The 1990s were a golden era for automotive engineering, especially when it came to engines that could survive decades of use. In a period when technology was rapidly evolving, manufacturers still relied on proven engineering practices, particularly cast iron blocks, to ensure reliability.

Cast iron, though heavier than aluminum, offered exceptional strength and thermal stability, which made these engines almost immortal when properly maintained.

Unlike modern engines that often sacrifice longevity for efficiency or lightweight construction, these 90s powerplants were built to endure abuse, high mileage, and even modifications beyond factory specifications. Enthusiasts today still seek out these engines for swaps, restorations, and high-performance projects because they represent a time when durability was prioritized alongside performance.

From diesel workhorses to sporty gasoline engines, the 90s cast iron blocks earned a reputation for being unkillable, capable of running well past 300,000 miles with minimal issues. These engines also tend to respond well to tuning and aftermarket upgrades because of their solid construction, thick cylinder walls, and robust internal components.

The combination of simplicity and strength meant fewer things could go wrong, and when they did, repairs were straightforward. Even in racing circles, many of these engines are still in use because they can handle high stress and heavy loads without catastrophic failure.

The engines of this era were not just about longevity; they delivered respectable power, torque, and reliability in daily driving, towing, or performance scenarios. They were also designed to withstand poor fuel quality, infrequent oil changes, and hard driving, which made them ideal for enthusiasts and everyday drivers alike.

Each engine on this list has its own story, from legendary V8s in trucks to inline-six gems in sports sedans, but they all share one thing in common: a cast-iron block that could survive almost anything. Understanding why these engines are so durable involves examining materials, design choices, and engineering philosophy that emphasized longevity over marginal efficiency gains.

The following sections highlight ten of the most unkillable engines from the 90s, explaining what made them special and why they remain highly respected in automotive circles.

1. Toyota 1UZ-FE V8

The Toyota 1UZ-FE V8 is a marvel of Japanese engineering, known for its smoothness and durability. This 4.0-liter V8 featured a cast iron block with aluminum heads, giving it an ideal balance of strength and weight reduction.

Its design allowed for high mileage without major issues, even in vehicles driven aggressively or with heavy loads. With a solid crankshaft, forged connecting rods, and reliable valvetrain components, it became a favorite for swaps into performance cars.

Owners of the 1UZ-FE often report that these engines can exceed 400,000 miles with proper maintenance. Regular oil changes and timing belt replacements are the primary concerns, but catastrophic failures are rare.

The engine also has a robust cooling system that prevents overheating under stress. Performance enthusiasts value its high-revving capability and responsiveness, which makes it adaptable for forced induction setups.

This V8 is known for tolerating modifications without losing reliability. Turbocharging or supercharging the 1UZ-FE can yield significant power gains, thanks to its sturdy internals. Cylinder wall thickness and main bearing design allow higher boost pressures than many contemporary engines.

The aftermarket support is strong, making rebuilds and upgrades accessible. This flexibility has cemented its status among tuners and mechanics who value longevity.

In terms of real-world use, the 1UZ-FE powered luxury sedans, coupes, and even SUVs. Its quiet operation and smooth power delivery made it ideal for long drives and towing scenarios. Despite being 30+ years old, many of these engines remain in daily use worldwide. They are praised for their resilience under extreme temperatures and diverse driving conditions.

Collectors and enthusiasts often look for the 1UZ-FE as a benchmark of reliability. Its combination of a cast iron block and proven Japanese engineering creates an engine that rarely lets owners down. In the 90s, it represented a blend of performance, luxury, and indestructibility that few other engines could match.

2. Chevrolet 5.7L Vortec V8

The Chevrolet 5.7L Vortec V8 dominated American trucks in the 1990s due to its unmatched durability. The 350 cubic inch V8 featured a cast iron block with generous main bearing caps and a forged steel crankshaft. This engine could handle high torque applications and heavy loads, making it ideal for trucks, SUVs, and vans. Its simplicity also meant fewer things could break during regular use.

These engines are famous for lasting well beyond 300,000 miles. Routine oil changes and occasional gasket replacements are usually all that’s required.

