Honda has long been celebrated for its engineering prowess and reliability, with many of its engines achieving near-mythical status for their longevity and resilience. From humble commuter cars to sportier models, Honda powerplants have gained a reputation for running hundreds of thousands of miles, often outliving the vehicles they power.

This reputation is built on decades of meticulous design, consistent innovation, and a deep understanding of mechanical durability. However, no manufacturer is immune to flaws or design missteps, and Honda’s history is also peppered with engines that, for various reasons, have developed reputations for premature failures and unexpected breakdowns.

Understanding which Honda engines are likely to outlast their chassis—and which are prone to untimely failure—is not only fascinating for enthusiasts and mechanics but is also essential for prospective buyers and owners who want to make informed decisions about maintenance and longevity.

Many Honda engines have become staples of the automotive world, praised for their robust construction, efficient designs, and resilience under stress. Engines like the B-series and K-series have been lauded for their ability to handle high mileage, aggressive driving, and demanding conditions while maintaining reliability.

Conversely, engines like some early J-series V6s and certain turbocharged variants have occasionally stumbled due to design oversights or the challenges of modern engineering trade-offs.

The longevity of an engine hinges on multiple factors: design philosophy, materials used, manufacturing tolerances, maintenance intervals, and operating conditions. Honda’s approach has often emphasized simplicity combined with smart engineering solutions such as VTEC variable valve timing, lightweight but strong materials, and efficient cooling and lubrication systems.

These elements work in harmony to reduce wear, prevent overheating, and maintain mechanical integrity over time. However, when any one of these factors falls short—whether through design compromises, manufacturing defects, or user neglect—the results can be disappointing and costly.

In this article, we delve into two contrasting groups within Honda’s extensive engine lineup. First, we explore five Honda engines renowned for their durability, engines that routinely clock in excess of 250,000 miles and are known to outlast the vehicles they power.

These engines showcase Honda’s ability to blend performance, efficiency, and longevity, often becoming favorites among tuners, restorers, and everyday drivers alike. We will look at the B-series, K-series, D-series, F-series, and L-series engines, examining the features and engineering principles that contribute to their legendary status.

On the other side of the spectrum, we will examine five Honda engines that have developed reputations for dying unexpectedly. These engines, despite Honda’s strong reputation, have demonstrated weaknesses—sometimes due to design flaws, sometimes due to the challenges posed by newer technologies like turbocharging or emissions controls.

The F22B, early J-series V6s, certain K24 variants, early R18s, and turbocharged L15B7s all carry cautionary tales about how even reliable brands can encounter stumbling blocks. We’ll unpack the issues these engines face, why they fail prematurely, and what owners can do—or should have done—to prevent these untimely ends.

This deep dive into Honda’s engine successes and failures is not just a technical exploration but a guide for enthusiasts, buyers, and mechanics. By understanding the engineering triumphs and challenges Honda has faced, readers can gain a richer appreciation of the brand’s legacy and the nuances involved in automotive durability.

Whether you are looking to buy a used Honda, maintain your current vehicle, or simply appreciate the art and science of engine design, this article will provide valuable insights into what makes some Honda engines almost indestructible while others struggle to stand the test of time.

ALSO READ: 5 Retired Models That Increased in Value and 5 That Didn’t

5 Honda Engines That Will Outlast the Chassis

1. The B-Series Engines (B16, B18)

The B-series engine family, especially the B16 and B18 variants, has become a benchmark in Honda’s engine history, revered for both their spirited performance and legendary durability.

Introduced in the late 1980s and dominating the 1990s with their presence in Civic Si, Integra, and CR-X models, these engines combine a remarkable ability to rev high with a mechanical design that favors strength and reliability.

The B-series architecture features a relatively simple DOHC setup with high-flow cylinder heads and a robust forged crankshaft and rods in the performance trims, which are essential in ensuring that the engine can endure not only long mileage but also aggressive driving. The use of forged internals in higher-spec variants greatly reduces the risk of failure from fatigue or stress over time, which contributes heavily to their longevity.

