Turbos have become a cornerstone of modern internal combustion engines, offering a way to extract more power and efficiency from smaller displacement engines. The appeal is obvious: more horsepower and torque without significantly increasing fuel consumption.

However, while the technology itself has matured over the decades, not all engines handle turbocharging equally. Some are built with components, cooling systems, and oiling strategies that allow the turbocharger to survive hundreds of thousands of miles without incident.

Others, for various reasons, tend to fail prematurely, often taking a significant portion of the engine along with them. Understanding which engines are robust and which ones are more fragile can make a huge difference for buyers and enthusiasts alike.

A turbocharger isn’t just a bolt-on accessory; it is highly sensitive to oil quality, heat cycles, and driving habits.

Engines that are prone to turbo failures often have weaknesses in lubrication pathways, poor thermal management, or overly aggressive tuning that stresses the rotating assembly beyond what the manufacturer intended.

On the other hand, engines that consistently run high mileage on original turbos often have oversized oil galleries, redundant cooling, and precision engineering that tolerates occasional neglect or abuse.

While many enthusiasts assume turbo failures are inevitable, the reality is that some designs have proven to be remarkably durable, with owners reporting over 300,000 miles on the original turbo without major service.

Conversely, there are turbocharged engines that are notorious for catastrophic failures, where even careful maintenance cannot fully prevent issues. This contrast makes the subject fascinating for anyone interested in automotive engineering, longevity, or performance.

By examining specific examples of both extremes, it becomes clear that turbo longevity is less about luck and more about engineering, design philosophy, and a deep understanding of how forced induction interacts with an engine over time.

The following sections will highlight five engines celebrated for their long-lasting turbos and five engines known for unexpected or frequent turbo failures, illustrating the stark difference between design success and repeated challenges.

