Engines are the heart of any vehicle, and their performance over time can make the difference between a reliable ride and constant mechanical headaches. Some engines have a reputation for maintaining smooth operation and reliability over many miles and years, often becoming the backbone of their manufacturer’s lineup.

Others, despite initial promise, tend to show roughness, lose efficiency, or develop problems sooner than expected. This article compares five engines celebrated for their longevity and smooth operation with five that often experience issues or decline rapidly.

Understanding what sets these engines apart can help car buyers, enthusiasts, and mechanics better appreciate the engineering decisions that impact durability and performance. Reliability depends on multiple factors, including design choices, manufacturing quality, materials used, and how well the engine can handle stress over time.

Smooth-running engines tend to have well-balanced components, efficient cooling, and robust construction, which all contribute to their ability to maintain power delivery and low vibration levels. Conversely, engines that turn rough quickly may suffer from poor design tolerances, inadequate cooling, or materials that wear out prematurely.

While routine maintenance plays a critical role in any engine’s lifespan, some engines simply have a higher baseline quality and design intelligence that allows them to perform better with less trouble.

The following lists showcase both sides of the spectrum by looking at specific examples from various manufacturers and engine families, highlighting the characteristics that make each engine stand out as either a reliable long-runner or one prone to early roughness.

Also Read: 5 Cars That Rarely Cause Buyer’s Regret vs 5 That Always Do

Engines That Keep Running Smoothly

1. Toyota 2JZ-GTE

The Toyota 2JZ-GTE engine has become a benchmark for durability and smooth operation in the automotive world. Introduced in the early 1990s as a high-performance inline-six for the Toyota Supra, it quickly earned a reputation for its ability to withstand extreme conditions without faltering.

This engine’s iron block provides immense strength, helping it resist warping and cracking even under high boost pressures. Coupled with forged steel internals such as crankshafts and connecting rods, the 2JZ-GTE is built to endure stress and minimize mechanical failures.

The engine’s smoothness can be credited to its inherently balanced inline-six configuration, which naturally reduces vibrations compared to V-type engines. This balance translates to less strain on mounts and ancillary components, meaning the engine remains steady and refined throughout its life.

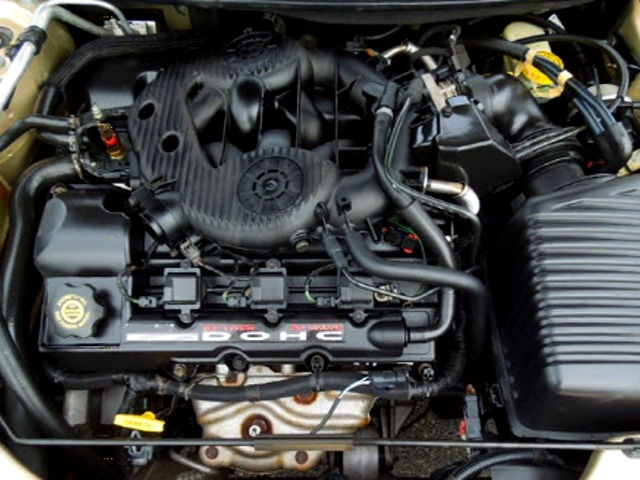

The valvetrain design of the 2JZ-GTE also contributes significantly to its smooth running. Its DOHC (double overhead camshaft) setup allows precise timing control for intake and exhaust valves, promoting efficient combustion and minimizing harshness during operation.

This precision results in a steady and predictable power delivery, free from the jerks or shakes often felt in less balanced turbocharged engines. Another contributing factor to smoothness is the engine’s cooling system.

The 2JZ-GTE features well-thought-out coolant passages and reliable thermostat controls, which help keep operating temperatures consistent and prevent overheating-related issues that can cause knocking or rough running. This robust cooling, paired with a quality oiling system, ensures internal components are well lubricated and operating in ideal conditions.

Many enthusiasts and professional tuners praise the 2JZ-GTE for its ability to maintain smoothness even when significantly modified. Its strong factory foundations mean that increasing power output does not necessarily come at the cost of engine harshness.

Whether in street-driven cars or competitive drag racing, the 2JZ-GTE holds a reputation for reliability and smooth performance over hundreds of thousands of miles. In addition, Toyota’s manufacturing quality and attention to detail in the assembly process result in consistent performance across engines, making the 2JZ-GTE a favorite among those who value longevity alongside power.

Finally, the community around the 2JZ-GTE contributes to its continued smooth operation. Many owners follow strict maintenance routines and use high-quality parts that extend engine life. The aftermarket support for replacement and upgrade components is vast, allowing enthusiasts to maintain or improve smoothness through better pistons, camshafts, and turbo components.

