 to 300,000-mile range.

The engine doesn’t have any chronic design flaws; instead, most issues come from a lack of maintenance. For example, neglecting oil changes can lead to timing chain tensioner failure, but this isn’t a flaw in the engine, just a result of poor upkeep. If maintained well, the timing chain system remains reliable, and the motor delivers consistent power throughout its life.

One of the reasons the K24 is so popular among enthusiasts is that it holds up well even when driven hard. It’s common to see these engines swapped into older Hondas for performance builds. That speaks volumes about its durability.

The cylinder walls are strong, the head design promotes efficient combustion, and even the internals are built to last. Maintenance-friendly access to parts like spark plugs, filters, and belts adds to its long-term affordability.

While no engine is invincible, the K24 shows just how far good maintenance can go. Regular valve adjustments (in earlier models), coolant flushes, and quality fluids are all that’s needed to keep it healthy. Whether it’s commuting or spirited driving, this engine handles it all with confidence as long as it’s treated right. It’s proof that reliability doesn’t mean boring, it just means smart engineering backed by owner responsibility.

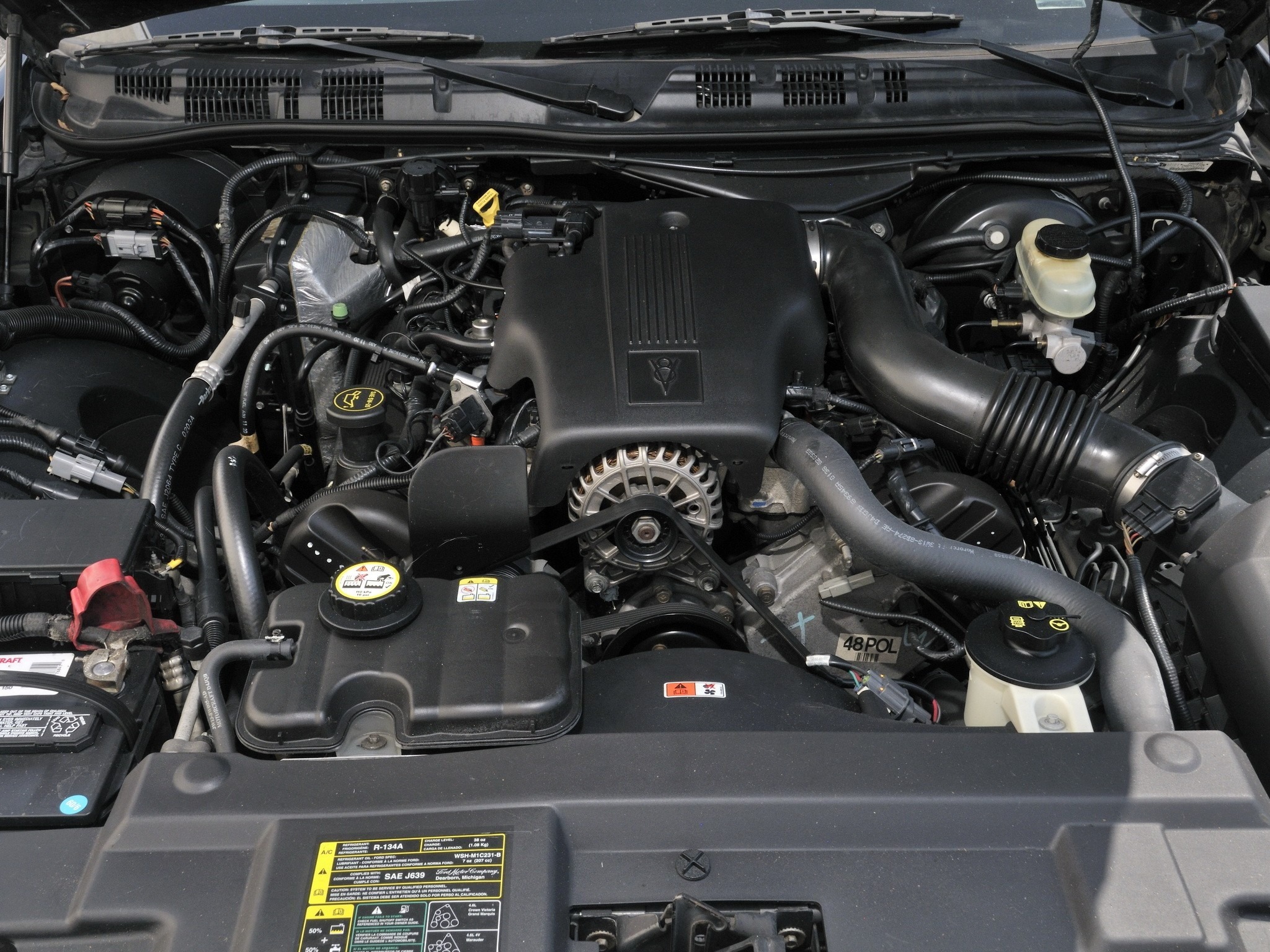

3. Ford Modular 4.6L V8

The Ford 4.6L Modular V8 served in a wide range of vehicles, from Mustangs and Crown Victorias to F-150s and Expeditions. Though not the most exciting engine in terms of horsepower, its track record for durability is solid. When properly maintained, these engines regularly cross the 300,000-mile mark without major repairs. The secret lies in the engine’s overbuilt nature and relatively simple design, especially in the 2-valve and 3-valve configurations.

The most common issues arise when owners neglect regular oil changes or cooling system upkeep. These engines are sensitive to sludge buildup, particularly in the timing components, but this problem is almost always linked to poor maintenance rather than faulty design.

With fresh oil and regular intervals, the engine stays clean and continues to run smoothly. The 4.6 also benefits from a strong iron block in many of its applications, making it resistant to heat and stress under load.

