The HEMI engine has earned a reputation for power, distinctive design, and the ability to handle heavy-duty applications, making it a favorite among muscle car enthusiasts, truck owners, and performance seekers.

Its hemispherical combustion chamber is unique in its efficiency at producing horsepower and torque, offering an unmistakable rumble that has become iconic in automotive culture.

Yet despite its strengths, the HEMI is not without drawbacks. Some models are known for higher maintenance needs, occasional oil consumption issues, and sensitivity to modifications or fuel quality.

These quirks, while manageable for some owners, can be a barrier for those looking for a long-lasting, reliable engine with fewer surprises over time.

For drivers who appreciate strong performance but value longevity and smooth operation, several engines from different manufacturers can serve as compelling alternatives.

These engines provide similar or even superior durability, fewer common issues, and often simpler maintenance requirements without sacrificing power.

While they may lack the instantly recognizable HEMI growl, they compensate with refined engineering, better fuel economy, and a reputation for extended service life.

Many of these engines have been used in a variety of vehicles, from pickups and SUVs to sedans and sports cars, demonstrating versatility across automotive applications.

Choosing an alternative to the HEMI does not necessarily mean compromising on performance. Some options feature advanced fuel injection systems, reinforced internal components, and improved cooling designs that make them highly resilient under heavy loads or extended use.

In addition, many modern engines have benefited from decades of incremental innovation, addressing common issues seen in older HEMI models, such as cylinder head gasket problems, valve train complexity, and overheating tendencies.

For enthusiasts who enjoy modifying or tuning engines, some alternatives provide a more predictable foundation with fewer delicate systems, making them easier to work with and more forgiving in daily operation.

This article highlights ten engines that can serve as strong HEMI alternatives, focusing on longevity, reliability, and user-friendliness. Each option has its own strengths, applications, and characteristics that may appeal to different types of drivers.

By examining these engines in detail, readers can gain insight into options that provide similar performance benefits while reducing the likelihood of maintenance headaches or unexpected quirks.

From V8 powerhouses to modern V6 designs, the following engines represent a balance of performance, durability, and adaptability, making them worthy candidates for those who admire the HEMI but seek a smoother ownership experience over the long term.

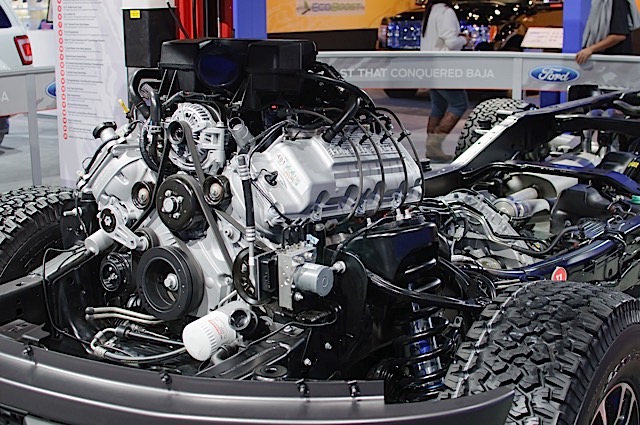

1. Ford 5.0L Coyote V8

The Ford 5.0L Coyote V8 has become a modern standard for reliable performance, earning praise for its balance between power output and longevity.

Its aluminum block and dual overhead camshaft design help reduce weight and improve efficiency, making it suitable for both daily driving and spirited performance applications.

Unlike the HEMI, which sometimes requires close attention to maintenance intervals and oil quality, the Coyote is known for consistent durability when serviced according to manufacturer guidelines.

Its modular architecture has allowed Ford to refine the engine over multiple generations, addressing potential weaknesses in earlier designs and improving long-term resilience.

Another advantage of the Coyote is its advanced variable cam timing system, which optimizes performance across a wide range of speeds without adding excessive complexity.

This system provides smooth power delivery, better fuel economy, and reduced stress on internal components.

Enthusiasts also appreciate the aftermarket support for this engine, allowing modifications without the high risk of mechanical failure that can sometimes accompany HEMI tuning.

Vehicles equipped with the Coyote, such as recent Mustang GTs and F-150 trucks, demonstrate that this engine can handle both high-performance scenarios and daily driving without frequent repairs or unexpected issues.

The construction of the 5.0L Coyote includes forged steel crankshafts and high-strength aluminum pistons, contributing to its long service life under demanding conditions.

Unlike some HEMI variants, which may show premature wear on certain components when pushed to extremes, the Coyote has a reputation for predictable durability, even in engines exceeding 150,000 miles with proper care.