Even high-mileage units often retain compression and reliability, making them a favorite among fleet operators. Overheating is rare due to the robust cooling system and thick cylinder walls. Long-term ownership reports show minimal failures of the core components.

Performance upgrades are well supported thanks to the engine’s strong bottom end. Mild camshaft swaps, intake improvements, or even forced induction are possible without major reinforcement. Its simplicity also allows easy maintenance, which is why mechanics appreciate the 5.7L Vortec. Replacement parts are abundant, and rebuilding these engines is often more cost-effective than replacing them.

The Vortec V8 powered a range of vehicles from pickups to vans, showing versatility in real-world applications. Owners report that the engines remain smooth even after decades of use, providing consistent power delivery. Many are still in service for towing, off-road, and commercial applications due to their reputation for toughness.

Enthusiasts value the engine for its ability to combine longevity and upgrade potential. Its cast iron block ensures structural integrity, and the straightforward design allows owners to modify without fear of catastrophic failure. The 5.7L Vortec remains a benchmark for reliable American V8s from the 1990s.

3. Ford 7.3L Power Stroke Diesel

The Ford 7.3L Power Stroke Diesel is legendary for durability and torque. Introduced in the late 90s, this cast iron block diesel engine was designed for heavy-duty trucks and long-haul applications. Its robust construction, including a forged steel crankshaft and high-strength cylinder liners, allowed it to withstand extreme loads. This engine became a favorite for both commercial and recreational use.

These engines are known to surpass 500,000 miles with proper maintenance. Cooling system integrity and fuel quality are key, but catastrophic failures are uncommon. The turbocharged versions of the 7.3L handled additional stress with ease, demonstrating the versatility of its engineering. Oil and filter changes, combined with fuel system upkeep, ensure decades of service.

Mechanics often praise the 7.3L for its simple yet effective design. Unlike modern diesels with excessive electronics, this engine uses mechanical and minimal electronic components. This simplicity enhances reliability and makes troubleshooting straightforward. The cast iron block and reinforced main caps absorb high torque without distortion, which is why it survives heavy towing.

Performance upgrades such as bigger turbos or improved intercooling are achievable without compromising engine life. The engine’s design allows for high boost levels and extended periods of heavy-duty operation. Diesel enthusiasts value the 7.3L for its ability to tolerate abuse while maintaining power delivery.

Long-term owners consistently report dependable operation even under harsh conditions. Vehicles with this engine remain in service for decades, often used for towing, off-road, and commercial hauling. Its reputation as an “unkillable” diesel engine is well-earned, and it continues to influence diesel engine design today.

4. Nissan RB26DETT Inline-Six

The Nissan RB26DETT Inline-Six is an icon of Japanese performance engineering. Found in the legendary Nissan Skyline GT-R, this 2.6-liter twin-turbo inline-six combined precision engineering with bulletproof reliability.

Its cast iron block provided a strong foundation for sustained high RPM operation, while the aluminum head allowed excellent heat dissipation. Engine balance and forged internals ensured that power delivery remained smooth, even under extreme stress from track use.

Despite being a high-revving engine, the RB26DETT rarely suffered catastrophic failure in stock form. Enthusiasts routinely report examples running past 300,000 miles without major rebuilds. Timing chain and clutch maintenance are essential, but the design is resilient.

The twin-turbo setup is integrated with a strong water-cooling system that prevents overheating even under spirited driving conditions. Its reputation for endurance comes not only from raw materials but also from meticulous engineering and quality control.

Performance tuning is a hallmark of this engine. With aftermarket support, power can be increased dramatically without sacrificing reliability. Forged pistons, upgraded turbos, and reinforced rods are often used to push output well beyond factory levels.

The engine’s cast iron block and robust crankshaft allow such modifications with minimal risk of structural failure. Tuners appreciate how it responds predictably to modifications, which is rare for a high-performance engine.

In real-world applications, the RB26DETT proved capable of handling track days, long highway runs, and spirited street driving. Its inline-six configuration provides smooth torque delivery and excellent throttle response.

