Diesel engines have a reputation for durability and longevity, often outlasting their gasoline counterparts by a significant margin. They are prized for their torque, fuel efficiency, and ability to handle heavy workloads, making them the go-to choice in trucks, commercial vehicles, and even some passenger cars.

However, not all diesel engines are created equal. While some can easily surpass 300,000 miles with proper maintenance, others tend to face serious problems much earlier, sometimes failing before even reaching 150,000 miles. This divergence often comes down to design, materials, manufacturing quality, and how well the engine is maintained.

Understanding which diesel engines have a reputation for lasting a very long time, and which ones are prone to premature failure, is essential for buyers, owners, and enthusiasts alike.

Factors like turbocharger quality, fuel injection systems, cooling designs, and the robustness of engine components play a huge role in longevity.

Additionally, diesel engines from certain manufacturers have earned strong followings because of their proven reliability, while others have developed a reputation for costly repairs and frustrating breakdowns.

This article breaks down five diesel engines widely regarded as “built to last” and contrasts them with five that tend to fail prematurely, often before hitting 150,000 miles.

The goal is to provide a clear, practical overview to help people make better choices when buying or maintaining diesel vehicles. Along the way, we’ll look at common issues that lead to failures and the characteristics that contribute to durability.

Also Read: 5 Hybrid Engines That Survive 300k Miles vs 5 That Don’t

5 Diesel Engines That Last Forever

1. Cummins 6BT 5.9L

The Cummins 6BT 5.9L is often considered the gold standard when it comes to durable diesel engines. Introduced in the late 1980s, this inline six-cylinder powerplant quickly earned a reputation for its simplicity and reliability. One of the most remarkable aspects of the 6BT is its straightforward mechanical design.

Unlike many modern engines that rely heavily on complex electronic systems, the 6BT uses a mechanical fuel injection pump and an indirect injection system that, while less fuel-efficient, is incredibly robust and easier to maintain.

The engine’s cast-iron block and forged steel crankshaft are engineered to withstand high stress and long periods of operation without significant wear. This means the engine is less prone to catastrophic failure and can handle heavy workloads, making it a favorite among truckers, farmers, and off-road enthusiasts.

Another factor that contributes to the 6BT’s longevity is its relative insensitivity to fuel quality and maintenance lapses. Thanks to its indirect injection design, the engine tolerates lower-quality fuel better than many modern diesels with direct injection.

The simplicity of its fuel system also reduces the risk of costly injection pump or injector failures. Many owners report that with consistent oil changes, fuel filtration, and cooling system upkeep, their 6BT engines have gone well beyond the 300,000-mile mark, with some exceeding 500,000 miles.

This longevity is further supported by the abundant aftermarket parts availability and a vast network of mechanics familiar with this engine, making repairs more affordable and manageable.

The 6BT also boasts an impressively smooth and steady torque curve. Its ability to generate strong low-end torque without excessive revving reduces mechanical strain on engine components and the drivetrain.

This not only improves the engine’s durability but also provides excellent towing and hauling capabilities, a crucial aspect for those using trucks in demanding environments.

The engine’s cooling system, designed to manage heat effectively even under heavy loads, prevents the kind of overheating issues that can drastically shorten an engine’s life.

Additionally, the 6BT’s exhaust and intake systems are designed with simplicity and durability in mind, avoiding the pitfalls of more modern emissions control devices that can fail prematurely.

Finally, the 6BT’s ease of maintenance and repair is a significant reason for its legendary status. The engine’s mechanical fuel pump, valve adjustments, and injector servicing are straightforward tasks that can be done without expensive diagnostics or specialized tools.

This accessibility encourages owners to perform regular preventive maintenance, which is key to long-term durability. The fact that many 6BT engines remain operational decades after their production ended is a testament to the engine’s thoughtful engineering and build quality.

This diesel powerplant remains a benchmark for anyone looking for a “bulletproof” engine that combines performance, simplicity, and unmatched longevity.