Owners often report fewer quirks related to fuel injection, ignition timing, or valve train alignment, reducing the risk of surprise failures. This reliability is reinforced by Ford’s continuous engineering improvements and the engine’s widespread use across multiple platforms.

Finally, the Coyote V8 excels in adaptability. Its relatively compact size and advanced engineering allow it to fit in a range of vehicles, from high-performance sports cars to full-size trucks, while maintaining reliability.

Drivers seeking the muscle-car experience without the sometimes finicky nature of a HEMI often find the Coyote to be a satisfying alternative.

Its combination of power, smooth operation, and predictable maintenance requirements make it an engine that owners can enjoy without constant worry about hidden mechanical issues.

2. Chevrolet LS3 6.2L V8

The Chevrolet LS3 6.2L V8 has gained a reputation for its robust construction, simplicity, and long-term durability. Part of the widely respected LS engine family, it shares a design philosophy that emphasizes straightforward engineering and reliability.

Its iron block and aluminum heads provide a balance of strength and weight reduction, allowing the engine to endure high mileage and demanding driving conditions.

Unlike some HEMI engines that require frequent attention to valve seals or head gaskets, the LS3 is known for its tolerance to prolonged use and minimal quirks in typical applications.

One key feature of the LS3 is its simplicity. With a pushrod design and fewer moving parts than a dual overhead cam engine, it has less potential for mechanical failure.

This characteristic makes the LS3 popular among builders, performance enthusiasts, and daily drivers alike.

The engine produces significant power naturally, reducing the need for forced induction to achieve high output. Even in stock form, it delivers strong acceleration and torque, satisfying the demands of both street performance and towing applications in trucks and SUVs.

The LS3 also benefits from a vast aftermarket ecosystem. Replacement parts are abundant, and upgrades are generally straightforward, reducing downtime and repair complexity. Many owners report engines running well past 200,000 miles with standard maintenance, including regular oil changes and routine inspections.

Its durability and predictable behavior under heavy loads make it a compelling choice for those who want the performance of a HEMI without worrying about recurring issues such as valve guide wear or overheating under extended use.

Finally, the LS3’s versatility makes it suitable for multiple vehicle types. It has been successfully installed in sports cars, muscle cars, trucks, and even kit cars, often without significant modification to support systems.

The engine’s strong bottom end and reliable fuel delivery system ensure consistent performance across different driving conditions.

For enthusiasts looking for a long-lasting engine that is easier to maintain than some HEMI models, the LS3 represents a practical and proven alternative, combining power, reliability, and adaptability in a compact package.

