American truck culture has always been shaped by engines that were built with purpose rather than polish. Torque, not speed, defined their identity, and reliability mattered more than refinement. From long highway pulls to farm roads, job sites, and mountain passes, these engines became trusted partners rather than mechanical parts.

They earned reputations through years of work, surviving abuse, neglect, and extreme conditions while continuing to deliver power when it was needed most. Owners did not talk about horsepower numbers first, they talked about how an engine felt when pulling weight, climbing grades, or starting on a cold morning.

What makes an engine legendary in the American truck space is not just output, but consistency. Many of these engines stayed in production for years with minimal changes because they simply worked. Mechanics learned them inside and out, parts were easy to source, and knowledge passed from one generation to the next.

Farmers, contractors, and fleet operators valued engines that could run forever if maintained reasonably well. These powerplants created loyalty that modern marketing cannot manufacture.

Torque is the common thread connecting all of these engines. It is the force that moves loads from a standstill, keeps trailers steady on inclines, and reduces strain on transmissions and drivetrains. American truck engines historically favored displacement and durability over complexity.

Cast iron blocks, conservative tuning, and straightforward designs allowed them to produce usable power at low engine speeds. This approach made them forgiving and dependable, even when pushed beyond their intended limits.

This article highlights ten American truck engines that earned legendary status through real world use. These engines powered work trucks, heavy duty pickups, and commercial rigs that built industries and supported communities. Each one left a lasting mark through torque delivery, longevity, and reputation.

They were not perfect, but they were dependable, and that dependability is why they are still remembered with respect today.

1. Cummins 5.9L 12 Valve

The Cummins 5.9L 12 valve diesel became famous for its mechanical simplicity and immense low end torque. Introduced in Dodge trucks in the late 1980s, it transformed the way people viewed diesel pickups.

Unlike many engines of its time, it relied on proven mechanical fuel injection and an inline six layout that ensured smooth operation. Owners appreciated that it was predictable, durable, and easy to maintain even under heavy loads.

This engine relied on mechanical fuel injection, making it less susceptible to electronic failures that plagued later diesel designs. Mechanics valued its straightforward setup because diagnostic work required minimal tools.

Operators in farms, construction, and freight discovered it could start easily in harsh winters. Even when pushed to the limits, the 12 valve rarely failed unexpectedly, adding to its legendary reputation.

Torque delivery was the defining characteristic of the 12 valve. Its power came at low rpm, which reduced stress on transmissions and drivetrains during heavy towing.

Drivers noted that climbing hills or pulling trailers felt effortless compared to gasoline engines of similar size. The combination of controllable power and reliability made it a favorite for long-term ownership.

Longevity sealed its legendary status. With proper maintenance, many 5.9L 12 valves surpassed 500,000 miles and still functioned reliably.

Enthusiasts embraced it for diesel performance builds while fleet operators counted on it for daily work. Its blend of simplicity, torque, and durability left a mark on both the aftermarket and work truck communities, establishing it as a cornerstone of diesel truck history.

2. Ford 7.3L Power Stroke

The Ford 7.3L Power Stroke earned respect for its balance of power, durability, and usability in a growing diesel market. Introduced in the mid-1990s, it offered drivers a diesel that was capable, yet approachable for everyday tasks.

Its torque delivery was smooth and steady across a wide range, allowing trucks to tow heavy loads without sacrificing drivability. Fleet operators and owner-operators quickly recognized its reliability and practical engineering.

Built with a robust cast iron block and conservative internal components, the 7.3L was engineered to last. Many engines reached half a million miles without major failures, demonstrating the power of solid design over complex electronics.

3Unlike newer, more fragile diesels, it tolerated neglect better and could run on varied fuel qualities. This made it ideal for commercial and rural environments alike.

Torque production was smooth and predictable, giving drivers confidence when towing trailers or hauling equipment on uneven terrain.

Low-end torque reduced the need for high rpm operation, which prolonged engine life and reduced stress on transmissions. The engine’s behavior inspired trust and made it particularly appealing to operators who valued consistency over peak numbers.