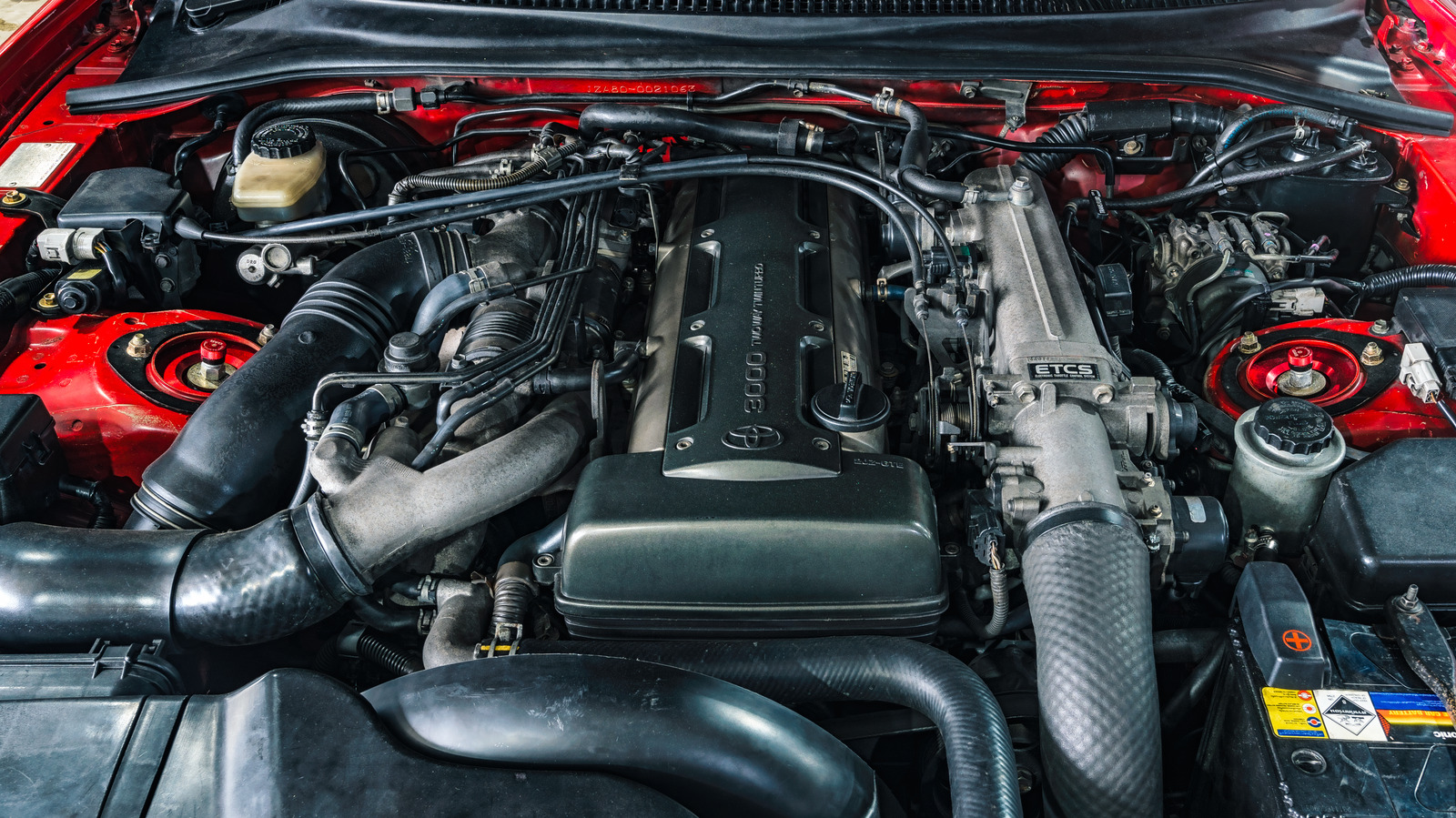

1. Toyota 2JZ-GTE

The 2JZ-GTE, found in the Toyota Supra MKIV, has earned a reputation that borders on mythical among car enthusiasts for its combination of raw performance and reliability.

While it is widely celebrated for its ability to handle extreme power levels when modified, its stock configuration is engineered to last, particularly the turbochargers.

These turbos are remarkably robust and can endure prolonged high RPM operation and elevated boost levels, provided the engine receives regular maintenance.

The combination of a cast iron block, forged internals, and a meticulously engineered head allows the engine to absorb stress without transferring undue strain to the turbo components.

This robust foundation makes the turbos far less likely to experience fatigue, cracking, or bearing failure compared to more lightly engineered designs.

Toyota’s engineers focused on ensuring that both cooling and lubrication systems were optimized for long-term durability.

The 2JZ-GTE features dedicated oil passages that supply a consistent flow of pressurized oil to the turbos, which is crucial in preventing bearing wear and coking, especially during repeated heat cycles.

Its water-cooled system maintains a stable operating temperature, ensuring that the turbine housing and bearings do not overheat.

The careful management of thermal stress, combined with a reliable lubrication network, enables the turbos to perform reliably over hundreds of thousands of miles. Many Supra owners have reported running their original turbos past 200,000 miles without major intervention, a testament to the engine’s thoughtful engineering.

Another factor in the 2JZ-GTE’s turbo longevity is its conservative factory tuning relative to the engine’s potential. Even though aftermarket enthusiasts can extract dramatically higher power, the OEM setup keeps boost and fuel delivery at moderate, sustainable levels.

This prevents constant overloading of the turbo shafts and bearings, reducing fatigue over time. The design also incorporates precise machining tolerances and high-quality materials in critical areas such as the turbine wheel, compressor housing, and seals, further contributing to durability.

Unlike some engines where turbos are stressed to the absolute limits of their design, the 2JZ-GTE maintains a margin of safety that significantly extends service life.

Finally, aftermarket support and part availability make maintaining a 2JZ-GTE relatively straightforward. While the original turbos are highly durable, owners have access to upgraded gaskets, oil lines, and performance kits that prevent potential stress points and extend component life even further.

