Reliability is one of the most valued traits in an engine, but not all engines are created equal. Most engines demand regular maintenance, timely oil changes, proper cooling system care, and consistent attention to filters and fluids.

Neglecting these tasks usually results in reduced performance, breakdowns, or even complete failure. However, some engines are exceptions to this rule. These rare workhorses can tolerate years of abuse, skipped services, and cheap parts, and still keep running like nothing happened.

In an ideal world, every vehicle owner would follow the maintenance schedule outlined in their owner’s manual. But reality often looks different. Busy lives, financial constraints, or simple forgetfulness lead to late oil changes and long-overdue tune-ups. That’s where certain engines prove their worth.

Some engines are built with a margin of safety so wide that they can survive conditions that would destroy a lesser powerplant. They’re not indestructible, but they’re remarkably resilient.

What makes these engines stand out isn’t fancy engineering or high-end performance. In fact, many of them are modest in power, using older or simpler technology. But that’s exactly why they last.

They’re not pushed to the limits. They rely on tried-and-true materials, simple mechanical systems, and conservative designs. These engines don’t need pampering, they just need fuel and a reason to run.

Also Read: 5 Cars That Survive The American Rust Belt vs 5 That Disintegrate

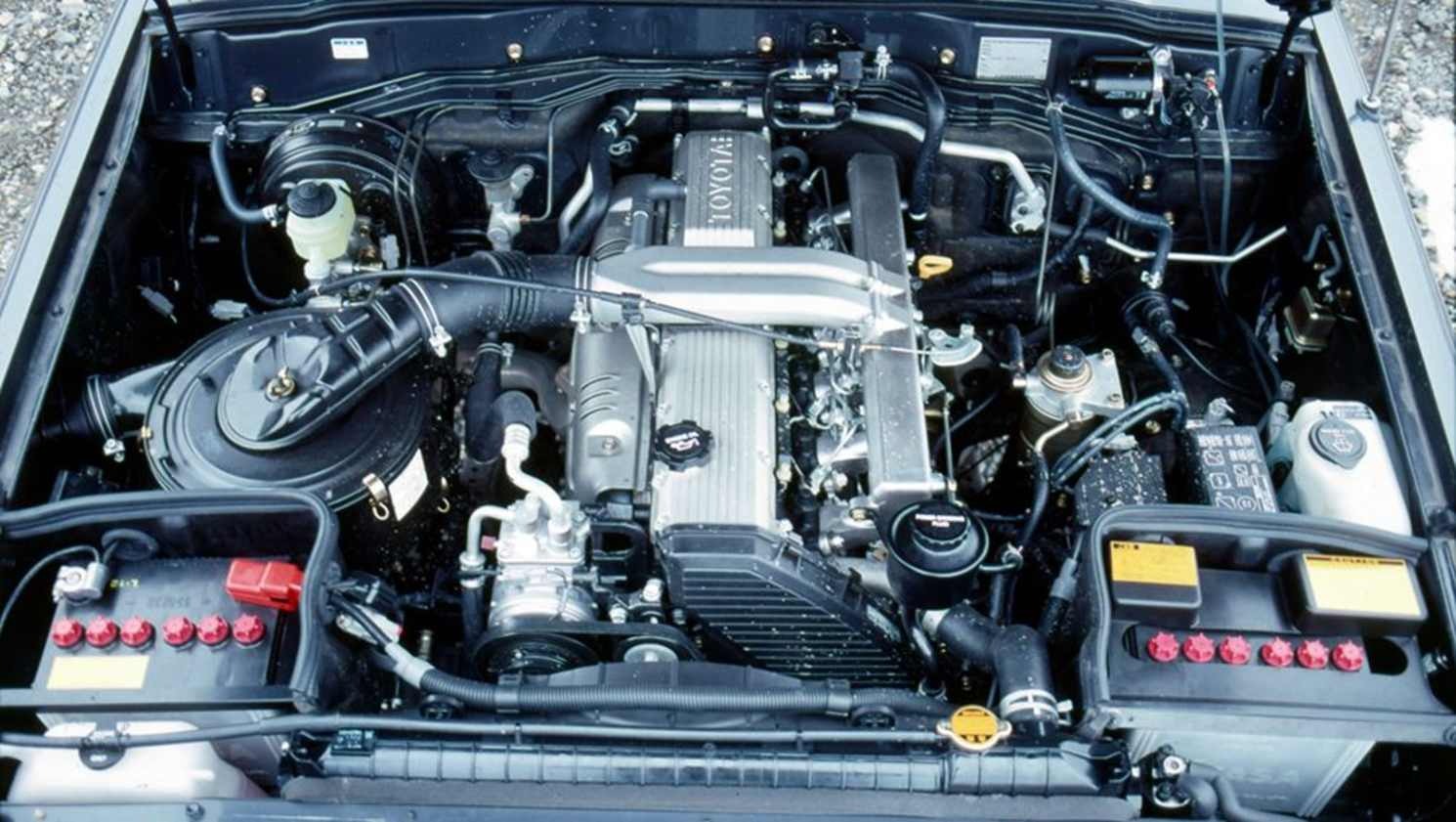

1. Toyota 22R/22RE (2.4L Inline-4)

The Toyota 22R and 22RE are icons of durability in the automotive world. Used extensively in Toyota pickups, the 4Runner, and even some Celicas, these engines developed a reputation that has endured for decades.