The 7.3L also benefited from strong aftermarket support and service familiarity. Mechanics understood it deeply, parts were readily available, and maintenance knowledge spread across decades.

These factors allowed trucks to remain on the road longer than almost any comparable engine. Its combination of durability, torque, and simplicity secured the 7.3L Power Stroke a permanent place in American diesel lore.

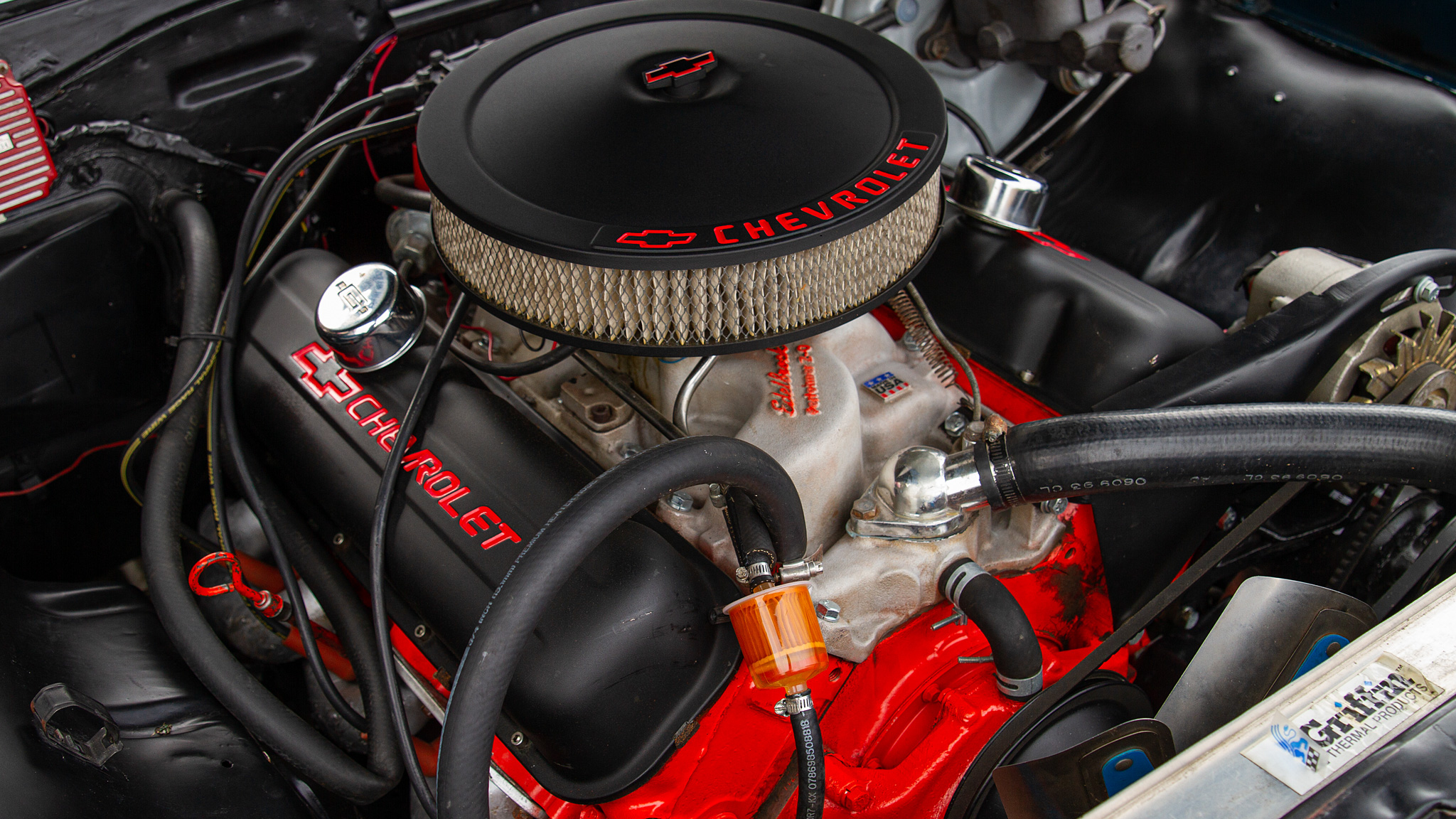

3. Chevrolet 454 Big Block

The Chevrolet 454 big block represented raw American muscle adapted for truck duty, and it quickly earned a reputation for brute force. Initially designed as a high-performance engine, it found an ideal role in heavy duty pickups and commercial trucks.