This culture of care and improvement has helped the 2JZ-GTE stay relevant and smooth-running decades after its introduction, making it a classic example of an engine that simply keeps going strong.

2. Honda K20

The Honda K20 engine series is well-regarded for its combination of performance, fuel efficiency, and above all, smooth operation over long periods. This four-cylinder engine uses a DOHC layout with Honda’s i-VTEC system, which adjusts valve lift and timing according to driving conditions.

The result is an engine that adapts seamlessly to various speeds and loads, maintaining steady and smooth power delivery without the sudden surges or drops that can cause vibrations or roughness.

The K20’s architecture is engineered to balance internal forces, reducing piston slap and minimizing friction losses, which contribute to longevity and smooth operation. Its aluminum block and head help dissipate heat efficiently, which is critical in avoiding hotspots that can cause knocking or rough idling.

Manufacturing precision is another key element in the K20’s smoothness. Honda’s commitment to tight tolerances means that internal components fit together perfectly, reducing unwanted movement and wear.

The high-quality piston rings and bearings ensure consistent compression and lubrication, further preventing rough running conditions that can arise from oil starvation or compression loss.

Additionally, the engine’s intake and exhaust systems are carefully designed to optimize airflow, resulting in even fuel distribution and combustion that is both efficient and stable. The smooth throttle response is also a product of the engine’s electronic control systems, which finely manage fuel injection and ignition timing to keep engine revolutions stable across varying driving scenarios.

Another reason the K20 remains smooth over time is its robust yet lightweight design, which reduces the stress on engine mounts and peripheral components. This not only improves ride comfort but also lowers the chances of component failure due to vibrations or stress fatigue.

Owners often report that even after extended periods of use, the K20 shows little sign of roughness or loss of refinement, which speaks to Honda’s engineering philosophy of blending performance with everyday reliability.

The engine also benefits from a well-planned maintenance schedule, with components like timing chains and water pumps designed for longevity, minimizing unexpected breakdowns that could affect smoothness.

Finally, the aftermarket and community support surrounding the K20 engine help ensure its smooth running nature continues well beyond factory specifications. Many enthusiasts upgrade their engines with balanced crankshafts, improved camshafts, and enhanced fuel management systems to further smooth out power delivery and extend engine life.

The accessibility of quality parts combined with Honda’s well-documented engineering contributes to the K20’s continued reputation as one of the most reliable and smooth-running engines in its class.

3. Ford Modular V8 (4.6L)

The Ford Modular V8, especially the 4.6L variant, stands out as an engine that combines strength, refinement, and durability. Launched in the 1990s as a replacement for older pushrod V8s, it represented a modern approach to V8 design with features such as overhead camshafts and improved combustion efficiency.

One reason for its smooth operation lies in its balanced firing order and sophisticated valvetrain, which minimizes vibrations often experienced in less refined V8s.

The 4.6L engine’s aluminum heads and cast-iron block provide a sturdy foundation that resists warping and cracking, maintaining consistent operation over many miles. Cross-bolted main bearing caps add structural integrity to the rotating assembly, reducing crankshaft flex and vibration.

Fuel delivery and ignition timing are managed carefully to ensure efficient and smooth combustion. The modular V8 employs electronic fuel injection and coil-on-plug ignition systems, which allow precise control over spark and fuel mix. This results in a powerband that feels linear and responsive, without sudden jerks or hesitations.

The engine also benefits from a robust cooling system that keeps temperatures stable and avoids overheating, which can lead to rough running or mechanical wear. Because the cooling and lubrication systems are designed for longevity, this engine can endure varied driving conditions from city traffic to highway cruising with minimal compromise in smoothness.

The 4.6L Modular V8 has proven itself across many platforms, including trucks, SUVs, and performance cars, each benefiting from the engine’s smooth-running character. Maintenance is relatively straightforward, and the availability of parts means owners can keep their engines in good shape without excessive expense.

Additionally, the engine’s design allows it to run smoothly even under heavy loads or high mileage conditions, which is why it is commonly found in vehicles that rack up large distances over their lifetimes. Drivers appreciate the quiet operation and the lack of harsh vibrations, which adds to driving comfort.

Finally, the engine’s widespread use has resulted in a large knowledge base and aftermarket support. Performance enthusiasts have access to upgraded components that can maintain or even improve the engine’s smoothness as power is increased.

Many owners report that with regular oil changes, cooling system upkeep, and proper tuning, the 4.6L Modular V8 remains a smooth and dependable engine for well beyond 200,000 miles, illustrating its durability and refinement in the competitive V8 market.