This ecosystem allows enthusiasts to preserve the longevity of the original turbo while enhancing performance elsewhere, meaning that with consistent care, the 2JZ-GTE remains a benchmark for turbo longevity in gasoline engines.

Regular oil changes, careful driving habits, and attention to cooling make it almost effortless to keep these engines and their turbos in top form for decades.

2. Nissan RB26DETT

The RB26DETT, the powerhouse engine behind the Nissan Skyline GT-R, has an impressive record for both performance and durability, and its turbochargers are no exception.

This engine features a dual-turbo layout that is carefully designed to distribute stress evenly between the two units.

With a strong cast iron block, reinforced cylinder head, and forged internals, the RB26DETT is capable of handling significant thermal and mechanical loads without compromising the turbos. In stock form, these turbos are not pushed to their absolute limits, giving them ample margin to endure high mileage under regular driving conditions.

One of the most critical aspects of the RB26DETT’s reliability is its cooling system. The engine incorporates water-cooled turbos, which is essential for dissipating the enormous heat generated by twin exhaust-driven turbines.

Oil flow is similarly prioritized, with dedicated channels feeding the turbos to maintain lubrication and prevent bearing wear.

These systems allow the turbos to operate at consistent temperatures even under spirited driving, reducing the risk of premature failure.

Unlike some modern engines that use lightweight components to save weight, the RB26DETT relies on durable materials that tolerate repeated heat cycles and prolonged boost, significantly improving turbo lifespan.

Another key factor is maintenance awareness. Owners who follow proper oil change intervals, use high-quality lubricants, and keep cooling systems in good condition can easily exceed 150,000 miles on original turbos.

The engine’s robust design means it is forgiving of minor lapses, but the longevity of the turbos is directly correlated with care.

Compared to engines that are tuned aggressively from the factory or rely on marginal oiling pathways, the RB26DETT maintains a strong record of lasting performance while remaining relatively trouble-free.

Finally, the aftermarket ecosystem for the RB26DETT supports longevity even under high-mileage use. Owners have access to upgraded oil restrictors, stronger intercoolers, and more efficient cooling components that reduce stress on the stock turbos.

Preventive maintenance practices such as these, combined with the engine’s durable design, make it common to find RB26DETT engines running past 200,000 miles on the original turbos without major issues.

This consistency has cemented the RB26DETT as a benchmark for turbo reliability in high-performance applications.

3. Volvo B5254T

The Volvo B5254T engine demonstrates that turbo longevity is not confined to high-performance sports cars.

This inline-five engine offers a combination of reliability, durability, and reasonable performance, making it popular in everyday vehicles. The engine’s configuration allows for smooth power delivery while minimizing stress on the turbocharger.

Its cast iron block and solid crankshaft absorb the stresses of boost without transferring excessive loads to the turbo bearings, which helps the turbo maintain its integrity over extended mileage.

Cooling and lubrication are key to the B5254T’s longevity. Oil is efficiently routed to the turbo, preventing bearing failure or oil coking.

Water-cooled turbos maintain steady operating temperatures even during prolonged use, ensuring the turbine housing does not exceed safe limits.

The engine’s conservative factory tuning also reduces turbo stress, as the manufacturer opted for moderate boost levels rather than pushing the boundaries of performance.

Together, these design elements allow stock turbos to consistently reach and surpass 200,000 miles without significant problems.

Another advantage is the engine’s simplicity and accessibility. While European engines often require specialized service knowledge, the B5254T is relatively straightforward to maintain. Routine inspections of oil and cooling systems are simple, and any preventive maintenance can be performed without complex disassembly.

Owners who follow recommended intervals consistently find that the turbo can last decades, a testament to Volvo’s emphasis on reliability and practical engineering.

Finally, the B5254T’s components are robust and well-engineered. The turbo itself is made from durable materials, and the entire system is designed to manage heat efficiently. Many owners have documented original turbos running past 250,000 miles without failure.

This combination of smart design, durability, and maintainability makes the B5254T a rare example of a reliable European turbocharged engine that can endure high mileage under everyday driving conditions.