Its massive displacement allowed it to produce enormous torque at low rpm, moving heavy trailers or equipment with minimal effort. Drivers appreciated the immediate response and strength inherent to its design.

In trucks, the 454’s torque made short work of demanding tasks such as towing and climbing grades. It delivered raw pulling power at the turn of the key, which reduced the need for constant gear shifting under load.

Even fully loaded trucks responded reliably, giving drivers confidence in situations where a smaller engine might falter. Its power was both impressive and usable for long hauls.

The big block design favored durability and reliability. Thick cast iron blocks, heavy-duty internals, and conservative tuning allowed it to endure sustained work without major mechanical issues.

While fuel consumption was significant, operators accepted this tradeoff for unmatched torque and longevity. Maintenance was straightforward, allowing even basic mechanics to keep it running reliably for decades.

Its legacy lives on through decades of loyal use and admiration from truck enthusiasts. Many 454 powered trucks remain on the road today, often exceeding 300,000 miles with minimal rebuilds.

The engine symbolizes an era when large displacement solved work and towing challenges, and it continues to serve as a benchmark for gasoline powered truck torque and reliability.

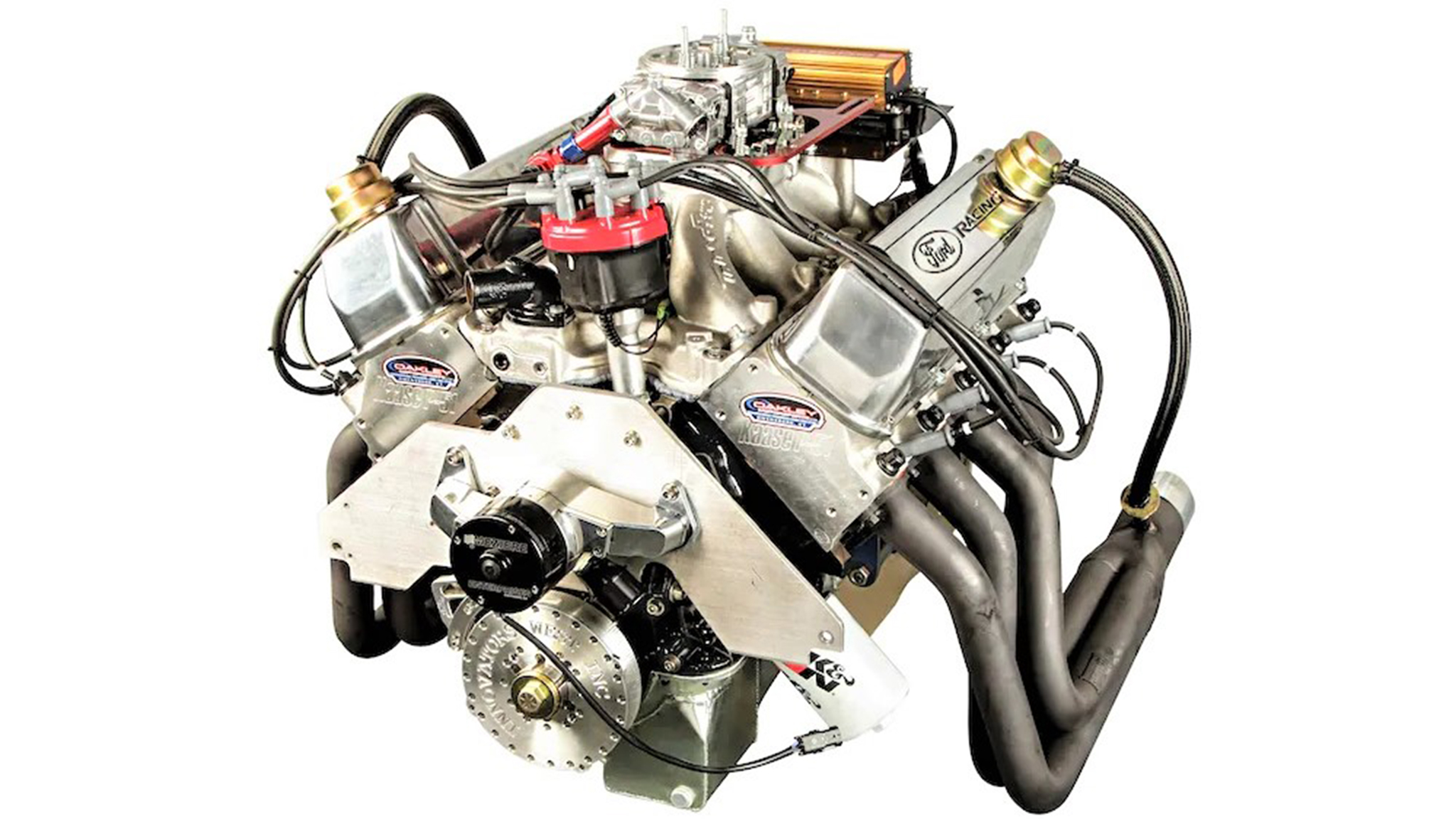

4. Ford 460 V8

The Ford 460 V8 was purpose-built for heavy duty applications, delivering significant torque for trucks, motorhomes, and commercial vehicles. Its massive displacement allowed it to move fully loaded vehicles with ease, making it a favorite among operators who required reliability over refinement.

Drivers valued the effortless pulling power that could handle steep grades, trailers, and equipment without stress on the drivetrain.

Engineered for longevity, the 460 used strong internal components and conservative tuning to ensure durability. It could withstand high miles under sustained loads without overheating or failing prematurely.

This ruggedness made it popular among fleet operators and long haul drivers. Many of these engines remained in service decades after their initial release, attesting to their resilience.

Torque delivery was steady and predictable, with the engine producing maximum pulling force at low rpm. This characteristic made it especially suitable for heavy loads and towing, as the engine provided power where it was needed most.

Drivers could count on the 460 to maintain speed on inclines without excessive gear shifting or overworking the motor.

Although fuel efficiency was not a priority, the engine earned respect through its consistent performance. It served faithfully in countless work vehicles, from pickups to commercial rigs. Its reputation for strength and reliability remains strong among truck enthusiasts, making the Ford 460 a symbol of classic American heavy duty engineering.