The B-series also benefits from an effective and well-thought-out cooling system, which addresses one of the most critical aspects of engine durability: heat management.

Overheating is a leading cause of premature engine failure, and Honda’s engineers made sure to design the cooling passages and radiators in a way that minimizes hotspots and maintains uniform temperature distribution throughout the engine block and cylinder head.

Combined with a reliable water pump and thermostats, this system ensures that the B-series can operate within its ideal temperature range, greatly reducing thermal stress on pistons, valves, and gaskets.

In addition to thermal management, the oiling system in these engines is notable for its use of oil squirters that spray oil directly under the pistons to cool them from below, a feature that greatly extends the life of piston rings and cylinder walls by reducing thermal expansion and friction.

Maintenance plays a vital role in unlocking the true longevity potential of B-series engines. Those owners who adhere strictly to timing belt replacement intervals, valve clearance adjustments, and regular oil changes tend to see these powerplants run smoothly beyond 300,000 miles without any significant overhaul.

The timing belt, while requiring replacement every 60,000 to 100,000 miles, depending on the model, is straightforward to service, and when changed properly with high-quality components, it rarely causes problems.

Moreover, the aftermarket support and enthusiast culture surrounding B-series engines is massive, meaning sourcing parts, upgrading components, and troubleshooting issues is well-documented and easily accessible.

This extensive community backing not only prolongs the lifespan of the engines but also fosters a culture of preservation and performance tuning that further cements the B-series’ legendary status.

Finally, the engines’ adaptability across various chassis and vehicle types also reflects their robustness. B-series engines have been known to outlive the vehicles they originally came in, often being transplanted into newer or more performance-focused builds.

The strong bottom end, reliable valve train, and proven fuel delivery system make them highly desirable candidates for swaps and rebuilds, underscoring just how durable and versatile these engines are.

In sum, the B-series engines are a shining example of Honda’s ability to create powerplants that are not only fun to drive but also remarkably tough, earning a spot as some of the longest-lasting engines in automotive history.

