When discussing engine reliability, one of the key concerns for any vehicle owner is the longevity of the head gasket. A head gasket failure can be catastrophic and expensive. It usually involves coolant and oil mixing, loss of compression, overheating, and in many cases, engine replacement.

Despite advances in engineering, some engines remain prone to these failures, especially those that are turbocharged, run hotter, or feature aluminum heads paired with cast iron blocks. However, not all engines fall into that category. Over the years, certain engines have gained a reputation for being nearly immune to head gasket problems, thanks to their smart design, effective thermal management, and durable materials.

The engines on this list are not necessarily the most powerful or the most modern. Instead, they are known for their resistance to a problem that has plagued internal combustion designs for decades. This doesn’t mean these engines are flawless or invincible.

Regular maintenance, including coolant flushes, proper oil changes, and watching temperature gauges, still plays a vital role. But what sets these engines apart is how rarely they suffer from head gasket failures under normal driving conditions. These engines have proven themselves in the real world, in daily commuting, high-mileage service, and even spirited driving.

Many manufacturers strive for tight tolerances and thermal expansion properties that keep the head gasket seated properly between the cylinder head and the engine block.

A good head gasket design, reinforced materials, proper torque sequences during assembly, and cylinder pressure management all contribute to a longer-lasting seal.

Engines that strike the right balance between performance and durability tend to hold up better over time. When owners report reaching over 200,000 or even 300,000 miles without any head gasket issues, that’s a strong indicator of good design choices.

Below is a list of eight engines that have stood the test of time. Each of them has a reputation for rarely blowing head gaskets, even when subjected to less-than-perfect driving habits.

Whether you’re a mechanic looking for dependable powerplants or a buyer looking for a used vehicle with fewer risks, these engines offer peace of mind. Let’s go through them one by one and understand what makes them so resistant to this common and costly failure.

Also Read: 5 Cars That Stay Reliable Beyond 300K vs 5 That Fall Apart Early

1. Toyota 2UZ-FE (4.7L V8)

The Toyota 2UZ-FE is a member of Toyota’s UZ engine family and is widely regarded as one of the most durable V8s ever built. It was commonly used in Toyota’s trucks and SUVs, such as the Land Cruiser, Sequoia, and Tundra. This engine is built with a cast iron block and aluminum heads, which can sometimes be problematic due to differences in thermal expansion.

However, in the case of the 2UZ-FE, Toyota engineered the head gasket and cooling system to such a high standard that failures in this area are almost unheard of. The engine maintains excellent thermal stability under both normal and heavy loads, which is essential for preventing head gasket issues.

One reason for the 2UZ-FE’s reputation is its conservative power output relative to its displacement. It’s not a high-strung engine that operates near its limit. Instead, it’s tuned for longevity, low-stress operation, and a wide torque band. That tuning philosophy contributes to its low rate of head gasket failures.

Even in applications where the engine is worked hard, such as towing or off-road driving, the 2UZ-FE remains cool and stable. Cooling passages within the block and head are carefully designed to avoid hotspots, which are often the culprits in gasket failures.

The head bolts used in the 2UZ-FE are strong and well-torqued from the factory, helping to maintain the clamping force needed to keep the gasket sealed. The multi-layer steel gasket design also improves durability compared to older composite materials.

Toyota’s attention to detail in this engine’s construction shows in the long list of high-mileage vehicles that continue to run smoothly without major engine repairs. It’s not unusual to find these engines running beyond 300,000 miles with original gaskets still intact.

From a serviceability perspective, the 2UZ-FE is straightforward for most experienced mechanics. Even in the rare case where a gasket issue might arise due to neglect or overheating, repairs are usually not too complex or expensive. This adds another layer of practicality for long-term ownership. Overall, the 2UZ-FE stands as a textbook example of reliability in an engine class that often suffers from heat-related failures.

2. Honda K24 (2.4L Inline-4)

Honda’s K24 engine has become one of the most respected four-cylinder engines in the world. Found in vehicles like the Accord, CR-V, and Element, the K24 has earned a solid reputation for durability, simplicity, and long service life.

One of its most characteristics is its resilience against head gasket failures. It handles thermal cycling very well, even in climates that fluctuate between extremes of hot and cold. This makes it a favorite among drivers who rely on their cars for daily commuting and long road trips without fear of catastrophic engine damage.

A key to the K24’s success lies in its balance of efficiency and cooling. The engine uses an aluminum block and head, but the combination is matched well in terms of expansion and thermal management.