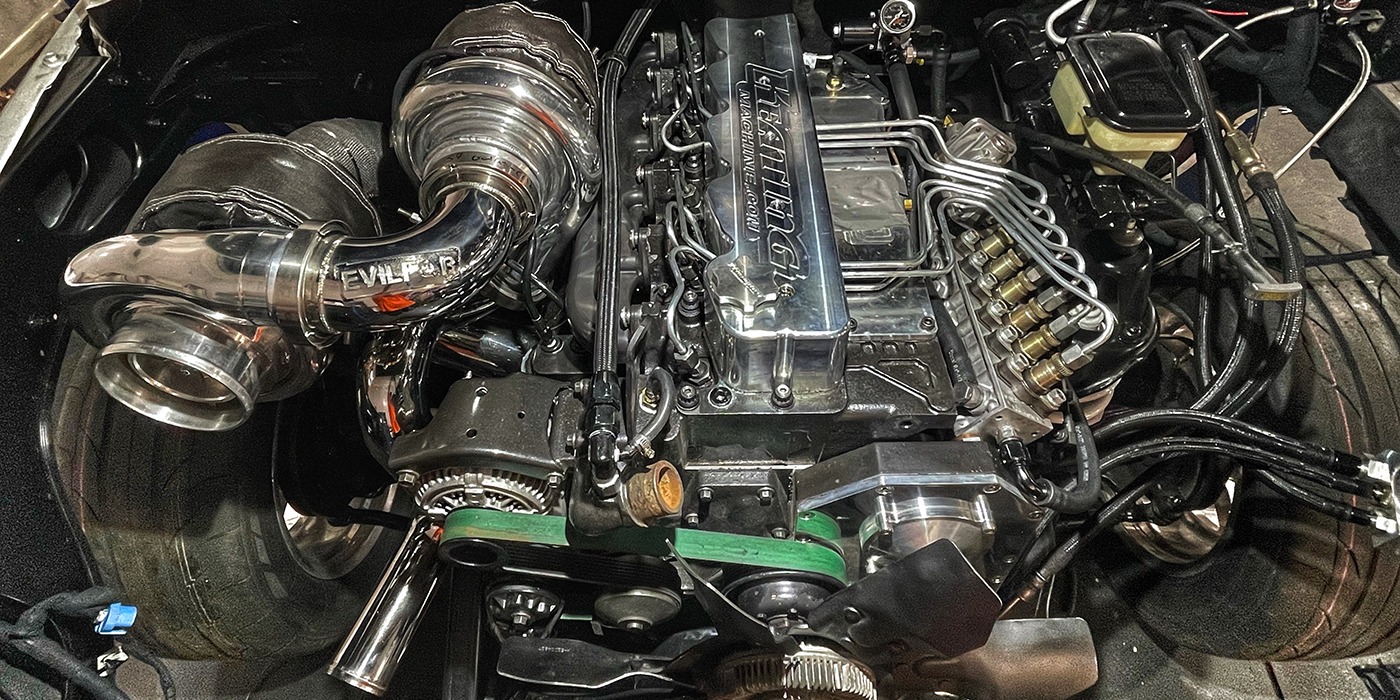

5. GM 6.6L Duramax LB7

The GM 6.6L Duramax LB7 revolutionized diesel pickup performance by combining modern engineering with robust torque output.

Released in the early 2000s, it represented GM’s first serious attempt to challenge Ford and Dodge in the diesel segment. It delivered significant pulling power and towing capability, while remaining manageable for everyday use, making it an ideal choice for both work and recreational trucks.

Torque production was smooth, consistent, and immediately noticeable at low rpm. Drivers quickly realized it could move heavy loads without demanding constant gear shifting or over-revving. This made the LB7 effective for towing trailers, hauling equipment, and handling steep inclines, giving operators confidence and control over their trucks.

The LB7 featured advanced fuel injection and electronic controls, which improved efficiency and responsiveness compared to older mechanical designs.

Although early units experienced injector issues, GM addressed these problems over time, allowing the engine to perform reliably. Properly maintained examples continue to deliver strong torque and durability years later.

The Duramax LB7 laid the foundation for GM’s future diesel dominance. Its blend of modern technology, high torque, and reliability earned it a permanent place in the hearts of truck owners. The engine demonstrated that American diesels could compete at a high level, offering power, control, and longevity in a single package.

6. Chrysler LA 360 V8

The Chrysler LA 360 V8 became a reliable workhorse in Dodge trucks during the 1970s and 1980s. It offered a balance of torque and simplicity, making it ideal for hauling, towing, and everyday truck duties.

Its compact design fit easily into engine bays while allowing room for repairs and upgrades. Drivers appreciated its straightforward engineering and predictable performance under load.

The engine emphasized durability and ease of maintenance. Early carbureted versions were simple to tune, while later fuel-injected models offered better fuel efficiency without sacrificing reliability.

Mechanics appreciated that parts were widely available and inexpensive. Operators could often keep the LA 360 running for decades with routine care and attention.

Torque output was well suited for trucks of its era, providing strong low-end power for moving heavy loads at moderate speeds. Drivers could handle large trailers and equipment without constantly overworking the motor.

Its torque curve made it forgiving during towing, reducing strain on transmissions and drivetrains. This reliability made it a favorite for commercial fleets and small businesses alike.

