Pickup trucks have always been more than tools for hauling and towing. They represent strength, reliability, and mechanical honesty, especially in markets where work and daily driving often blend together.

At the heart of many legendary pickups sits the V8 engine, a configuration that has shaped how trucks sound, feel, and perform for decades.

V8 engines brought smooth power delivery, strong low-end torque, and long service life, all of which mattered long before trucks became lifestyle vehicles. For farmers, contractors, and families alike, the engine under the hood determined whether a truck earned trust or frustration.

What makes a V8 engine great in a pickup truck is not raw horsepower alone. Durability, simplicity, cooling efficiency, and the ability to produce torque at low engine speeds matter far more than high rpm output.

Many of the engines remembered most fondly were not the most advanced for their time, yet they lasted hundreds of thousands of miles with basic maintenance.

Some were built with thick iron blocks and conservative tuning, while others introduced new technologies that later became industry standards. Each of these engines influenced how future trucks were designed and engineered.

Another reason V8 pickup engines stand out is emotional connection. Owners often form long-term bonds with trucks that start every morning, pull heavy loads without complaint, and survive years of abuse.

The sound of a V8 under load, the steady pull up a hill, and the confidence it inspires all contribute to its legacy. These engines became symbols of certain eras, representing American manufacturing priorities and mechanical philosophy at specific moments in history.

This article focuses on ten V8 engines that earned lasting respect in pickup trucks. Selection is based on reliability, impact, longevity, torque characteristics, and reputation among owners and mechanics.

Each engine section discusses design philosophy, real-world performance, maintenance traits, and historical importance. Together, these engines tell the story of how pickup trucks became powerful, dependable machines that continue to shape transportation culture today.

