In the world of automotive engineering, engines are the beating heart of any vehicle. They define the character, performance, reliability, and ultimately the reputation of a car manufacturer. For Hyundai, one of the world’s most prominent automakers, engines have been both a point of pride and a source of painful lessons.

Over the past few decades, Hyundai has grown from a budget-focused brand into a global powerhouse, competing with industry heavyweights in nearly every segment. This transformation has required a bold approach to innovation, design, and engineering.

Along the way, Hyundai has developed a variety of engines—some of which have become celebrated examples of durability and innovation, while others have faltered under the weight of rushed production, flawed execution, or insufficient long-term testing.

Like any automaker that’s undergone rapid expansion and technological evolution, Hyundai’s engine lineup includes both exceptional successes and frustrating failures. From small city hatchbacks to high-performance sport sedans and rugged SUVs, Hyundai’s engines have powered vehicles around the globe, often in extreme climates and under diverse driving conditions.

This real-world stress test has revealed which engines were overbuilt and reliable, and which ones were undercooked and error-prone. It’s not uncommon to find Hyundai vehicles with engines that deliver hundreds of thousands of trouble-free miles, testaments to the brand’s engineering improvements and commitment to quality.

At the same time, other Hyundai powerplants have earned infamy for oil consumption, carbon buildup, and premature failures that left owners disillusioned and frustrated. This article takes a comprehensive look at both ends of Hyundai’s engineering spectrum by highlighting five engines that have garnered praise and five that are widely considered disasters.

On the positive side, Hyundai has produced engines like the Lambda 3.8L V6 and the Smartstream 1.6L Turbo, which stand as pillars of innovation and endurance. These engines offer a harmonious blend of performance, fuel economy, and mechanical longevity.

They showcase what Hyundai does best when it combines thorough R&D with quality materials and intelligent design. Owners of vehicles with these engines often report high satisfaction, low maintenance costs, and excellent reliability over the long term.

Conversely, there’s another side to this story. Hyundai has also released engines that have caused major headaches for customers—engines that turned out to be liabilities rather than assets. Notorious examples like the early Theta II GDI engines or the problematic D4CB diesels serve as cautionary tales.

These engines suffered from issues such as excessive oil consumption, failing bearings, unreliable turbos, and carbon buildup. They triggered class-action lawsuits, widespread recalls, and damaged Hyundai’s otherwise growing reputation for quality.

In many cases, even routine maintenance couldn’t prevent these issues from developing, which only fueled consumer dissatisfaction and created distrust.

The goal of this article is not to simply praise or condemn Hyundai, but to offer a balanced, well-informed view of its engine history.

By understanding where Hyundai succeeded and where it stumbled, current and prospective buyers can make smarter purchasing decisions, and enthusiasts can appreciate the complexity and risk involved in automotive engineering.

For Hyundai, these lessons—both good and bad—have shaped the company’s trajectory, influenced its approach to quality control, and informed its development of future engine platforms. It’s a story of trial and error, resilience, and evolution.

Whether you’re a mechanic, a Hyundai owner, or just a curious car enthusiast, this guide will walk you through the engines that earned Hyundai accolades and the ones that caused frustration in the garage.

With clear analysis and detailed descriptions, we’ll highlight what worked, what didn’t, and why it all matters in the grand narrative of Hyundai’s journey to becoming a global automotive leader.

