When you pop the hood of a car, you’re staring at its heart — the engine. It’s one of the most important, expensive, and defining components of any vehicle.

While some engines are engineering marvels known to run for hundreds of thousands of miles with minimal issues, others have gained infamy for their constant breakdowns, oil leaks, overheating issues, and expensive repair bills.

If you’ve ever owned a car with a problematic engine, you know how quickly the thrill of driving can turn into a money pit of frustration.

The reliability of an engine is shaped by many factors: design simplicity, quality of materials, engineering tolerances, cooling system efficiency, and even how well it can handle neglect.

Reliable engines tend to be overbuilt, simple, and time-tested — the kind that can withstand years of abuse and still keep ticking.

On the other hand, some engines are plagued by overcomplicated systems, poor engineering choices, or cost-cutting measures that doom them to frequent breakdowns and costly fixes.

In this article, we’ll explore five engines that have earned legendary status for their bulletproof reliability, followed by five that are notoriously prone to problems.

Whether you’re shopping for a used car, restoring a project, or just a gearhead who loves talking engines, this list will give you a clear sense of which powerplants you can trust — and which ones to avoid like the plague.

Also Read: 10 Cars That Can Run Up to 250,000 Miles Without Major Repairs

Engines Known for Reliability

1. Toyota 2UZ-FE (4.7L V8)

The Toyota 2UZ-FE is an iron-block, 4.7-liter V8 that powered vehicles like the Toyota Land Cruiser, Sequoia, Tundra, and Lexus GX470.

Introduced in the late ’90s, it quickly gained a reputation as one of the most indestructible engines Toyota ever built, which is saying a lot, considering Toyota’s long history of reliable engineering.

The 2UZ-FE was overbuilt for its intended use, with thick cylinder walls, forged internals in some versions, and a cast-iron block designed to withstand abuse and heavy towing.

Part of what makes the 2UZ-FE so beloved is its tolerance for neglect. These engines have been known to survive with minimal maintenance, poor oil change intervals, and extreme off-road conditions.

In places like Australia, Africa, and the Middle East, where reliability can be a matter of survival, the 2UZ is considered a go-to powerplant. Many of these engines have comfortably exceeded 300,000 miles with no internal rebuilds, a feat that few modern engines can match without major work.

While not the most fuel-efficient or high-revving V8 out there, the 2UZ-FE offers smooth performance, low-end torque, and incredible durability. It’s also relatively simple by today’s standards: no turbochargers, no direct injection, and no complex electronics to worry about.

The engine’s conservative engineering and high build quality make it one of the most dependable V8s ever made — and a favorite among those who value long-term ownership over flashy features.

2. Honda K Series (K20, K24)

Honda’s K Series engines — particularly the K20 and K24 — are legendary for their blend of performance, efficiency, and near-bulletproof durability.

Found in everything from the Civic Si to the Accord and CR-V, these engines helped define a generation of enthusiasts and commuters alike.

With dual overhead cams, VTEC variable valve timing, and Honda’s famously tight build tolerances, the K Series delivers a strong, reliable driving experience with a redline that practically begs for spirited use.

One of the secrets to the K Series’ reliability is its efficient and well-balanced internal design. The engines use forged or hyper-eutectic pistons, a strong bottom end, and high-flow heads, which allow for excellent thermal management and long-term durability.

Even when turbocharged or modified for track use, K Series motors often hold together under stress where other engines might fail. This has made them extremely popular in the tuner world, with countless engine swaps and racing builds using K Motors as their foundation.

Maintenance is straightforward, and parts are widely available, making repairs affordable and simple. Regular oil changes, timing chain tensioner checks, and valve adjustments are all that’s typically required to keep a K motor humming for well over 200,000 miles.

Whether you’re commuting, racing, or building a project car, the K Series delivers performance without the headache — a hallmark of truly great engine design.