Many engines are still in service today, powering everything from restored Skylines to custom builds in other chassis. The combination of durability, performance, and tunability ensures it remains a favorite among collectors and enthusiasts alike.

Collectors and mechanics often cite the RB26DETT as an example of an engine that achieved peak performance without sacrificing reliability. Its cast iron block design resists warping and cracking under high pressure, and routine maintenance ensures it can remain in top condition for decades.

This engine embodies a rare balance of longevity and high-performance potential that few other engines from the 90s could match.

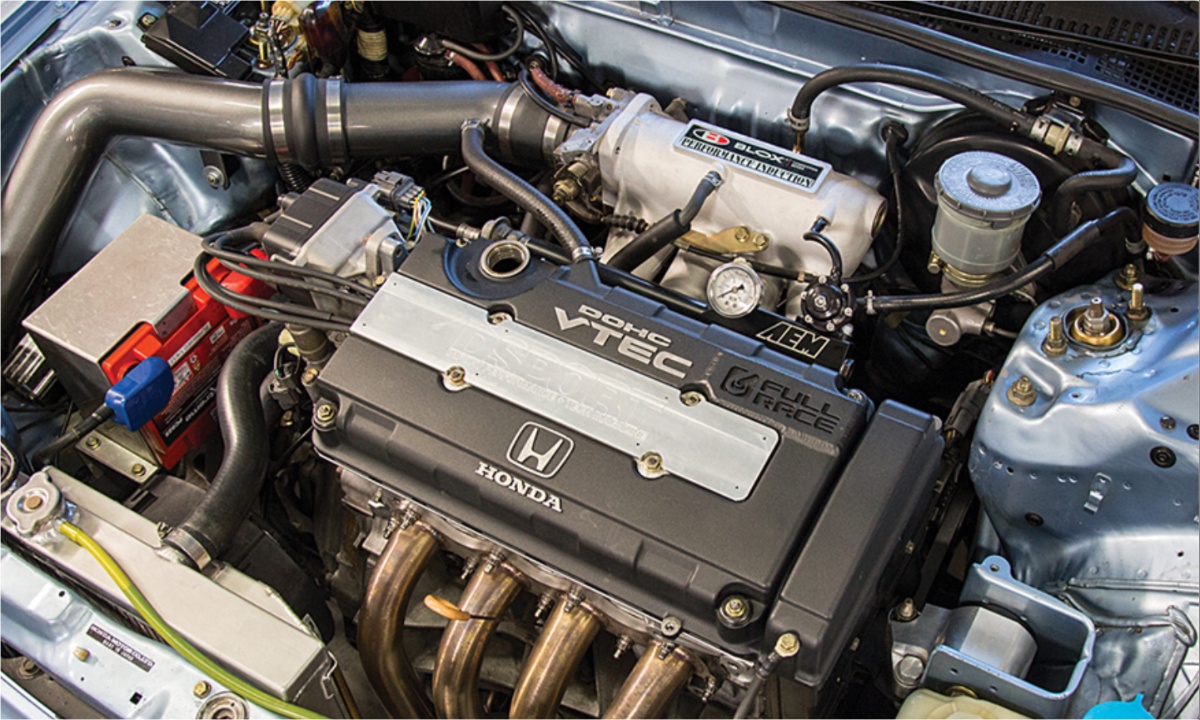

5. Honda B-Series B18C Inline-Four

The Honda B-Series B18C Inline-Four was a benchmark for lightweight performance and reliability. Known for its high-revving nature, the 1.8-liter DOHC engine powered vehicles such as the Honda Integra Type R.

Its cast iron cylinder sleeves inside an aluminum block ensured both strength and reduced weight. Enthusiasts valued it for its ability to rev beyond 8,000 RPM while remaining remarkably durable.

Even with high mileage, the B18C remains reliable with basic maintenance. Regular oil changes and valve adjustments are critical, but catastrophic failures are rare.

Honda’s precision engineering resulted in tight tolerances and high-quality materials that minimize wear over decades. Owners frequently report engines exceeding 250,000 miles without major internal rebuilds, demonstrating the longevity of this design.