2. Ford Power Stroke 7.3L (IDEX)

The Ford 7.3L Power Stroke, produced from 1994 through 2003, is often regarded as one of the most durable diesel engines in the pickup truck market. This engine utilized an indirect injection electronic (IDEX) fuel system, which merged the reliability of older indirect injection designs with the benefits of electronic fuel management.

Unlike many newer Power Stroke engines that are riddled with complex emissions systems, the 7.3L remained relatively simple. Its cast-iron block and forged steel components were designed to endure high loads and heavy use, and the engine’s rugged design made it ideal for towing, hauling, and daily work.

Because it avoided some of the pitfalls of high-pressure common rail systems and variable geometry turbos, the 7.3L was less prone to mechanical failures.

One key to the 7.3L’s longevity is its resilience to maintenance schedules and operational conditions. Many 7.3L Power Stroke engines have been known to surpass 300,000 miles with just routine oil and filter changes, along with fuel filter replacements.

The electronic controls helped optimize fuel delivery and combustion, but without introducing excessive complexity or delicate components that often plague newer diesel engines.

The turbocharger, a fixed geometry unit, was built for reliability rather than peak performance, further enhancing the engine’s ability to withstand abuse. The fuel injection system was robust, avoiding the costly injector and pump failures seen in later Power Stroke models.

The 7.3L’s torque output is strong and delivered in a smooth, predictable manner, reducing wear on the engine and drivetrain components.

This engine was often praised for its balance of power and durability, making it a favorite choice for commercial operators and individual owners who needed a diesel that could take serious abuse and keep running.

The cooling system was also a significant advantage, designed to prevent overheating and maintain consistent operating temperatures even during demanding tasks.

Owners and mechanics alike appreciate how straightforward it is to service the 7.3L, with many components accessible and easy to replace without specialized tools or extensive disassembly.

In addition, the extensive aftermarket support and a vast community of enthusiasts mean that parts, modifications, and repairs are both accessible and affordable. This keeps these engines on the road longer than many modern diesels with more complex and delicate systems.

The Ford 7.3L Power Stroke is a shining example of engineering focused on reliability, simplicity, and longevity. Its proven track record in real-world conditions has solidified its place as one of the most durable diesel engines ever made.

3. Mercedes-Benz OM617 3.0L

The Mercedes-Benz OM617 engine is a classic example of German engineering focused on durability and reliability. This inline five-cylinder diesel engine, produced from the late 1970s to the mid-1980s, is widely recognized for its rugged construction and ability to withstand extreme conditions over long periods.

The OM617’s cast-iron block and head provide exceptional strength and resistance to warping or cracking, which are common failure points in less robust engines.

Its mechanical fuel injection system is simple yet precise, delivering fuel efficiently without the complexities of modern electronic systems. This simplicity makes the engine easier to maintain and less prone to electronic or sensor failures.

Another reason for the OM617’s legendary longevity is its overbuilt components. The thick cylinder walls, durable piston rings, and high-quality bearings ensure that the engine can endure years of high mileage without significant wear.

Additionally, the indirect injection design spreads combustion heat more evenly, reducing stress on the cylinder head and valves.

The cooling and lubrication systems were engineered to maintain consistent operating temperatures and oil pressure, which are critical for preventing premature engine wear. The engine’s design emphasizes conservative operation rather than pushing the limits of performance, contributing to its long service life.

Owners and enthusiasts have reported examples of OM617 engines reaching 500,000 miles and beyond without major rebuilds.

This engine also demonstrates remarkable tolerance to neglect compared to more modern diesels. It can continue running smoothly even with extended oil change intervals or occasional fuel quality issues.

The engine’s straightforward design means repairs are generally affordable, and parts remain available thanks to the widespread use of the engine in Mercedes-Benz vehicles and commercial applications around the world.