2. The K-Series Engines (K20, K24)

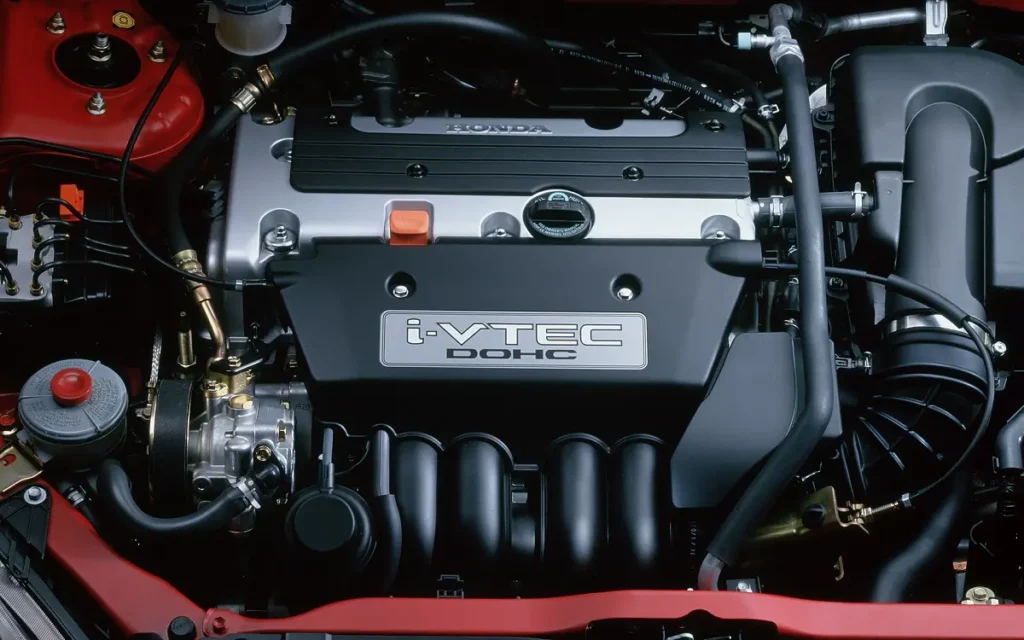

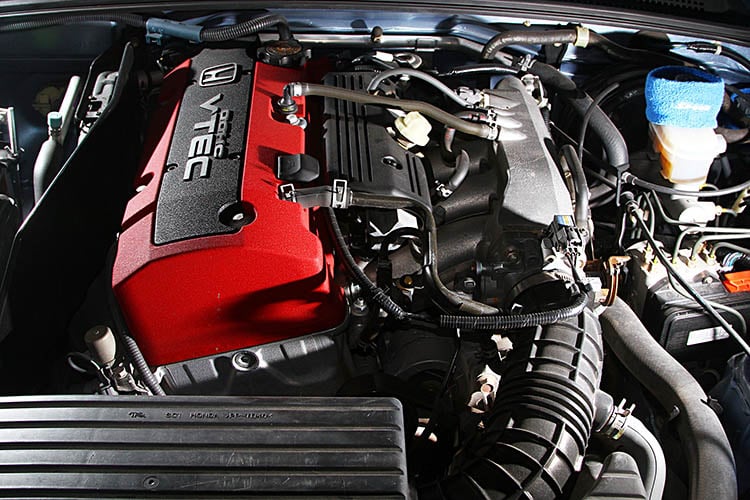

When Honda introduced the K-series engine family in the early 2000s, it represented a significant technological leap forward in terms of efficiency, power delivery, and durability. The K20 and K24 engines quickly garnered a reputation for being some of the most reliable and long-lasting powerplants Honda ever produced, becoming a favorite among enthusiasts and daily drivers alike.

These all-aluminum engines incorporate Honda’s advanced i-VTEC variable valve timing system, which optimizes power and efficiency without compromising reliability. The design simplicity, married with cutting-edge engineering, resulted in an engine that not only produces impressive power per liter but also boasts an impressive service life that routinely surpasses 250,000 miles.

One of the standout features of the K-series is its timing chain-driven setup, a notable departure from the timing belts used in many earlier Honda engines. Timing chains generally require less maintenance and are less prone to sudden failure compared to belts, which can snap and cause catastrophic engine damage.

The timing chain tensioners and guides in the K-series are engineered to maintain proper tension over the engine’s lifespan, although some early models required minor improvements to address wear. The result is an engine with significantly reduced risk of timing-related failures, contributing substantially to its longevity.

Additionally, the K-series uses direct oil feed systems that ensure critical components, such as camshafts and variable valve timing mechanisms, receive sufficient lubrication even under high load or extreme conditions, which is crucial for maintaining mechanical integrity over extended periods.

Cooling is another area where the K-series shines. These engines are designed with highly efficient cooling jackets and radiators capable of handling the thermal loads produced by modern fuel injection and advanced valve timing.

Honda’s engineers carefully optimized the combustion chamber and piston design to reduce heat buildup and avoid detonation or knocking, conditions that can accelerate wear and cause engine damage.

The result is a thermally stable powerplant that maintains consistent operating temperatures, reducing stress on gaskets, seals, and internal components. Combined with proper oil changes using high-quality synthetic lubricants, the K-series engines can run for hundreds of thousands of miles with minimal issues.

Furthermore, the K-series engine’s internals, particularly in the higher-performance trims like the K20A found in the Civic Type R, feature forged pistons and stronger connecting rods. This enhances the engine’s ability to handle high RPMs and increased power without suffering premature fatigue or failure.

This robustness, coupled with Honda’s precision engineering, has made the K-series a favorite for both stock reliability and tuning potential.

The engine’s versatility extends from compact cars to sporty coupes and even lightweight race cars, proving its durability across a wide range of applications. Enthusiasts and mechanics alike praise the K-series for its combination of refinement, reliability, and the ability to outlast many of the chassis they were originally installed in.