This engine responded exceptionally well to modifications. Naturally aspirated or turbocharged, the B18C could produce significant power with minimal internal changes. Its robust bottom end, forged crankshaft, and high-flow head design made it ideal for tuning. Many enthusiasts have used it for engine swaps into lightweight chassis, exploiting both its reliability and high-revving nature.

Daily driving was never a problem for the B18C. Its smooth power delivery, efficient fuel consumption, and consistent reliability made it practical as well as sporty. The balance between performance and durability contributed to its reputation as one of the most unkillable inline-fours from the 90s. Maintenance accessibility also helped, with parts readily available and repair procedures straightforward.

The B18C remains a symbol of Honda’s engineering philosophy in the 1990s. It proved that a small displacement engine could combine reliability with performance, offering a long lifespan and excellent aftermarket support. Enthusiasts continue to seek these engines for restorations, swaps, and motorsport projects, cementing their status as classics.

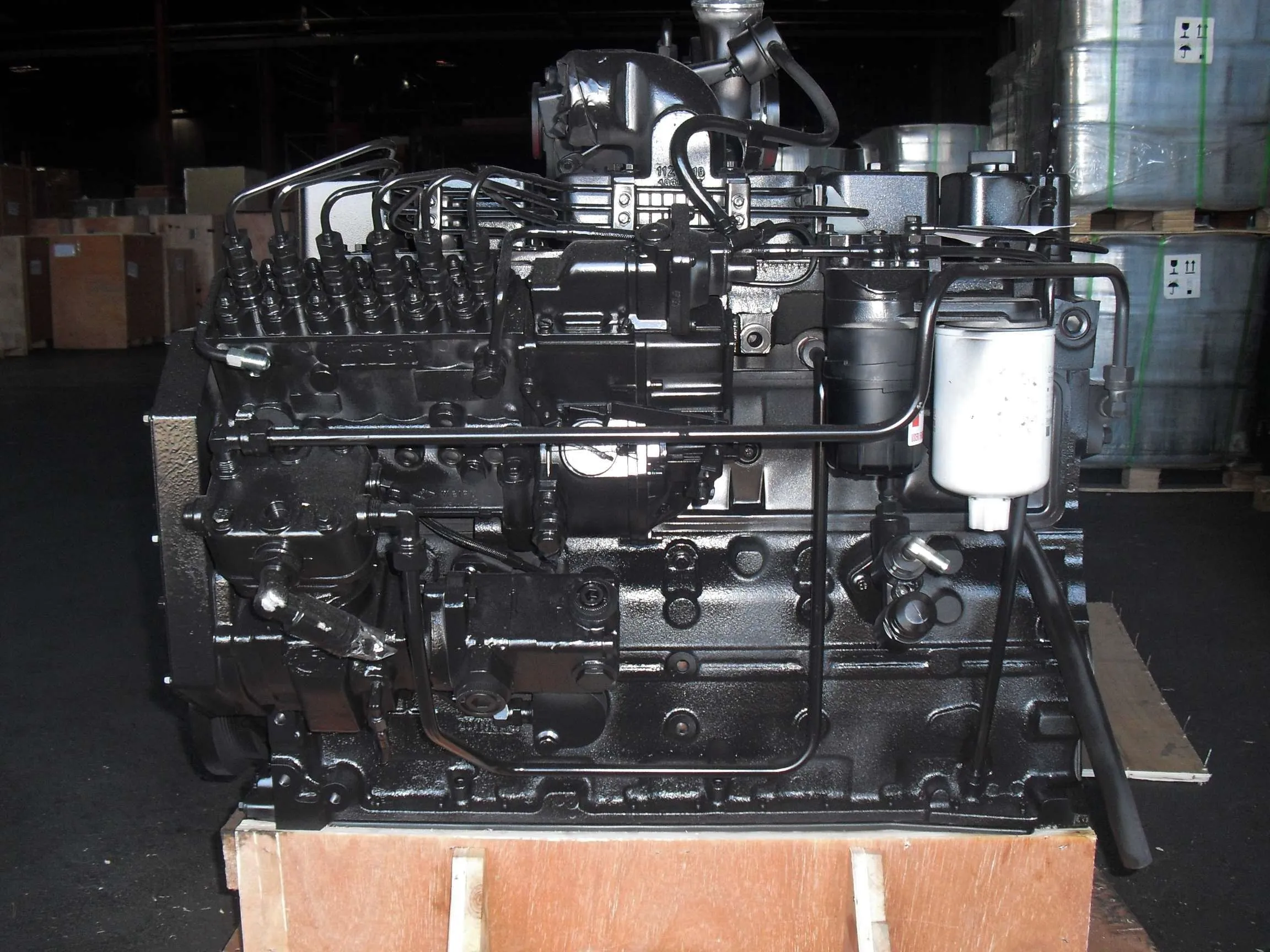

6. Cummins 5.9L 12-Valve Diesel

The Cummins 5.9L 12-Valve Diesel is often considered indestructible among diesel enthusiasts. Installed in trucks such as the Dodge Ram 2500, it featured a cast iron block with forged components that could handle massive torque.

The engine’s mechanical fuel injection system contributed to reliability, avoiding complex electronics that could fail in harsh environments. Its simplicity and strength made it ideal for both commercial and personal heavy-duty use.

This diesel is renowned for exceeding 500,000 miles with proper care. Regular fuel system maintenance and lubrication are essential, but the design is extremely robust. Engine longevity owes much to the thick cylinder walls, high-strength crankshaft, and durable connecting rods. Even under heavy towing, off-road work, or long-haul driving, this engine rarely experienced failure.

Mechanics appreciate the 12-valve Cummins for its serviceability. Routine repairs are straightforward, and parts are widely available. The straightforward mechanical systems reduce downtime and cost of maintenance. The cast iron block resists warping, and reinforced main caps protect the engine under extreme torque, making it a favorite for diesel enthusiasts and fleets alike.