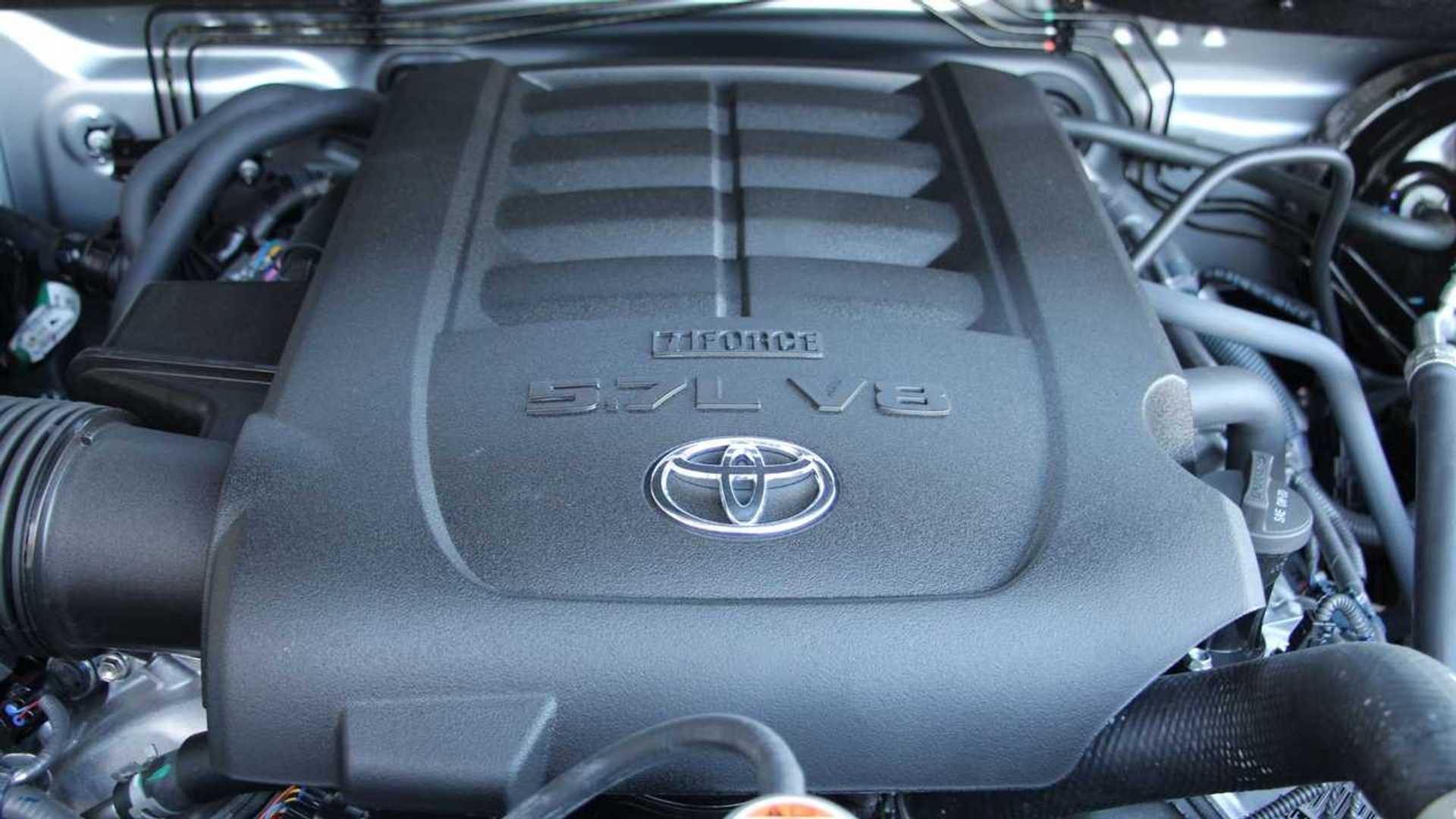

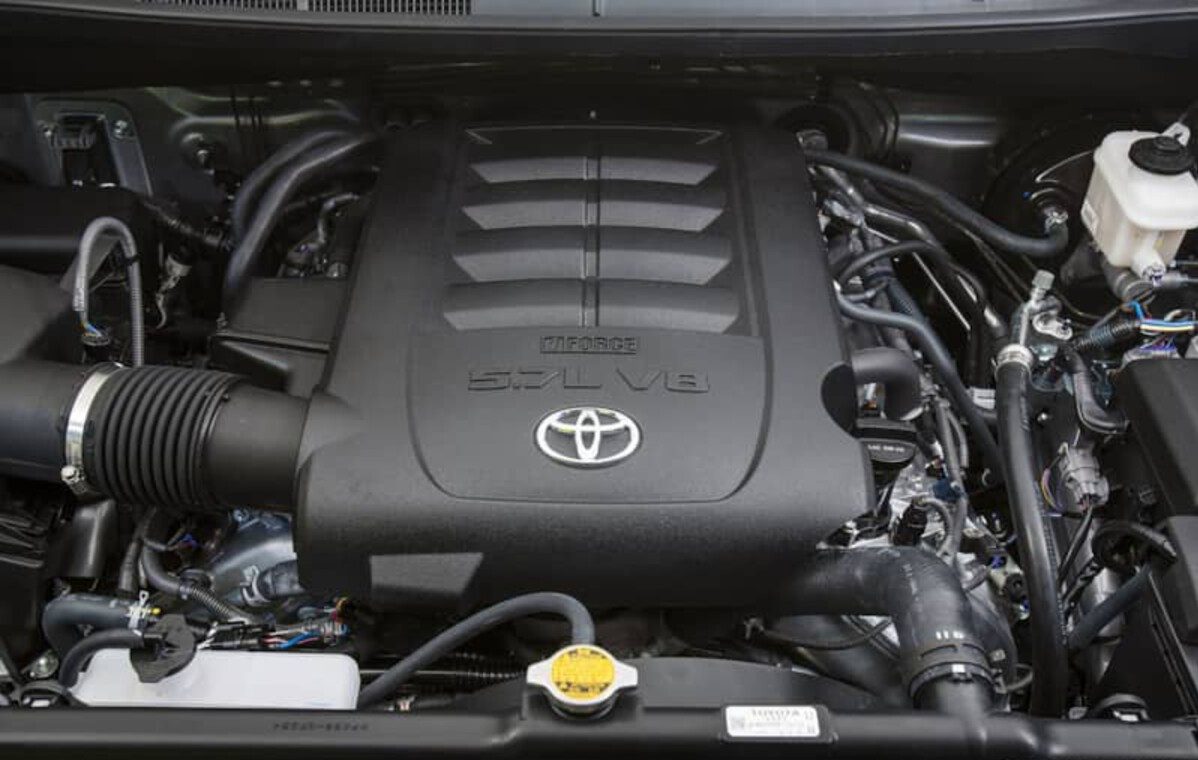

3. Toyota 5.7L i-Force V8

Toyota’s 5.7L i-Force V8 stands out as a durable engine, especially in trucks and SUVs, where longevity is paramount. Its iron block and forged components provide structural integrity, allowing it to handle heavy towing and off-road conditions without significant stress.

