Mercedes-Benz has been building engines for over a century, and during that time, the brand has earned a reputation for durability, performance, and engineering excellence. Yet not all Mercedes engines are created equal.

Some power plants have proven themselves to be nearly indestructible, racking up hundreds of thousands of miles with little more than routine maintenance. Others, despite being engineered with high ambitions, have gained notoriety for chronic problems, expensive repairs, or poor reliability over time.

This contrast between reliability and unreliability is not uncommon in the automotive world, but with a name like Mercedes, expectations are higher. Many buyers assume that because a car wears the three-pointed star, every component will last indefinitely.

While some engines have truly lived up to that belief, others have caused significant frustration for owners and mechanics alike. The reasons vary, from overly complex designs and poor material choices to rushed engineering or cost-cutting during production.

It’s important to remember that engine performance isn’t only about horsepower or torque figures. Longevity, ease of maintenance, thermal efficiency, and resistance to internal wear all play equally important roles.

Engines that last for decades tend to have solid, well-tested designs with conservative tuning. Those that fail often include unnecessary complications, poorly thought-out cooling systems, or flawed internal components that wear out prematurely.

In this article, we’ll look at five Mercedes engines that have stood the test of time, developing a strong following for their reliability and long-term performance. Then, we’ll examine five engines that are often regarded as problematic, frequently showing up on mechanics’ lifts and owner complaint forums.

Whether you’re a long-time Mercedes enthusiast or someone considering a used model, knowing which engines to seek out, and which ones to avoid, can save you money, time, and future headaches.

Also Read: 12 Vehicles That Stay Reliable Even With Multiple Owners

5 Mercedes Engines That Run Forever

1. OM617 (3.0L Inline-5 Diesel)

The OM617 is often referred to as one of the most reliable diesel engines ever made. Found primarily in the 1970s and 1980s Mercedes W123 and W126 models, this 3.0-liter inline-5 diesel engine has become a legend for its sheer durability. Many of these engines have been documented to exceed 500,000 miles without requiring a major rebuild, and some examples are still running today with original internals.

One of the reasons the OM617 is so dependable is its simplicity. It features mechanical fuel injection, a robust cast-iron block, and very few electronic components.

The engine was overbuilt in many areas, including oversized bearings and thick cylinder walls, which allowed it to handle wear and tear far better than more modern, lightweight engines. The low compression ratios and modest horsepower figures helped minimize stress on the engine internals, further enhancing its longevity.

Another key factor in its long life is the conservative tuning. The OM617 isn’t a fast engine by any means, but that was never the goal. It was built for endurance rather than performance. That’s why it’s common to see these engines in old taxis, military vehicles, and even converted biodiesel setups across the globe. They don’t just survive abuse, they thrive under it.

Maintenance is also relatively easy. The design allows for access to most components without needing to remove the engine, and parts are generally available due to the high number of units produced. The OM617 has become synonymous with long-term reliability and is a prime example of how a well-designed engine can outlast the car around it.

2. M104 (3.2L Inline-6)

The M104 engine, produced throughout the 1990s, is another example of a Mercedes engine that simply refuses to quit. Found in cars like the W124 E320 and early W210 E-Class, this 3.2L inline-6 was known for delivering smooth performance and bulletproof reliability.

With proper maintenance, these engines often pass 300,000 miles with ease, and enthusiasts still praise them for their refined driving experience.

The M104 combines a solid cast-iron block with an aluminum cylinder head, which allows it to be both durable and relatively lightweight for its time.

Unlike some of its V6 successors, this inline-6 is naturally balanced and doesn’t suffer from vibration issues. It was designed during a time when Mercedes engineers were given more freedom to over-engineer components rather than cut costs.

This engine does have a few quirks, such as potential head gasket leaks around 150,000 miles, but these are well-documented and easy to prevent with routine care. When maintained properly, the M104 delivers consistent power, good fuel economy for its era, and a smooth ride that still feels modern today. It’s a favorite among DIY mechanics for its accessibility and traditional mechanical layout.

Many car owners consider the M104 as the last of the “old-school” Mercedes engines before the brand started integrating more electronics and cost-cutting measures into their designs. Its track record over the past few decades makes it a go-to choice for those looking for a dependable, long-lasting powertrain without the worries that come with newer models.

3. OM606 (3.0L Inline-6 Diesel)

Following in the footsteps of the OM617, the OM606 took diesel reliability to a more refined level. This 3.0-liter inline-6 turbo diesel engine was used in the mid-to-late 1990s in models like the W210 E300. It is widely regarded as the last of the truly mechanical Mercedes diesels, despite having some electronic controls for emission purposes.