Another point in its favor is that parts are cheap and widely available. There are millions of these engines out there, so replacement parts and service knowledge are abundant.

This keeps maintenance costs low, which in turn encourages better upkeep from owners. The engines are forgiving to some extent, but when treated right, they rarely disappoint. Police fleets, taxis, and long-haul work trucks all offer evidence of this engine’s capability when well-maintained.

The Modular 4.6L may not be flashy, but it has a reputation for outlasting expectations. As long as you keep the oil fresh, coolant in check, and spark plugs properly torqued, this engine will keep running. It’s an example of how a large, slightly underpowered V8 can be a long-term asset for owners who value dependability over outright speed.

4. GM 3800 Series II (3.8L V6)

The GM 3800 Series II engine has long been celebrated for its exceptional durability and surprising fuel efficiency for a V6. Found in cars like the Buick LeSabre, Pontiac Bonneville, and Chevrolet Impala, this engine has earned a cult following for its ability to run well past 250,000 miles with relatively few issues. While not the most modern power plant, it showcases what old-school engineering can accomplish when paired with regular care.

One of the key aspects of the 3800’s reliability is its simplicity. There’s no turbocharging, no exotic materials, and very little that’s overcomplicated. Basic maintenance, oil changes, coolant flushes, and intake gasket monitoring, keeps the engine in solid condition. The one notorious problem this engine faced was intake manifold failure, but even that issue was well documented and relatively inexpensive to fix. Once addressed, the engine goes back to being a tank.

It’s not uncommon to find these engines in older cars still running without smoke, knocks, or significant loss of power. The torque curve is smooth, the idle is steady, and the fuel economy is respectable even by today’s standards. The transmission paired with it often fails before the engine does, which says a lot. Junkyards across the country are full of working 3800s pulled from rusted-out cars that still ran perfectly.

The 3800 also has an excellent tolerance for different driving styles and conditions. Whether it’s driven gently on the highway or subjected to harsh stop-and-go traffic in city use, it maintains composure with minimal degradation over time.