Unlike some HEMI engines that require meticulous maintenance to avoid oil consumption or overheating issues, the i-Force V8 has earned praise for its straightforward maintenance schedule and mechanical reliability.

Vehicles such as the Toyota Tundra and Sequoia equipped with this engine often achieve high mileage with minimal repairs.

This engine is known for its smooth torque delivery, which contributes to a confident driving experience under load. The timing chain design eliminates the need for frequent belt replacements, a small but meaningful difference compared to some engines that require more maintenance.

Additionally, the i-Force V8 features a simple intake and fuel delivery system that reduces the likelihood of clogging or component failure, enhancing reliability in diverse conditions, from city streets to rugged terrain.

Owners frequently highlight the engine’s ability to endure extended high-load operation without significant issues. Unlike certain HEMI models prone to valve or head gasket problems when pushed beyond stock limits, the i-Force maintains structural integrity and consistent performance.

Toyota’s engineering emphasizes redundancy in critical components, such as cooling and lubrication systems, reducing the risk of catastrophic failures even when subjected to sustained stress.

Furthermore, the i-Force V8’s reputation for longevity is supported by widespread evidence of high-mileage vehicles exceeding 300,000 miles with routine maintenance.

This durability, combined with moderate complexity and predictable repair costs, makes it an appealing choice for drivers who need a reliable, long-lasting V8 without the quirks often associated with the HEMI.

It is an engine that balances power and endurance, capable of handling both performance demands and practical daily driving needs with minimal fuss.

4. GM 6.6L Duramax Diesel V8

The GM 6.6L Duramax diesel V8 has earned a strong reputation for durability, especially in heavy-duty trucks, where longevity under extreme conditions is a top priority.

Unlike gasoline engines, diesel designs inherently operate with lower RPMs and higher compression, which often translates to longer engine life when paired with proper maintenance.

The Duramax is engineered with reinforced components, including a robust cast-iron block, forged steel crankshaft, and high-strength connecting rods, all of which contribute to its ability to endure continuous high-torque output.

Its reliability in towing and hauling applications surpasses many gasoline HEMI engines, which can be sensitive to sustained high-load operation, making the Duramax a preferred choice for owners who demand both power and resilience.

One of the distinguishing features of the 6.6L Duramax is its advanced fuel system, which utilizes high-pressure common-rail injection to ensure efficient combustion while maintaining engine longevity. Unlike some HEMI engines that occasionally encounter fuel delivery or valve timing quirks, the Duramax system is designed for precision and consistency.

This results in smoother operation even under demanding conditions, with fewer surprises over extended periods of heavy use. The electronic engine management system provides real-time monitoring and adjustments to maintain optimal performance, reducing the risk of premature wear on critical components.

Durability is further enhanced by the engine’s cooling and lubrication systems, which are designed to handle the high stresses of diesel operation.

The Duramax features a robust cooling circuit and high-capacity oil circulation, ensuring that temperatures remain stable even during prolonged towing or off-road activity.

Many owners report reaching well over 300,000 miles without major engine rebuilds, a level of longevity that is difficult to match with many high-performance HEMI variants.

Maintenance intervals are predictable, and routine servicing such as oil and filter changes is straightforward, adding to the engine’s reliability.

Finally, the 6.6L Duramax offers impressive torque and towing capacity while maintaining mechanical simplicity relative to some gasoline V8s. Its design allows for aftermarket support and tuning options without the high risk of internal damage common with some HEMI setups.

For drivers who require a powerplant capable of sustained heavy-duty performance with minimal quirks and long-term durability, the Duramax diesel V8 represents a compelling alternative.

It combines strength, reliability, and engineering foresight, making it a highly practical choice for those seeking longevity over flash or extreme modifications.