4. BMW M54 Inline-6

The BMW M54 inline-six engine is often regarded as the pinnacle of smooth and refined engine design. Inline-six engines inherently possess excellent primary and secondary balance, which means the forces generated by piston movement counteract each other more effectively than in V6 or four-cylinder engines.

This mechanical harmony results in fewer vibrations transmitted to the chassis and cabin, enhancing ride comfort and engine longevity.

The M54 builds on this natural balance with an aluminum block and heads that keep weight low while maintaining strength and heat dissipation. The precision machining of internal components ensures tight clearances, which minimizes friction and promotes efficient power transfer.

In addition to its structural design, the M54 utilizes BMW’s VANOS variable valve timing system. This technology adjusts valve timing based on RPM and load, optimizing combustion and power delivery for smooth transitions across the rev range.

The engine’s intake manifold and fuel injection system are calibrated to ensure a consistent and balanced air-fuel mixture, which prevents rough idling or uneven power output. This careful calibration means drivers experience a linear and responsive throttle feel, free of hesitation or surging.

The combination of mechanical balance and electronic control produces an engine that remains smooth and composed during acceleration, cruising, and even cold starts.

The M54’s cooling and lubrication systems also contribute significantly to its smooth-running reputation. With a well-designed radiator, thermostat, and oil pump, the engine maintains ideal operating temperatures and reduces thermal stress on key components.

This results in less wear and tear, allowing the engine to run smoothly even after extensive use. While some individual components such as valve cover gaskets and cooling system parts are known to require periodic attention, the core engine block and internals rarely suffer from rough running or vibration issues if properly maintained.

Lastly, the BMW community and aftermarket provide ample support for keeping the M54 running smoothly for many years. Owners routinely perform preventative maintenance and use high-quality fluids and parts to extend engine life.

Many enthusiasts also choose to upgrade components like ignition coils and intake systems to maintain smooth power delivery as mileage climbs. This focus on care combined with the engine’s inherently smooth design has helped the M54 maintain its status as one of the best naturally aspirated inline-sixes ever produced.

5. Subaru EJ25

The Subaru EJ25 boxer engine is known for its unique design that contributes to smoothness and balanced operation. Unlike inline or V-shaped engines, the flat “boxer” layout positions cylinders horizontally and opposed to each other.

This setup inherently cancels out many of the vibrations common in other engine types, resulting in a very smooth and stable running experience.

The EJ25’s aluminum construction for both block and heads provides lightness that helps manage heat effectively, reducing the risk of hotspots or overheating that can cause engine roughness. The engine also uses a sophisticated cooling system tailored to the boxer layout, ensuring consistent temperature control across all cylinders.

The fuel injection and ignition systems in the EJ25 are designed to work harmoniously with the engine’s physical balance. The injection system delivers fuel evenly to each cylinder, while the ignition timing is finely controlled to optimize combustion efficiency.

This attention to detail helps prevent misfires, rough idling, and uneven power delivery, all of which contribute to a smooth driving experience. The engine’s valvetrain and timing mechanisms are engineered to maintain tight tolerances, minimizing internal wear and preserving smooth operation over time.

Despite some known issues, such as head gasket failures in earlier models, the EJ25 engine has earned praise for its durability and smoothness when well-maintained. Its unique design means it operates quietly and with minimal vibration, even in higher-performance applications like the Subaru WRX.

The boxer configuration also lowers the vehicle’s center of gravity, which enhances handling and driver confidence, indirectly contributing to a sense of smoothness and refinement.

Many Subaru owners report that with proper upkeep, the EJ25 continues to run smoothly for well beyond 150,000 miles, making it a reliable choice for those seeking a balance of performance and longevity.

Finally, the community surrounding Subaru engines emphasizes preventative maintenance and quality parts, which helps maintain the EJ25’s smooth operation.

Enthusiasts often upgrade cooling components, oil systems, and intake setups to keep the engine running well under demanding conditions. The combination of unique design and dedicated care has allowed the EJ25 to remain a smooth-running engine choice for decades.

Also Read: 5 Cars That Survive The American Rust Belt vs 5 That Disintegrate

Engines That Turn Rough Quick

1. Volkswagen 2.0 TSI EA888 Gen 1

The first-generation Volkswagen 2.0 TSI EA888 engine is well-known for its early onset of rough-running problems, despite its modern features and performance potential. This turbocharged inline-four engine incorporates direct fuel injection and variable valve timing, technologies designed to boost efficiency and power output.