Also Read: Top 10 Worst and 10 Best Trucks for Towing

5 Hyundai Engines That Deserve Praise

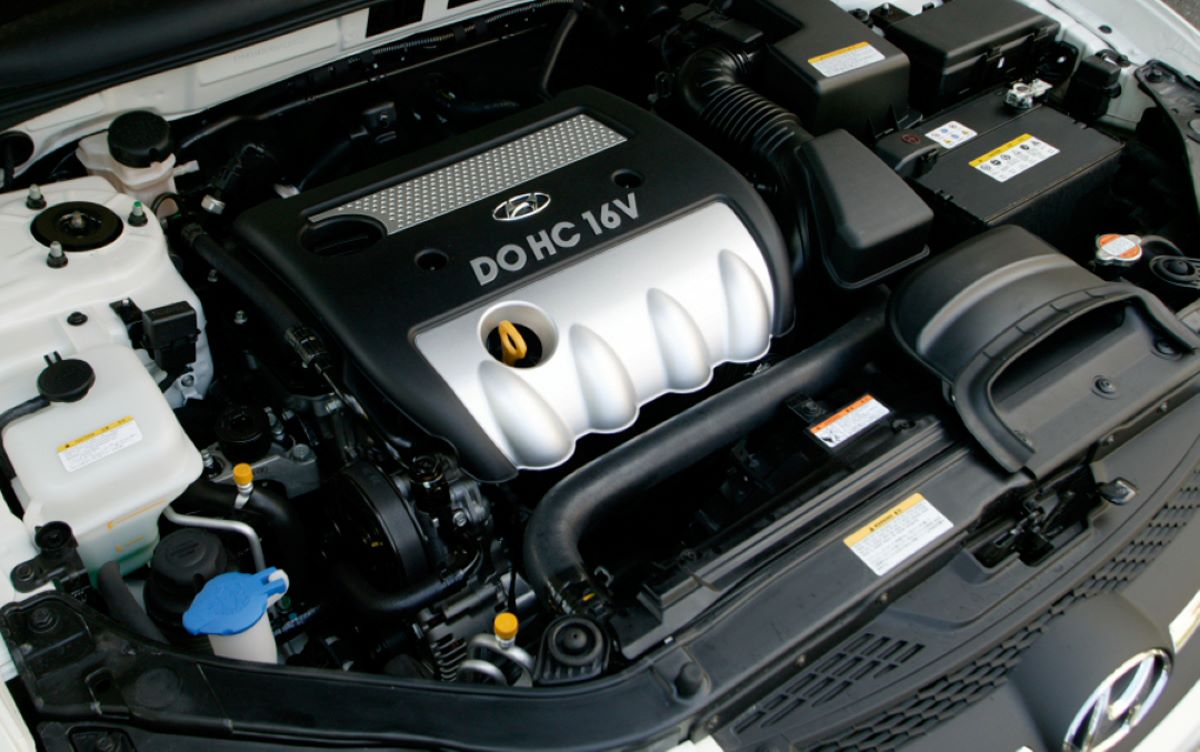

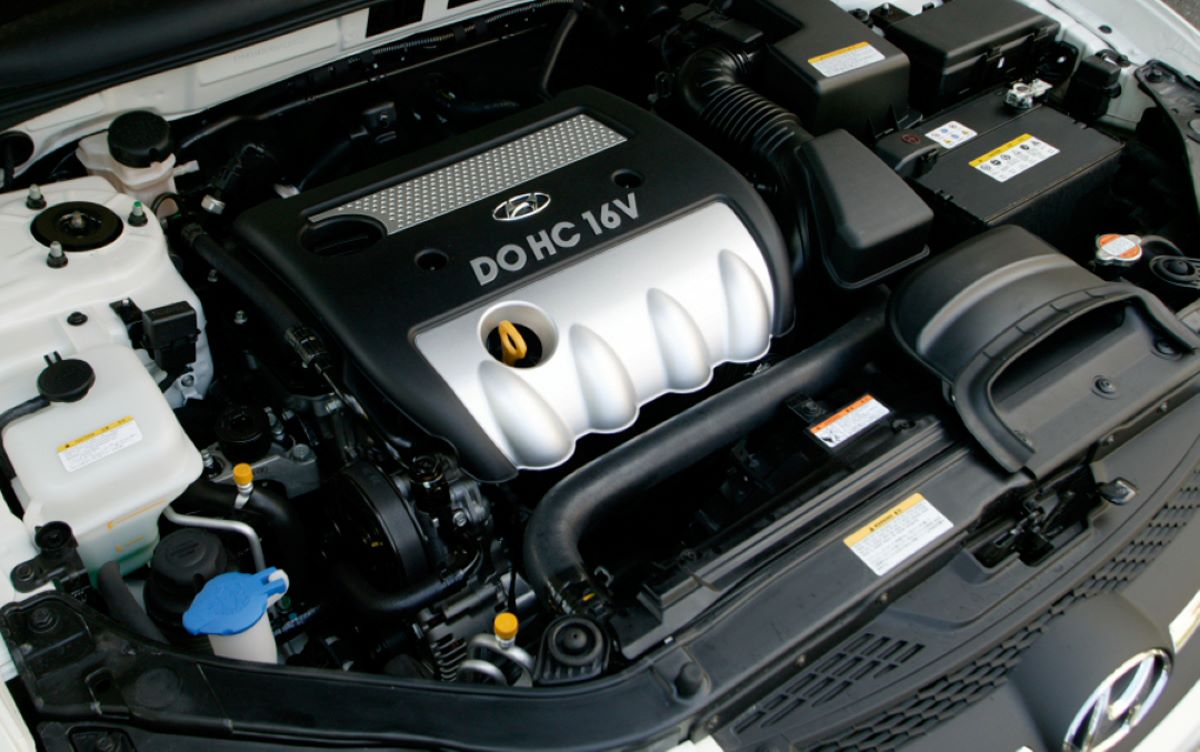

1. Hyundai Theta II 2.4L GDI Engine (G4KJ)

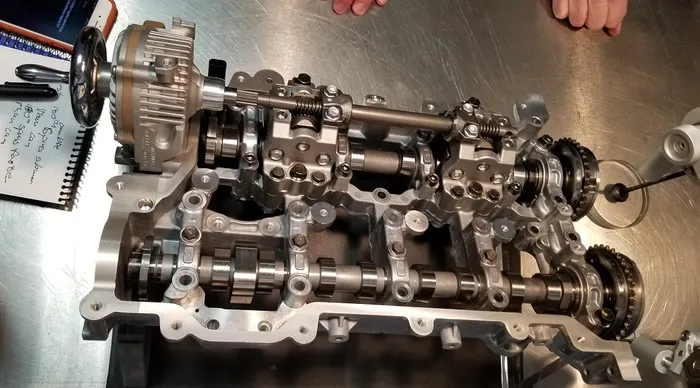

The Hyundai Theta II 2.4L Gasoline Direct Injection (GDI) engine has been a cornerstone of Hyundai’s powertrain lineup for well over a decade, powering popular models such as the Hyundai Sonata, Tucson, and Santa Fe.

What sets the Theta II apart is its blend of modern technology and solid engineering principles, which enables it to deliver a commendable balance of power, fuel efficiency, and durability.

The GDI system allows for more precise fuel delivery directly into the combustion chamber, which not only improves combustion efficiency but also enhances throttle response and reduces emissions.

Compared to traditional fuel injection systems, the Theta II’s GDI technology provides a noticeable improvement in low-end torque, making daily driving smooth and responsive without sacrificing highway cruising comfort.

Another critical factor in the Theta II’s praise-worthy reputation is its robust construction. Hyundai incorporated forged steel crankshafts and lightweight pistons designed to withstand the stresses of long-term use, making the engine reliable over extended mileage.

Despite some initial reports of minor issues such as timing chain tensioner noise and carbon buildup (common in many GDI engines), Hyundai responded by updating components and improving maintenance recommendations, which have largely mitigated those early concerns.

Enthusiasts and everyday drivers alike appreciate the engine’s ability to perform consistently even under varied driving conditions — from stop-and-go city traffic to highway cruising. Furthermore, its widespread use across several models attests to its versatility and solid engineering pedigree, making it one of Hyundai’s most dependable engines.