The powerband is tuned for everyday usability rather than aggressive performance, so the engine is never strained in normal use. For older drivers and fleet owners, this was ideal: an engine that didn’t beg to be pushed hard but was always ready to work when needed.

And because it didn’t have advanced tech like variable valve timing or direct injection, fewer things could go wrong over the long haul.

Another advantage is the low cost of upkeep. Because of the engine’s wide availability and the sheer number of GM vehicles that used it, parts are abundant and affordable. Everything from water pumps to sensors can be replaced cheaply, and even full engine swaps are often less expensive than repairing more modern, complicated powertrains.

Even as newer engines become more efficient and high-tech, few offer the mechanical confidence of the 3800. If given clean oil, proper coolant levels, and basic gasket care, it can outlast engines half its size and twice its complexity. It’s a testament to how regular maintenance paired with good design can extend engine life far beyond what most manufacturers anticipate.

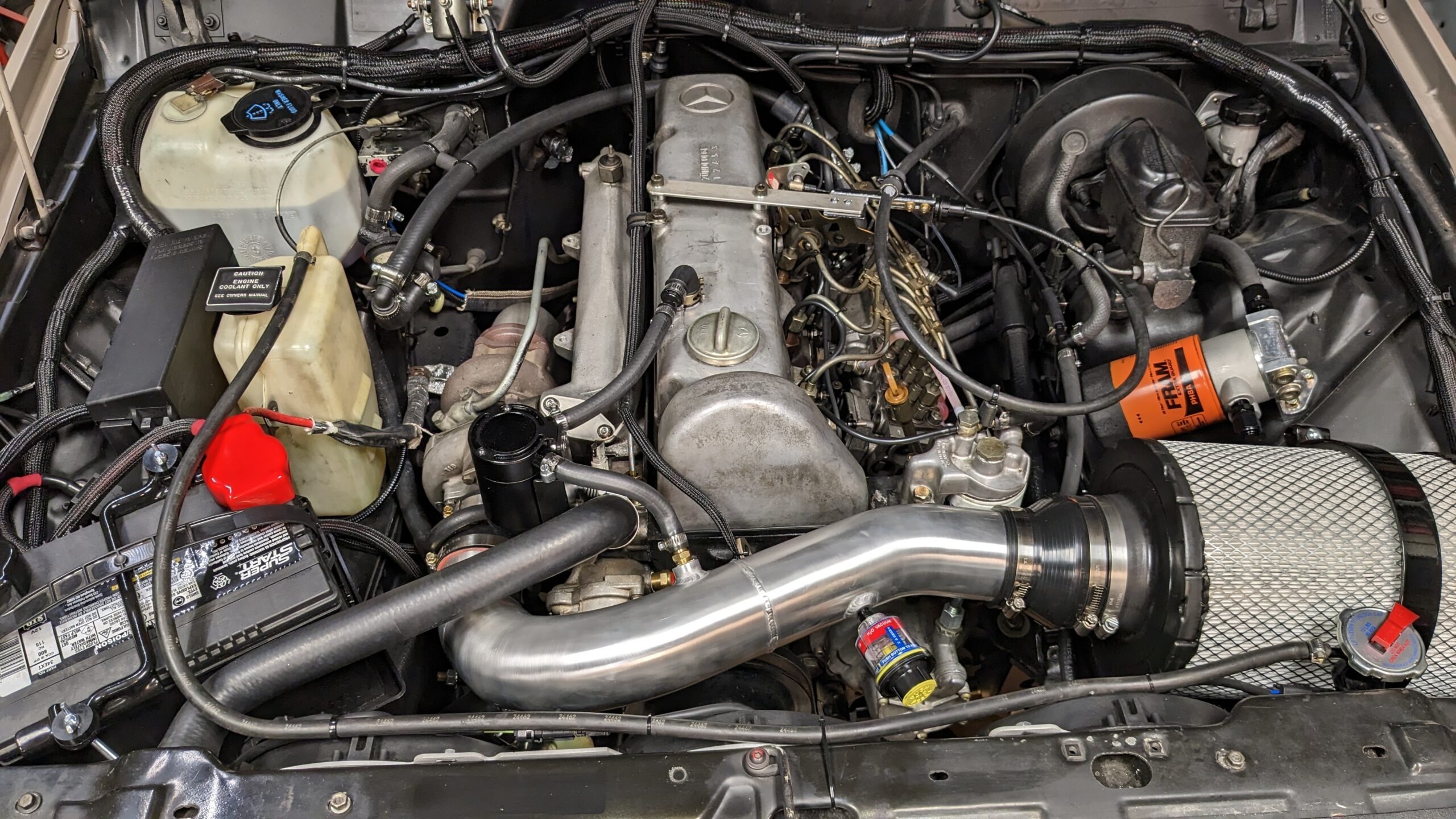

5. Mercedes-Benz OM617 (3.0L Diesel I5)

The OM617 diesel engine, used in Mercedes-Benz vehicles from the 1970s to the mid-1980s, is a legend in the world of longevity. Known for powering the W123 and early W126 chassis, this inline-five diesel became famous for reaching mileage figures most modern engines only dream of.

There are countless examples of these engines surpassing 500,000 miles, and some even approach or exceed the million-mile mark. The key to this incredible lifespan is simple: meticulous engineering and diligent maintenance.

The OM617 was built at a time when Mercedes was overbuilding everything, especially their engines. Featuring a cast iron block and head, the engine is inherently strong and thermally stable. It was designed to run on low-quality diesel and endure extended periods of operation under tough conditions.

These characteristics made it a favorite in markets with unreliable fuel and extreme climates. However, it demands regular care. Clean oil is critical, as the engine has tight clearances and depends heavily on lubrication. Fuel filters must be changed on schedule, and valve adjustments are needed every 15,000 miles. Skip these, and the engine loses efficiency and can wear prematurely.