With a rugged cast-iron block, a single overhead camshaft, and modest compression ratios, the 22R family is built for resilience, not speed. The 22RE, the fuel-injected version, offered slight improvements in efficiency and drivability while maintaining the same bulletproof characteristics.

One of the defining traits of the 22R is its simplicity. Unlike modern engines packed with sensors and complex systems, the 22R operates on basic mechanical principles that are easy to understand and fix.

The carbureted versions, in particular, can run with minimal wiring and no electronic interference. That makes them ideal for off-road builds, remote driving, or any situation where field repairs might be necessary.

Another major contributor to the engine’s longevity is its forgiving internal design. Timing chains are long-lasting, and even when they do begin to rattle from worn guides, the engine often continues to run.

Oil leaks are common on higher-mileage engines, but they’re usually not catastrophic. Even if the oil level drops dangerously low, many of these engines will keep running long enough to get home or to a shop.

Despite poor maintenance, 22R engines are often found running in junkyard vehicles, with unknown service histories and over 200,000 miles on the odometer.

It’s not unusual to see them idle smoothly after sitting for years, needing only fresh fuel and a charged battery. These engines were also designed to run on lower-octane fuel, another reason they’re favored in regions with inconsistent fuel quality.

Even enthusiasts admit to running these engines hard, skipping oil changes, or using generic parts without any noticeable impact on performance. If a head gasket does fail due to overheating or age, the engine is straightforward to repair and return to service.

This kind of durability is rare in modern powerplants, and it’s what continues to keep the 22R/22RE relevant among both collectors and drivers who want something that just works.