It features good coolant flow around the cylinder bores and across the head, which helps to maintain even temperature distribution. When engines heat unevenly, they often suffer warping that leads to gasket failure. That’s not an issue here. Honda’s engineering choices paid off with a powerplant that remains stable under varying load conditions.

Another reason why the K24 avoids head gasket problems is the relatively low stress it’s subjected to in stock form. The engine was designed more for efficiency and drivability than high performance. It operates at moderate compression levels and rarely sees extreme cylinder pressures unless heavily modified. As a result, the head gasket is not pushed to its limits under normal use. Even in performance applications, with turbocharging or tuning, the K24 tends to hold up well when built properly.

The engine’s simple design and ease of maintenance also contribute to its long-term health. It’s not difficult to replace worn parts before they become a problem, and issues like overheating are rare as long as coolant and oil levels are kept in check.

This engine has been praised not only by mechanics but also by tuners and enthusiasts who recognize its strength. Whether in a stock Accord or a track-built Civic, the K24 has earned its reputation as one of the toughest engines in its class.

3. GM LS1 (5.7L V8)

The LS1 engine marked a major step forward for General Motors when it debuted in the late 1990s. Used in performance cars like the Corvette and Camaro, as well as later in various truck platforms, the LS1 combines power with impressive reliability.

Despite its high output and performance credentials, the LS1 rarely suffers from head gasket failures. That’s partly due to its use of aluminum for both the head and block, which means similar thermal expansion rates and fewer stresses on the gasket during warm-up and cool-down cycles.

One of the biggest reasons for the LS1’s longevity is its robust engineering. The head gaskets are made from multi-layer steel, and the head bolts are torqued in a precise pattern that maintains even pressure across the sealing surface.

These design choices ensure that combustion pressure stays where it’s supposed to be, and coolant doesn’t leak into the combustion chambers. Even in high-mileage engines, it’s common to see original head gaskets still doing their job without issue.

Another factor is the LS1’s efficient cooling system. The coolant flow was carefully designed to avoid hotspots, and the use of an electric fan in many applications helps the engine maintain a consistent operating temperature.

Overheating is a common cause of head gasket failure, and because the LS1 avoids this problem in most cases, its gaskets live a long and healthy life. It’s also worth noting that many LS1-equipped vehicles are enthusiast-owned, which means they tend to be maintained better than average.

In performance builds, the LS1 is often pushed far beyond its stock specifications, and yet it still maintains a reputation for reliability. With upgraded gaskets and head studs, it can handle forced induction or high-compression setups with minimal issues.

The factory configuration, however, is more than sufficient for most drivers. It offers a rare combination of performance and durability that few V8s can match. This makes it a popular choice for swaps, restomods, and custom builds, where reliability is just as important as horsepower.

4. Ford 4.9L Inline-6 (300 I6)

The Ford 300 inline-six engine is one of the most legendary powerplants in American automotive history. Used primarily in Ford trucks and vans from the 1960s through the 1990s, this engine was built for work, and it shows.

It’s a low-revving, torque-rich engine with a strong cast iron block and head. Unlike many modern engines, the 300 I6 operates under low stress and is designed for longevity, not speed. Because of its sturdy build and conservative design, head gasket issues are extremely rare, even after hundreds of thousands of miles.

One of the most significant strengths of the 300 is its ability to tolerate abuse. It’s not uncommon to find these engines running with little maintenance, yet still holding compression and avoiding major internal failures. The thick casting of the head and block, combined with strong head bolts and a simple cooling system, means there’s less opportunity for something to go wrong. The engine doesn’t run hot under normal conditions, and the head gasket is

That even heat profile across the head and block reduces the chances of warping, and as a result, the head gasket remains well-sealed over the lifespan of the engine.

In terms of design, the 300 I6 is about as rugged as they come. Its long-stroke architecture delivers great low-end torque, and the engine block itself is overbuilt for the power it produces. This over-engineering creates a strong base for long-term durability.

The head gasket is not subjected to high combustion pressures, as the compression ratio is relatively low. This helps the gasket maintain integrity even as the engine ages. It’s an engine made to haul loads, run at low RPMs, and start every morning regardless of weather or wear.

Another reason this engine avoids head gasket problems is its mechanical simplicity. There are fewer potential failure points, and the cooling system is easy to maintain. With cast iron on both the head and block, thermal expansion is matched, further reducing stress on the gasket.

Some may view cast iron as outdated or heavy, but when it comes to durability, it’s hard to beat. The heavier mass of the engine helps stabilize temperatures, making sudden heat spikes less likely. The result is a steady operating temperature that keeps components like the head gasket well-protected.