One reason the OM617 lasts so long is that it’s never stressed. With only about 120 horsepower in its most powerful versions, the engine operates at a low strain level. This reduces internal pressure and heat, keeping parts from wearing down quickly.

Many owners compare it to a tractor motor, slow but unstoppable. Its simplicity also plays a role. No turbos (in earlier versions), no electronic injectors, and minimal emissions systems mean fewer failure points. It’s an engine built for a time when serviceability mattered more than innovation.

For those willing to follow the schedule, this engine gives back generously. It may smoke a little, and acceleration is far from modern expectations, but it runs year after year with very little complaint. Mechanics love it because everything is accessible, and parts are still available due to the large number of engines produced. In today’s world of disposable powertrains, the OM617 is a reminder of what’s possible when maintenance and mechanical design align perfectly.

Also Read: 5 Cars With Affordable Parts vs 5 That Cost a Fortune

5 Engines That Break No Matter What

1. BMW N54 (3.0L Turbo I6)

The BMW N54 engine debuted with excitement, promising thrilling performance through twin turbochargers and direct injection. It delivered on that promise, at least initially. Found in cars like the 335i, 135i, and early 740i models, the N54 was praised for its smooth power delivery and tuning potential.

However, it quickly earned a reputation as a nightmare in long-term ownership, plagued with problems that often arise regardless of how well the engine is maintained. Even owners who follow service intervals meticulously find themselves battling chronic issues that stem more from design flaws than negligence.

High-pressure fuel pump (HPFP) failures are perhaps the most notorious issue with the N54. Even under warranty, owners frequently had to replace these pumps multiple times, and BMW eventually issued recalls and extended warranties for them. But that’s just the start.

The engine is also known for problems with the turbochargers themselves, specifically the wastegate actuators, which develop annoying rattles and eventually fail. These issues occur even on engines with regular oil changes and premium fuel. In fact, some owners report problems beginning as early as 60,000 miles, a time when most engines are just getting comfortable.