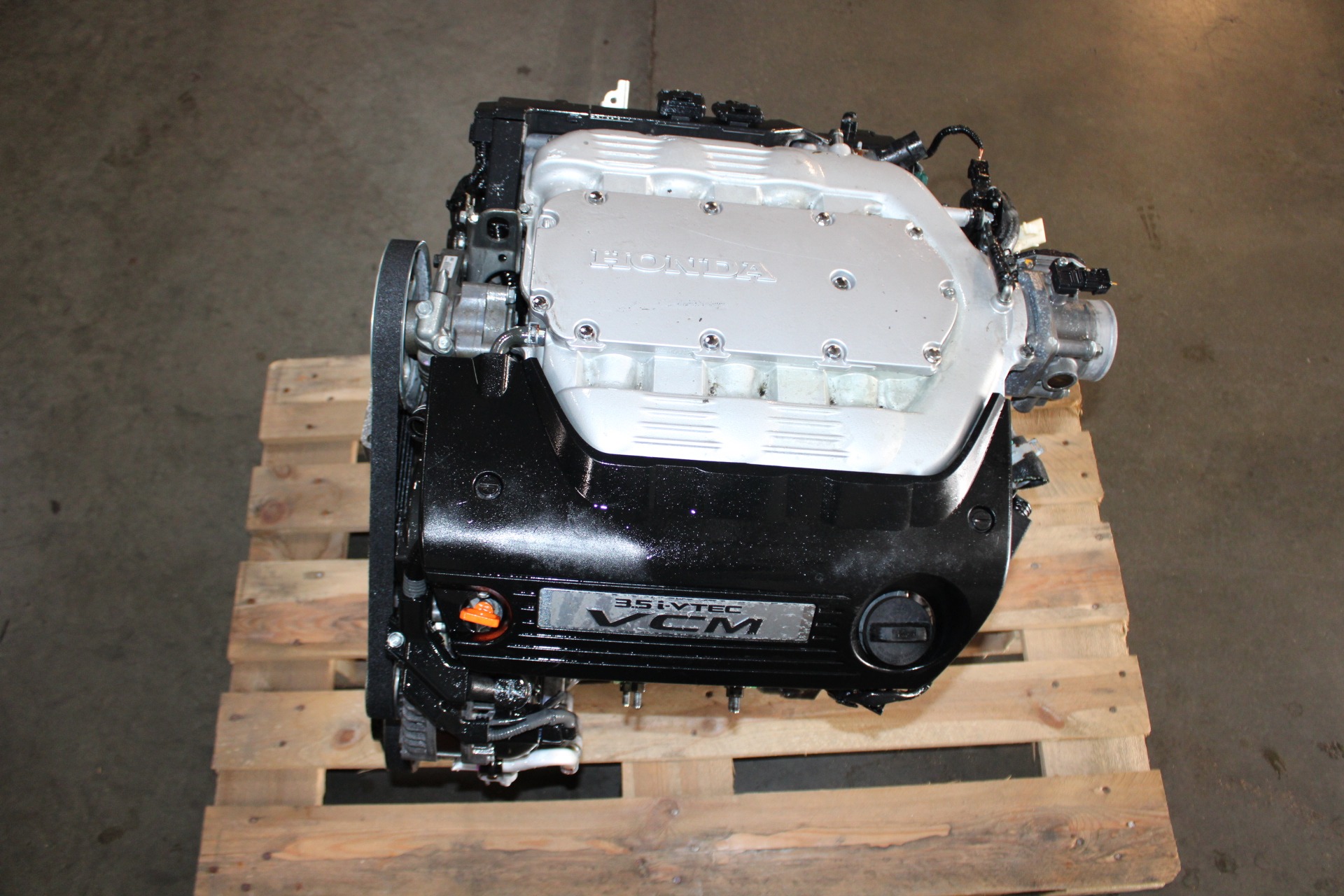

5. Honda 3.5L V6 VTEC

The Honda 3.5L V6 with VTEC technology provides a alternative for drivers who seek a balance between reliability, performance, and fuel efficiency.

While it is smaller than typical V8s, this engine’s engineering focus on smooth power delivery and advanced variable valve timing allows it to produce impressive output without the maintenance complications often associated with a HEMI.

Honda has long emphasized precision manufacturing, tight tolerances, and robust materials, resulting in an engine that operates cleanly and consistently for hundreds of thousands of miles.

Its aluminum block and cylinder head construction reduce weight while maintaining structural integrity, enhancing both performance and efficiency.

One of the key strengths of the 3.5L V6 is its VTEC system, which adjusts valve lift and timing depending on engine speed to optimize both power and efficiency.

Unlike HEMI engines, where certain high-RPM behaviors or cylinder head designs can lead to quirks or accelerated wear, the VTEC mechanism operates reliably when properly maintained.

This adaptability allows the engine to perform well in a variety of driving scenarios, from spirited acceleration to long-distance commuting, without causing undue stress on internal components.

The engine’s reputation for smoothness and predictable behavior makes it a favorite among owners who value consistent performance over raw muscle.