The LA 360 developed a loyal following among truck enthusiasts and practical owners. Many engines remain in service today, powering vintage trucks and classic Dodge pickups. Its reputation for dependability came from real-world performance rather than marketing claims. The engine earned respect for delivering consistent, usable torque over decades of hard work.

7. International Harvester 7.3 IDI

The International Harvester 7.3 IDI diesel established a reputation for toughness and reliability before the rise of modern Power Stroke engines. Introduced in the late 1980s, it featured an indirect injection design that simplified fuel delivery and reduced maintenance issues.

While not as powerful as newer diesels, its torque delivery was steady, predictable, and highly useful for work trucks. Farmers, contractors, and fleet operators valued its simplicity and resilience.

Torque was the engine’s defining characteristic, coming in at low rpm and allowing trucks to handle heavy loads efficiently. It was particularly effective for towing and hauling on rugged terrain. Drivers noticed how the engine delivered strength consistently without requiring high speeds. Its torque curve made even fully loaded trucks feel manageable.

The IDI design offered practical benefits beyond performance. Cold starts were easier than other diesels of the era, and the engine tolerated lower-quality fuels better than many competitors.

Repairs were straightforward, and the lack of complex electronics made it highly serviceable in remote areas. Owners could maintain the engine with basic tools and knowledge, which contributed to its legendary status.

Longevity defined the 7.3 IDI’s legacy. Many trucks powered by this engine achieved high mileage with minimal issues. It played a crucial role in the evolution of diesel pickups, bridging the gap between mechanical simplicity and modern performance. Its contribution to American diesel history remains significant, and it continues to inspire loyalty among collectors and enthusiasts.

8. Chevrolet Small Block 350

The Chevrolet Small Block 350 became one of the most iconic and versatile engines in American automotive history. In trucks, it offered a combination of reliable torque, easy maintenance, and widespread availability that made it a practical choice for work and personal use. Its compact design allowed it to fit in a variety of platforms, from pickups to SUVs, without sacrificing performance.

Torque output was modest compared to larger engines, but it was consistent and highly usable for light to medium duty hauling. Drivers appreciated how the 350 could move loads efficiently without requiring aggressive driving. Its power delivery suited everyday work trucks, giving operators confidence when carrying cargo or towing smaller trailers.

Durability came from a simple, proven design that could tolerate long hours and heavy use. Cast iron blocks, robust internal components, and straightforward engineering allowed the engine to withstand neglect better than many competitors.

Maintenance was accessible, and replacement parts were inexpensive and easy to source, making the engine highly practical for long-term ownership.

The 350’s impact extended beyond raw performance. It became a foundational engine for the American aftermarket and truck communities, supporting countless rebuilds, swaps, and upgrades.

In trucks, it earned a reputation for dependability and adaptability, proving that a small block could perform big work. Its legendary status stems from decades of real-world service and widespread familiarity.

9. Ford 300 Inline Six

The Ford 300 Inline Six is renowned for its torque and reliability, particularly in long bed trucks and commercial work vehicles. Its long stroke design focused on low rpm power, which suited towing, hauling, and heavy load applications.

Many operators preferred it over larger V8s because it offered predictable performance with minimal maintenance. Its straightforward design made it an ideal engine for drivers who valued dependability over complexity.

The inline six configuration ensured smooth operation and excellent balance under load. Torque was accessible at low speeds, which helped trucks maintain control when moving heavy cargo or navigating steep inclines.

Drivers could rely on the engine for long hauls without worrying about excessive stress on mechanical components, making it a favorite for commercial fleets.

Maintenance and repairs were simple, thanks to a durable cast iron block and easily serviceable components. The engine tolerated high mileage and hard use, with many examples lasting well beyond 300,000 miles. Its longevity made it a staple among operators in agriculture, construction, and delivery industries.

The 300 Inline Six remains a celebrated engine among truck enthusiasts and collectors. Its reputation for reliability was earned in real-world applications, where it consistently delivered the torque necessary for demanding work. The engine represents a practical, no-nonsense approach to truck power that few modern engines replicate.