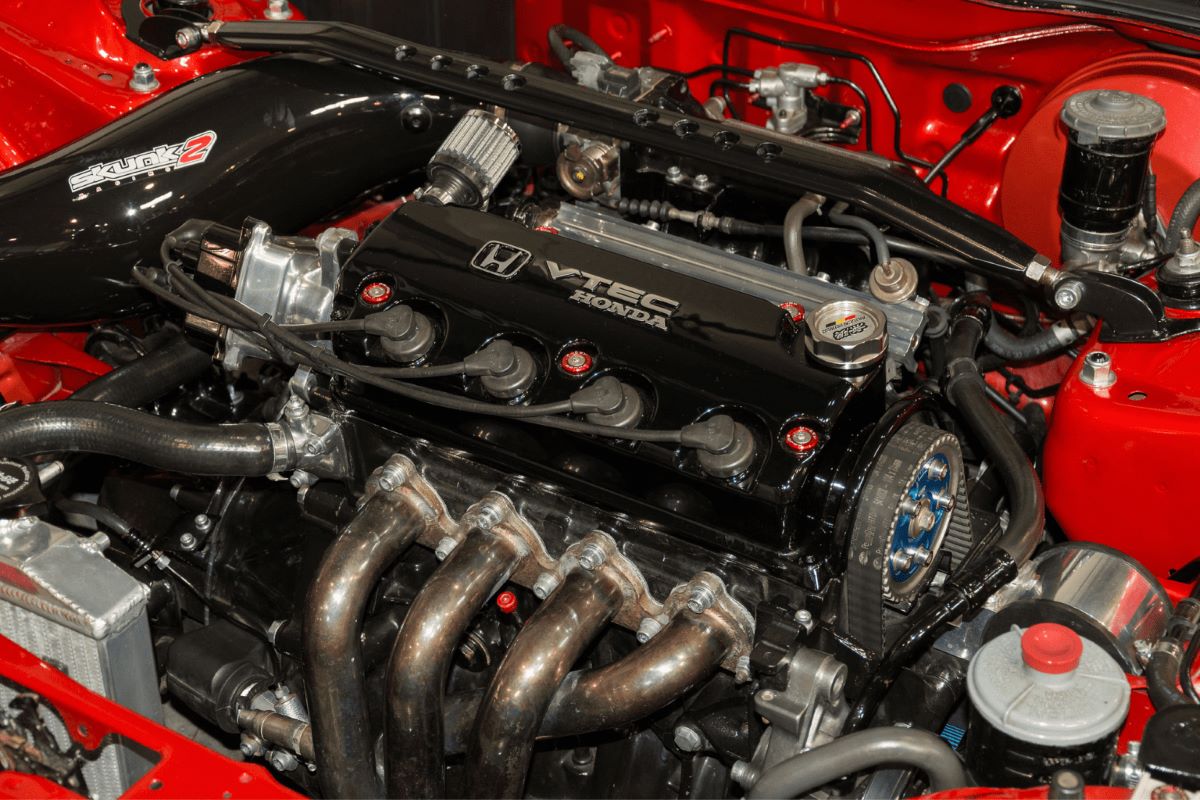

2. Honda D-Series (1.5L & 1.6L Inline-4)

The Honda D-series engine lineup is best known for its use in Civics, CRXs, and Del Sols from the late 1980s to the early 2000s. What it lacks in power, it more than makes up for in durability. These small displacement engines were built to be economical, but Honda’s attention to detail made them incredibly resistant to mechanical failure, even when they weren’t treated well.

The secret to the D-series engine’s success lies in its conservative design and quality materials. Although capable of high RPM operation, most owners used them for commuting and city driving, meaning they rarely saw abusive high-revving behavior.

However, even when pushed beyond their intended use, such as in amateur racing or street tuning, these engines held up far better than expected.

Even more impressive is the way they tolerate missed maintenance. Oil changes can be skipped, filters can be clogged, and timing belts can be overdue by tens of thousands of miles, yet these engines often keep running. They might lose power or develop a knock, but outright failure is rare. Many owners only discover maintenance problems when trying to fix something unrelated.

Another advantage is accessibility. The engine bay of a D-series Honda is simple and spacious compared to modern cars. Repairs are easy to perform, and parts are widely available.

This led to many novice mechanics learning their trade on these engines, often making mistakes along the way. Even so, the engines survived the learning curve and earned the nickname “un-killable” in many enthusiast circles.

Although the non-VTEC models are usually regarded as the most reliable, even VTEC-equipped D-series engines show strong resilience. Some will smoke or burn oil after high mileage, but they almost always keep running.

Whether it’s a teenager’s first car, a daily driver with 300,000 miles, or a beater with three owners and no records, the D-series proves that great engineering can overcome poor care.

3. GM 3800 Series II (3.8L V6)

General Motors’ 3800 Series II engine, used extensively from the mid-1990s through the 2000s, is a powerhouse when it comes to mechanical resilience. It powered everything from the Buick LeSabre to the Pontiac Grand Prix and even some Chevy Impalas.

This engine wasn’t just a workhorse, it was one of the few GM engines from that era that could survive prolonged neglect without giving up.

Built with a cast-iron block and strong internals, the 3800 Series II was designed with longevity in mind. Its pushrod design and overhead valves might seem outdated, but that simplicity reduced the number of failure points.

This engine ran cool, idled smoothly, and delivered plenty of low-end torque. It was also one of the few V6s that didn’t need a timing belt, using a durable chain instead.

One of the more remarkable aspects of the 3800 is how well it tolerates common problems like coolant leaks, worn spark plugs, or gummed-up sensors. In many engines, such issues would cause stalling or serious driveability issues.

With the 3800, most of these problems cause little more than a check engine light or slight drop in fuel efficiency. The engine often continues to operate normally.

This engine was also heavily used in fleet vehicles, where long idling periods and minimal maintenance are common. Taxi drivers and police departments found the 3800 dependable even under constant use. Many of these cars exceeded 300,000 miles with only the most essential maintenance performed, often oil changes done sporadically or with bargain-bin products.

If there’s a downside, it’s the upper intake manifold made of plastic on some models, which could fail and cause coolant to leak into the combustion chamber. Even so, the engine rarely suffered catastrophic failure because of it.

A quick replacement of the manifold usually solved the problem. That kind of recoverability, combined with its strong baseline design, makes the 3800 Series II a legend in reliable engine circles.

4. Ford 4.9L Inline-6 (300 I6)

Ford’s 4.9-liter inline-six engine, more commonly known as the 300 I6, is one of the most respected truck engines in American history. Used in the F-Series and Econoline vans for decades, this engine was known for its raw simplicity and insane toughness.