4. Mitsubishi 4G63T (early Evo models)

The 4G63T engine from early Mitsubishi Lancer Evolution models is a legendary inline-four turbo that demonstrates the balance between performance and longevity.

Its design emphasizes durability, with forged internals, a cast iron block, and a robust turbo system that is engineered to survive repeated thermal and mechanical stress.

The twin-scroll turbo design improves spool and efficiency, reducing heat retention in the exhaust and preventing premature bearing wear, making it particularly effective for high-mileage applications.

The engine’s conservative stock tuning allows the turbo to operate well within its capabilities. Even though the engine is capable of much higher power output, the OEM setup keeps boost and fuel delivery at levels that limit fatigue on the turbo components.

Oil flow is prioritized through dedicated galleries, while cooling systems maintain relatively stable temperatures during prolonged driving, reducing stress on the turbine and bearings.

These design choices make the 4G63T capable of enduring hundreds of thousands of miles on the original turbos, provided maintenance is followed.

Preventive care is vital for the 4G63T. Regular oil and coolant changes, attention to warm-up and cool-down periods, and occasional inspection of the turbo oil lines greatly extend life.

The engine layout allows for relatively easy maintenance, making it accessible for enthusiasts and mechanics alike. Combined with its robust design, these factors make it common to see original turbos exceed 200,000 miles without catastrophic failure.

Finally, aftermarket support enhances turbo longevity for the 4G63T. Owners can source upgraded gaskets, stronger oil lines, and improved intercooler setups that prevent stress-related failures.

While some drivers push the engine to high-performance levels, many examples remain reliable at stock boost levels for extended periods.

The combination of careful engineering, accessible maintenance, and conservative design philosophy ensures the 4G63T turbos are among the most durable in the performance car segment.

5. Ford 6.7L Power Stroke (2011–2019)

The Ford 6.7L Power Stroke diesel engine demonstrates that turbo longevity is achievable in heavy-duty applications, not just in sports cars. Designed for trucks, this engine emphasizes reliability, durability, and consistent performance under prolonged heavy loads.

The turbo itself is engineered to handle long hours of operation and high boost levels without suffering premature bearing or shaft failure. Its water-cooled design and durable materials ensure that thermal stress is effectively managed even under demanding conditions.

The 6.7L Power Stroke features a strong block, reinforced head, and heavy-duty internals that absorb the stress generated by forced induction. Oil supply to the turbo is carefully managed to prevent coking or bearing wear, even under prolonged high-load conditions.

Diesel engines naturally operate at lower RPMs for a given power output compared to gasoline engines, reducing the rotational stress on turbo components and further enhancing longevity.

Owners consistently report original turbos lasting well over 300,000 miles, often exceeding the life of other engine components.

Temperature management is another critical factor. The engine uses advanced intercooling and cooling systems that prevent exhaust gases from overheating the turbo housing.

These measures protect the bearings and seals, allowing consistent operation in a wide range of driving conditions. Routine maintenance of oil and filters ensures these systems continue to function optimally, preserving turbo life over the long term.

Finally, Ford’s engineering philosophy for the 6.7L Power Stroke prioritizes reliability over extreme performance. The turbo system is designed to survive sustained duty cycles without failure, and the engine’s conservative boost strategy ensures longevity.

Combined with proper maintenance and attention to oil quality, this engine is a prime example of how turbo longevity can be achieved even in heavy-duty, high-mileage applications. Many trucks have surpassed half a million miles on original turbos, demonstrating the effectiveness of careful design and engineering foresight.