What sets the OM606 apart is its combination of traditional diesel durability and relatively modern performance. It uses a cast-iron block with an aluminum head, mechanical injection pump (in the non-turbo versions), and a 24-valve DOHC layout. While more complex than the OM617, it still retains many of the same overbuilt features that contribute to its exceptional longevity.

Many enthusiasts regard the OM606 as the best Mercedes diesel engine of all time. With the addition of a turbocharger in later versions, it offered significantly more power while still maintaining the diesel economy and long life Mercedes diesels were known for.

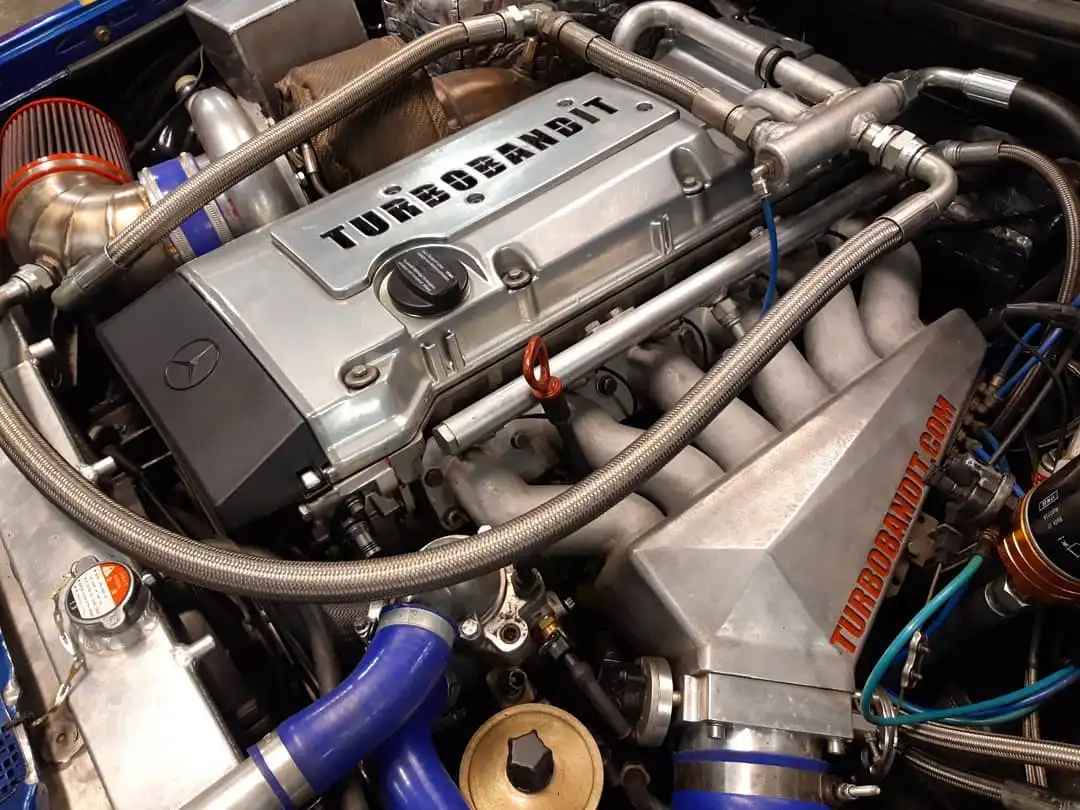

Some owners have modified these engines to produce over 400 horsepower, proving that even with increased output, the block and internals can handle significant stress.

Like other long-lasting engines, the key is maintenance. Keep the oil fresh, monitor for any minor leaks, and address wear-and-tear items like glow plugs and injector seals. If taken care of, the OM606 can easily last for 500,000 miles or more. It remains a favorite for enthusiasts who want a diesel Mercedes that blends old-school durability with more modern drivability.

4. M113 (4.3L and 5.0L V8)

The M113 V8, used widely throughout the 2000s, is often referred to as one of the best gasoline engines Mercedes has ever built. Found in the E430, S500, ML500, and even the AMG-tuned versions, this engine is well-known for its mix of performance and reliability. Unlike some of the later V8s, the M113 has aged exceptionally well and continues to gain respect for its long-term dependability.

The engine uses a combination of aluminum alloy components with silicon-impregnated cylinder linings, which help reduce wear and improve cooling. It also avoids the balance shaft and timing chain issues that plagued later V6 and V8 designs. With regular oil changes and basic upkeep, the M113 has been known to go well past 300,000 miles with minimal trouble.