3. The D-Series Engines (D15, D16)

The D-series engines, particularly the D15 and D16 variants, represent Honda’s commitment to building efficient, reliable, and low-maintenance powerplants primarily aimed at economy models such as the Civic.

While lacking the high-revving excitement of their B- and K-series siblings, D-series engines have earned respect as rugged, straightforward engines that can easily rack up impressive mileage with minimal intervention.

These SOHC engines employ a simple design philosophy that favors fewer parts, lower operating stresses, and robust materials, which altogether make them ideal for drivers who value durability and low running costs above outright performance.

One of the critical factors behind the D-series’ longevity is its relatively low compression ratios and conservative tuning. These characteristics reduce the internal stresses and thermal loads that cause wear and tear on components like pistons, rings, and valves.

The engine’s simple valve train and lack of complex variable valve timing systems mean fewer components are subject to failure or require adjustment over the life of the engine.

Furthermore, the use of a timing belt rather than a chain, while necessitating maintenance at prescribed intervals, means the engine operates quietly and reliably with proper service. Many D-series engines have been documented to surpass 200,000 miles with original internals intact, provided owners maintain oil and coolant properly.

The D-series also benefits from a well-engineered cooling system that prevents overheating, a common killer of engines in daily-use cars. Its cooling passages and thermostat work effectively to keep the engine in its optimal temperature range even in demanding stop-and-go driving conditions.

Oil delivery is simple but effective, providing sufficient lubrication without the complications seen in more advanced engines. Additionally, the simplicity of the D-series makes repairs and maintenance straightforward and affordable, which indirectly contributes to its long life as owners are more likely to keep up with preventative upkeep.

Finally, the D-series engines have a reputation for being forgiving to imperfect maintenance. Many examples survive with minimal repairs despite occasional neglect, which is a testament to their inherent mechanical resilience.

These engines are favored in the used market for their proven track record of durability, ease of maintenance, and the abundance of affordable parts. The D-series exemplifies Honda’s ability to build everyday engines that reliably deliver service for years, often far outlasting the vehicles they power.

4. The F-Series Engines (F20, F22)

The F-series engines, particularly the F20 and F22 variants, are another group of Honda powerplants well known for their durability and balanced performance. Found primarily in mid-size vehicles such as the Accord and Prelude from the late 1980s through the 1990s, these engines occupy a sweet spot between the smaller D-series and the sportier B-series.

The F-series typically features either SOHC or DOHC cylinder heads and is recognized for providing strong low-end torque, a smooth powerband, and a build quality that allows for extended service lives.

One factor that contributes significantly to the F-series’ longevity is its larger displacement. By producing power through increased displacement rather than high RPMs, the engine reduces strain on internal parts, decreasing wear rates and prolonging lifespan.

The F-series engines also utilize a durable aluminum block and cylinder head that efficiently dissipate heat and resist warping or cracking, common culprits in premature engine failures.

The valves, camshafts, and timing components in the F-series are engineered to withstand the stresses of everyday driving and occasional spirited use, providing a reliable service window often exceeding 250,000 miles.

The oiling and cooling systems in the F-series further enhance its reputation for reliability. Honda implemented well-designed oil passages that ensure consistent lubrication of the camshafts, crankshaft, and valvetrain components, mitigating the risk of accelerated wear due to friction or heat.

Cooling system components are similarly robust, with many owners reporting few issues with overheating or cooling failures. The timing belt system, while requiring scheduled maintenance, is relatively easy to replace and, when properly serviced, rarely causes engine damage.

Importantly, the F-series’ combination of dependable performance and proven durability makes it a popular choice for those who want a no-nonsense, long-lasting engine with enough torque for everyday driving needs.

This balance has allowed many F-series engines to outlast the vehicles they were originally installed in, making them sought after in the used engine market for replacements and rebuilds. The F-series is a testament to Honda’s ability to engineer engines that withstand the test of time without sacrificing everyday usability.