Engines That Grenade Their Turbos

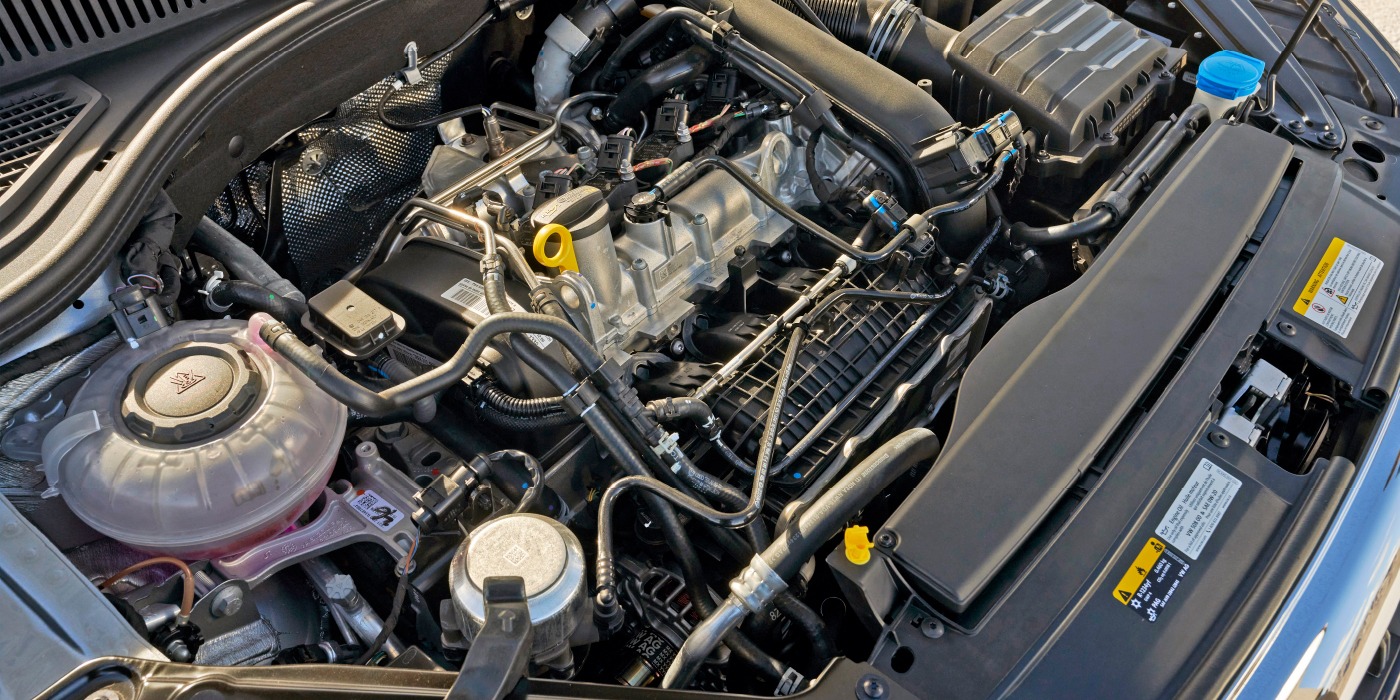

1. Volkswagen 1.8T (early AEB/AGU models)

The early Volkswagen 1.8T engines, particularly those with the AEB and AGU codes, are notorious for putting tremendous stress on their turbochargers.

These engines were designed to deliver impressive power relative to their displacement, but the stock turbos were often undersized and made from materials that struggled under prolonged heat cycles.

As a result, even moderate driving conditions can accelerate bearing wear, cause oil coking, and lead to compressor wheel damage.

Owners frequently report turbo failure anywhere between 80,000 and 120,000 miles, especially if oil change intervals were neglected or lower-quality oil was used.

The 1.8T engine’s design contributes directly to turbo fragility. Oil passages to the turbo are relatively narrow, and the turbos themselves are mounted in locations that experience extreme heat from the exhaust manifold.

Repeated short trips or stop-and-go driving prevent proper oil temperatures and flow, creating conditions where the turbo bearings degrade more quickly than expected.

Additionally, the early 1.8T engines lacked effective turbo cooling via water jackets, leaving the turbine housing to absorb significant heat, which accelerates the breakdown of seals and lubricant.

Another factor that contributes to turbo failure is the factory tuning. Volkswagen tuned these engines for relatively high boost levels for a small-displacement turbo, which inherently increases thermal and mechanical stress.