It wasn’t pretty or fast, but if you needed something that could keep going through thick and thin, the 300 I6 was the engine to trust. What made the 300 so reliable was its design. With a long-stroke inline-six layout, it provided smooth, low-end torque that made it ideal for hauling and towing.

The cast-iron block and head could take serious thermal abuse, and the gear-driven timing setup removed a common point of failure. Even the carburetors used on older models were known for being easy to rebuild and forgiving of wear.

The engine was often found in work trucks, many of which were subjected to extreme use with very little care. Some had oil that hadn’t been changed in 20,000 miles or more.

Others ran with overheating issues or broken sensors. Yet time and again, these engines kept running. If they started to misfire or stall, a quick replacement of plugs or a carb adjustment would usually bring them back to life.

Owners tell stories of these engines being run with no coolant, dirty oil, or misfiring for months. And somehow, they rarely died. The power output was modest, which meant the engine didn’t generate much internal stress. That helped with longevity, but it also made the engine a bit of a slug on the highway. Still, for farm use, fleet use, or general abuse, it was unbeatable.

In modern times, enthusiasts often seek out these engines for restoration projects or custom builds, knowing they’re almost impossible to wear out. Even today, trucks with the 300 I6 are still seen plowing snow, pulling trailers, or just running reliably on back roads across America. It’s one of the few engines that can truly be called “overbuilt” in every sense of the word.

5. Mercedes-Benz OM617 (3.0L Inline-5 Diesel)

The Mercedes-Benz OM617 is one of the most well-regarded diesel engines ever made. Built during an era when durability was a top priority for the brand, this 3.0-liter five-cylinder diesel was used in the W123 and W126 chassis, including models like the 240D, 300D, and 300TD. Despite being slow, heavy, and noisy, it developed a reputation for surviving just about anything.

Its mechanical fuel injection system didn’t rely on computers or complex wiring. The fuel pump and injectors were built to extremely tight tolerances and could tolerate variations in diesel quality. Many vehicles equipped with this engine were used as taxis in Europe, the Middle East, and Africa, where roads were poor and maintenance was sporadic at best.

One reason the OM617 lasted so long was its forgiving nature. Even with infrequent oil changes, clogged air filters, and worn glow plugs, the engine would start and run. It might smoke, vibrate, or struggle in the cold, but it rarely quit entirely. Mechanics around the world learned to trust the OM617 because it would limp home when everything else had failed.

The cast-iron block and head could take extreme temperature changes and mechanical wear. Even after overheating or driving with contaminated fuel, the OM617 was often still repairable. Timing chains lasted well beyond their recommended intervals, and valve adjustments could be ignored without immediate consequences.

For decades, the OM617 has remained a favorite in the DIY and prepping community. People have transplanted it into other vehicles, run it on alternative fuels like waste vegetable oil, and put it through every kind of stress test imaginable.

Through all that, it keeps proving that good engineering and robust construction can stand up to neglect better than any modern electronic engine ever could.