The OM617’s reputation extends beyond just passenger cars; it was used in ambulances, taxis, and trucks, vehicles that demand high reliability and minimal downtime.

Its ability to keep running under tough conditions, combined with the ease of maintenance, made it a favorite among mechanics and owners who value durability above all else. Even decades after production ended, the OM617 remains a benchmark for longevity and reliability in diesel engines.

4. Toyota 1HD-T/1HD-FT

The Toyota 1HD series, particularly the 1HD-T and 1HD-FT engines, are inline six-cylinder diesels that have earned a strong reputation for toughness and endurance, especially in off-road and rugged environments. These engines were primarily installed in the Toyota Land Cruiser, a vehicle already known for its reliability.

The 1HD-T was a turbocharged engine with an indirect injection system, while the later 1HD-FT upgraded to direct injection, improving power and efficiency. Both engines were designed with a focus on durability, featuring a cast-iron block and forged internals capable of handling high stress without compromising reliability.

One standout characteristic of the 1HD series is their ability to perform consistently in some of the most challenging conditions on the planet. Whether navigating deserts, mountains, or muddy trails, these engines maintain steady power delivery without overheating or excessive wear.

The turbochargers fitted to the 1HD series are robust, maintaining boost pressure reliably with minimal failures reported. Toyota engineers paid close attention to fuel delivery and filtration systems, minimizing common diesel issues such as injector clogging and fuel contamination. The cooling system is similarly well-designed to prevent temperature spikes that can shorten engine life.

The 1HD engines respond well to routine maintenance, including oil changes, fuel filter replacements, and injector cleaning. Toyota’s conservative approach to engine tuning avoids pushing components beyond their limits, which significantly contributes to longevity.

Many owners have reported surpassing 300,000 miles with little more than standard maintenance. Moreover, the availability of parts and the strong global Toyota support network mean that repairs and replacements can be managed even in remote locations.

This combination of durability, simplicity, and reliability has made the 1HD series a favorite among overlanders, expedition drivers, and those needing a dependable diesel engine capable of enduring years of harsh use.

The 1HD series continues to be regarded as one of the most long-lasting diesel engines ever built, perfectly suited for applications where failure is not an option.

5. International Harvester DT466

The International Harvester DT466 is a heavy-duty inline-six diesel engine that has earned a reputation for toughness and longevity in commercial trucking and vocational applications. Introduced in the 1980s, it became a mainstay in school buses, delivery trucks, and other vehicles requiring dependable diesel power.

One of the DT466’s most important design features is its simple yet rugged mechanical fuel injection pump system. This system is easier to maintain and less prone to failure than many modern electronic injection setups, which often require specialized tools and knowledge.

The DT466 is built with a strong cast-iron block and robust cylinder heads, designed to withstand the high stresses of commercial use. Its cooling system is engineered to handle heavy loads without overheating, while the turbocharger, though not high-tech, is known for reliability when properly maintained.

This engine’s components were designed for easy serviceability, which is a critical advantage in fleet environments where minimizing downtime is paramount.

Many fleet operators have found that with proper routine maintenance, including regular oil changes, fuel system upkeep, and cooling system checks, the DT466 engines can last well beyond 500,000 miles.

This longevity, combined with the availability of rebuilt engines and aftermarket parts, makes the DT466 a favorite for those looking for a diesel engine that can endure years of tough work. The engine is also known for its smooth power delivery, which helps reduce stress on drivetrains and other vehicle systems.

In addition to its durability, the DT466 is praised for its consistent performance over long service intervals. Operators often report that these engines maintain fuel efficiency and power without frequent repairs.

The balance between robust engineering and practical serviceability makes the DT466 a standout choice for those seeking an engine that truly lasts through decades of hard use.