While this allowed the cars to deliver spirited performance out of the box, it also meant the turbo was frequently operating near its design limit.

Over time, the combination of high exhaust temperatures, bearing stress, and oil coking often leads to catastrophic failure, sometimes in the form of a seized turbo or a shredded compressor wheel.

Finally, aftermarket modifications exacerbate the issue. Many 1.8T owners install larger injectors, remapped ECUs, or upgraded intercoolers without upgrading the turbo or addressing lubrication and cooling concerns.

This practice often pushes the original turbo beyond safe limits, dramatically reducing its lifespan. Even with careful maintenance, the 1.8T’s early turbos are widely considered fragile, and replacement or upgrade is often inevitable once the engine surpasses 120,000 miles.

2. Subaru EJ25 Turbo (late 2000s WRX/STI)

The Subaru EJ25 turbo engines, particularly in WRX and STI models of the late 2000s, are infamous for destroying their turbos under normal driving conditions.

These engines were designed with a focus on peak performance and high RPM operation, but the stock turbos were undersized relative to the engine’s potential.

High exhaust gas temperatures, combined with aggressive factory boost curves, place significant thermal and mechanical stress on the turbine and bearings, leading to premature wear and failure.

Many owners have experienced turbo failure at 60,000 to 100,000 miles, even when following recommended maintenance.

Cooling and lubrication systems in the EJ25 turbo engines are a key weakness. While the engine is equipped with oil cooling passages, these are relatively tight and prone to clogging, especially if oil changes are missed or if low-quality oil is used. The turbos are also mounted close to the exhaust manifold, causing them to absorb excessive heat.

Over time, heat cycles warp the turbine housing, degrade seals, and result in excessive shaft play, which leads to a catastrophic failure. Water-cooling helps, but the system is often insufficient to fully compensate for repeated high-temperature operation under spirited driving.

Factory tuning exacerbates these weaknesses. Subaru engineered these engines for strong mid-range torque and high peak horsepower, which meant high boost pressures at relatively low engine speeds.

This forces the turbo to spool quickly and operate under high stress for extended periods, accelerating wear on the bearings and turbine wheel.

Unlike engines engineered for long-term turbo longevity, the EJ25 turbo sees extreme temperature swings and shaft loads during everyday use, which shorten its service life considerably.

Aftermarket modifications often accelerate the inevitable. Increasing boost or upgrading the fueling without addressing the turbo’s cooling and oiling limitations can quickly lead to failure. Additionally, heat-soaked intake systems and inadequate intercooling further increase the strain on the turbine.

While the EJ25 is celebrated for its performance potential, its stock turbo is known to be one of the least durable among modern production engines, and replacements or upgrades are common once the engine surpasses moderate mileage.