5. The L-Series Engines (L15, L13)

The L-series engines, introduced in the late 2000s, represent Honda’s modern approach to creating efficient, compact powerplants primarily for small cars like the Fit and HR-V. Despite being relatively new compared to older Honda engines, the L-series has rapidly developed a reputation for exceptional longevity and reliability, often outliving the vehicles they power.

These SOHC engines incorporate advanced i-VTEC technology, which optimizes valve timing for fuel efficiency while maintaining durability, ensuring they meet modern emissions standards without sacrificing long-term dependability.

One key to the L-series’ durability is its compact and lightweight aluminum design combined with a focus on simplicity. The engines are designed with fewer moving parts and optimized oiling and cooling systems that minimize the risk of wear and overheating.

Despite their small size, L-series engines maintain robust construction standards, with piston rings, cylinder walls, and valves designed to resist premature wear. The relatively low compression ratios and conservative power output reduce the mechanical and thermal stresses that can shorten engine life, further enhancing longevity.

The cooling system on L-series engines is highly efficient, employing modern thermostats and radiator designs that maintain optimal operating temperatures even in hot climates or heavy traffic.

Oil flow is carefully controlled to critical engine parts to ensure continuous lubrication without excessive oil consumption, a problem that sometimes plagues newer engines from other manufacturers. These design choices make the L-series highly resistant to common causes of engine failure such as overheating, oil starvation, and detonation.

Owners frequently report L-series engines surpassing 200,000 miles with little more than routine maintenance such as oil changes, air filter replacements, and timely servicing of belts and fluids. The modern manufacturing processes Honda applies to these engines also ensure tighter tolerances and higher quality control, reducing the chances of manufacturing defects that might cause early failures.

The L-series is an excellent example of how Honda continues to refine its approach to engine design, combining fuel efficiency, performance, and durability into a package that consistently outlasts the vehicles it powers.

5 Honda Engines That Die Unexpectedly

1. The F22B Engine

The F22B engine, found predominantly in the Honda Accord and Prelude models from the early to mid-1990s, has gained a reputation that unfortunately leans more toward unpredictability and premature failures rather than longevity. Unlike some of Honda’s other well-regarded engines, the F22B was plagued by design choices and engineering compromises that led to issues such as head gasket failures and oil consumption problems.

One of the main contributors to these problems is the engine’s cylinder head design, which suffered from poor cooling efficiency in critical areas. This caused hotspots that led to the deterioration of the head gasket material over time, especially in higher mileage engines or those exposed to poor maintenance conditions.

The result was coolant leaks into the combustion chamber or oil passages, creating a cascade of reliability issues that often culminated in catastrophic engine failure if left unaddressed. Moreover, the F22B’s valve seals and piston rings were also points of concern, as oil consumption became a common complaint among owners.

The excessive oil burning not only created smoke and pollution problems but also reduced engine lubrication efficiency, leading to accelerated wear on the cylinder walls and piston skirts. When lubrication suffers, the engine’s internal components run hotter and encounter greater friction, which can cause irreversible damage.

Despite Honda’s attempts to refine the engine over its production cycle, the F22B never fully escaped these fundamental design weaknesses. For owners who neglected routine maintenance or drove the cars hard, the chances of early engine failure increased dramatically.

Another factor that contributed to the F22B’s inconsistent durability was its timing belt-driven valvetrain. Timing belts are inherently maintenance-heavy components, and failure to replace them at the manufacturer’s recommended intervals often results in severe engine damage due to valve-to-piston contact, a classic “interference engine” problem.

Unfortunately, this was a common source of unexpected engine death for many F22B-powered vehicles because some owners either forgot or delayed belt replacement, or the belt tensioners and pulleys failed prematurely. These failures could lead to a sudden and total breakdown, leaving the engine unusable without a major rebuild or replacement.