Performance upgrades are possible without endangering durability. Many tuners add turbochargers, intercoolers, and larger injectors to increase power, and the engine can handle these changes with minimal risk. Its reputation for strength makes it a preferred choice for enthusiasts seeking both longevity and performance.

Long-term ownership reports highlight remarkable reliability under extreme conditions. Trucks equipped with this engine have been used for decades, often as daily drivers or work vehicles. The Cummins 5.9L 12-valve remains a benchmark for unkillable diesel engines, with a legacy that continues in modern diesel applications.

7. GM 6.5L Turbo Diesel V8

The GM 6.5L Turbo Diesel V8 was GM’s answer for durable diesel performance in pickups and SUVs during the 1990s. Built with a cast iron block and heavy-duty internals, it could handle heavy towing and extreme road conditions without issue.

The turbocharged versions added extra power, yet the robust construction ensured that reliability remained a priority. Its mechanical simplicity meant fewer points of failure, contributing to its reputation as nearly indestructible.

Owners of the 6.5L report engines regularly exceeding 300,000 miles with minimal problems. Maintenance focuses mainly on fuel system components and coolant upkeep, while the cast iron block rarely shows wear even under extreme torque loads.

Cooling efficiency and oil capacity allow the engine to run hot and long without warping or cracking. Fleet operators favored these engines due to their dependability and low long-term repair costs.

The engine responds well to modifications, particularly in the turbocharged versions. Upgrades like larger turbos, intercoolers, and stronger injectors are common, and the block’s strength allows for these changes without concern for catastrophic failure. The 6.5L’s reliability makes it ideal for enthusiasts seeking both longevity and power for off-road or towing purposes.

Real-world performance shows versatility, as these V8-powered pickups, vans, and SUVs all handled heavy loads and daily driving demands efficiently. Owners report smooth operation even after decades, demonstrating the benefits of its conservative engineering. The combination of torque, longevity, and serviceability makes it one of the most respected diesels of the 90s.