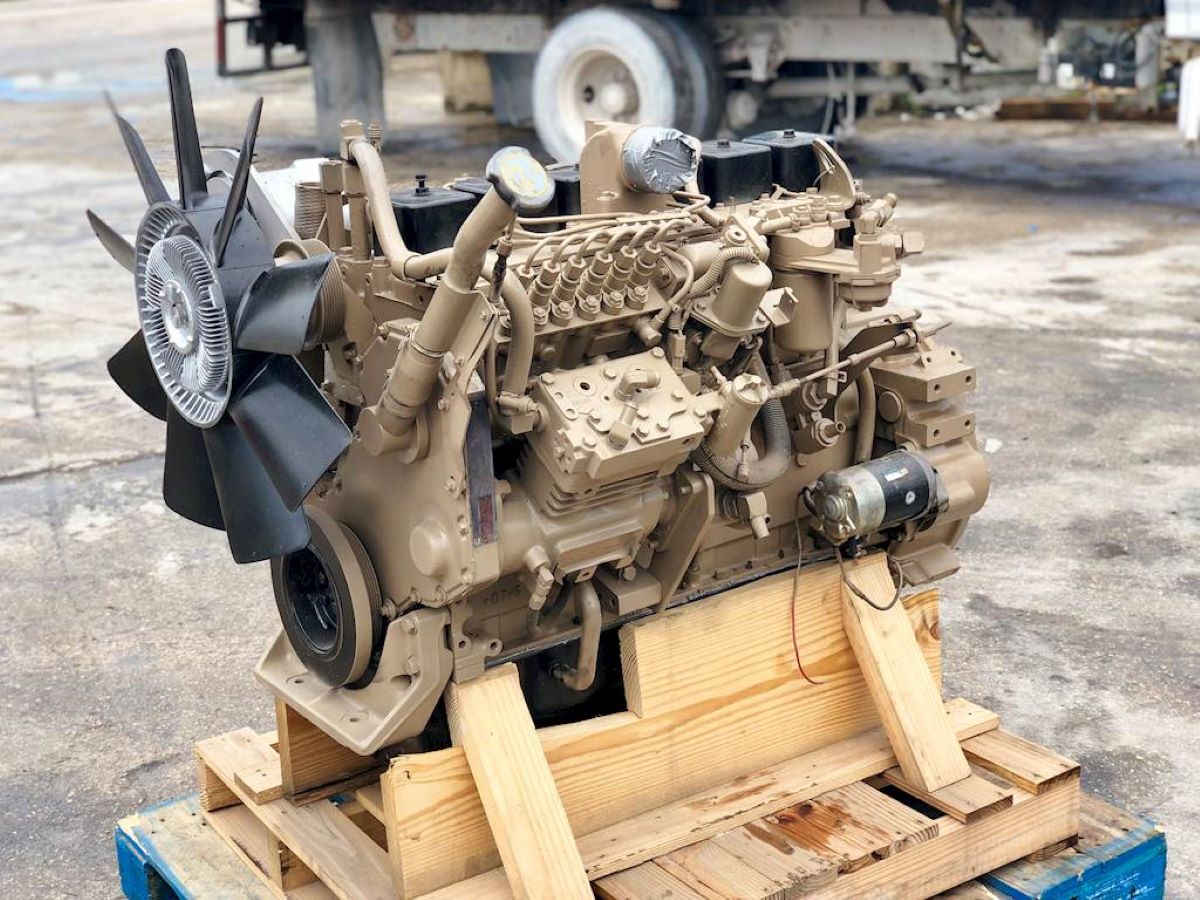

6. Cummins 6BT 5.9L Inline-6 Diesel

The Cummins 6BT 5.9-liter inline-six diesel engine has earned a legendary status among diesel enthusiasts, commercial drivers, and off-road adventurers alike. Introduced in the late 1980s, this engine was a staple in Dodge Ram pickups, agricultural machinery, and industrial equipment.

Its reputation for reliability comes from a combination of rugged design, simplicity, and the ability to tolerate poor or infrequent maintenance.

One of the key strengths of the 6BT is its mechanical fuel injection system. Unlike modern electronically controlled common-rail diesels, the 6BT uses a robust, mechanical injection pump that is much less sensitive to fuel quality and electrical gremlins.

This mechanical simplicity means fewer sensors to fail and less dependence on computer control, making it a favorite in environments where sophisticated diagnostic tools or spare parts may be scarce.

The 6BT’s block and heads are cast iron, giving it excellent durability and resistance to warping, even in cases of overheating. The engine also has a large displacement and a long stroke, which means it doesn’t have to work as hard to produce torque.

This reduces stress on components and helps it maintain performance even when oil changes are skipped or air filters become clogged.

Owners of 6BT-powered vehicles often report that the engine can survive running on poor-quality fuel or running with a dirty air filter for thousands of miles without issue. Although performance may suffer under such conditions, catastrophic failure is rare.

When repairs are needed, the 6BT is relatively easy to service, with parts widely available and a large community of mechanics familiar with its quirks.

In many cases, the Cummins 6BT has been known to reach half a million miles or more with minimal internal overhaul. This longevity combined with excellent torque output makes it a go-to engine for both work and recreation, proving that it can handle abuse and neglect without quitting.