Also Read: 12 Upgraded 2025 Trucks Built to Withstand Abuse

5 Diesel Engines That Fail Before 150k

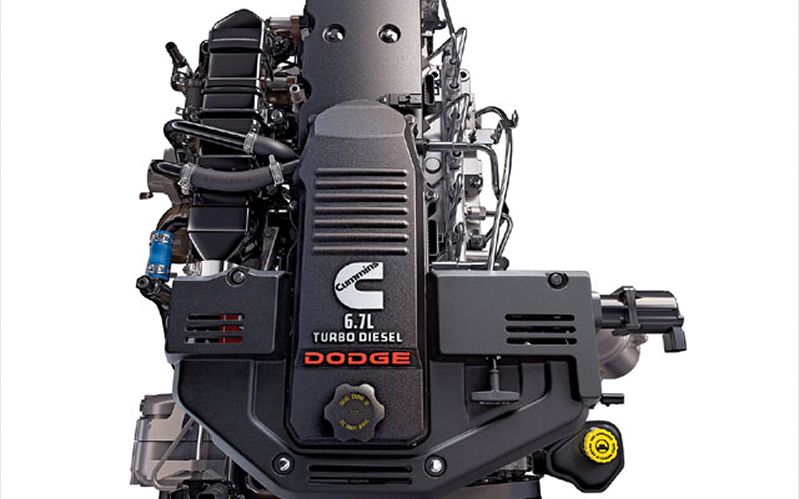

1. Dodge Cummins 6.7L (Early Models)

The early versions of the Dodge Cummins 6.7L engine, particularly those produced between 2007 and 2012, have gained a notorious reputation for reliability problems that often cause failures well before reaching 150,000 miles.

While the 6.7L Cummins was designed to deliver high power and meet stringent emissions standards, the trade-off was a more complex engine system with added components that can fail prematurely. One of the biggest issues is related to the high-pressure common rail fuel injection system.

These injectors operate under extremely high pressures and are prone to clogging or malfunction, which leads to rough running, loss of power, and expensive repairs. The fuel system’s complexity also means that even routine maintenance requires specialized knowledge and tools, making proper upkeep more difficult for average owners.

Another significant problem area is the engine’s emissions control components, such as the Diesel Particulate Filter (DPF) and Exhaust Gas Recirculation (EGR) system. These parts are prone to clogging or failure, especially in vehicles used for short trips or stop-and-go driving where the system cannot properly regenerate.

When the DPF or EGR malfunctions, it often causes increased backpressure in the engine, leading to turbocharger damage and decreased engine performance.

Repairing or replacing these systems is costly, and many owners have reported recurring issues, even after replacements. The complexity and sensitivity of these emissions controls contribute to reduced engine life, as they add stress and potential failure points to the powertrain.

The turbocharger on early 6.7L models is another common failure point. The turbo is subjected to high heat and pressure, and if cooling or lubrication is compromised due to clogged oil passages or soot buildup, the turbo can fail prematurely.

Turbocharger failure often leads to a cascade of engine problems, including metal debris contamination in the oil and further damage to the engine internals.

This vulnerability is exacerbated by the engine’s design, which prioritizes emissions compliance and performance but sometimes at the expense of durability. Many owners have expressed frustration with the balance Dodge struck between power, emissions, and long-term reliability in these early 6.7L models.

Lastly, the complexity of the 6.7L Cummins engine means that when problems arise, repairs can be very expensive. Specialized diagnostic equipment is often required to pinpoint issues, and some repairs can involve major engine disassembly.

This level of complexity contrasts sharply with older Cummins engines known for their simplicity and longevity. Because of these issues, many early 6.7L Cummins engines fail or require major overhauls well before the 150,000-mile mark, causing dissatisfaction among owners who expect the legendary Cummins durability to continue.

2. GM Duramax LML 6.6L

The GM Duramax LML 6.6L engine, produced from 2011 to 2016, initially offered impressive power and emissions compliance but developed a reputation for failures before 150,000 miles in many cases. One of the most significant problems with this engine involves its high-pressure common rail fuel system, which uses piezoelectric injectors.