Durability is also a major advantage of this Honda V6. Its robust internals, including forged steel connecting rods and high-strength pistons in select variants, are built to withstand extended use under normal or moderately demanding conditions.

Oil consumption is typically minimal, and the timing chain design eliminates the need for frequent belt replacements, a source of common maintenance issues in some alternative engines. Owners frequently report vehicles surpassing 250,000 miles without major engine repairs, a testament to the meticulous engineering standards Honda applies to its powerplants.

Finally, the engine’s versatility allows it to serve in a range of vehicles, from sedans to SUVs, providing strong performance and low maintenance requirements. Unlike certain high-strung V8s, the 3.5L V6 offers a balance of power, refinement, and dependability.

For those who want an engine that performs well, requires minimal attention, and has few quirks compared to the HEMI, this Honda design represents a reliable and long-lasting option that can handle both daily driving and moderate performance demands with confidence.

6. Nissan VK56DE 5.6L V8

The Nissan VK56DE 5.6L V8 is another engine known for its strong reliability and long service life, making it a credible alternative to the HEMI.

Found in vehicles such as the Nissan Titan and Armada, the VK56DE was designed to combine robust performance with durability suitable for heavy-duty use.

Its iron block and aluminum heads provide a sturdy yet lightweight structure, ensuring the engine can handle towing, off-road stress, and long-distance driving without premature wear.

Unlike certain HEMI variants that may show quirks in cylinder head longevity or oil consumption, the VK56DE exhibits consistent performance with minimal issues when maintained properly.

One of the standout features of this engine is its smooth torque curve. Producing ample low-end torque, it provides effortless acceleration and towing capability while reducing strain on the transmission and drivetrain. This characteristic makes it particularly suitable for trucks and SUVs where engine longevity under load is critical.

The VK56DE also incorporates a reliable fuel injection and ignition system that is simple to service and less prone to the idiosyncrasies sometimes observed in HEMI engines, contributing to fewer unexpected maintenance challenges.

Durability in the VK56DE is enhanced by high-quality internal components, including forged crankshafts and pistons in most production models. The engine’s valvetrain is straightforward and less sensitive to timing variations, reducing the risk of mechanical problems under extended use.

Cooling and lubrication systems are also engineered for reliability, helping maintain optimal operating temperatures and preventing overheating during demanding conditions.

Owners regularly report that VK56DE-equipped vehicles perform well beyond 200,000 miles with minimal repairs, reinforcing the engine’s reputation for longevity.

Finally, the engine’s adaptability and predictable performance make it attractive for both everyday drivers and enthusiasts seeking reliable V8 power. Its relatively uncomplicated design, combined with solid engineering, ensures fewer quirks and surprises over time compared to some HEMI engines.

Whether used for towing, highway cruising, or light performance modifications, the VK56DE remains a dependable choice, delivering the balance of power, smoothness, and durability that long-term owners often prioritize.

7. Lexus/Toyota 3UR-FE 5.7L V8

The Lexus and Toyota 3UR-FE 5.7L V8 offers a compelling combination of smooth power delivery, durability, and refined engineering, making it a strong alternative to the HEMI.

Primarily found in vehicles such as the Toyota Tundra, Sequoia, and Lexus LX570, this engine was designed with heavy-duty applications in mind while maintaining a quiet and reliable performance profile.

Its construction includes an iron block and aluminum cylinder heads, which balance durability with weight efficiency, allowing the engine to endure rigorous towing and long-distance driving with minimal issues.

Unlike some HEMI engines that may require careful attention to oil consumption and valve adjustments, the 3UR-FE is engineered for predictable, long-term performance.

One of the engine’s key advantages is its naturally broad torque curve. This V8 provides ample low-end and mid-range torque, making acceleration and towing effortless without the need for constant high-rev operation.

This characteristic reduces mechanical stress over time, contributing to the engine’s long-term reliability.

Fuel injection and ignition systems are designed for simplicity and consistency, resulting in fewer quirks or sensitive components that often require specialized maintenance. As a result, owners report fewer surprises with the 3UR-FE compared to some HEMI engines, particularly in high-mileage applications.

The internal components of the 3UR-FE are designed to endure heavy use. Forged steel crankshafts, high-strength pistons, and durable camshafts contribute to a long-lasting engine foundation.

Additionally, Toyota’s robust cooling and lubrication systems ensure stable operating temperatures and optimal oil flow, which is essential for preventing wear during prolonged high-load operation.

These engineering choices make it possible for vehicles equipped with the 3UR-FE to exceed 250,000 miles with routine maintenance, demonstrating the engine’s resilience under a variety of demanding conditions.