Fuel economy also ranks highly in the Theta II’s favor. Its advanced combustion controls and variable valve timing help maximize efficiency without compromising output.

For a mid-size sedan or compact SUV engine, delivering around 180 to 190 horsepower with decent torque figures, it strikes a sweet spot between spirited driving and economical commuting.

Owners who maintain the engine properly, using recommended synthetic oils and timely servicing, frequently report long-lasting performance, often exceeding 150,000 to 200,000 miles with minimal issues. This durability and refinement have cemented the Theta II 2.4L GDI’s place among Hyundai’s most respected engines.

2. Hyundai Lambda 3.8L V6 Engine

The Lambda 3.8L V6 engine stands out as Hyundai’s flagship naturally aspirated V6 offering for larger vehicles like the Santa Fe, Genesis, and Azera. It is praised for its smooth, refined operation and strong torque delivery, which suits the heavier vehicles it powers.

One of the Lambda’s defining characteristics is its all-aluminum construction, including both the block and cylinder heads, which significantly reduces engine weight and improves vehicle handling dynamics. This weight saving also contributes to improved fuel efficiency compared to traditional cast iron engines of similar displacement.

Technologically, the Lambda incorporates dual Continuously Variable Valve Timing (CVVT) on both intake and exhaust valves. This system optimizes valve timing based on engine load and speed, allowing for enhanced power output, better fuel economy, and reduced emissions.

The engine’s design facilitates a broad and usable torque curve, meaning drivers experience smooth acceleration from idle through the redline without the “peakiness” common in less refined V6 engines. The 3.8L Lambda produces around 290 horsepower and 260 lb-ft of torque, enough to provide confident and comfortable acceleration for SUVs and sedans alike.