Another major flaw lies in the engine’s use of direct injection without additional cleaning systems. Over time, carbon builds up on the intake valves, choking the engine and causing rough idling and poor performance.

Walnut blasting, an expensive cleaning procedure, becomes a necessary maintenance item every 50,000 to 70,000 miles. No amount of oil changes or good driving habits can prevent it. This maintenance cost is substantial and unavoidable. Even with top-tier care, the engine ages poorly compared to naturally aspirated alternatives.

Add to that the complexity of the N54’s cooling system, its sensitive sensors, and the general cost of BMW-specific parts, and it becomes clear that this is not a long-term-friendly engine.

Enthusiasts may love the way it drives, and tuners appreciate its power potential, but even among high-performance engines, the N54 stands out for needing a ridiculous amount of attention to remain functional. It’s the kind of engine that looks good on paper, feels great on the road, but breaks hearts in the repair shop.

2. Subaru EJ25 (2.5L H4)

The Subaru EJ25 engine, particularly in turbocharged form, has developed a notorious reputation among car enthusiasts and owners alike. Found in models such as the WRX, Forester XT, and Legacy GT, it is often blamed for a litany of issues that can appear regardless of how meticulously the owner maintains it.

Despite Subaru’s loyal fanbase and the engine’s performance appeal, this powerplant is often more of a ticking time bomb than a reliable piece of engineering.

The most infamous issue associated with the EJ25 is head gasket failure. While Subaru did attempt to revise the gasket design over the years, many of these engines still end up leaking coolant and oil through the gaskets, often before reaching 100,000 miles.

Even owners who change the oil religiously and use high-quality coolant aren’t immune. The problem lies in the engine’s flat-four design, which puts extra thermal stress on the gaskets, especially during extended heat cycles. The issue isn’t always immediately catastrophic, but it leads to slow leaks, overheating, and eventually expensive repairs that require the engine to be pulled apart.

Oil consumption is another chronic issue. The EJ25, particularly in turbo form, tends to burn oil at a rate higher than most engines, even when new. Subaru once called this “normal,” much to the dismay of owners who found themselves topping off oil between every fill-up.

The ringland failure issue, where the piston rings fail and cause loss of compression, is yet another concern that can result in full engine replacement. Again, these failures often happen in well-maintained vehicles, indicating a deeper issue with the internal design and materials.

The turbocharged versions of the EJ25 are also particularly fragile. Many suffer from premature turbo failure due to oil starvation or bearing wear, even with good maintenance practices. The oil passages are narrow, and sludge can build up despite frequent oil changes, leading to seized turbos or worse.

Add in timing belt service every 100,000 miles and the complexity of accessing key engine components, and the EJ25 becomes an expensive and unreliable engine to live with. It’s a frustrating engine because many owners are careful, only to find themselves with a failed motor anyway.

3. Chrysler 2.7L V6 (Used in early 2000s Dodge/Chrysler vehicles)

The Chrysler 2.7L V6 engine, most commonly found in vehicles like the Dodge Intrepid, Chrysler Sebring, and Concorde during the early 2000s, is widely recognized as one of the most failure-prone engines of the modern era. On paper, it seemed like a decent engine: lightweight, relatively efficient, and compact enough for front-wheel-drive applications.

However, in real-world use, it developed a reputation for catastrophic failure, often before reaching 100,000 miles. The worst part is that many of these failures occurred even when owners followed the manufacturer’s recommended maintenance schedule.

One of the biggest problems with the 2.7L V6 lies in its poorly designed internal oiling system. The narrow oil passages and small capacity oil pump make it extremely sensitive to sludge buildup.

This means that even slightly extended oil change intervals or the use of lower-quality oil can result in clogged passages, starved components, and severe internal wear. Even owners who were diligent about changing their oil every 3,000 to 5,000 miles reported sludge-related failures. It’s not a matter of neglect; it’s a flawed engine design that gives minimal margin for error.