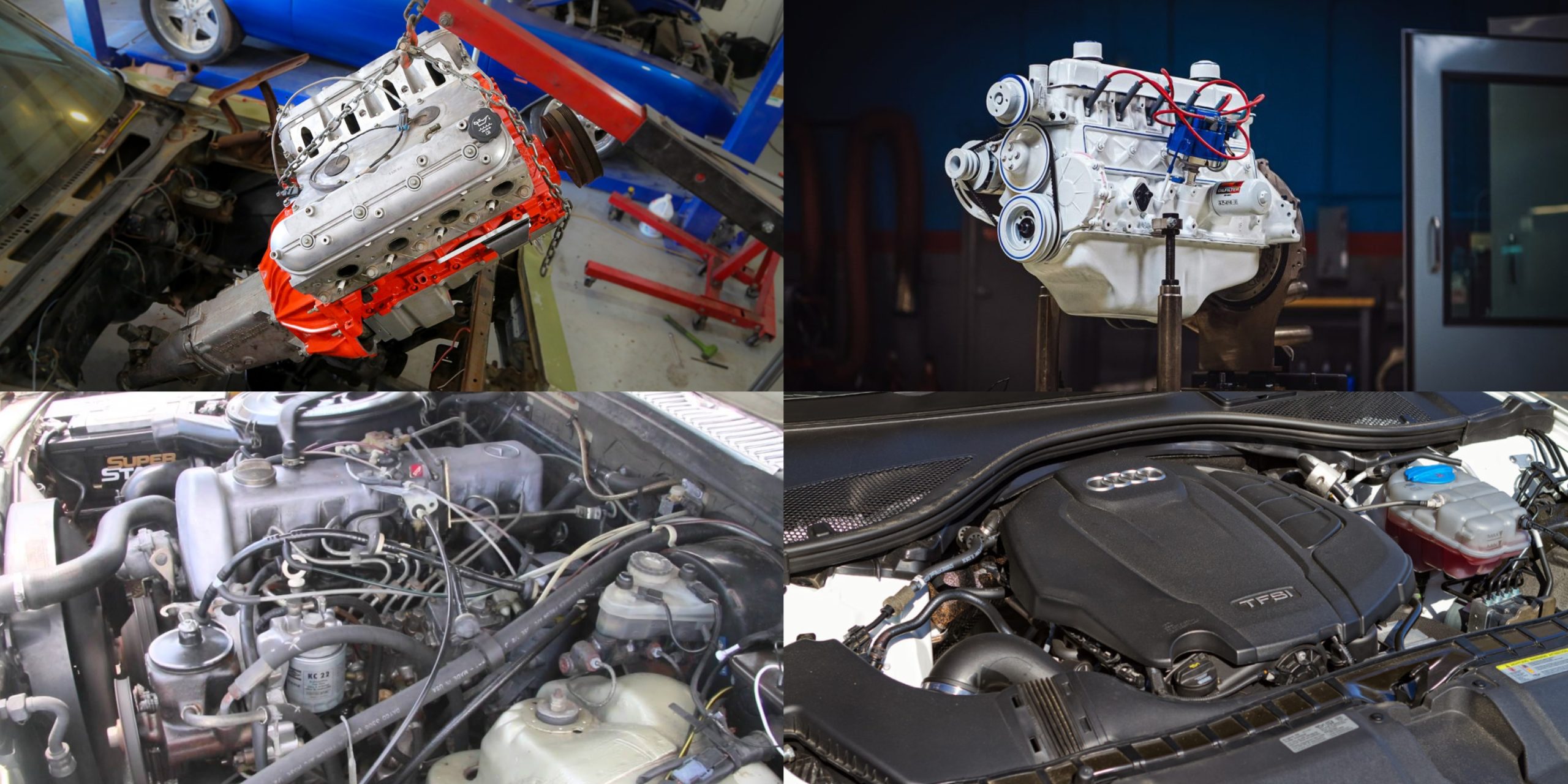

3. GM LS Series (e.g., LS1, LS3)

General Motors struck gold with the LS engine family, starting with the LS1 in 1997 and continuing through the modern LS3 and beyond. These small-block V8s are incredibly popular for a reason: they’re simple, durable, powerful, and endlessly adaptable.

The LS engines have powered everything from Corvettes and Camaros to trucks and SUVs, and they’ve become the go-to choice for engine swaps across the world, showing up in everything from Miatas to Ferraris.

The LS engine’s reliability stems from a combination of old-school simplicity and modern engineering. With a pushrod design, aluminum or iron blocks, and proven components, LS engines are known to last well beyond 250,000 miles with basic maintenance.

They’re not high-revving race engines by nature, but they deliver loads of low-end torque and have a very forgiving design that makes them easy to maintain and repair. The modular architecture also means parts are cheap, interchangeable, and readily available — a DIY mechanic’s dream.

Beyond reliability, LS engines shine because of their flexibility. Want to turbocharge it? Supercharge it? Swap it into a 30-year-old sports car? No problem.