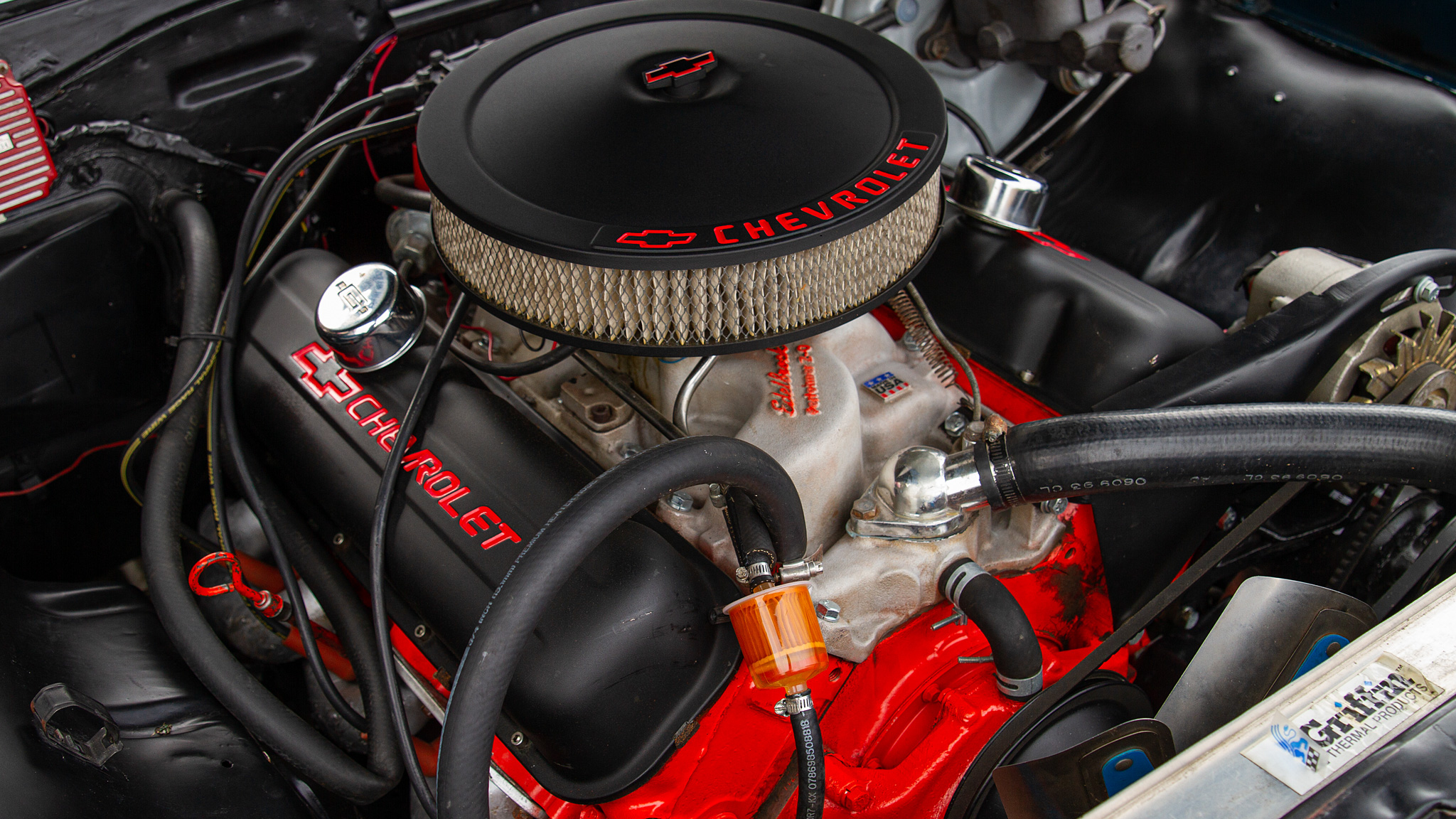

Chevrolet Small Block 350 V8

The Chevrolet 350 cubic inch small block V8 is one of the most influential engines ever placed in a pickup truck. Introduced in 1967 as part of Chevrolet’s small-block family, it quickly became the backbone of both Chevrolet and GMC trucks, shaping the identity of American pickups for decades.

The 350 was designed to combine compact size, mechanical simplicity, and excellent torque delivery, all while remaining relatively lightweight compared to big-block alternatives. Its balance of strength and manageability meant it could easily handle heavy loads while remaining responsive for everyday driving.

For decades, it served as the go-to engine for work trucks, family haulers, and even early performance pickups, showing an unmatched versatility.

The engine’s adaptability allowed it to fit into smaller engine bays without sacrificing power, which gave designers more freedom in creating trucks with practical layouts.

One of the 350’s most remarkable features was its modularity. Over the years, Chevrolet offered multiple carbureted and fuel-injected versions, along with different compression ratios and camshaft profiles, which allowed the engine to meet a wide range of power and efficiency requirements.

This adaptability made it simple for mechanics to swap parts, rebuild engines, or upgrade components without a complete redesign. Many of the improvements were backward-compatible, meaning an older 350 could be updated with newer technology without major modifications.

For truck owners, this ensured long-term maintainability and parts availability, reinforcing the 350’s reputation as a “forever engine.” The engine’s simplicity also meant that even less experienced mechanics could perform routine maintenance, rebuilds, and upgrades, making it highly accessible to a wide user base.

Durability played a major role in the 350’s legendary status. The engine’s cast-iron block and cylinder heads managed heat exceptionally well, allowing trucks to operate in extreme conditions, from desert heat to cold northern winters.

The robust crankshaft, connecting rods, and bearings handled high mileage and heavy towing without major issues.

Many 350-equipped trucks routinely surpassed 300,000 miles with basic oil changes and careful maintenance. Farmers, contractors, and recreational users alike relied on these engines because they could tolerate abuse and maintain consistent performance over years of use.

Beyond raw longevity, the engine offered a smooth and predictable power curve, which made trucks easy to drive even when fully loaded, a crucial feature before electronic engine management systems became standard.