Timing chain tensioners and water pumps were also major weak points. In many cases, the water pump, which is internally driven by the timing chain, would begin leaking into the crankcase. This would dilute the oil with coolant, causing a loss of lubrication and rapid internal wear.

What made the situation worse was that diagnosing the water pump leak wasn’t easy, and by the time symptoms like coolant loss or milkshake-colored oil appeared, the damage was often already done. Fixing it wasn’t cheap either; the engine often had to be pulled for a proper repair, and many chose to replace the engine entirely instead.

4. Mazda 2.3L DISI Turbo (Used in Mazdaspeed3, Mazdaspeed6, CX-7)

The 2.3L DISI Turbo engine, used in performance-oriented Mazdas like the Mazdaspeed3, Mazdaspeed6, and even the CX-7 crossover, is another engine that gained early attention for its punchy turbocharged performance but eventually revealed itself as fragile and expensive to maintain.

Despite Mazda’s engineering reputation for reliability in naturally aspirated platforms, the DISI Turbo was prone to serious issues, many of which weren’t preventable through standard maintenance. Even well-maintained examples have succumbed to failures that seemed inevitable.

Rod bearing failures are another common issue. The engine is known to suffer from oil starvation at high RPMs or during hard driving, especially if the oil isn’t checked frequently. The stock oil control system doesn’t always keep up, leading to early bearing wear and even thrown rods.

It’s not unusual for these engines to fail before 100,000 miles despite regular oil changes. And because the Mazdaspeed community often attracts performance enthusiasts, many of these engines are driven hard, something they weren’t built to handle for long.

The turbocharger system also presents problems. The stock K04 turbo suffers from wastegate problems and seals that tend to wear quickly, leading to oil consumption and degraded performance. Over time, even stock turbos begin to leak or produce inconsistent boost.

Add to that the fact that the engine bay is cramped and difficult to work on, and you get an engine that is both high-maintenance and unreliable. Owners who take meticulous care of their engines still find themselves dealing with blown seals, carbon buildup, and bottom-end failures. The DISI Turbo had great potential, but its durability failed to match its performance.

5. Volkswagen/Audi 2.0 TSI (EA888 Gen 1 & 2)

The early generations of the VW/Audi 2.0 TSI engine (specifically Gen 1 and Gen 2 of the EA888 family) are among the most infamous engines for reliability concerns across the automotive community.

Found in a wide range of vehicles including the Volkswagen GTI, Passat, Jetta GLI, and Audi A4, A5, and A3, the engine initially impressed with strong performance, smooth torque delivery, and good fuel economy. However, over time, it became clear that the 2.0 TSI had serious flaws that couldn’t simply be managed with routine care.

The most well-documented issue is the engine’s timing chain tensioner system. Early TSI models used a defective tensioner design that could fail without warning, allowing the timing chain to jump teeth or completely dislodge. This often led to catastrophic valve and piston damage, an interference engine’s worst-case scenario.

Many owners experienced complete engine failure with little to no prior symptoms, even with regular maintenance. Volkswagen issued updated parts and eventually revised the design, but many engines were already affected, and the damage was irreversible.

Oil consumption is another critical failure point. Early EA888 engines are known for excessive oil burning, sometimes requiring a quart every 500 to 1,000 miles. VW dealerships often dismissed this as “normal” usage, frustrating owners who had to constantly monitor oil levels and top off between changes.

The root cause often stemmed from faulty piston rings and valve guide wear, which couldn’t be resolved without a full rebuild or engine replacement. Even synthetic oil, changed on time, couldn’t compensate for the poor internal sealing and combustion inefficiencies.

The early 2.0 TSI represents an engine that was ambitious in its design but rushed in its execution. While later generations addressed many of the flaws, the Gen 1 and Gen 2 models remain cautionary tales.

For many, the combination of complex systems and poor reliability meant that maintenance simply wasn’t enough to ensure longevity. Even responsible owners found themselves trapped in a cycle of repairs that made the engine’s promising performance hardly worth the effort.