The massive aftermarket support and huge enthusiast community mean that LS engines are some of the most supported and documented engines in history. Whether you’re chasing horsepower or just want a long-lasting engine, the LS series delivers with very few downsides.

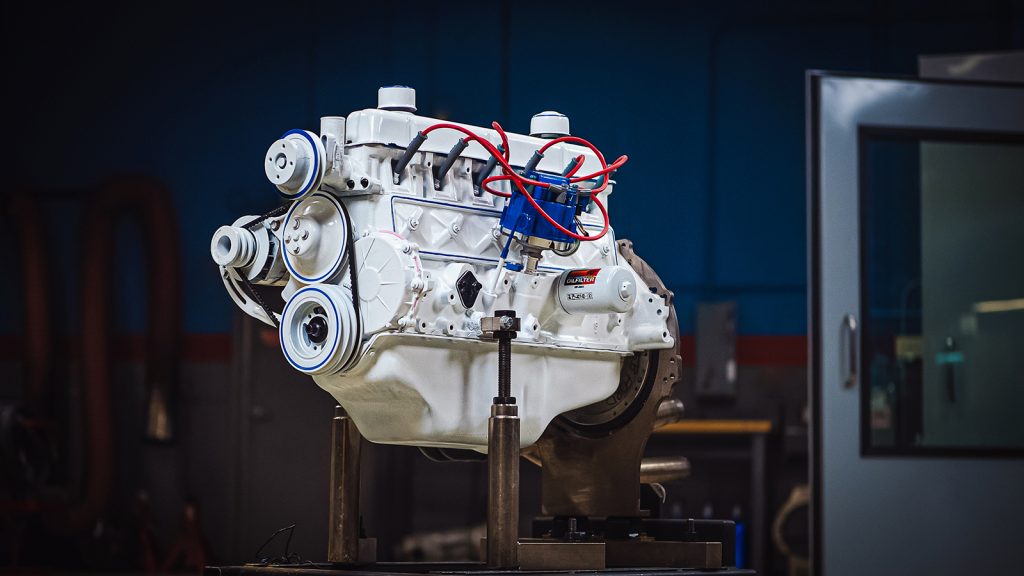

4. Ford 300 Inline-6

The Ford 300 Inline-6 — also known as the 4.9L I6 — is a workhorse of an engine that earned its stripes in trucks, vans, and industrial equipment for decades.

Produced from the 1960s through the mid-1990s, this engine is best known for one thing: it just won’t die. With a cast-iron block and head, a simple OHV (overhead valve) layout, and massive low-end torque, the 300 I6 is built for heavy-duty, no-nonsense reliability.

What made the 300 so bulletproof was its simplicity and low-stress operation. It wasn’t built for speed or performance — it was built to pull, tow, and endure. With fewer moving parts than modern engines and generous tolerances, the 300 I6 can take a beating and still keep going.

Farmers, fleet operators, and tradesmen swore by these engines, often racking up 300,000–400,000 miles with little more than regular oil changes and basic maintenance.

The 300 I6 also gained a reputation as being extremely easy to work on. Spark plugs are easy to reach, there’s plenty of space under the hood, and the architecture is straightforward.

Even today, mechanics and enthusiasts praise the engine for its longevity and ease of repair. It’s not flashy, but the Ford 300 Inline-6 remains one of the toughest and most respected engines in American automotive history.

5. Mercedes-Benz OM617 Diesel

If you want to talk about engines that could run forever, the Mercedes-Benz OM617 5-cylinder diesel belongs in the conversation.

Found in models like the W123 300D and early G-Wagens, this 3.0-liter inline-five diesel engine is renowned for lasting half a million miles or more with minimal issues.

Built during an era when Mercedes engineering prioritized durability over cost savings, the OM617 is as close as you can get to an indestructible diesel.

The engine’s secret lies in its overengineered design. Everything from the forged internals to the solid cast-iron block was made to endure extreme operating conditions.

These engines were built to run on low-quality fuel, survive cold starts in harsh climates, and keep moving even with worn components.

They aren’t quick, with slow acceleration and modest horsepower, but they’re as reliable as sunrise. That’s why they were popular in Europe, Africa, and the Middle East, often used as taxis or military vehicles.

What further boosts the OM617’s reputation is its mechanical simplicity. There are no complex electronics or turbochargers in most versions, and the fuel injection system is mechanical, meaning fewer parts to fail and easier troubleshooting.