Reliability is a cornerstone of Lambda’s reputation. Many owners have reported that these engines run smoothly well beyond the 200,000-mile mark when properly maintained. Common maintenance includes regular oil changes and inspections of the timing chain components, which are durable but should be monitored.

Unlike some turbocharged or direct-injected engines that may suffer from carbon buildup or early wear, the naturally aspirated Lambda V6 is generally free from these issues, contributing to its longevity. The combination of power, refinement, and durability makes the Lambda 3.8L an engine Hyundai enthusiasts and everyday drivers trust.

3. Hyundai Kappa 1.0L and 1.2L Engines

The Hyundai Kappa engine family, including the 1.0L and 1.2L inline-4 variants, is an excellent example of Hyundai’s ability to engineer small, efficient, and reliable engines tailored for urban and economy cars.

Found in vehicles like the Hyundai i10, Accent, and some models of the Venue, the Kappa engines have earned praise for their simplicity, fuel economy, and surprisingly lively performance relative to their displacement.

Despite their compact size, these engines manage to produce respectable horsepower figures—typically in the 70 to 85 hp range—and deliver smooth drivability in tight city conditions.

Technically, the Kappa engines employ dual overhead camshafts (DOHC) and Continuously Variable Valve Timing (CVVT), allowing them to optimize valve timing for both fuel efficiency and performance depending on driving conditions.

Their relatively low weight and compact dimensions make them an ideal choice for smaller vehicles, contributing to nimble handling and lower overall vehicle weight.

In addition, the Kappa series engines are known for their robustness and low maintenance costs, making them attractive to cost-conscious consumers and fleet operators alike.

From a reliability standpoint, the Kappa engines have few major complaints, with many vehicles clocking well over 100,000 miles without significant engine issues. Routine maintenance like oil and filter changes, combined with attention to cooling systems, is generally sufficient to keep these engines running smoothly.

They have proven to be durable powerplants, especially when compared to some competitors in the same segment. Hyundai’s continued use and improvement of the Kappa series in various markets speaks volumes about its success and engineering quality.

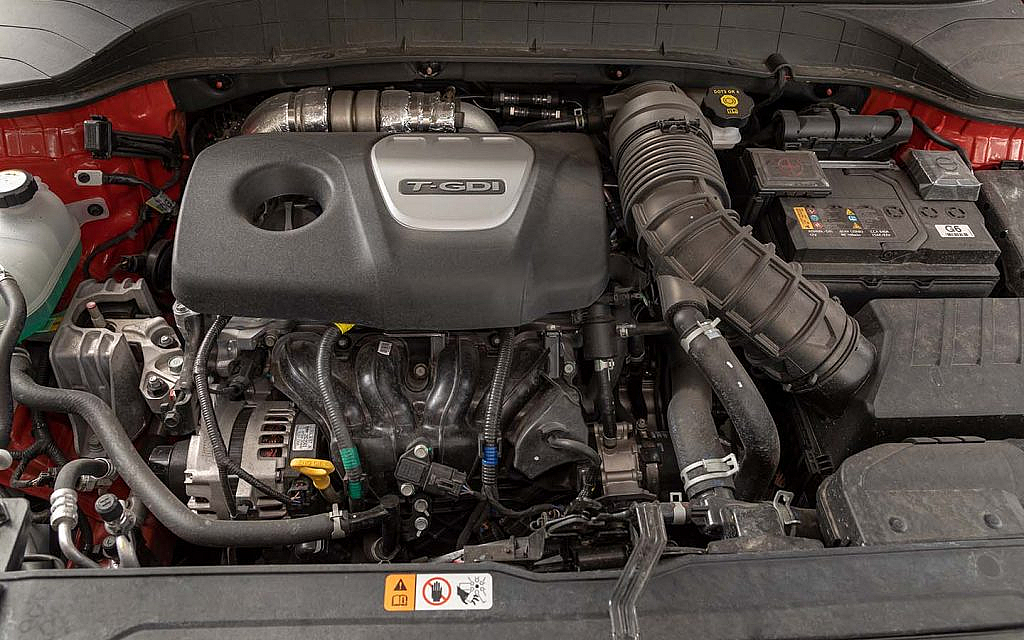

4. Hyundai Smartstream G1.6 Turbo Engine

The 1.6-liter turbocharged engine from Hyundai’s latest Smartstream family is a major step forward in the company’s engine technology, designed to meet increasingly strict emissions regulations while delivering spirited performance and improved fuel economy.

Used in models such as the Hyundai Kona, Elantra, and Tucson, this engine incorporates advanced engineering techniques, including friction reduction technologies, enhanced cooling systems, and optimized combustion chamber designs.