Also Read: 5 Cars That Rarely Cause Buyer’s Regret vs 5 That Always Do

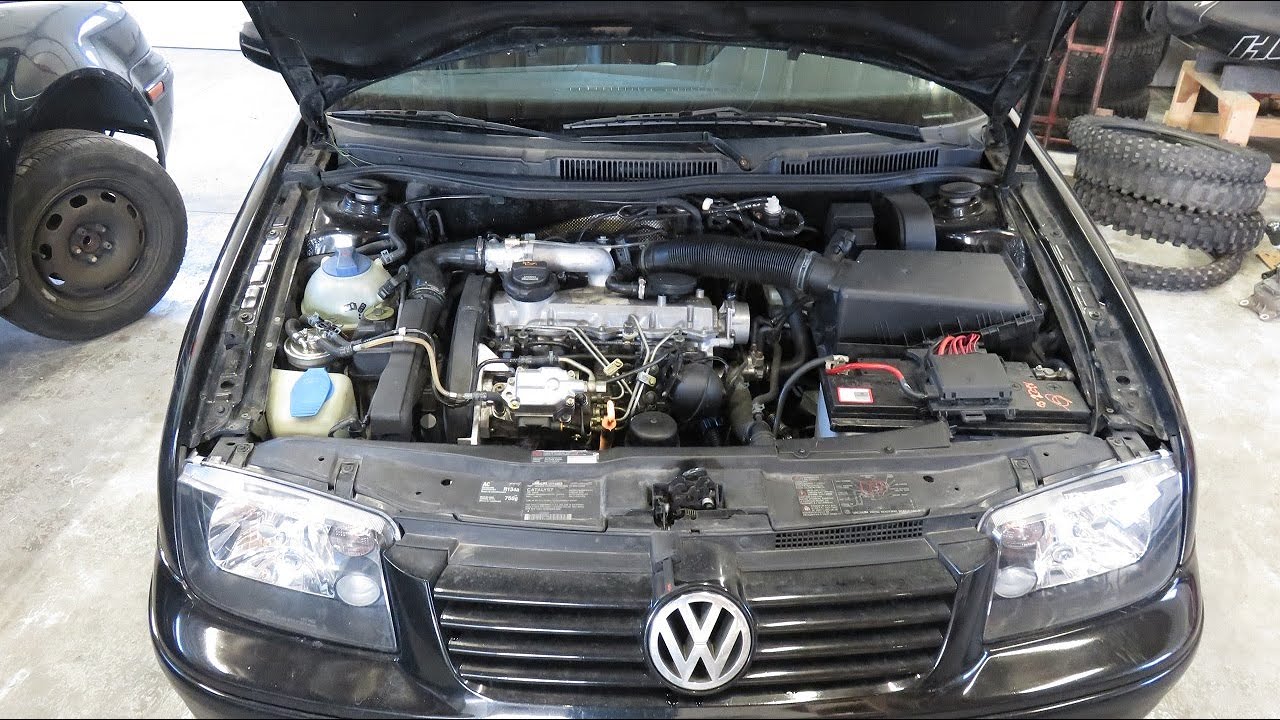

7. Volkswagen 1.9L TDI (Older PD Pump Diesel)

The Volkswagen 1.9-liter TDI engine, particularly the earlier pump- or Pumpe-Düse (PD) versions, developed a strong reputation for robustness and fuel efficiency. Introduced in the mid-1990s, these engines powered countless Golfs, Jettas, and Passats and became popular worldwide, especially in Europe and developing markets.

While modern versions of the TDI use sophisticated common-rail injection systems, the older PD engines feature a simpler unit injector setup that combines the fuel pump and injector into one component.

This system is highly durable and mechanically precise, enabling the engine to handle poor fuel quality and extended service intervals with fewer issues than more electronically complex diesel systems.

One of the reasons the 1.9L PD TDI remains reliable despite neglect is its overbuilt internals. The cast-iron block is robust, and the cylinder heads have proven resistant to cracking or warping.

The direct injection system helps maintain fuel economy and performance, even when filters are dirty or oil changes are delayed. It also has a relatively low compression ratio compared to older diesels, which reduces the likelihood of mechanical failures.

In many cases, owners of these engines have driven them to 300,000 miles or more without any major rebuilds. Even with occasional neglect, the engine will start reliably and maintain decent power. When problems do arise, the engines are often more forgiving than newer diesel designs, allowing for extended use before repairs become necessary.

The 1.9L TDI also benefits from an enthusiastic aftermarket and a vast community of owners. This means replacement parts are readily available, and DIY repairs are often straightforward. Its balance of economy, durability, and relative simplicity makes it a preferred choice for those looking for an engine that won’t quit when maintenance is less than ideal.

8. Toyota 1HZ (4.2L Inline-6 Diesel)

The Toyota 1HZ diesel engine is a mainstay in the Land Cruiser 70 and 80 series and other heavy-duty vehicles worldwide. Known for its simplicity and reliability, the 1HZ continues to impress users with its ability to run strong, even when maintenance is spotty or conditions are harsh.

This naturally aspirated diesel is free from complicated electronics and emissions gear found in newer engines, making it mechanically simple and easy to repair.

The 1HZ’s cast-iron block and head can endure significant abuse, including overheating, poor-quality fuel, and extended intervals between oil changes. Its low compression ratio and straightforward injection system contribute to its longevity by reducing internal stresses.

Many owners report running these engines in remote locations where scheduled maintenance is challenging, such as mining sites, rural areas, and off-road expeditions. Despite long periods between services, these engines rarely suffer catastrophic failure. Instead, they tend to lose some performance or start consuming oil but continue to operate reliably.