The 5.0L version offers a great mix of power and refinement, while the 4.3L is often seen as the more conservative, long-lasting variant. Both share the same architecture and benefit from strong internals. Owners frequently praise how the M113 “just works,” with few if any major mechanical failures. Even AMG-tuned variants like the E55, which produce significantly more power, remain surprisingly reliable given their output.

This engine also responds well to spirited driving, and when paired with a strong transmission, it delivers a truly enjoyable experience behind the wheel. For anyone looking at used Mercedes V8 models from the early 2000s, the presence of the M113 is often considered a green flag, a rare example of performance without constant worry.

5. M111 (2.3L Inline-4)

The M111 engine, especially in its 2.3L supercharged form, is another dependable powerplant that refuses to quit. Used in models like the C230 Kompressor and SLK230, this engine has built a solid reputation for being low-maintenance and long-lasting. While it doesn’t offer high-end performance, its mechanical simplicity and durability make it a favorite for those who value dependability.

This inline-4 uses a cast-iron block and an aluminum head, along with a relatively straightforward supercharger system that adds power without overly complicating the design. It’s easy to work on, parts are widely available, and even higher-mileage examples tend to start right up with minimal drama. There are few known major flaws, and most issues that arise are minor and predictable.

One reason for the M111’s longevity is that it was designed during a time when Mercedes still prioritized engineering robustness over aggressive innovation. It can run on lower-grade fuels, tolerates wide temperature swings, and has proven to be a stable, consistent performer across many different driving environments. For many owners, it’s the type of engine that just needs oil, fuel, and

5 Mercedes Engines That Constantly Fail

1. M272 (3.5L V6)

The M272 engine, introduced in the mid-2000s, is often remembered for its early promise and later disappointment. On paper, it seemed like a modern and efficient V6, offering smooth power delivery, improved fuel economy, and a lightweight aluminum construction.

Found in a wide range of models, including the E350, C350, ML350, and CLS350, it quickly became one of Mercedes-Benz’s most common engines during that time. However, not long after these vehicles hit the road in larger numbers, patterns of mechanical failure began to emerge, and they weren’t minor quirks; they were expensive, often catastrophic issues.

One of the most well-known problems associated with the M272 is the balance shaft gear wear. The gear, located inside the engine block, wears prematurely due to poor metallurgy. When it wears out, the timing chain loses proper synchronization, leading to a check engine light, rough idle, reduced power, and eventually engine failure if not addressed.

The cost to repair this issue is substantial, usually requiring the entire engine to be opened up and the balance shaft gear replaced. For many owners, this is a multi-thousand-dollar repair that often exceeds the value of the vehicle. Worse still, the affected range of engines covers several years, making it difficult to find a used M272 engine that isn’t at risk.

Another concern is with the variable intake manifold, which uses plastic flaps to alter airflow for better low-end torque and high-end power. These flaps are prone to breaking or getting stuck, causing erratic performance and poor fuel economy.

Replacement is not cheap, and since the manifold is usually replaced as a unit, it’s a costly fix for a relatively small component failure. This issue compounds the frustrations that come with owning a car powered by the M272, particularly after the warranty period ends.

While not every M272 engine fails, and some owners have enjoyed relatively trouble-free use with regular maintenance, the reputation of the engine has been severely tarnished.

It’s often avoided by used car buyers and mechanics alike, primarily because even low-mileage examples can be at risk for expensive repairs. As a result, the M272 has become a cautionary tale, a warning that not all modern engines from respected automakers live up to expectations, and that durability cannot be assumed based solely on branding.

2. M273 (4.6L and 5.5L V8)

Closely related to the M272, the M273 V8 was designed to bring the same modern engineering principles to Mercedes’ larger-displacement engines. It shared many design elements, including the troublesome balance shaft gear concept, though in the M273, it’s referred to as the “idler gear.”

Found in the S550, CLS550, GL450, and various other luxury models, this engine aimed to deliver high performance with improved efficiency and lower emissions. However, much like its smaller sibling, it ended up being known more for its issues than its innovations.

The most significant problem with the M273 is again related to internal gear wear. The idler gear tends to degrade prematurely, leading to the same sort of timing chain misalignment seen in the M272. Symptoms range from rough starting and misfires to check engine lights and, in extreme cases, complete engine failure.