Enthusiasts today still seek out these engines for diesel swaps and off-grid builds, trusting in their unmatched reliability. If your priority is long-term dependability and you don’t mind taking it slow, the OM617 is a world-class choice.

Engines That Constantly Need Repairs

1. Subaru EJ25 (2.5L H4)

The Subaru EJ25, particularly the versions found in late ’90s to mid-2000s models like the Impreza, Forester, and Outback, is infamous for one major issue: head gasket failure.

While Subaru’s boxer engine layout helps with a low center of gravity and smooth performance, it also creates cooling challenges, especially in the EJ25.

These engines frequently suffered from internal and external head gasket leaks, sometimes as early as 60,000 miles, leading to coolant loss, overheating, and expensive repair bills. The problem was compounded by Subaru’s design decisions and manufacturing quality during those years.

The gaskets used in early EJ25s weren’t robust enough to handle thermal cycling over time, and because of the boxer layout, the cylinder heads lie horizontally, which means fluids and combustion gases can pool differently than in inline or V-shaped engines.

Once the head gaskets fail, the repair isn’t cheap, typically requiring several hours of labor and potentially resurfacing the heads, making it one of the more costly common engine repairs out there.

Even aside from the gasket issues, the EJ25 has been criticized for oil consumption, piston slap in colder climates, and fragility when pushed hard. While the WRX and STI versions of the EJ25 can make solid power, they require religious maintenance and tuning care.

For the average daily driver, the EJ25 is a gamble — and a reminder that engine design matters as much as how it’s marketed. It’s not the worst engine ever made, but it’s one of the most consistently troublesome.

2. BMW N63 (4.4L Twin-Turbo V8)

The BMW N63 engine, found in models like the 550i, 750i, and X5 50i from the late 2000s onward, is a case study in overengineering gone wrong. On paper, the N63 is impressive — a twin-turbocharged 4.4-liter V8 with serious power and torque.

But in reality, it’s plagued with reliability nightmares, so much so that BMW issued a massive “Customer Care Package” to address widespread failures. From oil consumption to timing chain stretch and turbocharger failure, the N63 is a maintenance headache few owners forget.

One of the engine’s main issues lies in its “hot-vee” design, with turbochargers mounted in the valley of the V8, rather than outside of it.

While this layout improves throttle response and reduces turbo lag, it also traps heat inside the engine, leading to premature failure of gaskets, valve stem seals, turbos, and more.

Over time, this constant heat stress leads to breakdowns that require expensive, labor-intensive repairs. It’s not uncommon to see repair bills exceeding $5,000 to $10,000 on aging N63-equipped vehicles.

The N63 also suffers from timing chain problems that can cause catastrophic engine failure if not addressed.

Combine that with direct injection carbon buildup, battery drain issues from the auxiliary systems, and oil burning that rivals two-stroke dirt bikes, and you’ve got a high-performance engine that rarely goes the distance without wallet-draining attention. It’s an engineering marvel, yes — but one that turned ownership into a nightmare for many.

3. Chrysler 2.7L V6

The Chrysler 2.7-liter V6, used in vehicles like the Chrysler Sebring, Dodge Intrepid, and Dodge Stratus in the late ’90s and early 2000s, is one of the most notorious engines in modern automotive history.

It was intended to be a smooth, efficient powerplant, but instead it became known for sludge buildup, timing chain failures, and total engine death well before 100,000 miles in many cases. Owners frequently found themselves facing full engine replacements just a few years after purchase.

The major issue with the 2.7L was its poor oiling system. It had narrow oil passages and a tendency to run hot, which led to oil sludge forming quickly, especially if owners didn’t change their oil frequently or used subpar oil.

Unfortunately, Chrysler didn’t adequately warn consumers about the necessity of more frequent oil changes, and many engines suffered complete failure due to clogged oil passages, worn camshaft bearings, and oil starvation.

Making matters worse, repairs on the 2.7L were far from simple. The engine’s packaging meant even basic jobs like a water pump replacement could become a nightmare, as the water pump was driven by the timing chain and located inside the engine, requiring significant disassembly.

Once the engine began developing problems, it often made more financial sense to scrap the vehicle than to repair it. The 2.7L is a textbook example of how poor engineering can doom a car’s reputation and resale value.