The 1HZ also benefits from Toyota’s reputation for high-quality manufacturing standards. Though it’s a no-frills engine, every component is designed to last. Valve adjustments can be overdue, and glow plugs can fail, but the engine will start and run, sometimes with a noticeable loss of smoothness but without stopping entirely.

Long-term durability, simplicity, and the ability to work in severe environments make the 1HZ a favorite for anyone who needs a dependable engine that won’t complain when regular maintenance isn’t possible.

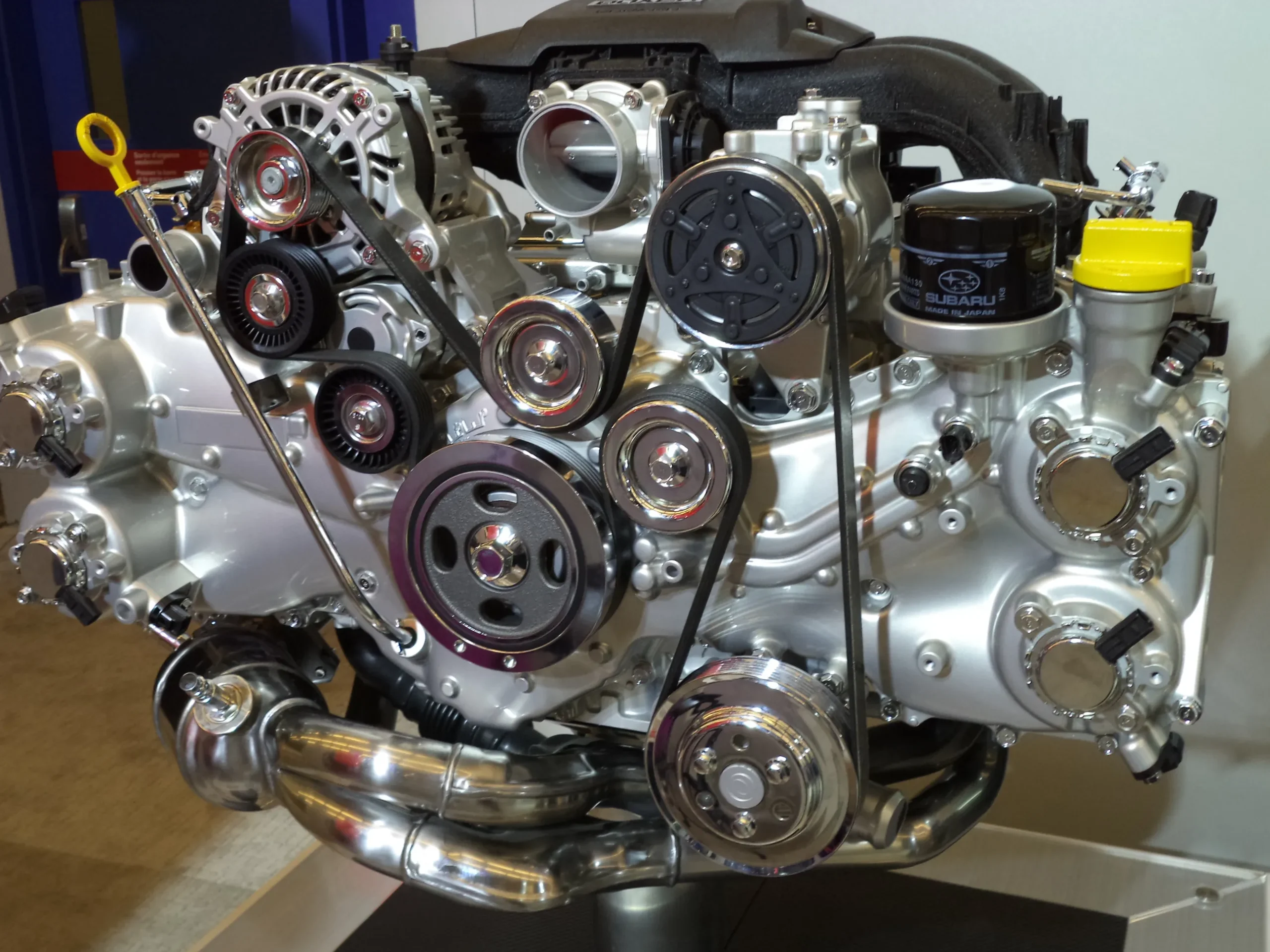

9. Subaru EJ25 (2.5L Boxer-4)

The Subaru EJ25 engine, especially the naturally aspirated versions found in many Outbacks, Foresters, and Legacy models, has earned a reputation for ruggedness and resilience. While the turbocharged variants often get attention for performance, the NA EJ25 engines are generally more reliable, especially when maintenance is less than perfect.