However, the direct injection system also leads to a common issue: carbon buildup on the intake valves. Unlike port-injected engines, where fuel helps wash away deposits, direct injection sprays fuel directly into the combustion chamber, leaving intake valves vulnerable to collecting carbon deposits over time.

This buildup restricts airflow, causes uneven combustion, and leads to symptoms such as rough idling, hesitation, and loss of smoothness during operation.

In addition to carbon buildup, the EA888 Gen 1 engine suffers from timing chain tensioner and guide wear that can result in premature timing chain slack. When timing chains become loose or misaligned, valve timing can become erratic, further contributing to rough engine operation and increased engine noise.

Owners often notice these symptoms starting around 60,000 to 80,000 miles, at which point repairs become necessary to restore smooth running. Furthermore, some EA888 Gen 1 engines experience excessive oil consumption due to piston ring and valve stem seal wear, which compounds roughness by allowing combustion chamber oil contamination and incomplete combustion.

Electrical issues also play a role in the engine’s early decline. Coil pack failures and sensor malfunctions can cause misfires, rough idling, and hesitation, especially when not diagnosed promptly.

Because these issues tend to surface relatively early, the reputation of the EA888 Gen 1 is that of an engine that requires attentive maintenance and occasional expensive repairs to maintain its smooth-running character.

Despite these drawbacks, the EA888 platform has evolved, and later generations have addressed many of these problems, but the first generation remains a cautionary example of potential rough-running tendencies.

Finally, the maintenance demands and sensitivity of this engine mean that owners who are not diligent in servicing it often experience a steep decline in engine smoothness. Frequent oil changes using the correct synthetic oil, timely replacement of spark plugs and ignition coils, and periodic intake cleaning are essential to keep the engine running well.

Without this attention, the 2.0 TSI EA888 Gen 1 can quickly transition from a smooth and powerful engine to one marked by rough running and mechanical issues, which affects drivability and owner satisfaction.

2. Jeep 2.7L V6

The Jeep 2.7L V6 engine has long been associated with rough-running issues and mechanical problems that tend to arise earlier than expected in many vehicles. This engine, used in several Jeep and Dodge models during the early 2000s, was intended to provide a balance of power and fuel efficiency but often fell short in reliability.

One of the core issues relates to the timing chain tensioner, which can wear out and lose tension, causing timing chains to slap and potentially skip teeth on the sprockets. This leads to irregular valve timing and engine misfires, both of which contribute to rough idling and uneven power delivery.

The 2.7L V6 is also notorious for overheating problems, partly due to a cooling system that struggles under heavy loads or extreme conditions. Overheating causes metal components to expand beyond design tolerances, which can lead to warping, gasket failures, and compromised combustion chamber sealing.

These factors significantly contribute to the engine running rough and can accelerate wear on pistons and cylinder walls. Moreover, when the engine overheats, oil viscosity can change, reducing lubrication quality and increasing friction between moving parts, which exacerbates rough-running symptoms.

Another challenge for the 2.7L V6 is its tendency to develop oil sludge if routine maintenance is neglected. The engine’s cooling and oil circulation systems are sensitive to contamination, and poor maintenance or extended oil change intervals can result in sludge buildup that restricts oil flow.

Reduced lubrication causes increased wear on camshafts, lifters, and bearings, all of which are critical to maintaining smooth engine operation. Sludge buildup also impairs the timing chain tensioner’s effectiveness, further compounding timing and rough-running issues.

The combination of mechanical weaknesses, cooling challenges, and maintenance sensitivity means the Jeep 2.7L V6 often turns rough much sooner than competing engines.

Owners who adhere strictly to maintenance schedules and perform early repairs can mitigate some of these problems, but the engine’s design and material choices inherently limit its long-term smoothness and reliability. Consequently, this engine remains a less desirable choice for those seeking an engine that will run smoothly for many years without significant intervention.

3. Chrysler 2.0L Turbo (Neon SRT-4 Engine)

The Chrysler 2.0L turbocharged four-cylinder engine, famously used in the Neon SRT-4, is known for impressive power and spirited performance, but it also carries a reputation for developing rough-running issues relatively early in its life cycle.

This engine was designed with an iron block and aluminum head, and while it delivers strong output for its size, its cooling system has been a weak point. Inadequate cooling capacity, combined with high thermal loads from forced induction, often leads to overheating, which in turn causes head gasket failures.

These failures can manifest as rough idling, misfires, and a noticeable drop in smoothness as combustion chamber sealing is compromised.

The turbocharger adds considerable stress to the engine’s internal components. While turbocharging increases power and torque, it also raises cylinder pressures and temperatures, which accelerate wear on pistons, rings, and bearings.