While these injectors provide excellent performance and fuel efficiency, they can be prone to failure or clogging due to contamination or poor fuel quality. Injector failure often causes rough idling, loss of power, and increased fuel consumption.

Additionally, the fuel pump can suffer premature wear, compounding fuel delivery problems and potentially leading to engine stalling or damage.

Another major concern with the LML Duramax relates to its emissions system, particularly the Diesel Particulate Filter (DPF) and Selective Catalytic Reduction (SCR) systems. These components are essential for meeting environmental regulations but can create maintenance headaches.

The DPF requires periodic regeneration to burn off accumulated soot, but frequent short trips or stop-and-go traffic can prevent proper regeneration. This leads to clogged filters and increased backpressure, which reduces engine performance and can cause premature turbocharger failure.

Additionally, the SCR system requires Diesel Exhaust Fluid (DEF), and any issues with the DEF dosing or quality can cause engine warning lights and limp mode, forcing costly repairs or component replacements.

The turbocharger on the LML Duramax is also a potential weak spot. While designed to be durable, turbo failure does occur due to issues like soot buildup, oil contamination, or worn bearings. Because the turbo is critical for maintaining power and efficiency, its failure often results in severe engine damage if not addressed promptly.

Cooling system problems can exacerbate these failures, particularly if the radiator or intercooler becomes clogged or damaged. This combination of fuel system, emissions, and turbocharger vulnerabilities means that many LML Duramax engines experience significant mechanical issues well before the 150,000-mile threshold.

Lastly, repair costs for the LML Duramax tend to be high. The advanced electronics, sophisticated emissions controls, and high-pressure fuel system require expensive parts and specialized diagnostic tools.

Unlike simpler older diesels, the LML demands proactive maintenance and careful attention to fuel and oil quality to avoid costly breakdowns. Many owners find that even with proper care, these engines may not achieve the long life associated with earlier Duramax versions, causing frustration and higher ownership costs.

3. Volkswagen TDI PD (Pump Düse) Engines (2004–2009)

Volkswagen’s TDI PD (Pump Düse or unit injector) engines, widely used between 2004 and 2009, are known for their fuel efficiency and power but also for several reliability issues that can lead to failure before 150,000 miles.

The PD injection system, while innovative, is prone to high wear due to the extreme pressures and precise timing required for each injector.

Over time, the unit injectors can develop leaks, fail electronically, or lose efficiency, which leads to rough running, poor fuel economy, and sometimes catastrophic engine damage if unaddressed.

Repairing or replacing the unit injectors is expensive and often requires the removal of the cylinder head, adding labor costs.

Another common problem with these Volkswagen diesels is related to the timing chain system. The PD engines use a timing chain tensioner that is known to wear prematurely, resulting in slack that can cause the chain to jump or skip teeth. This can lead to valve timing issues and severe engine damage, including bent valves or piston contact.

Many owners experience rattling noises from the timing chain area and must replace the tensioner or the entire chain early in the engine’s life. These timing chain problems are not only expensive to fix but also significantly reduce the engine’s reliability.

The turbochargers on TDI PD engines also have a history of failure. Because the turbos operate under high stress and heat, they require proper oil supply and cooling to maintain longevity. If oil change intervals are neglected or poor-quality oil is used, the turbo can fail prematurely.

Turbo failure often results in reduced power and can cause engine damage due to metal debris circulating in the oil. Additionally, the EGR and intake systems on these engines tend to clog with carbon buildup, leading to rough running and the need for frequent cleaning or replacement of parts.

Lastly, the diesel particulate filter (DPF) system introduced in later PD models adds another potential point of failure. If the DPF becomes clogged or the regeneration process is interrupted, it can cause increased backpressure and reduced engine performance.

Combined with the other mechanical and electronic issues, these problems frequently result in Volkswagen PD engines failing or requiring major repairs before reaching 150,000 miles, which frustrates many owners who expected a longer-lasting powerplant.