One of the key attributes of the Smartstream G1.6 turbo is its ability to provide strong low-end and mid-range torque—often exceeding 180 lb-ft—which results in a responsive driving experience, especially in city and suburban environments where frequent acceleration is required.

The turbocharger is engineered for quick spool-up and reduced turbo lag, overcoming one of the common drawbacks of small turbo engines. This translates to a driving feel that’s both lively and smooth, without the roughness sometimes associated with turbocharged four-cylinder engines.

Reliability for the Smartstream turbo has been promising based on early feedback. Hyundai has learned from previous generations of turbo engines, improving oil circulation and cooling to better manage thermal stresses. The use of direct injection combined with port injection helps reduce carbon buildup, a common problem in earlier turbocharged GDI engines.

Owners benefit from Hyundai’s extended warranties and well-established service networks, making the Smartstream G1.6 a strong contender in the modern compact performance segment.

5. Hyundai R-Series Diesel Engines (R 2.0L CRDi)

Diesel engines in the Hyundai lineup, particularly the R-series 2.0L Common Rail Direct Injection (CRDi) units, have garnered praise in markets where diesel is prevalent. Found in models like the Tucson, Santa Fe, and even commercial vehicles, the R-series diesels are celebrated for their excellent fuel economy, strong torque delivery, and long service life.

Diesel engines naturally provide higher low-end torque, which is ideal for towing and off-road use, and Hyundai’s CRDi technology further refines this by precisely controlling fuel injection timing and pressure to optimize combustion efficiency.

One of the reasons for the R-series diesel’s positive reputation is its robust build quality. The engine features a cast iron block, which adds durability, and a reinforced crankshaft designed to withstand high compression ratios typical of diesel combustion.

The CRDi system reduces emissions and noise compared to older diesel engines, improving drivability and environmental friendliness. Regular maintenance, including timely fuel filter changes and injector servicing, helps these engines reach well beyond 200,000 miles.

Additionally, the R-series engines benefit from Hyundai’s continual software updates and improvements in turbocharger technology, enhancing both performance and reliability. Many owners report dependable performance even in demanding conditions, from long highway hauls to rugged terrain.

This combination of power, efficiency, and durability has solidified the R-series 2.0L CRDi as one of Hyundai’s most dependable and well-regarded engines.

5 Hyundai Engines That Are Considered Disasters

1. Hyundai Theta II 2.0L and 2.4L GDI Engines (Early Models)

Despite its broad use and later improvements, the early iterations of the Theta II 2.0L and 2.4L GDI engines are among Hyundai’s most problematic powerplants. These engines, especially those produced between 2011 and 2015, were plagued by serious reliability issues that sparked widespread consumer complaints, class-action lawsuits, and multiple recalls.

One of the most troubling issues was the presence of metallic debris left behind during the manufacturing process, which led to premature wear of engine bearings.

As these bearings deteriorated, they often caused severe knocking noises and, in many cases, complete engine seizure. This was not a minor defect — it was a catastrophic failure that affected tens of thousands of vehicles across the Hyundai and Kia lineups.

Another common problem with these early Theta II engines was excessive oil consumption. Owners frequently reported needing to add quarts of oil between oil changes, and some experienced sudden oil pressure loss without warning. In extreme cases, this led to total engine failure, sometimes while the vehicle was in motion — a serious safety hazard.

Compounding the issue, Hyundai initially struggled with diagnostic transparency and warranty responsiveness, leading to frustration and a loss of consumer trust. It wasn’t until significant media coverage and regulatory pressure that Hyundai began issuing extended warranties and offering engine replacements under recall campaigns.

Additionally, the Theta II’s use of Gasoline Direct Injection (GDI) introduced another headache: carbon buildup on intake valves. Unlike port fuel injection, which washes intake valves with fuel, GDI systems do not provide this cleaning benefit.

Over time, carbon deposits reduced airflow and affected performance, leading to rough idling, decreased fuel economy, and poor throttle response. While Hyundai eventually redesigned components and improved quality control, the early Theta II engines left a lasting stain on Hyundai’s reputation for reliability and are still widely considered a major misstep.

2. Hyundai Beta 2.0L Engine (Pre-2006 Models)

The Beta 2.0L engine, especially those manufactured before the 2006 model year, was one of Hyundai’s less refined and more problematic engine platforms. Found in models such as the Hyundai Elantra, Tiburon, and early Tucson, this engine suffered from a host of mechanical issues that hindered its reputation and long-term viability.