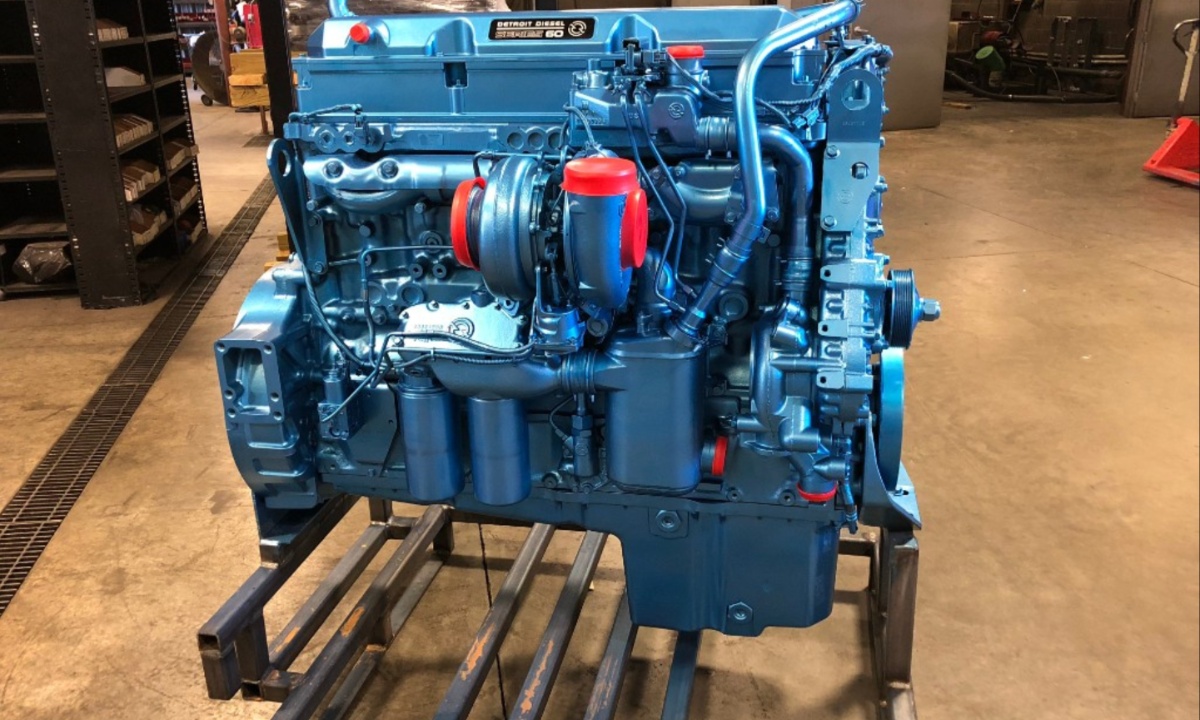

10. Detroit Diesel 6.71

The Detroit Diesel 6.71 was a workhorse in commercial trucks, construction equipment, and heavy-duty pickups. Its two-stroke design allowed immense torque output, which made it ideal for industrial and hauling applications.

Though loud and smoky by modern standards, its performance was unmatched for moving heavy loads reliably. The engine’s distinctive sound became a recognizable hallmark of American diesel power.

Torque delivery was immediate and relentless, giving operators confidence when handling fully loaded rigs. The engine excelled at maintaining speed under heavy stress, which made it a favorite in trucking, logging, and construction industries.

Drivers valued its ability to keep working even under extreme conditions, often outperforming larger engines in real-world applications.

Its two-stroke design simplified certain mechanical systems while delivering consistent performance. While fuel consumption was high and emissions were heavy, the engine prioritized durability over efficiency. Parts were durable and repairs were manageable for experienced mechanics, allowing many 6.71 engines to operate for decades without major overhauls.

The Detroit Diesel 6.71 became an enduring symbol of industrial strength and reliability. Its influence extended beyond trucks, powering equipment that built infrastructure and supported commerce. Its legacy is defined by unmatched torque, legendary durability, and a relentless work ethic that few engines can match today.