Repair costs are similarly high, with most shops quoting several thousand dollars for a proper fix. Given that many of the affected vehicles are now outside of their warranty coverage, this often leads to vehicles being sold off, parked indefinitely, or sent to salvage yards.

Another major concern is the variable intake manifold, which, like the M272’s, relies on internal flaps and linkages made from plastic. These components break down over time and mileage, causing drivability issues that are expensive to correct.

Additionally, oil consumption problems are not uncommon. Worn valve guides and seals lead to oil burning, which not only reduces engine efficiency but can also cause long-term damage to emissions systems like catalytic converters and oxygen sensors.

The M273’s issues are particularly frustrating because they undermine what could have been a truly impressive powerplant. The engine delivers strong acceleration and a refined driving feel when it’s functioning properly.

But owners are often forced to weigh the benefits of that power against the very real possibility of costly repairs. For many, the decision to steer clear is an easy one. The M273 is yet another example of how a flawed component in an otherwise good engine design can render the entire unit unreliable and expensive to own over time.

3. OM642 (3.0L V6 Diesel)

The OM642 diesel engine, introduced in the mid-2000s and used in a wide array of models like the E320 CDI, ML320 Bluetec, Jeep Grand Cherokee CRD, and Sprinter vans, initially appeared to be a solid and efficient modern diesel. It promised great torque, improved fuel economy, and compliance with stricter emissions regulations.

However, over time, this engine has become synonymous with complex, hard-to-diagnose issues that often result in repeated repairs and owner dissatisfaction. While it isn’t necessarily unreliable in terms of catastrophic failure, its many small, interconnected problems make it one of the most frustrating Mercedes engines to live with.

One of the most consistent complaints about the OM642 is oil cooler leakage. The engine uses a complex oil cooler setup that sits deep within the V of the engine block. The cooler is sealed with gaskets made from poor-quality material that often degrade, leading to oil leaks that are both messy and expensive to fix.

Replacing the seals requires removal of the intake manifold, turbo, and other major components. Even with genuine Mercedes replacement parts, the problem can reoccur, making this a recurring expense for some unlucky owners.

Another major issue involves the diesel particulate filter (DPF) and related emissions components. The OM642 was designed to meet increasingly strict emissions standards, but the hardware used to achieve that goal, including EGR valves, swirl flap motors, and DPF sensors, is prone to failure.

These systems clog easily, especially when the vehicle is not driven regularly at highway speeds. Repairing or replacing these components is costly, and the symptoms of failure (such as limp mode, warning lights, or poor fuel economy) are often hard to trace without dealership-level diagnostic tools.

Turbocharger issues also crop up with some regularity. The OM642 uses a variable geometry turbo, which can stick or fail due to carbon buildup. When that happens, boost pressure is compromised, and drivability suffers. Given the tight space in the engine bay and the complexity of the turbo system, even diagnosing the issue can be time-consuming and expensive.

While some owners manage to avoid these issues with meticulous maintenance and diesel-specific care, many find the engine to be more trouble than it’s worth, especially once the miles start adding up. It may not always fail catastrophically, but the cumulative burden of multiple problems makes the OM642 a strong candidate on this list.

4. M156 (6.2L AMG V8)

At first glance, the M156 engine seems like it wouldn’t belong on a list of problematic engines. After all, this hand-built 6.2L V8 is an AMG masterpiece, delivering thrilling power and a raw, mechanical soundtrack that has won over countless enthusiasts.

Found in vehicles like the C63 AMG, E63 AMG, SL63 AMG, and SLS AMG, the M156 was designed to be a naturally aspirated powerhouse that could take on the best from BMW’s M division and Audi’s RS lineup. While it succeeded in those areas, it also gained notoriety for some deeply concerning reliability issues that affected many early units.

The most infamous of these is the premature wear of the camshaft lobes and lifters. The M156 uses a unique valvetrain setup that wasn’t entirely compatible with the materials and lubrication systems Mercedes used at the time. In many cases, owners reported ticking noises, misfires, and loss of power due to excessive wear in the valvetrain.

If not caught early, these issues can lead to catastrophic engine failure. The cost of repair is extremely high, often involving a complete top-end rebuild or replacement engine. AMG initially denied widespread issues, which led to lawsuits and long-term damage to the engine’s reputation.

Another problem is with the head bolts. Some early versions of the M156 suffered from faulty bolts that could snap under load, leading to coolant leaks or even internal engine damage. Mercedes eventually revised the design, but by that time, many engines had already experienced failures. The issue required pulling the engine to replace all bolts with updated versions, a job that costs thousands of dollars and is often only discovered after damage has occurred.