The cultural impact of the 350 cannot be overstated. Its use in a variety of vehicles, including muscle cars, SUVs, and light trucks, meant that mechanics and enthusiasts across North America shared extensive knowledge of the engine’s characteristics.

Owners often formed a deep attachment to their 350-equipped pickups, not only for their performance but for the sense of reliability and trust they provided.

In pickup applications, the engine’s blend of simplicity, strength, and versatility set a benchmark for future V8s. It became a symbol of an era when trucks were designed to last, be easily repaired, and provide dependable work capability, solidifying its place as one of the most influential engines in automotive history.

Ford 302 Windsor V8

The Ford 302 Windsor V8, also referred to as the 5.0-liter V8, has long been celebrated for its reliability and adaptability in pickup trucks.

Originally introduced in the late 1960s as part of Ford’s small-block family, it was initially designed with performance in mind but quickly found a home in trucks due to its compact size and predictable torque output.

Its relatively lightweight design made it easier to handle compared to larger engines while providing adequate towing and hauling capabilities.

For many truck buyers, the 302 represented a balance between efficiency, performance, and long-term dependability. Its size allowed it to fit into a range of F-Series models without requiring major alterations to the frame or drivetrain, making it a versatile choice across the lineup.

A major advantage of the 302 was its torque delivery at low to mid-range rpm, which made trucks equipped with it ideal for work applications. While the engine did not produce massive horsepower figures, it excelled in providing usable pulling power under everyday conditions.

For contractors, small business owners, and recreational users, this meant trucks could tow trailers, haul equipment, and carry loads without struggling or overstressing the drivetrain.

Ford also offered a variety of carburetor and fuel-injected versions over time, along with improvements in ignition and cooling systems, allowing the engine to remain relevant for decades.

This adaptability ensured that the 302 could be modernized without losing its core reliability, keeping older trucks competitive with newer models.

Durability and longevity became hallmarks of the 302’s reputation. The engine featured a cast-iron block and heads designed to endure high mileage and long-term use under heavy loads.

Many F-Series trucks equipped with the 302 accumulated over 200,000 miles with minimal major repairs, making it a favorite among fleets and individual owners who valued longevity over raw speed.

Its straightforward mechanical layout made servicing accessible, allowing routine maintenance and minor repairs to be handled easily without specialized tools or advanced diagnostic systems.

The combination of reliability, ease of maintenance, and solid low-end torque made the 302 a dependable engine in virtually any pickup application.

The 302 Windsor also achieved cultural significance, particularly in the American truck market. It became synonymous with dependable Ford pickups, appearing across generations and building a strong legacy.

Its compact size and adaptability meant that it could continue to perform well even as trucks became larger and more complex over time.

Owners and mechanics developed extensive knowledge of its quirks, strengths, and weaknesses, ensuring that the engine’s reputation for reliability was reinforced through practical experience.

In truck applications, the 302 proved that a smaller V8 could offer performance, reliability, and maintainability in a balanced package that appealed to a wide spectrum of buyers.