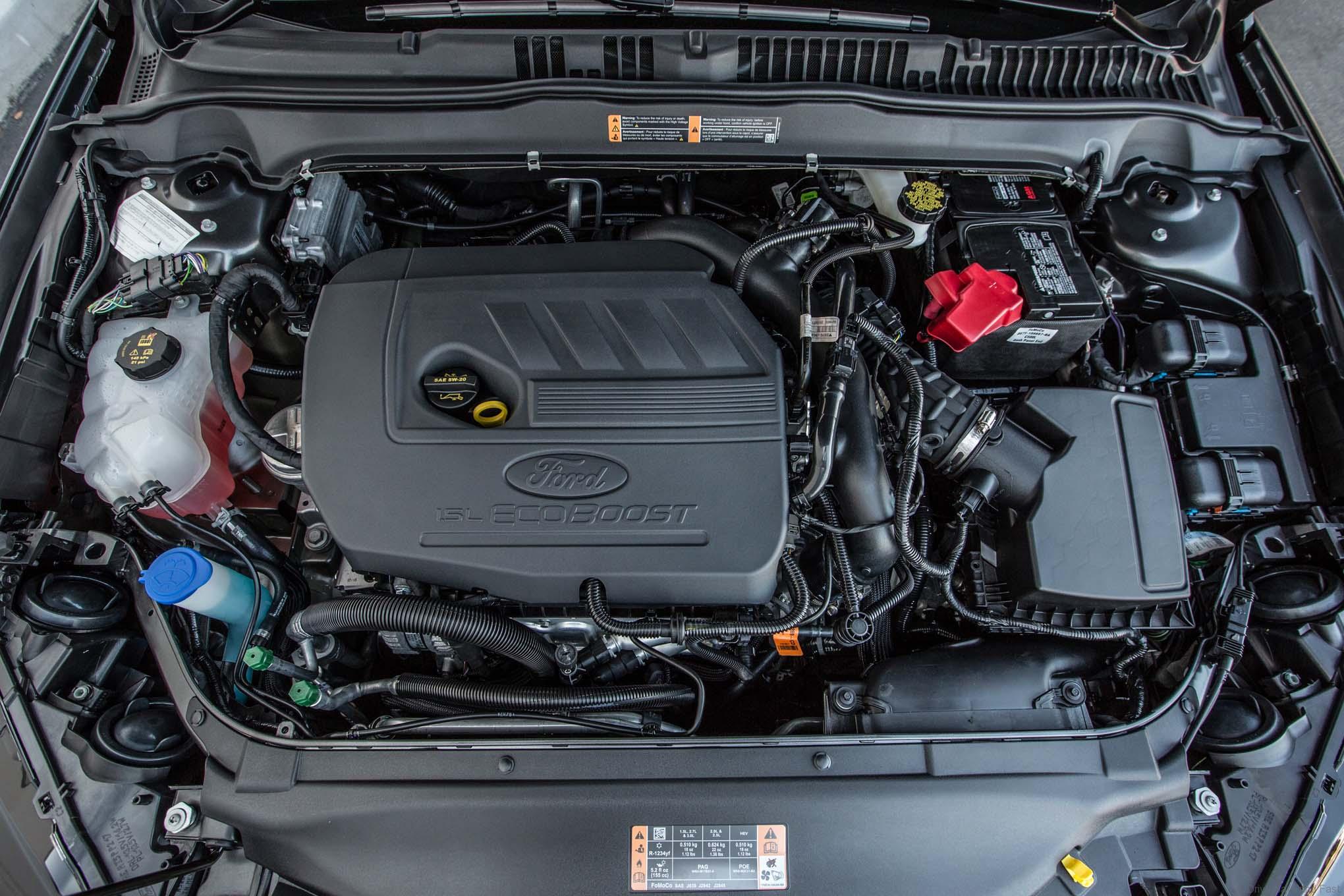

3. Ford EcoBoost 2.0L (early 2013–2016 models)

The 2.0L EcoBoost engine in early Ford models, including the Focus ST and Escape, is known for impressive performance but also for a tendency to destroy its turbos under prolonged use.

These engines were designed for compact cars and SUVs with a focus on power-to-weight ratio, but the stock turbos are small and operate at high boost pressures from low RPM.

The result is extremely high exhaust temperatures and significant bearing stress, making turbo failure common at mileage levels as low as 60,000 to 100,000 miles in some cases.

The 2.0L EcoBoost engine’s layout contributes to the issue. Its turbos are mounted in close proximity to the exhaust manifold, which exposes them to heat spikes. Oil supply is routed through tight channels, and any lapse in maintenance can cause coking or bearing wear.

Additionally, the twin-scroll design, while intended to improve spool, often leads to uneven thermal distribution, creating hotspots in the turbine housing.

These factors make the original turbo more likely to experience premature shaft or seal failure compared to engines designed with longevity in mind.

High factory boost levels are another stress factor. Ford engineers pushed the turbo to generate significant torque from very low RPM, but this approach increases mechanical strain on the turbine wheel and bearings.

The turbos operate under near-maximum stress even during routine driving, reducing their lifespan dramatically. While these engines can be reliable when meticulously maintained, any deviation from strict maintenance schedules often leads to accelerated turbo degradation, making replacement a frequent necessity.