Finally, the 3UR-FE is valued for its refinement and adaptability. It provides strong performance without aggressive quirks that can make ownership unpredictable.

Drivers who prioritize longevity and low-maintenance V8 power find this engine particularly appealing, as it combines dependable construction with a smooth and responsive driving experience.

Whether used in trucks for towing, SUVs for family travel, or lightly modified performance applications, the 3UR-FE represents a practical, long-lived alternative to the HEMI, offering reliability without sacrificing the V8 driving experience.

8. GM 4.8L/5.3L LS V8 Series

The GM small-block V8 engines, specifically the 4.8L and 5.3L LS series, have earned a reputation for reliability, simplicity, and versatility.

Built with an iron block and aluminum heads, these engines combine strength with manageable weight, allowing them to handle high mileage and moderate performance upgrades without significant issues.

Compared to certain HEMI engines that may encounter valve train or oiling quirks, the LS series is known for consistent operation, predictable maintenance, and a proven track record across a wide range of vehicles, including trucks, SUVs, and performance cars.

These engines are often praised for their ability to balance performance with long-term durability, making them attractive for both daily driving and enthusiasts seeking modifications without compromising reliability.

One of the primary benefits of the 4.8L and 5.3L LS engines is their mechanical simplicity. Featuring a pushrod design with a straightforward valvetrain, these engines have fewer moving parts than many dual overhead cam designs, reducing the likelihood of mechanical failure.

Fuel and ignition systems are robust, and the engines generally tolerate minor modifications or tuning without introducing long-term issues.

Owners frequently report that vehicles equipped with LS engines surpass 200,000 miles with standard maintenance, and high-mileage examples exceeding 300,000 miles are not uncommon.

This long-term dependability sets them apart from some HEMI engines, which occasionally require closer attention to valve guides, gaskets, or cooling issues.

Durability is reinforced by high-quality internal components, including forged or cast crankshafts, reliable pistons, and robust cylinder heads designed to manage heat and stress efficiently.

Cooling and oiling systems are also engineered to support both daily driving and moderate towing or performance applications.

The LS series can handle sustained operation at high loads without significant wear, contributing to its reputation as a long-lived power plant.

Additionally, the engines benefit from a vast aftermarket ecosystem, making repairs, upgrades, and maintenance both accessible and cost-effective, further enhancing reliability.

Finally, the LS V8 series offers remarkable versatility. Its compact architecture allows installation in various vehicles without extensive modification, and its smooth, responsive power delivery makes it suitable for trucks, SUVs, and performance cars alike.

For those seeking a long-lasting, reliable engine with a solid performance foundation, the 4.8L and 5.3L LS series provide a proven alternative to the HEMI.

Their combination of durability, straightforward design, and adaptability ensures that owners can enjoy V8 performance with fewer maintenance surprises and minimal quirks over the long term.

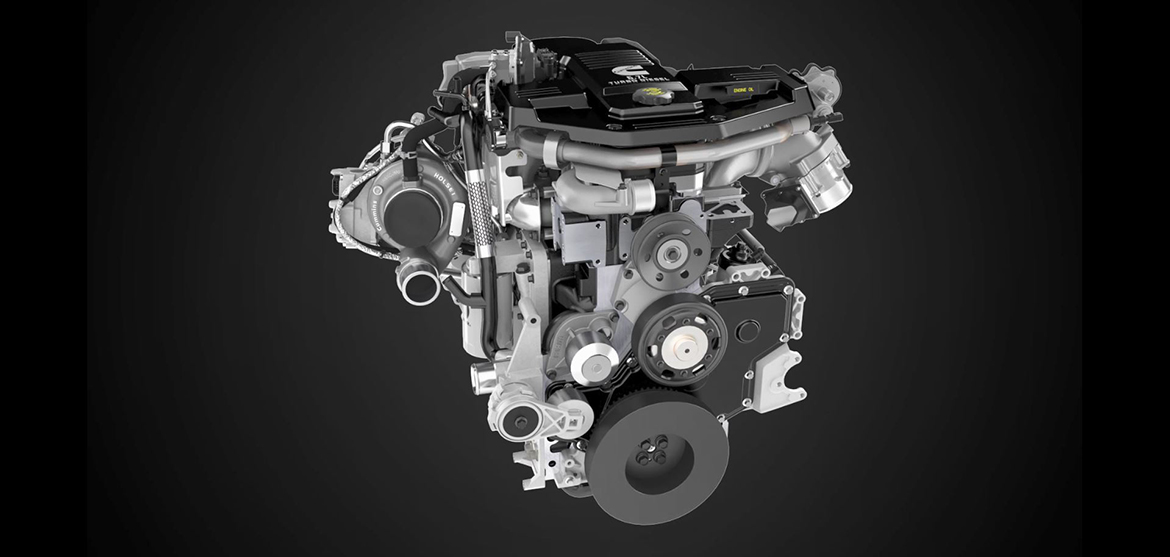

9. Cummins 6.7L Turbo Diesel I6

The Cummins 6.7L turbo diesel inline-six is widely regarded as one of the most durable and long-lasting engines available in heavy-duty trucks.