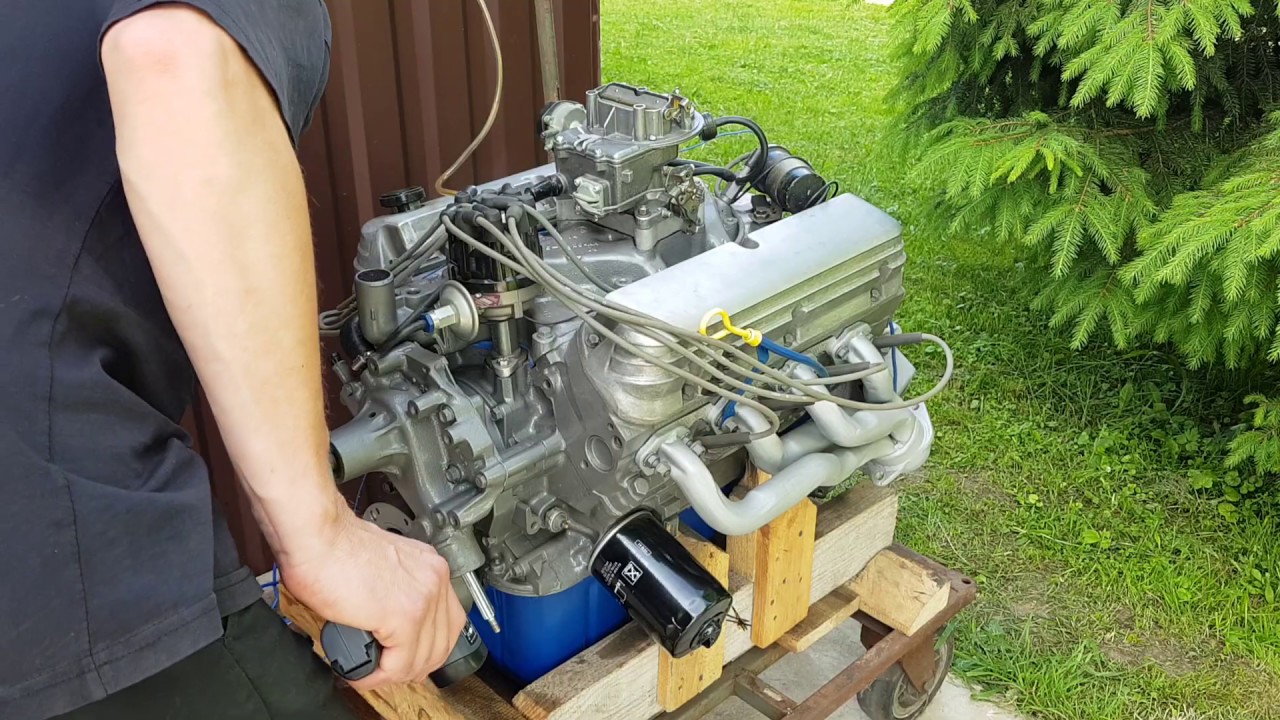

Dodge 318 LA V8

The Dodge 318 LA V8 was introduced in the late 1960s as part of Chrysler’s LA engine family and quickly gained a reputation as a workhorse in pickup trucks. Although it rarely made headlines for high performance, its conservative design made it exceptionally reliable and durable.

The 318 was engineered to prioritize long-term functionality over peak horsepower, an approach that suited truck buyers who needed steady and predictable performance.

Its torque curve was well-suited for low-speed hauling and towing, allowing drivers to move moderate loads without excessive engine strain. The LA V8 was also relatively lightweight compared to big blocks, which helped maintain good handling and payload capacity in medium-duty pickups.

Durability remained a defining characteristic of the Dodge 318. Its iron block and heads could endure years of heavy-duty use, while the internal components, including crankshaft, rods, and pistons, were designed to tolerate stress and heat over long periods.

Trucks equipped with 318 engines were known to accumulate hundreds of thousands of miles without major rebuilds when maintained with regular oil changes and attention to cooling systems.

The engine’s reliability under load reinforced the idea that low-stress design, rather than cutting-edge technology, was often more important for practical truck applications.

The 318 LA also carved a niche in pickup truck culture. Its reputation for “never quitting” made it a trusted choice for work and recreational trucks alike. While it lacked the excitement of high-output engines, its predictability and endurance fostered confidence among owners.

Mechanics and enthusiasts recognized the engine for its mechanical honesty, ease of maintenance, and ability to handle decades of use without significant issues. In pickup history, the 318 stands as a prime example of a conservative but highly reliable V8 that met the real-world needs of drivers and workers.

Ford 460 Big Block V8

The Ford 460 big block V8 is an example of raw strength engineered specifically for heavy-duty pickup trucks. Introduced in the late 1960s, the engine quickly became the powerplant of choice for three-quarter-ton and one-ton F-Series trucks.