Chief among these problems was a recurring tendency for the head gasket to fail prematurely. The failure of this critical component could lead to coolant mixing with engine oil, overheating, and eventually warped cylinder heads or even total engine failure if not addressed promptly.

Timing belt reliability was another weak point. Unlike timing chains, which tend to last longer and require less frequent replacement, the Beta’s timing belt was prone to early wear and breakage.

If the belt snapped while the engine was running, the result was often catastrophic engine damage due to the interference engine design, where pistons and valves share the same physical space and can collide.

This meant expensive repairs or full engine replacements — a worst-case scenario for any owner trying to maintain a budget-friendly car. Routine belt replacements could mitigate this risk, but many consumers were either unaware or unprepared for such a crucial maintenance item.

Further compounding the Beta engine’s issues were less-than-stellar fuel economy, excessive vibration, and inconsistent idle behavior. These problems stemmed from poor engine mounts and rudimentary fuel management systems.

Although Hyundai made improvements in the later stages of the Beta engine’s life cycle, including switching to a dual overhead camshaft (DOHC) design and improving emissions control, these fixes were too little, too late for the early adopters. As a result, the Beta 2.0L engine is often cited by mechanics and enthusiasts as one of Hyundai’s most troublesome pre-2006 powertrains.

3. Hyundai D4CB 2.5L CRDi Diesel Engine (Early Models)

The Hyundai D4CB 2.5L CRDi diesel engine, used primarily in the Terracan, H-1 van, and early Santa Fe models in diesel-centric markets, seemed promising on paper — a strong, torquey engine for utility and off-road vehicles.

However, early models of the D4CB engine developed a reputation for being mechanically delicate and unreliable, especially under the high-load demands for which they were marketed.

A significant issue was the engine’s high-pressure fuel injectors, which were prone to clogging and failure. When these injectors malfunctioned, they could deliver improper fuel quantities, leading to hard starts, misfiring, and poor acceleration — all symptoms that made the vehicles feel sluggish and unpredictable.

Turbocharger failure was another frequently reported issue. The D4CB used a variable geometry turbocharger designed to provide a broad power band, but these turbos were sensitive to oil quality and service intervals.

If not maintained meticulously, the turbo could fail, often without warning, leading to a dramatic loss of power and expensive repair bills.

Some owners also reported increased exhaust smoke — a symptom of either turbo or injector issues — which further hurt the engine’s environmental performance and regulatory compliance in some regions.

In addition to fuel system and turbo concerns, the D4CB engine was vulnerable to timing chain tensioner failures, which led to noisy operation and potential engine damage if not caught early. Crankshaft position sensors were another Achilles’ heel, and failures often resulted in stalling and no-start conditions.

These cumulative issues made the D4CB diesel a high-maintenance engine that required constant vigilance, and it gained a reputation among owners and mechanics as being too temperamental for regular use. Hyundai eventually refined the design, but early D4CB-equipped models remain a cautionary tale in diesel ownership.