The GM 6.5L Turbo Diesel remains a benchmark for dependable diesel power. Its cast iron block, robust crankshaft, and reinforced cylinder walls ensure structural integrity under high stress. Even in the modern era, it is sought after for restoration, swaps, and heavy-duty builds due to its legendary toughness.

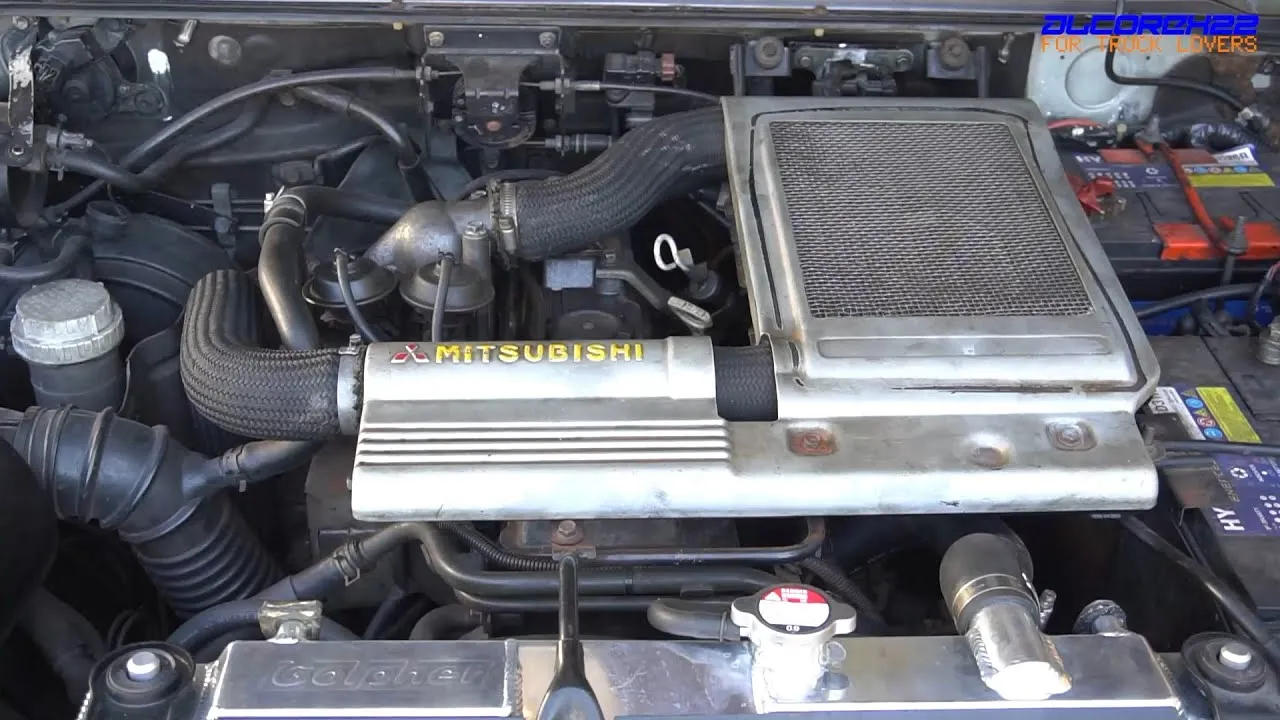

8. Mitsubishi 4M40 Diesel Inline-Four

The Mitsubishi 4M40 Diesel Inline-Four was designed for rugged durability in SUVs and trucks like the Mitsubishi Pajero. Its cast-iron block allowed it to endure high compression and extreme off-road conditions. Despite being an inline-four, it delivered sufficient torque for towing and climbing steep terrain. The combination of simplicity, mechanical injection systems, and robust internals made it highly reliable.

This engine is known to surpass 400,000 miles with proper care. Key maintenance includes timely oil changes, valve adjustments, and fuel filter replacements. The strong cast iron block and forged internals reduce the likelihood of catastrophic failure, even with heavy loads or aggressive driving. Many examples are still in service today in remote or harsh environments.