With a displacement of 460 cubic inches, it was capable of generating enormous torque at low engine speeds, making it ideal for towing large trailers, hauling heavy equipment, and performing sustained work in demanding conditions.

Unlike smaller V8s, the 460 did not need to operate at high rpm to produce usable power, which reduced internal wear and increased longevity when trucks were heavily loaded. Its combination of power and torque allowed trucks to move massive payloads effortlessly, cementing its place in the history of work vehicles.

Durability was central to the 460’s design. The engine’s iron block, thick cylinder walls, and robust internal components allowed it to withstand years of demanding use. Cooling systems were engineered to manage heat effectively, a necessity for heavy-duty applications that involved towing or operating in hot climates.

Although fuel economy was never a strong point, users accepted this as a reasonable tradeoff for unmatched capability. Maintenance was relatively simple for such a large engine, and experienced mechanics could service it efficiently, making it a practical choice despite its size.

Culturally, the 460 represented an era when trucks were built primarily for work and reliability, rather than efficiency or compact design. Its presence in heavy-duty pickups became a symbol of brute force and endurance, inspiring confidence in drivers who relied on trucks for demanding tasks.

The engine’s role extended beyond mechanical performance; it shaped the perception of what a powerful, dependable pickup could achieve. Even decades later, the Ford 460 remains an icon among enthusiasts who value large-displacement engines for their unmatched torque and reliability.

Chevrolet 454 Big Block V8

The Chevrolet 454 big block V8 is one of the most legendary high-displacement engines ever installed in pickup trucks. Introduced in the early 1970s as part of Chevrolet’s big block family, it quickly gained fame for its extraordinary torque output and durability.

With a displacement of 454 cubic inches, the engine was capable of moving heavy loads and towing massive trailers with ease, making it a favorite among commercial operators, recreational users, and those who needed serious work capability.

Its large bore and stroke allowed the engine to generate impressive low-end torque, which made trucks feel effortless when hauling or climbing steep grades. Unlike smaller engines, the 454 could maintain performance under extreme conditions without overheating or losing reliability.

Torque delivery defined the 454’s reputation. The engine produced a steady and strong pull across the rpm range, which allowed fully loaded trucks to accelerate smoothly without putting excessive strain on the drivetrain. This characteristic made the engine especially suitable for towing boats, campers, or equipment trailers.

Owners valued the engine’s ability to perform consistently in real-world conditions, knowing that the truck could manage both short bursts of heavy load and prolonged towing tasks without issue. The engine’s combination of torque and durability allowed it to handle applications where smaller engines would struggle or overheat.

The durability of the 454 was reinforced by its heavy construction. Thick cast-iron blocks, robust crankshafts, and reinforced connecting rods enabled the engine to endure significant stress.

Cylinder heads were designed to optimize airflow for power and cooling, contributing to both performance and longevity.

While fuel consumption was high, users considered this an acceptable tradeoff for the engine’s extraordinary capability.

Many 454-equipped trucks became legendary for logging hundreds of thousands of miles without significant rebuilds, a testament to careful engineering and conservative tuning.