Owners and mechanics alike respect the 300 I6 for its ability to keep running even when neglected. It’s a favorite among farmers, tradespeople, and old-school truck enthusiasts who value simplicity and reliability over speed. Many examples are still on the road today, some with mileage well past the 400,000 mark and no signs of head gasket failure. This engine was not built to impress with specs on paper, it was built to last, and it has done exactly that for decades.

5. Toyota 22RE (2.4L Inline-4)

The Toyota 22RE is one of those engines that has earned its reputation the hard way, through decades of use in real-world conditions. Found in the Toyota Pickup, 4Runner, and other models throughout the 1980s and 1990s, this 2.4L four-cylinder engine is a legendary workhorse.

It may not be fast or particularly high-tech, but it’s remarkably robust, especially when it comes to head gasket reliability. It’s not unusual to find original 22RE engines with over 300,000 miles and no internal engine work, let alone a blown head gasket.

One of the 22RE’s biggest advantages is its simple yet solid construction. The cast iron block and aluminum head combo can sometimes be a red flag for gasket issues due to differences in thermal expansion, but Toyota engineered this setup very carefully.

The engine operates at relatively low temperatures and pressures, which puts less strain on the head gasket. Combined with proper bolt torque specifications and high-quality gasket materials, the 22RE rarely develops sealing problems, even under heavy use.

Another factor that contributes to the 22RE’s resilience is its forgiving nature when it comes to cooling. Even if the cooling system isn’t in perfect shape, the engine tends to tolerate heat better than most.

That doesn’t mean it’s immune to abuse, but it certainly won’t fail at the first sign of a clogged radiator or a weak thermostat. Routine maintenance is simple and affordable, making it easy for owners to keep things in working order. When problems do occur, they are usually inexpensive and straightforward to fix, which encourages better long-term care.

There is a reason that the 22RE has become a cult favorite among off-roaders, overlanders, and anyone looking for dependable transportation in rough terrain. The engine isn’t stressed by high revs or turbocharging, and it was designed with reliability as a top priority.

While it’s not uncommon for cylinder head leaks to appear eventually in very high-mileage engines, they tend to result from external factors rather than any fundamental flaw in the engine design. In terms of head gasket reliability, the 22RE is about as bulletproof as a four-cylinder can get.

Also Read: 5 Nissan Models That Outlive Expectations vs 5 That Fail Early

6. BMW M54 (2.5L/3.0L Inline-6)

The BMW M54 engine, used in models like the E46 3-Series and E39 5-Series, may surprise some people with its inclusion on this list. BMW engines are often associated with complexity and maintenance demands, but the M54 stands out as one of the more reliable powerplants the brand has produced, especially in terms of head gasket durability.

While other components like cooling system parts and valve cover gaskets may wear out, the M54 head gasket rarely fails unless the engine has been severely overheated.

Part of this reliability comes from BMW’s engineering approach to thermal management. The M54 features a sophisticated cooling system with a balanced flow of coolant through the block and head. When functioning properly, this keeps temperatures well-regulated and avoids the hotspots that typically cause gasket problems.

The aluminum block and head expand and contract at similar rates, reducing mechanical stress on the gasket itself. As long as the cooling system is maintained, the head gasket will often last the life of the engine.

Another aspect of the M54’s strength is its overall design balance. The engine produces a healthy amount of power without pushing the limits of its components. Compression ratios are moderate, and the inline-six layout allows for smooth operation with even distribution of combustion forces.

This smoothness plays a role in the longevity of internal components, including the head gasket. Unlike higher-strung BMW engines like the N54 or S-series motors, the M54 is relatively unstressed and well-suited for daily driving over hundreds of thousands of miles.

Even among enthusiasts who push these cars harder, head gasket issues are rarely the failure point. It’s more likely that a water pump or radiator hose will give out long before any internal damage occurs. When overheating does happen, the aluminum construction makes the engine more sensitive, but in regular use and with routine maintenance, the M54 remains strong. For anyone looking at a used BMW with an M54 under the hood, head gasket failure is far from the top of the worry list.

7. Chrysler 318 (5.2L V8)

The Chrysler 318 engine, part of the LA engine family, is a classic example of American durability. Produced from the late 1960s through the early 2000s, the 318 was used in everything from muscle cars to pickup trucks to police vehicles.

Its reputation for toughness and reliability is well deserved, and one of the most impressive aspects of this engine is how infrequently it suffers from head gasket issues. Even after decades of use, many 318s are still running on their original gaskets.