One unique aspect of the EJ25 is its boxer layout, which lowers the center of gravity and provides smooth power delivery. However, this design also means that certain maintenance tasks can be more difficult, which sometimes leads owners to skip or delay them.

Despite that, many EJ25s have lasted hundreds of thousands of miles with oil changes missed or timing belt replacements delayed.

Subaru’s use of iron sleeves within aluminum blocks gives the EJ25 durability against wear and overheating. Even when owners fail to change the oil regularly, the engine tends to hold up better than many of its competitors. Problems like head gasket leaks are relatively common in older models, but even then, the engine usually keeps running and can often be fixed without full teardown.

The EJ25’s valvetrain and cooling system are known to be robust, although some owners report issues with oil consumption as the engine ages. Still, compared to other engines in its class, the EJ25 stands out for its ability to take neglect and keep going. Whether used in snowy mountain towns or humid coastal regions, it delivers reliable service for many years.

Because these engines were widely produced and used in various Subaru models, parts are plentiful and repairs are generally affordable. Enthusiasts and daily drivers alike praise the EJ25 for being an engine that, while not invincible, tolerates real-world abuse better than expected.

10. Isuzu 4BD1T (3.9L Turbo Diesel Inline-4)

The Isuzu 4BD1T turbo diesel engine has long been a favorite among commercial operators, farmers, and anyone who needs a tough, reliable engine with minimal fuss. Found in trucks and vans worldwide, this 3.9-liter turbocharged inline-four diesel combines the power of forced induction with the simplicity and reliability of an older mechanical design.

One reason the 4BD1T thrives despite poor maintenance is its rugged construction. The block and heads are cast iron, capable of withstanding harsh conditions, including extreme heat and dirt ingress. Its indirect injection system is simpler than modern direct-injection diesels, which makes it more tolerant of low-quality fuel and delayed servicing.

The engine’s turbocharger adds power but is also designed to be durable and easy to rebuild. Many operators report running these engines for tens of thousands of miles on a single turbo, even with less-than-ideal maintenance habits. The mechanical fuel pump and injector setup means fewer electronic components are vulnerable to failure.

Because of its reliability, the 4BD1T is often found in remote or harsh environments where servicing options are limited. Whether hauling loads through rough terrain or powering a work truck on a farm, this engine can take a beating and keep running. It’s common to find examples with over 300,000 miles still in daily use.

Its straightforward design also means that repairs are generally simple and parts are still readily available in many parts of the world. For anyone needing a diesel engine that won’t quit even when maintenance is minimal or inconsistent, the 4BD1T is a strong contender.

11. Nissan TD42 (4.2L Diesel Inline-6)

The Nissan TD42 engine is a 4.2-liter inline-six diesel powerhouse found in models like the Nissan Patrol and some commercial trucks. It has earned a reputation as one of the most reliable diesel engines, especially in harsh environments such as Australia’s outback and parts of the Middle East. Its long-standing durability comes from a conservative design focused on longevity rather than outright performance.

The TD42 uses a mechanically controlled fuel injection system that doesn’t rely heavily on electronics, which makes it less vulnerable to electrical failures or sensor issues often triggered by poor maintenance.

The engine’s heavy cast-iron block and head add a layer of toughness, enabling it to handle heat and wear better than many contemporary diesels. Even under conditions of dirty fuel or infrequent oil changes, the TD42 has shown the ability to keep running reliably.

A common reason for the TD42’s survival in neglected states is its robustness against overheating. Many modern engines will warp or crack their heads under heat stress, but the TD42’s iron construction can endure more abuse.

This means owners sometimes run the engine with coolant leaks, faulty thermostats, or clogged radiators for longer periods without catastrophic failure. That said, such conditions may eventually lead to reduced power or increased oil consumption, but not outright breakdown.

Additionally, the TD42’s torque curve is very forgiving. It produces strong low-end torque but doesn’t push components to their limits, which means internal wear happens slowly. Even when some parts wear prematurely, like injector pumps or glow plugs, the engine continues to operate, often with only a minor drop in efficiency or starting ability.

Many drivers in remote regions swear by the TD42 for its “just works” mentality. It’s not the quietest or most refined diesel, but it’s easy to fix with basic tools and parts, which makes it invaluable where service centers are few and far between. For those seeking an engine that can take rough treatment and still get the job done day after day, the Nissan TD42 remains a top choice.