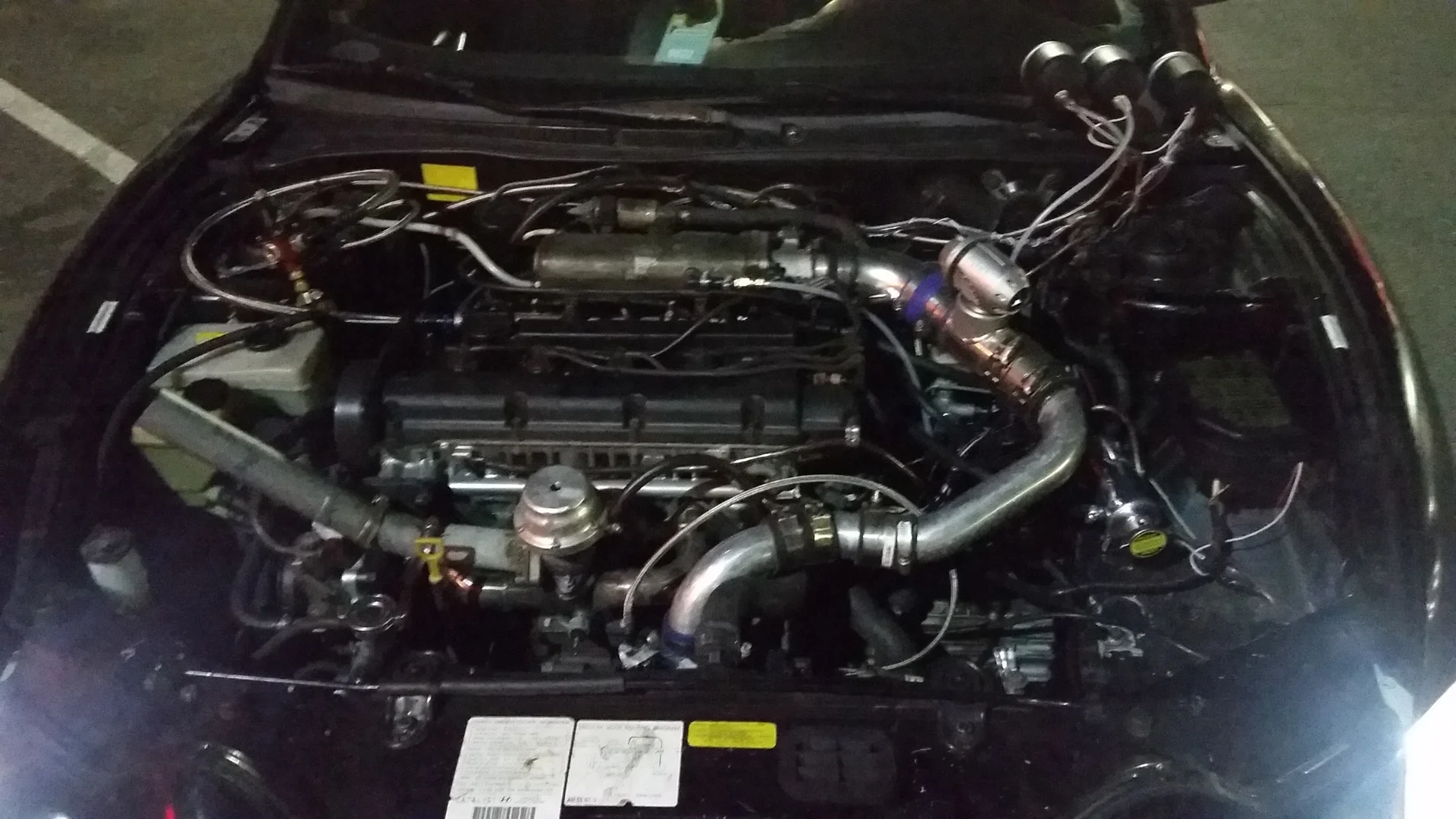

4. Hyundai 1.6L Turbo GDI Engine (First-Gen Versions)

When Hyundai introduced its first-generation 1.6L Turbo GDI engine, used in models such as the Veloster Turbo, Elantra Sport, and Tucson, it aimed to deliver a sporty, fuel-efficient option for performance-minded drivers. While the power output and throttle response were commendable, the engine quickly developed a problematic track record. One of the most pressing concerns was severe carbon buildup on the intake valves, a byproduct of the GDI system.

Without fuel flowing over the valves to clean them, they would accumulate thick deposits over time, leading to rough idling, hesitation, and reduced fuel economy. These issues often required expensive walnut shell blasting procedures to resolve, not exactly routine maintenance for most owners.

Another major flaw was related to oil consumption and premature turbocharger failure. Drivers often noticed blue smoke from the exhaust, which signaled oil burning within the combustion chamber, usually from worn valve guides or faulty piston rings. Some reported adding oil every 1,000–2,000 miles just to keep the engine from running dry.

The turbochargers, meanwhile, were not known for their longevity, especially in models that saw spirited driving. The combination of poor heat management and inconsistent oil flow often led to early turbo failure, with repair costs running into the thousands.

Compounding these mechanical flaws were complaints about engine knock and pinging, sometimes even when using the recommended octane fuel. ECU tuning and overly aggressive ignition timing were often blamed, and Hyundai issued software updates in some cases, but they didn’t solve the root mechanical issues.

While later versions of this engine saw some improvement with dual-injection setups (combining port and direct injection), the early 1.6L Turbo GDI engines remain a cautionary example of Hyundai’s early struggles with forced induction technology.

5. Hyundai 3.3L V6 (G6DB) in Select Model Years

The 3.3L V6 engine, codenamed G6DB, featured in mid-2000s Hyundai models like the Sonata, Azera, and Santa Fe, was a promising step toward more refined, powerful family sedans and SUVs. However, in certain model years — especially 2006 through 2009 — this engine displayed reliability issues that undermined its otherwise solid performance credentials.