One of the main reasons for the 318’s reliability is its cast-iron block and head construction. This creates a stable thermal environment where the head and block expand at similar rates. That stability reduces the stress on the head gasket, especially during temperature changes and heavy load conditions.

Unlike aluminum-headed engines that can suffer from warping or hot spots, the 318 keeps things cool and consistent, even when towing or idling in traffic on a hot day.

In terms of combustion pressure, the 318 is not particularly high-performance in stock form. It was designed more for longevity than horsepower, and the moderate compression ratios reflect that. Lower cylinder pressures reduce the amount of stress on the head gasket, allowing it to maintain a seal over time.

The engine also features strong head bolts and a proven torque sequence, which further helps preserve the integrity of the gasket. Even when these engines are rebuilt or modified, head gasket issues are rarely the weak link.

The simplicity of the engine design also plays a role in its success. With few moving parts and straightforward access to cooling system components, it’s easy for mechanics and owners to keep the engine in good shape.

Routine maintenance, such as flushing the coolant and replacing hoses, is cheap and easy, helping to prevent the overheating that typically leads to gasket failure. Among American V8s, the Chrysler 318 stands out not just for its longevity but for how consistently it avoids one of the most common catastrophic failures in engine history.

8. Subaru EJ22 (2.2L Flat-4)

Subaru engines have had a mixed reputation when it comes to head gaskets. Some, like the EJ25, are notorious for failures. But the EJ22 stands in contrast to that trend. Produced from the early 1990s through the early 2000s, the EJ22 was used in cars like the Legacy, Impreza, and Outback. This 2.2L flat-four engine earned a strong reputation for being far more durable than its successors, especially when it comes to head gasket reliability.

One of the biggest strengths of the EJ22 is its conservative power output and low-stress design. It was never built for speed or high RPMs, and that modest performance kept internal pressures low. Lower cylinder pressure directly benefits the head gasket, as it doesn’t have to seal against extreme force.

Additionally, the EJ22 uses a non-interference valve design in many versions, meaning that even if the timing belt fails, the pistons won’t damage the valves. This adds another layer of longevity and cost-saving for owners.

Subaru also improved the design of the head gaskets used in the EJ22 compared to other engines in the EJ family. These gaskets are typically composite and reinforced with metal in critical areas. When matched with the more conservative cooling system and combustion pressures of the EJ22, they tend to hold up extremely well.

Failures are rare unless the engine is severely overheated or poorly maintained. Even in those situations, the EJ22 is often easier to repair than newer Subaru engines.

Enthusiasts and mechanics often recommend the EJ22 as the “bulletproof” Subaru engine. It’s commonly used in engine swaps to replace problematic EJ25s in older vehicles. While the flat-four layout presents some challenges for engine work, once dialed in, the EJ22 will run reliably for hundreds of thousands of miles.

It doesn’t demand high-end oils, complex electronics, or turbocharged care. It simply runs, and keeps running, making it one of the best Subaru engines ever made in terms of head gasket durability.