Despite these drawbacks, the F22B still has some redeeming qualities, such as decent low-end torque and smooth drivability, which made it popular during its heyday. However, its mechanical vulnerabilities and maintenance sensitivity meant that many of these engines did not live up to Honda’s usual reputation for bulletproof reliability.

When they did fail, the breakdowns often came abruptly and with little warning, turning what might have been a long-lasting powerplant into a costly headache for owners. It’s a classic example of an engine whose design trade-offs prioritized immediate performance gains or cost savings over enduring durability.

2. The J-Series V6 Engines (J30, J35 Early Models)

Honda’s J-series V6 engines, particularly the early 3.0L J30 and 3.5L J35 models from the late 1990s and early 2000s, marked Honda’s first serious foray into the V6 market.

While these engines offered smooth power delivery and respectable performance in vehicles like the Accord V6 and Odyssey minivan, their early iterations were unfortunately marred by a series of reliability issues that led to premature failures and unexpected breakdowns.

One of the most notorious problems centered around the timing chain tensioners and guides, which were prone to wear and failure, especially in the initial production years. When these components failed, the timing chain could jump teeth or even slip entirely, throwing the engine’s timing out of sync and causing serious valve damage.

Beyond timing chain issues, many early J-series engines also suffered from coolant leaks stemming from faulty water pumps and leaky gaskets. These leaks often went unnoticed until they caused overheating, warping cylinder heads, or damaging the head gasket.

The combination of these cooling system flaws and timing chain vulnerabilities meant that without vigilant maintenance and early repairs, these engines were susceptible to unexpected and costly failures.

Additionally, oil consumption was a known concern with some J-series engines, largely due to piston ring wear and valve guide seal deterioration, further complicating their reliability profile.

What made these failures particularly frustrating for owners was that the symptoms often appeared suddenly and without much warning. The smooth-running V6 would suddenly exhibit warning signs like coolant loss, overheating, or unusual engine noises, and before long, catastrophic failure could follow.

These issues dented Honda’s otherwise sterling reputation for durability and required many owners to replace or rebuild engines far earlier than expected.

Honda engineers did address some of these early problems in later versions of the J-series engines by redesigning tensioners, improving cooling system components, and refining internal seals, but the early models remain a cautionary tale in Honda’s engine lineup.

Maintenance on early J-series engines is critical, and many of the premature failures were linked to neglect or delays in addressing known weak points. For example, replacing timing chain tensioners at the first sign of rattle or slack is essential to prevent the chain from skipping.

Similarly, proactive coolant system maintenance can help avoid overheating-related head gasket failures. However, for many owners unaware of these quirks, the unexpected demise of their V6 was both costly and disappointing. This highlights the importance of understanding specific engine design vulnerabilities to maintain longevity and avoid sudden failures.

3. The K24A4 Engine (Early K24 Models)

While the K-series as a whole is celebrated for its longevity, some early versions of the K24 engine, particularly the K24A4 found in early 2000s Accords and CR-Vs, developed a reputation for premature head gasket failures and other reliability issues.

Unlike the later and more refined K24 variants, the early K24A4 engines had a cylinder head and block design that proved prone to overheating and gasket deterioration under certain conditions. These issues often manifested as coolant leaks, white smoke from the exhaust, and rough running, all symptoms indicative of a failing head gasket.

One root cause of these failures was the engine’s cooling system, which in early K24A4s lacked some of the improvements found in later versions. Inefficient coolant flow and localized overheating created stress points that compromised the head gasket material over time.

While the engine block and head were made from durable aluminum alloys, the mating surfaces and gasket materials were less resistant to the harsh thermal cycles the engine endured.

In addition to thermal challenges, some early K24A4 engines experienced problems with the timing chain tensioner and guides, similar to those seen in J-series V6 engines. Timing chain noise and eventual failure could lead to timing issues that further exacerbate engine stress and accelerated wear.

Owners who maintained strict adherence to coolant changes, timing chain inspections, and temperature monitoring were more likely to avoid catastrophic failures, but many drivers were caught off guard by the sudden nature of these problems.