One of the most common complaints involved excessive oil consumption, often due to premature valve stem seal wear. As the seals degraded, oil would seep into the combustion chamber, leading to smoke emissions, reduced efficiency, and increased emissions output.

Timing chain tensioners and guides were another sore spot. In multiple cases, these components wore out or broke prematurely, leading to chain slack, engine noise, and even timing misalignment.

Since the G6DB is an interference engine, a mistimed chain could cause catastrophic damage to valves and pistons. The cost of repair, often requiring full engine teardown, made this a major concern for owners, especially once the vehicle was out of warranty.

Another criticism of the G6DB engine was its refinement. Compared to competitors’ V6s of the era, Hyundai’s unit sometimes exhibited excessive vibration and roughness at idle or under load. While not necessarily a sign of mechanical failure, it diminished the perceived quality of the vehicle and made the engine feel less polished.

Despite being powerful on paper (with outputs around 240 hp), these issues combined to make certain model years of the G6DB one of Hyundai’s less impressive V6 efforts, prompting many to seek alternative powertrains in subsequent purchases.

ALSO READ: 10 Cars That Place USB Ports in the Worst Spots

Engines are more than just mechanical parts — they are the lifeblood of a car’s performance, reliability, and long-term value. Hyundai’s diverse engine portfolio reflects its broader evolution as a company: a brand once considered budget and basic that has grown into an international competitor known for technological ambition and bold innovation.

As this article has shown, Hyundai’s track record in engine development is a mixed bag of impressive achievements and disappointing setbacks.

The five engines that deserve praise illustrate how thoughtful engineering, investment in R&D, and learning from past mistakes can produce powertrains that are not only powerful but dependable and efficient. On the other hand, the five disaster engines show what happens when cost-cutting, rushed development, or untested new technologies go unchecked.

Engines like the Lambda 3.8L V6 and Smartstream 1.6L Turbo have proven that Hyundai can compete at a high level when it comes to delivering balanced performance and efficiency. These engines highlight Hyundai’s ability to deliver smoothness, power, and economy in everyday driving scenarios, all while maintaining long-term reliability.

They demonstrate Hyundai’s growing competency in designing engines that are globally competitive — engines that can be trusted by drivers in markets from North America to Europe to Asia. Moreover, these engines represent the future for Hyundai: cleaner, more efficient, and more adaptable to the evolving demands of consumers and environmental regulations.

In contrast, engines such as the early Theta II GDI or the D4CB diesel reveal the pitfalls that can occur when ambition outpaces quality control. Despite their innovative designs on paper, these engines often fell short in real-world performance, leading to consumer complaints, warranty claims, and, in some cases, legal battles.

For many owners, what was meant to be a reliable vehicle became a financial and mechanical burden. These failures didn’t just tarnish Hyundai’s image temporarily—they had lasting consequences in terms of brand trust and customer loyalty. Yet, they also acted as catalysts for change, pushing Hyundai to reevaluate its manufacturing standards and customer support strategies.

One important takeaway from this exploration is the critical role of continuous improvement in automotive engineering. While some Hyundai engines failed early and dramatically, the company has shown an admirable willingness to respond.

Whether it was issuing recalls, extending warranties, or redesigning flawed systems, Hyundai has often taken steps to address its missteps, albeit sometimes under pressure.

This responsiveness has helped the brand recover its credibility and build better, more reliable products over time. It’s a journey marked by both stumbles and strides, and one that highlights the competitive nature of the automotive industry, where excellence is not an option but a requirement for survival.

For prospective buyers and automotive enthusiasts alike, the lesson is clear: do your homework. Knowing the track record of an engine can mean the difference between years of worry-free driving and unexpected repair bills.

Fortunately, Hyundai’s recent engine offerings, especially those in the Smartstream and later GDI families, are significantly more refined and reliable than some of their predecessors.

The company’s trajectory continues to move upward, and its commitment to electrification, hybrid technologies, and efficiency-first design promises even better powertrains shortly.

In conclusion, Hyundai’s engine history is a microcosm of its corporate growth, full of lessons learned, ground gained, and occasional missteps. The praised engines stand as milestones of what Hyundai can achieve at its best, while the disaster engines serve as reminders that quality control and rigorous testing are non-negotiable in this fiercely competitive space.

By learning from both the triumphs and the failures, Hyundai is poised to write the next chapter of its story with smarter, cleaner, and more reliable engines that meet the needs of a new generation of drivers.

For now, recognizing the good and acknowledging the bad is what truly helps us understand the road Hyundai has traveled—and where it’s heading next.