To make matters worse, the M156 suffers from relatively poor fuel economy and high maintenance costs in general. Spark plug changes are labor-intensive, and oil consumption is higher than average. Combined with the fear of major failures, many would-be buyers have been scared off from owning what is otherwise a performance icon.

While some enthusiasts are willing to accept the risks in exchange for the reward of 500+ horsepower, the M156 remains a controversial engine, loved for its performance but dreaded for its potential mechanical liabilities.

5. M274 (2.0L Turbo Inline-4)

The M274 engine represents Mercedes-Benz’s more recent attempt at building a compact, efficient, turbocharged inline-4 to power a wide range of vehicles. It replaced the earlier M271 and was used extensively in models like the C-Class (C300), E-Class (E300), GLC300, and even entry-level AMG 43 variants with tuning enhancements.

While the engine does offer solid performance and decent fuel economy, its track record for long-term reliability has been disappointing, especially as these vehicles start aging and accumulating miles.

One of the primary issues with the M274 engine is carbon buildup on the intake valves. As a direct-injection engine, fuel is sprayed directly into the combustion chamber rather than over the intake valves.

This leads to unburned oil vapors and debris accumulating on the valves, reducing airflow and efficiency over time. In severe cases, this can lead to rough idling, misfires, and significant loss of power. The only real solution is walnut blasting or chemical cleaning, which can be costly and must be done regularly to maintain proper performance.

Timing chain and tensioner issues have also been reported. On some vehicles, the timing chain stretches prematurely or the tensioner fails, leading to a rattling noise on cold starts and eventual engine damage if not addressed. The repair is not as extensive as with the M272 or M273, but it is still expensive enough to be a concern for used car buyers. Unfortunately, these problems often arise well after the warranty has expired, leaving owners with unexpected costs.

Another concern is oil consumption and leaking, particularly from the rear main seal and valve cover gaskets. These leaks can be difficult to diagnose and often require significant labor to fix. Combined with the already fragile timing components, this creates a scenario where multiple systems can fail around the same time, compounding repair costs and leading many owners to lose confidence in the engine’s long-term durability.

While some M274 engines have gone 100,000+ miles without major incident, others have required major work much earlier. The inconsistency is part of the problem, there’s no clear predictor of which engines will fail and which won’t. As a result, many buyers and mechanics treat the M274 with caution.

It serves as a reminder that even the most modern Mercedes engines can suffer from serious flaws, especially when pushed to meet efficiency and emissions targets at the expense of mechanical longevity.

Also Read: 10 Compact SUVs That Survive Harsh Winters Offering Durability

Mercedes-Benz has built its reputation on engineering excellence, luxury, and performance. However, as this article illustrates, not every engine bearing the Mercedes star lives up to that legacy. Some power plants are marvels of mechanical durability, capable of running for decades with only basic maintenance.

Others have proven to be expensive liabilities, plagued by flawed components, complex designs, or poor material choices that undermine long-term reliability.

The engines that stand out for their longevity, like the OM617, OM606, M104, M111, and M113, were often products of a different era at Mercedes-Benz. During those times, engineers prioritized build quality and mechanical simplicity over cutting-edge features or aggressive performance.

These engines tend to be overbuilt, relatively easy to service, and designed to run under harsh conditions without failure. They’ve become the benchmark for what a long-lasting engine should look like, and many are still on the road today, doing exactly what they were designed to do.

In contrast, the engines that frequently fail, such as the M272, M273, OM642, M156, and M274, reflect the increasing complexity of modern automotive engineering. They were built during a period when emissions regulations tightened, consumer demands increased, and cost-cutting became a larger factor in product development.

Many of these engines were ambitious in design, but they introduced critical weaknesses: balance shaft failures, oil leaks, carbon buildup, and poorly engineered components that tend to wear out far earlier than expected. While not every engine in these families is guaranteed to fail, the risk is high enough that cautious buyers are often advised to steer clear unless service history is flawless and preventative repairs have already been done.

For anyone considering a used Mercedes, understanding which engines have a proven track record and which have a reputation for problems can make all the difference. It’s not just about horsepower or luxury features. The engine is the heart of the vehicle, and if it isn’t reliable, the entire ownership experience suffers.

Mercedes-Benz still produces vehicles that can run for hundreds of thousands of miles, but identifying the right engine is key. Choosing wisely means gaining the comfort, performance, and prestige Mercedes is known for, without the headaches and financial strain that come from a problematic powerplant.