Unlike V8 gasoline engines, its inline-six layout, combined with the efficiency of turbocharging, allows for balanced operation, reduced vibration, and prolonged mechanical life.

Cummins engines are engineered for sustained high-torque output, heavy towing, and extreme operating conditions, and their reputation for longevity is unmatched in the diesel category.

Vehicles equipped with the 6.7L Cummins routinely achieve over 400,000 miles with regular maintenance, a level of endurance that few gasoline HEMI engines can match.

One of the defining characteristics of this engine is its mechanical robustness. Components such as forged steel crankshafts, high-strength pistons, and reinforced cylinder heads are engineered to withstand extreme stress and heat.

The turbocharging system is also designed for reliability, providing power without compromising the core durability of the engine.

Unlike some HEMI engines that may develop quirks related to valve operation, cylinder head design, or oil consumption under load, the 6.7L Cummins offers predictable performance with minimal intervention, even in demanding commercial or off-road applications.

The engine’s fuel and injection systems are engineered for efficiency and longevity. High-pressure common-rail injection delivers precise fuel metering, reducing wear on internal components while maximizing torque and fuel economy.

Cooling and lubrication systems are overbuilt to handle extended high-load conditions, ensuring stable operating temperatures and consistent oil flow.

These features collectively reduce the risk of overheating, wear, and premature failure, making the 6.7L Cummins a reliable choice for drivers who prioritize engine life and minimal quirks over raw gasoline performance.

Finally, the Cummins 6.7L I6 provides an ideal blend of torque, durability, and maintenance predictability. It excels in applications that demand extended operation under heavy loads, including towing, hauling, and commercial use.

While its characteristics differ from the traditional muscle-car appeal of a HEMI, the Cummins delivers a dependable driving experience, long-term reliability, and minimal maintenance surprises.

Its engineering emphasizes endurance and stability, offering owners a level of confidence and peace of mind that is difficult to achieve with many high-performance V8 gasoline engines.

10. Ford 6.2L V8 Boss

The Ford 6.2L V8, often referred to as the Boss engine, combines powerful performance with a reputation for long-term reliability and ruggedness.

Primarily used in Ford Super Duty trucks, F-150 Raptor models, and select performance vehicles, this engine is designed to handle both high-performance scenarios and heavy-duty applications without frequent maintenance concerns.

Its cast-iron block and forged internals provide structural integrity, allowing it to endure prolonged high-stress operation, including towing, hauling, and off-road use.

Unlike certain HEMI engines, which may develop quirks in valve trains or cylinder heads under heavy use, the 6.2L Boss maintains predictable performance and mechanical reliability with routine service.

The engine delivers a broad torque curve, providing effortless power for acceleration and towing. Its pushrod design and overhead valve configuration simplify maintenance and reduce the number of components that could potentially fail over time.

Fuel injection, ignition systems, and cooling circuits are engineered to operate efficiently and consistently, minimizing issues that are sometimes seen in high-strung gasoline V8 engines.

This reliability, combined with the engine’s power output, makes it a popular choice among truck owners and performance enthusiasts who want a dependable V8 without constant attention to quirks.

Durable internal components are a hallmark of the 6.2L Boss engine. Forged steel crankshafts, high-strength pistons, and robust valve train components ensure the engine can handle prolonged high-RPM use and heavy loads without accelerated wear.

Cooling and lubrication systems are designed to support sustained operation, even in extreme conditions, reducing the likelihood of overheating or mechanical failure.

Many owners report engines performing well beyond 200,000 miles with standard maintenance, highlighting the engine’s long-term resilience.

Finally, the 6.2L Boss V8 offers a versatile platform for a range of applications. Its power delivery, durability, and relatively simple design make it suitable for trucks, SUVs, and performance vehicles alike.

Unlike some HEMI engines, which may demand careful attention to prevent quirks from affecting long-term operation, the Boss V8 provides a reliable foundation for daily driving, towing, or moderate performance modification.

For drivers seeking an alternative to the HEMI with fewer complications and extended longevity, the Ford 6.2L V8 stands out as a strong and dependable option.