9. Mercedes-Benz OM617 (3.0L Inline-5 Diesel)

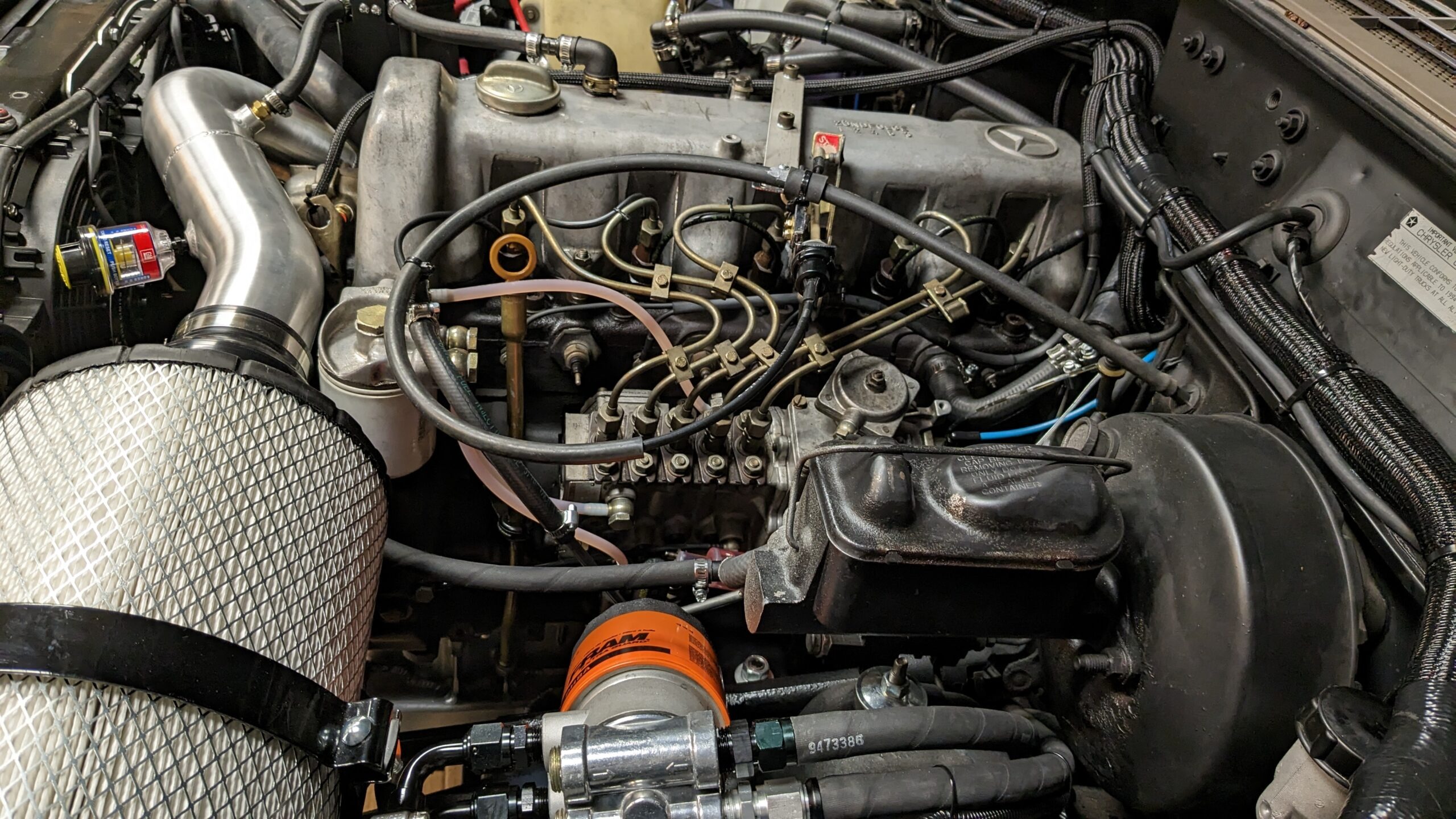

The Mercedes-Benz OM617 engine, a 3.0L inline-5 diesel used in the 1970s and 1980s, has earned legendary status for its durability and mechanical simplicity. Found in models like the W123 300D and 300SD, this engine is known for running smoothly for half a million miles or more with very few internal issues.

One of its most celebrated qualities is how infrequently it experiences head gasket failures. Despite being a diesel engine, which naturally has higher cylinder pressures than gasoline engines, the OM617 holds up remarkably well, largely because of its overbuilt nature and conservative performance profile.

The cast iron block and head are among the main reasons for the OM617’s resilience. Both components are heavy and designed with longevity in mind. Since they expand at nearly the same rate under heat, the stress on the head gasket is minimal.

This uniform expansion greatly reduces the risk of leaks or warping, which are common triggers for head gasket failures in less durable engines. The head gasket itself is a thick, composite design that was meant to last the lifetime of the engine, provided it’s not subjected to abuse. As long as the cooling system is maintained and the engine isn’t overheated repeatedly, it’s unlikely the head gasket will ever need to be replaced.

Another key factor is the engine’s low specific output. The OM617 is not fast. It was never intended to deliver performance, but rather to provide consistent, reliable torque for daily driving and highway cruising. The relatively low RPM range and low-stress operation mean that the head gasket doesn’t have to endure the constant hammering of high combustion forces.

In turbocharged versions like the OM617A, Mercedes kept boost levels conservative to preserve the same level of reliability. Even those engines, with proper maintenance, resist head gasket problems that often plague other turbocharged diesels of the same era.

What truly cements the OM617’s place on this list is the real-world data. Countless diesel Mercedes vehicles equipped with this engine are still on the road today, many with over 400,000 miles and original head gaskets intact. Owners and mechanics often joke that the car will rust out long before the engine fails, and it’s not an exaggeration.

This engine has proven itself under the harshest conditions, from city taxis in Europe to rural farm trucks in North America, and it continues to be one of the most respected diesel engines ever built. When it comes to engines that rarely blow a head gasket, the OM617 deserves its spot without question.