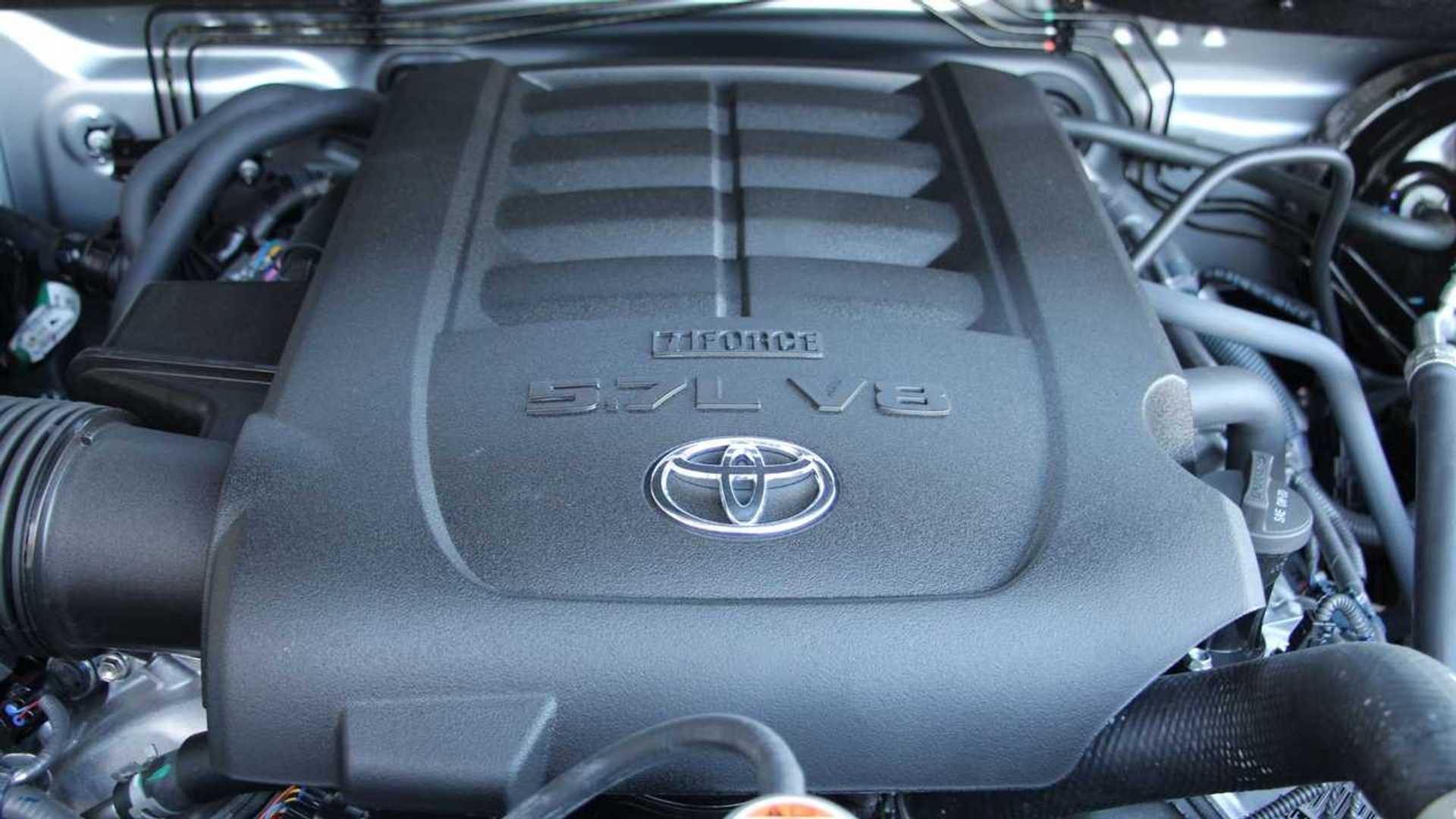

Toyota 5.7L i-Force V8

The Toyota 5.7L i-Force V8 marked a significant step for Toyota in the full-size pickup market, demonstrating that the company could produce engines that combined reliability with high output.

Introduced in the mid-2000s for the Tundra, this engine was Toyota’s response to the demands of North American truck buyers accustomed to powerful V8s from domestic manufacturers.

With 5.7 liters of displacement, the i-Force delivered strong torque across a wide rpm range, which made towing and hauling effortless.

Its dual overhead cam design, combined with modern fuel injection and variable valve timing, allowed it to produce smooth, linear power while remaining remarkably efficient for a V8 of its size.