4. Navistar 7.3L Power Stroke (2004–2007)

The 2004 to 2007 Navistar 7.3L Power Stroke, used in Ford trucks, has a reputation for failing prematurely compared to its older 7.3L predecessor. While the original 7.3L Power Stroke was celebrated for its durability, the later Navistar variant introduced complex emissions components that negatively impacted reliability.

One of the most problems is the oil cooler system, which is prone to failure and can lead to mixing of engine oil and coolant. This issue causes contamination of both fluids and can result in catastrophic engine damage if not detected early.

The oil cooler failure is often accompanied by overheating and loss of lubrication, accelerating engine wear. Another critical problem area is the fuel injection system.

The Navistar 7.3L switched to a high-pressure common rail design, which introduced new failure modes not seen in the previous mechanical injection system. Injectors and fuel pumps often fail early, leading to rough running, loss of power, and costly repairs.

Additionally, the complexity of the fuel system makes troubleshooting and repair more difficult and expensive. Owners frequently report injector failures and the need for costly rebuilds or replacements well before 150,000 miles.

The turbocharger and EGR system on these engines also tend to clog or malfunction. The EGR valve can become stuck or clogged with soot, leading to poor engine performance, increased emissions, and overheating.

Turbo failure due to oil contamination or insufficient cooling is common and often results in significant engine damage. These systems require frequent maintenance to prevent early failure, but even with diligent care, many owners experience premature breakdowns.

Lastly, the cooling system in the Navistar 7.3L has weaknesses that can cause overheating and reduce engine life. Radiator failures, thermostat issues, and coolant leaks are common complaints. Combined with the oil cooler and emissions-related problems, the engine often requires major repairs or replacement before reaching 150,000 miles.

This is a marked departure from the original 7.3L’s legendary durability and has led to a loss of confidence among many Ford Power Stroke owners.

5. BMW N57 Diesel Engine

The BMW N57 is a turbocharged inline-six diesel engine used in various BMW models from around 2008 onward. While it delivers strong performance and relatively good fuel economy, the N57 has developed a reputation for reliability issues that can cause premature failures before reaching 150,000 miles.

One of the main problems lies in the engine’s timing chain system. The timing chain tensioner and guides have been known to wear prematurely, which can cause the chain to become loose and jump timing.

This results in engine misfires, rough running, and in severe cases, catastrophic engine damage if the valves and pistons collide. Repairing timing chain problems in the N57 engine is expensive and labor-intensive, often requiring removal of the engine’s front cover and significant disassembly.

Another issue common to the N57 is related to the turbocharger system. The N57 uses multiple turbochargers (in some versions, a twin-turbo setup), which are complex and sensitive components.

Turbo failure is often caused by oil supply problems, carbon buildup, or bearing wear. When a turbo fails, it can send debris into the engine, causing further damage, and repairs or replacements are costly. The cooling system also plays a role here; any failure in coolant flow can exacerbate turbo wear and lead to overheating.

The high-pressure fuel system is another weak point. The N57 uses common rail fuel injection with piezoelectric injectors, which are prone to failure or clogging, especially if poor-quality fuel is used. Injector problems lead to rough running, reduced power, and increased emissions.

Replacing injectors is expensive and involves considerable labor. Additionally, the EGR system and Diesel Particulate Filter (DPF) are prone to clogging, requiring frequent maintenance or replacement to keep the engine running properly.

Finally, the N57’s electronic control systems, while advanced, add layers of complexity that can result in sensor failures, wiring issues, and control module errors. These problems often trigger warning lights and limp mode, forcing costly diagnostics and repairs.

The combination of mechanical wear, emissions system complications, and electronic vulnerabilities means that many N57 engines face premature failures or expensive repairs before 150,000 miles, disappointing many BMW diesel owners who expect higher durability.