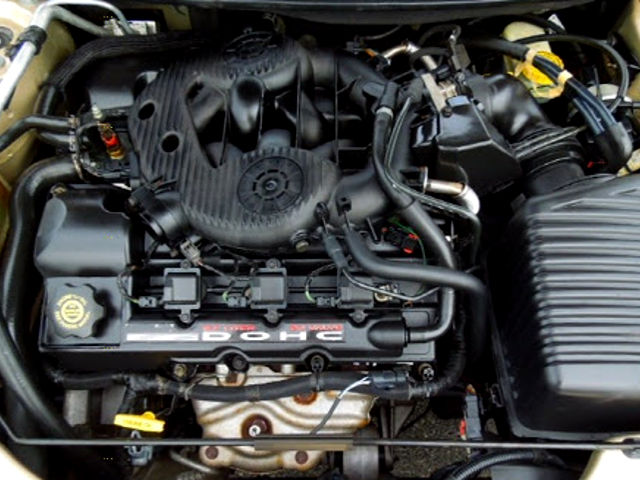

4. Audi 2.0T TFSI (Early Versions)

Audi’s early 2.0T TFSI engines, found in models like the A4, A5, and VW GTI between 2005 and 2011, are a perfect example of how modern technology can backfire when not properly executed.

These engines introduced direct injection and turbocharging to a wider audience, but with it came a host of chronic problems, including oil consumption, carbon buildup, and timing chain tensioner failures that could lead to total engine destruction if not addressed promptly.

The carbon buildup is perhaps the most notorious issue. Because of direct injection, fuel doesn’t wash over the intake valves, and over time, carbon deposits accumulate on the valves, choking airflow and causing performance degradation, misfires, and poor fuel economy.

Cleaning this buildup is an expensive process that often requires walnut shell blasting or full intake disassembly, sometimes as early as 40,000 miles. And it’s not a one-time fix — it’s a recurring issue that plagues many DI engines of this era.

Then there’s the oil consumption. Early 2.0T engines were infamous for burning a quart of oil every 500 to 1,000 miles, sometimes more.

Audi did eventually address this with updated pistons and rings in later versions, but many owners were left footing the bill or topping up oil constantly to avoid damage.

Combine that with delicate PCV systems, water pump failures, and timing tensioner issues, and you’ve got an engine that requires vigilance — and sometimes, prayers — to make it to high mileage without incident.

5. Mazda Rotary (13B, Renesis)

Mazda’s rotary engines — particularly the 13B from the RX-7 and the Renesis from the RX-8 — are legendary in some circles, but not because they’re reliable. Known for their high-revving nature and compact size, rotary engines offer a unique driving experience.

But they’re also infamous for apex seal wear, oil consumption, and short service lives. Most rotary-powered cars need major engine work by 100,000 miles — if they even make it that far — and regular maintenance is essential just to keep them alive.

The main issue is the design itself. Rotary engines use spinning rotors instead of pistons, and they rely on apex seals (which act like piston rings) to maintain compression. These seals wear out relatively quickly, especially under hard driving or improper maintenance.

Once they fail, compression drops, and the engine becomes difficult (or impossible) to start. And because rebuilding a rotary is a specialized job, it’s often prohibitively expensive or simply not worth it to many owners.

Add to that the fact that rotary engines burn oil by design (oil is injected into the combustion chamber to lubricate the rotors), and you’ve got an engine that demands constant attention.

Many owners simply weren’t aware of this and treated them like regular piston engines, leading to premature failures.

While rotary engines are beloved for their uniqueness and performance, they’re undeniably high-maintenance and fragile, making them one of the least reliable engine choices for daily driving.

Also Read: 10 Best Hybrid Cars of 2025 That Balance Fuel Efficiency, Reliability, and Everyday Comfort

An engine can make or break a vehicle — literally and financially. While some engines like the Toyota 2UZ-FE, Honda K Series, and Mercedes OM617 are trusted for their bulletproof design and long-term reliability, others like the BMW N63, Subaru EJ25, and Chrysler 2.7L V6 have earned their reputations as time bombs under the hood.

Knowing which engines to trust — and which to avoid — can save you thousands of dollars and countless headaches over the life of your vehicle.

Whether you’re a first-time car buyer, a gearhead, or someone just trying to avoid the next mechanic visit, engine reliability should always be part of your research.

Remember: the car might look great and drive fine now, but what’s under the hood will determine if you love it for years or regret it after the warranty ends.