The engine was engineered to handle the rigors of both commercial work and long-distance highway driving, reflecting Toyota’s philosophy of combining durability with refined engineering.

Durability was a key consideration in the engine’s design. Toyota used high-strength components and a robust bottom end to reduce wear and stress over long-term use.

Cooling and lubrication systems were engineered for optimal performance, ensuring the engine could handle repeated towing, payload hauling, and long highway trips without excessive wear.

The i-Force also incorporated modern technologies that improved fuel efficiency without sacrificing strength, allowing truck owners to enjoy both power and reasonable running costs. This combination of reliability and efficiency helped Toyota gain trust in a market historically dominated by American V8s.

Culturally, the 5.7L i-Force V8 reshaped perceptions of non-American pickups in the heavy-duty segment. Truck buyers who previously associated full-size trucks with domestic brands began to recognize Toyota as a viable alternative capable of competing in both performance and dependability.

The engine’s reputation for longevity and consistent power delivery contributed to the Tundra’s strong resale value and positive owner reviews.

In pickup history, the i-Force V8 represents a modern interpretation of the V8 philosophy: high torque, reliability, and durability, packaged with contemporary engineering that addresses efficiency and emissions without sacrificing performance.

GM LS 6.0L V8

The GM LS 6.0L V8 was a major evolution in General Motors’ V8 lineup, bridging the gap between traditional pushrod engines and modern performance-oriented designs.

Introduced in the early 2000s in trucks and SUVs, the 6.0L LS combined improved airflow, lightweight components, and modern engine management systems while retaining the fundamental pushrod architecture that made earlier small and big blocks durable.

Its design allowed it to produce impressive torque at relatively low rpm, making it ideal for full-size pickups that needed to tow and haul heavy loads consistently.

The engine’s aluminum heads and forged components reduced weight while improving performance, without compromising the toughness required for commercial or daily-use trucks.

Durability and maintenance accessibility were central to the LS 6.0L’s design philosophy. The pushrod layout minimized moving parts compared to overhead cam engines, reducing the likelihood of catastrophic failures.

Cylinder walls, crankshafts, and connecting rods were engineered to handle high torque and repeated stress, making the engine long-lasting even under demanding conditions.

Many LS-equipped trucks have logged hundreds of thousands of miles with minimal internal wear, highlighting the effectiveness of GM’s engineering. Regular maintenance such as oil changes and cooling system checks was sufficient to keep the engine in top condition, emphasizing its suitability for heavy-duty applications.

The 6.0L LS V8 also influenced pickup culture and engineering trends. Its modern construction, reliability, and adaptability contributed to the widespread popularity of the LS family among enthusiasts and mechanics.

The engine’s combination of power, durability, and modification potential made it an iconic choice for those who wanted both workhorse reliability and tunable performance.

In the context of automotive history, the LS 6.0L represents a milestone in balancing traditional American V8 design with modern engineering, proving that long-lasting power and drivability could coexist with contemporary technology.

Nissan Endurance 5.6L V8

The Nissan Endurance 5.6L V8 showcased the company’s ability to design a full-size truck engine that emphasized reliability and smooth power delivery. Introduced in the Titan in the early 2000s, the engine aimed to compete with American V8s by combining robust construction with modern fuel management technologies.

With 5.6 liters of displacement, the Endurance produced substantial low-end torque, making towing and hauling straightforward tasks for everyday users.

Its design prioritized predictable performance and low-stress operation over extreme horsepower figures, reflecting Nissan’s commitment to durability and long-term dependability. By combining a cast-iron block with aluminum heads, the engine balanced weight and strength, making it a durable choice for full-size pickups.

Durability considerations extended to the engine’s internal design. Components such as the crankshaft, rods, and pistons were engineered to withstand prolonged stress and high temperatures. Cooling systems were optimized for heavy-duty use, allowing trucks to operate efficiently even in challenging climates.