Aftermarket tuning and modifications often worsen the problem. Many owners remap the ECU for higher performance or install larger intercoolers without upgrading the oiling system or turbo internals, pushing the small stock turbos beyond their limits.

Even stock use can be stressful on the original units, but once modifications are introduced, failure is almost inevitable. Early EcoBoost turbos have a reputation for short service life, and while newer revisions have improved reliability, the original designs are considered fragile under normal use.

4. BMW N54 (335i and 135i, 2007–2010)

The BMW N54 inline-six turbo engines are revered for their performance but are notorious for killing stock turbos prematurely. Equipped with twin turbos, these engines produce high boost levels that place enormous thermal and mechanical stress on the small OEM units.

Many owners report turbo failure between 70,000 and 120,000 miles, often accompanied by oil leaks or compressor shaft play. The turbos were designed more for performance than longevity, making them prone to early failure under everyday driving conditions.

Cooling and lubrication play a critical role in the N54’s turbo fragility. Oil is supplied through relatively narrow passages, and overheating or delayed oil changes can cause bearing failure quickly.

The turbos are positioned near the hot exhaust manifolds, and prolonged driving under high load creates heat cycles that warp the turbine housing or degrade seals. BMW attempted to mitigate this with water-cooled housings, but the system is often insufficient for repeated high-performance driving, leading to early failure.

The factory tuning of the N54 further accelerates turbo wear. Boost builds aggressively, and the engine produces high torque at low RPMs, which forces the turbos to spool quickly and endure stress almost constantly.

This design choice prioritizes performance over longevity and contributes to the reputation for turbo-related issues. Even conscientious maintenance cannot fully prevent premature failure, as the turbos are operating near their mechanical limits under normal conditions.

Aftermarket modifications often make the problem worse. Owners who remap the ECU or increase fueling and boost without upgrading the turbo’s oiling or cooling system risk catastrophic failure.

The N54’s stock turbos are fragile compared to other modern turbo engines designed for longevity, and replacement turbos are common for higher-mileage vehicles. While the engine itself can last much longer, the original turbos are widely regarded as a weak point.

5. Audi 2.0T FSI (early 2008–2012 models)

The early Audi 2.0T FSI engines, used in models like the A4 and A5, are known for efficient performance but also for turbo reliability issues. The stock turbochargers on these engines are relatively small and exposed to high thermal loads, making them prone to early failure.

Many owners experience turbo bearing wear, oil leaks, or shaft failure between 70,000 and 120,000 miles, particularly if oil changes are delayed or lower-quality oils are used.

The combination of high boost and tight packaging creates stress conditions that often shorten the life of the original turbo.

The engine’s cooling and lubrication setup contributes to these failures. Oil passages are tight and can become clogged with carbon deposits or sludge if maintenance is neglected. Water-cooling helps, but heat retention in the turbine housing remains high, creating stress on seals and bearings.

The proximity of the turbo to the exhaust manifold exposes it to repeated thermal spikes, further accelerating wear. Regular short trips and stop-and-go driving exacerbate the problem, as the turbos never reach optimal operating temperatures for proper lubrication.

Factory boost and tuning are another factor. Audi designed the engine to produce strong mid-range torque and peak horsepower, which forces the small turbo to operate under high loads almost constantly.

The resulting high turbine speeds and pressure levels stress the shaft and bearings, making failure more likely than in engines designed for longevity. Even with careful maintenance, early turbo replacement is common, highlighting a design tradeoff between performance and durability.

Aftermarket upgrades, while tempting for enthusiasts, often increase failure risk. Remapped ECUs, larger injectors, and modified exhausts push the turbos beyond their thermal and mechanical limits.

Without upgrading the oil supply, cooling, and internal components, these modifications accelerate turbo wear dramatically.

As a result, the early 2.0T FSI turbos are considered fragile, and many high-mileage examples require replacement or significant rebuilds to maintain performance and reliability.