The premature head gasket failures often occurred between 100,000 and 150,000 miles, well below what Honda enthusiasts typically expect from the brand. As a result, the K24A4 engine earned a mixed reputation that somewhat tarnished the otherwise stellar image of the K-series family.

Despite these drawbacks, the K24A4 still possesses many of the fundamental strengths of the K-series, including excellent power delivery and efficient fuel consumption. However, the early design flaws in cooling and timing components serve as a reminder that even the most reliable engine families can have weak points.

Honda addressed many of these issues in later K24 variants by upgrading cooling passages, improving gasket materials, and refining timing chain components. For current owners of early K24 engines, vigilance and preventive maintenance are key to avoiding unexpected engine deaths and extending service life.

4. The R18 Engine (Early Models)

The R18 engine, which powers early versions of the Honda Civic starting in the mid-2000s, is another engine that has gained notoriety for its unexpected failures and shorter-than-anticipated lifespan. While it was praised at launch for its fuel efficiency and smooth operation, many owners soon reported problems related to oil consumption, valve train noise, and in severe cases, engine seizure.

The root causes of these issues often stemmed from the engine’s design compromises aimed at meeting strict emissions and fuel economy regulations while keeping costs low.

One of the main trouble spots in the early R18 engines was the piston ring design, which allowed excessive oil to pass into the combustion chamber, resulting in premature oil consumption and buildup of deposits on valves and spark plugs. This oil burning not only created smoke but also reduced the effectiveness of the engine’s lubrication, accelerating wear on cylinder walls and pistons.

Another significant issue was valve lifter failure, where the hydraulic lifters that help maintain zero valve clearance would collapse or clog, resulting in a noisy valvetrain and reduced engine performance. These valve train problems often signaled underlying mechanical degradation and foretold a shorter engine life if left unresolved.

In addition to mechanical wear, some R18 engines suffered from overheating issues due to cooling system inefficiencies, such as faulty thermostats or inadequate radiator performance. Overheating can warp cylinder heads, blow head gaskets, and cause extensive damage that often results in the engine dying prematurely.

Moreover, many early R18 engines were equipped with timing chains and variable valve timing systems that, while designed to reduce maintenance, sometimes exhibited premature chain guide wear or tensioner failures. When these timing components failed, it often led to catastrophic internal damage, requiring full engine rebuilds or replacements.

The problems experienced with the early R18 highlight the challenges Honda faced in balancing environmental regulations, performance, and reliability in a modern engine.

While many owners never encountered major issues, those who did often found repairs expensive and unexpected, given Honda’s historical reliability. The R18 serves as a reminder that new engine technologies, while innovative, can sometimes introduce new failure points that take time to address.

5. The L15B7 Engine (Turbocharged L-Series)

The L15B7 engine, a turbocharged variant of Honda’s L-series introduced in the mid-2010s in vehicles like the Civic Si, represents the brand’s latest attempt to combine small displacement with forced induction to meet modern efficiency and power demands.

However, despite its advanced engineering and impressive power-to-weight ratio, the L15B7 has been reported to suffer from unexpected failures related to turbocharger reliability, carbon buildup, and cooling system issues.

These problems are partly a result of the increased thermal and mechanical stresses placed on a small engine by turbocharging, which can accelerate wear on components not originally designed for such loads.

One of the major concerns with the L15B7 is carbon buildup on intake valves, a common issue for direct-injected turbo engines. Because fuel is injected directly into the cylinder rather than the intake tract, the intake valves do not get cleaned by fuel spray, causing deposits to accumulate over time.

This buildup can reduce engine efficiency, cause misfires, and increase the likelihood of valve damage or premature wear. In severe cases, it can lead to loss of compression and sudden engine performance degradation. While this issue is somewhat universal among direct injection engines, the L15B7 seems to be particularly susceptible due to its specific intake and combustion chamber design.