The 4M40 offers excellent upgrade potential for off-road enthusiasts. Turbocharging and intercooler additions are common modifications that can significantly boost torque and power. Its mechanical fuel system allows precise tuning without relying heavily on electronics. Off-road tuners prize the engine’s durability, as it can survive harsh terrain that would destroy weaker engines.

Every day use demonstrates its resilience, with owners reporting smooth operation across diverse conditions, from deserts to mountains. Even with high mileage, compression remains strong, and cooling systems maintain consistent temperature regulation. Its longevity has made it a favorite among adventure drivers seeking reliable, long-lasting engines.

The Mitsubishi 4M40 remains an enduring symbol of engineering reliability. Its combination of a cast iron block, robust internals, and simple mechanics allows decades of trouble-free service. For off-road enthusiasts and long-term owners, it continues to represent the type of durable engineering that defined the 1990s diesel era.

9. Toyota 2JZ-GTE Inline-Six

The Toyota 2JZ-GTE Inline-Six is one of the most famous performance engines of the 1990s. Its 3.0-liter twin-turbo inline-six used a cast iron block, which contributed to its legendary strength.

The engine could handle immense horsepower and torque without internal failure, making it popular in racing, street tuning, and high-performance builds. The aluminum head allowed for efficient heat management, while forged internals ensured longevity under extreme conditions.

Owners often report stock engines exceeding 300,000 miles with minimal issues, and even heavily modified setups remain reliable. Regular oil changes, timing belt maintenance, and cooling system attention are essential, but catastrophic failures are rare. Its reputation for durability is reinforced by the engine’s ability to endure forced induction and high boost levels without structural compromise.

The 2JZ-GTE is extremely popular among tuners because of its upgrade potential. Twin-turbo setups can easily exceed 700–1,000 horsepower with appropriate modifications. The cast iron block and forged crankshaft allow high-stress applications without worry. Aftermarket support is extensive, including performance internals, turbo kits, and cooling solutions, which reinforces its legendary status.

Despite its performance pedigree, the engine remains smooth, refined, and efficient for normal driving. Many vehicles equipped with the 2JZ-GTE are still in use today, showing remarkable longevity even with decades of service. Its versatility in stock and modified form underscores the careful engineering and quality materials used.

The 2JZ-GTE’s durability makes it a benchmark for high-performance engines. Its cast iron block, thick cylinder walls, and robust internal components ensure structural integrity even at extreme power levels. For collectors, tuners, and racing enthusiasts, this engine continues to define unkillable engineering from the 1990s.

10. Lexus 1G-GTE Inline-Six

The Lexus 1G-GTE Inline-Six was the turbocharged variant of the 1G series, found in the early Lexus IS models and Toyota Soarer. Featuring a cast iron block with aluminum heads, it combined reliability with refined performance.

Its turbocharged design provided spirited acceleration without sacrificing the durability expected from Toyota engineering. The engine’s design prioritized longevity while maintaining power and drivability for both street and track applications.

Long-term owners report engines lasting well past 300,000 miles with careful maintenance. Regular oil changes, timing belt replacements, and turbo inspections are the main concerns, while the cast-iron block remains virtually indestructible.

Cooling efficiency and well-designed internal components prevent overheating or warping even in high-performance situations. The engine balances reliability with spirited driving, making it versatile across various uses.

The 1G-GTE responds well to aftermarket enhancements. Turbo upgrades, intercoolers, and intake improvements can boost performance significantly without compromising reliability. Its strong block and forged components allow modifications that would destroy weaker engines. The engine is highly regarded by tuners for maintaining structural integrity under extreme loads.

Real-world driving shows its durability across multiple conditions, from highway commuting to spirited driving on mountain roads. Owners appreciate the smooth torque delivery and consistent performance even at high mileage. Its combination of strength, power, and refinement embodies Toyota’s approach to performance engines in the 1990s.

The Lexus 1G-GTE remains a symbol of engineering excellence. Its cast iron block, robust internals, and careful design ensure longevity and adaptability for both stock and modified applications. For enthusiasts seeking a reliable turbocharged engine from the 1990s, the 1G-GTE is a perfect example of unkillable engineering.