The added mechanical and thermal strain can cause components to wear prematurely and contribute to rough running conditions. Moreover, the turbo system itself requires proper maintenance to avoid boost leaks or compressor inefficiencies that result in inconsistent power delivery and engine hesitation.

Fuel delivery issues also affect the smoothness of this engine. The direct injection system, although designed for performance, can suffer from irregular fuel spray patterns and injector clogging, leading to uneven combustion and misfires.

The combination of mechanical, thermal, and fuel system challenges makes this engine sensitive to maintenance practices. Without careful attention to cooling system integrity, oil quality, and turbocharger health, the 2.0L turbo can quickly develop rough running symptoms that degrade driving experience.

Owners who push this engine hard, such as in aggressive driving or racing scenarios, often report that roughness and mechanical failures can appear within relatively low mileage.

While the Neon SRT-4’s engine remains popular for tuning and aftermarket support, it is important to recognize that its smooth operation depends heavily on careful maintenance and conservative use, making it less suitable for drivers looking for a low-maintenance, smooth-running daily driver.

4. Land Rover V8 (4.0L and 4.6L)

The Land Rover 4.0L and 4.6L V8 engines have long been a source of mixed reviews when it comes to durability and smooth running over time. While initially praised for their power and refinement, these engines tend to develop rough-running symptoms sooner than many competitors, especially when subjected to typical off-road stresses or inconsistent maintenance.

One of the main issues lies in timing chain tensioners, which are prone to wear and failure. When tensioners malfunction, the timing chains can rattle, causing irregular valve timing, misfires, and rough idling. These problems significantly degrade smooth running characteristics and often require expensive repairs to correct.

Additionally, the engines have a history of coolant leaks and overheating issues. The aluminum heads and block are vulnerable to stress and cracking if cooling system components like water pumps and thermostats fail or are poorly maintained.

Overheating leads to head gasket failures and cylinder warping, which directly impact combustion chamber sealing and cause rough running, loss of power, and increased vibration. These engines also employ variable valve timing systems that, when malfunctioning, can further contribute to uneven power delivery and roughness.

Oil circulation in these V8s is critical for smooth operation, but the design has been criticized for sometimes allowing oil starvation or buildup of sludge if maintenance is not rigorous.

Oil issues degrade the lubrication of critical moving parts such as camshafts, lifters, and bearings, causing increased friction, noise, and rough engine behavior. Owners who neglect oil changes or use subpar oil quality often experience premature engine wear that manifests as rough running and reliability problems.

Despite their power and the appeal of Land Rover vehicles, the 4.0L and 4.6L V8 engines require diligent maintenance and early intervention to avoid rough-running issues. The combination of mechanical wear points, cooling system weaknesses, and oiling challenges means these engines are often less smooth in the long term compared to rivals.

As a result, many Land Rover owners find themselves addressing rough-running problems as a common part of ownership, especially after the first 100,000 miles.

5. Mitsubishi 4G63T (Early Models)

The early Mitsubishi 4G63T turbocharged inline-four engine, famous for powering the first-generation Lancer Evolution models, is revered for its performance potential but also criticized for developing rough-running issues if not maintained meticulously.

This engine uses a robust cast-iron block and aluminum heads and features a turbocharger that significantly increases output. However, the combination of forced induction and early-generation materials and designs led to vulnerabilities such as head gasket failures and overheating, which in turn cause rough idling and uneven power delivery.

One major contributing factor to roughness in the 4G63T is the cooling system’s inability to manage the high thermal loads generated by turbocharging consistently. Overheating can warp cylinder heads and degrade gasket seals, resulting in loss of compression and combustion irregularities.

Additionally, early versions of this engine were prone to carbon buildup on valves and piston ring wear, both of which reduce engine smoothness by causing misfires and incomplete combustion.

The turbocharger itself adds stress to the internal components, increasing wear on pistons, rings, and bearings. If oil quality or quantity is compromised, these parts can degrade rapidly, further contributing to rough operation. Turbo lag and boost inconsistencies can also lead to fluctuations in power delivery that feel rough or uneven to the driver, especially if the turbo system’s maintenance is neglected.

Despite its performance capabilities and devoted following, the 4G63T requires consistent maintenance and care to avoid developing rough-running symptoms. Many early owners experienced roughness and mechanical issues as the engine aged, highlighting its sensitivity to cooling, lubrication, and timing component conditions.

With proper attention, however, the 4G63T can be kept running relatively smoothly, though it is generally considered less forgiving than more modern or robust engines.