Turbocharger failures have also been reported, often linked to oil supply issues, heat soak, or mechanical fatigue from prolonged high boost use. When the turbo fails, it can lead to a sudden loss of power and potentially damage the engine if debris from the turbo enters the intake tract.

Additionally, the L15B7’s cooling system is under more strain than naturally aspirated engines, and overheating risks are increased if the cooling components are not properly maintained or if coolant leaks develop. Overheating can quickly lead to head gasket failures or warped components, shortening the engine’s lifespan.

Despite these challenges, the L15B7 remains a powerful and technologically advanced engine with many loyal users. However, the complexity and stresses of turbocharging mean that without meticulous maintenance and careful driving habits, these engines can fail unexpectedly and at mileage levels that surprise many owners.

This modern turbocharged L-series serves as a cautionary example that while smaller turbo engines offer efficiency and power gains, they also require a heightened level of care to achieve the durability Honda is known for.

ALSO READ: 5 Cars With Zero Depreciation Over 5 Years and 5 That Drop Instantly

Honda’s legacy as a manufacturer of durable, efficient, and performance-oriented engines is undeniable. The company has built a brand synonymous with reliability, and many of its power plants have become industry benchmarks for longevity. However, as this article has shown, not all Honda engines are created equal when it comes to standing the test of time.

The stories of the five engines that outlast their chassis and the five that have surprised owners with unexpected failures reveal a nuanced picture of automotive engineering, one shaped by innovation, compromise, and evolving technology.

The engines that endure the longest—such as the B-series, K-series, D-series, F-series, and newer L-series—demonstrate Honda’s capacity for designing powerplants that are robust, efficient, and forgiving. These engines benefit from simple yet effective engineering solutions: strong internal components, well-designed cooling and oiling systems, and timing mechanisms that minimize catastrophic failures.

Their durability is often enhanced by an enthusiastic community of owners and aftermarket support, making maintenance and repairs accessible and affordable. Moreover, these engines have proven their versatility by being swapped into various chassis, tuned for higher performance, and adapted for diverse applications, further extending their lifespan beyond initial expectations.

On the flip side, the engines that have developed reputations for early failure highlight the complexities and risks inherent in automotive engineering.

The F22B’s head gasket woes, early J-series V6 timing chain issues, early K24A4 cooling and gasket failures, R18 valve train and oil consumption problems, and the turbocharged L15B7’s carbon buildup and turbocharger challenges illustrate how design choices, material limitations, and new technologies can sometimes backfire.

These cases underscore the importance of rigorous maintenance and proactive care but also remind us that even established manufacturers face hurdles as they push the boundaries of performance and efficiency.

Importantly, many of the “unexpected failure” engines improved over time as Honda refined designs, addressed known issues, and implemented better quality control measures.

This iterative process reflects the automotive industry’s ongoing effort to balance performance, emissions, cost, and durability—a balancing act that becomes more challenging as regulations tighten and consumer demands evolve. For owners, understanding the particular vulnerabilities of their engine model can mean the difference between early failure and long-term reliability.

For buyers and enthusiasts, the takeaway is clear: not all Honda engines are equally bulletproof, but with knowledge, careful maintenance, and attention to early warning signs, many of Honda’s engines can deliver exceptional service life.

Investing in preventative care, replacing timing belts or chains on schedule, monitoring coolant and oil health, and addressing symptoms promptly can significantly improve engine longevity. Additionally, selecting models with proven reliable engines can save money and headaches in the long run.

In conclusion, Honda’s engine lineup offers a fascinating study in contrasts—between those engines that exemplify longevity and those that serve as cautionary tales. This dichotomy enriches our understanding of what it takes to build a reliable engine and the factors that influence whether it will outlast its chassis or succumb to premature failure.

Honda’s commitment to engineering excellence remains strong, and its ongoing innovations promise that future engines will continue to push the envelope of durability and performance.

By learning from past successes and failures, owners and enthusiasts can better navigate the world of Honda engines, ensuring they choose and maintain powerplants that meet their needs and stand the test of time.