The engine’s straightforward architecture made maintenance accessible, and replacement parts were designed to be both durable and widely available. These factors contributed to the Endurance V8’s reputation as a reliable workhorse capable of lasting hundreds of thousands of miles with minimal issues.

In terms of cultural impact, the Endurance 5.6L V8 demonstrated that Japanese manufacturers could create V8 engines that met or exceeded the expectations of traditional American truck buyers.

While Nissan did not have decades of domestic truck legacy to draw upon, the Endurance V8 earned respect through its combination of durability, torque delivery, and reliability under load.

Its presence in the Titan helped establish Nissan as a credible contender in the full-size pickup market, showing that a well-engineered V8 could succeed outside the traditional American industry. The engine remains a noteworthy example of engineering that prioritized function and longevity over flashy performance numbers.

Dodge 360 Magnum V8

The Dodge 360 Magnum V8 represented Chrysler’s efforts to modernize its V8 lineup while retaining the durability and mechanical simplicity that truck owners valued. Introduced in the mid-1980s, the 360 Magnum featured improved cylinder heads, fuel injection, and emissions control compared to older LA engines.

Its design allowed it to produce higher torque and horsepower while maintaining the mechanical reliability that made earlier engines popular in Ram pickups.

With 360 cubic inches of displacement, the engine offered a strong low-end pull, making towing and hauling more manageable for both light- and medium-duty trucks. Its adaptability meant it could serve in both commercial and recreational contexts, highlighting its versatility.

Durability was enhanced through the use of robust internal components and a cast-iron block. The crankshaft, pistons, and connecting rods were designed to withstand high stress, and cooling systems were engineered to handle repeated towing and payload tasks.

Even under continuous heavy-duty use, the engine showed impressive longevity, often outlasting other drivetrain components in the trucks it powered. Regular maintenance kept the Magnum V8 performing well, and its straightforward mechanical layout made repairs and rebuilds more accessible than more complex modern engines.

The 360 Magnum also contributed to Chrysler’s reputation in the full-size truck segment. By combining improved performance with proven durability, the engine bridged the gap between older pushrod designs and modern powerplants.

Its presence in Ram pickups helped the company maintain competitiveness against Ford and Chevrolet while offering truck buyers an engine that could handle both work and everyday driving.

In pickup history, the 360 Magnum exemplifies Chrysler’s ability to evolve its engines to meet contemporary demands without abandoning the qualities that truck owners had come to trust.

International Harvester SV 392 V8

The International Harvester SV 392 V8 stands out for its industrial-strength design and focus on durability. Developed in the late 1950s and used primarily in heavy-duty pickups and commercial trucks, the engine emphasized longevity and reliability above all else.

With 392 cubic inches of displacement, the SV 392 delivered steady low-end torque that allowed trucks to perform demanding work tasks without overheating or experiencing premature wear.

Its industrial engineering approach prioritized conservative tuning, robust materials, and simplicity, making it an engine that could survive decades of harsh operation, including farm work, construction, and off-road hauling.

One of the defining features of the SV 392 was its torque delivery. The engine provided a constant and reliable pull at low rpm, which was essential for heavy-duty pickups that often needed to start with a full load or operate under demanding conditions.

Unlike engines designed for speed or high-revving performance, the SV 392 focused on providing predictable power that minimized stress on transmissions and drivetrains.

This philosophy ensured that trucks could remain operational in challenging environments, from muddy fields to steep inclines, reinforcing the engine’s reputation for resilience.

In pickup truck history, the SV 392 represents the pinnacle of industrial-strength V8 design. Its legacy lies not in speed or cutting-edge technology but in mechanical honesty, durability, and the ability to perform reliably under extreme conditions.

The engine exemplifies an era when trucks were engineered for endurance and practical utility, providing power that owners could depend on for years. Its influence is evident in later heavy-duty truck engines, which continue to prioritize torque, reliability, and resilience in the same spirit as the SV 392.