Safety has always been a paramount concern in automotive design, shaping how vehicles evolve through decades of technological progress and regulatory changes.

Consumers naturally assume that newer models automatically bring enhanced safety, thanks to advancements like airbags, electronic stability control, and driver-assist technologies. However, this is not always the case.

In many instances, the progression of car design, driven by factors such as fuel efficiency, emissions standards, and cost-cutting, has resulted in unintended safety regressions.

Structural compromises, lighter materials, and overreliance on electronic aids sometimes undermine the fundamental crashworthiness that older generations of cars provided.

This complex interplay between innovation and safety has created a curious landscape where some older vehicles, designed in an era prioritizing heavy-duty build quality and mechanical robustness, remain safer in crashes than their sleeker, lighter, and more technologically advanced descendants.

In this article, we explore two contrasting phenomena in automotive safety: vehicles where older generations outperform newer models in occupant protection, and models where the evolution has unfortunately led to a regression in crash safety.

Through detailed examination of five vehicles where the older generation was demonstrably safer, we highlight the enduring value of robust steel frames, simpler mechanical designs, and sheer vehicle mass.

Conversely, we analyze five cars where recent redesigns, despite incorporating cutting-edge electronics, have seen structural integrity compromised due to weight reduction and material changes, leading to higher risks during collisions.

By delving into these case studies, this article aims to provide a nuanced understanding that vehicle safety is multifaceted. It reminds us that while technological innovation is vital, it cannot fully replace the physical protections inherent in well-engineered, solidly built vehicles.

The lessons drawn here underscore the importance for consumers, manufacturers, and regulators alike to carefully balance advances in efficiency and technology with an uncompromising commitment to occupant protection.

Also Read: 5 Used Cars That Pass Inspection Every Time and 5 That Always Need Something

5 Cars Where Older Generations Were Safer

1. Jeep Grand Cherokee (Early 2000s vs. Recent Models)

The Jeep Grand Cherokee WJ generation (1999–2004) earned a reputation for its rugged durability and robust safety due largely to its body-on-frame construction and heavyweight design.

Unlike many modern SUVs that transitioned to unibody frames for weight savings and improved handling, the WJ retained a heavy steel ladder-frame that absorbed and distributed crash forces exceptionally well.

This frame, combined with thick steel reinforcements in key areas such as the doors, roof pillars, and floor pan, meant that in a collision, the vehicle’s structure could resist intrusion effectively, protecting passengers from direct impact forces.

The WJ’s overall heft was both a blessing and a curse, making it less nimble but far more resilient in severe accidents. Additionally, its suspension geometry and high ride height contributed to stability and reduced the likelihood of rollovers, a crucial factor in SUV safety.

The later WK2 Grand Cherokee models (2011 onward), by contrast, represent a significant shift toward a unibody chassis with extensive use of lighter aluminum and high-strength steel alloys aimed at improving fuel economy and agility. However, this structural lightening also introduced challenges in crash energy management.

The unibody design relies heavily on carefully engineered crumple zones to absorb collision forces, but these zones can sometimes be overwhelmed in high-energy crashes, leading to increased cabin intrusion.

Furthermore, the shift toward electronic safety aids such as stability control and multiple airbags, while beneficial, cannot fully compensate for fundamental structural weaknesses.

Real-world crash data and IIHS tests have revealed that newer Grand Cherokees occasionally underperform in side-impact and rollover ratings compared to their older counterparts.

Another dimension to consider is the repairability and durability of the older Grand Cherokee. Its straightforward, mechanical design meant fewer electronic components vulnerable to failure after an accident, improving the reliability of safety-critical systems over the vehicle’s life.

The newer models, with their complex sensor arrays and integrated driver assistance, introduce potential points of failure that, if malfunctioning, can reduce the effectiveness of safety features during crashes.

Additionally, the older WJ’s more simplistic interior and mechanical simplicity contributed to occupant survival in severe collisions because fewer sharp or protruding elements inside the cabin might cause injury.

Lastly, consumer perceptions and anecdotal crash reports often praise the early 2000s Grand Cherokee for its “tank-like” feeling in accidents.

While this phrase may carry a nostalgic bias, it reflects a real-world appreciation for the WJ’s ability to maintain occupant space and protect its passengers in crashes involving both smaller vehicles and roadside obstacles.

The legacy of this generation serves as a reminder that while automotive design is evolving toward efficiency and technology, the sheer mass and steel robustness of older SUVs remain powerful contributors to occupant safety.

2. Volvo 240 Series (1974-1993)

The Volvo 240 is widely celebrated as one of the most durable and safest cars of its era, establishing a legacy rooted in the company’s deep commitment to passive safety engineering.

Unlike modern vehicles that emphasize electronic aids and active safety systems, the 240’s safety design centered around an exceptionally strong steel safety cage, built from thick-gauge steel that created a rigid shell protecting occupants from intrusion during collisions.

The boxy shape was no accident; it allowed engineers to maximize structural integrity in all directions, providing predictable deformation patterns and reducing the risk of occupant injury.

Volvo’s pioneering three-point seatbelt was standard well before legislation mandated it, highlighting their safety-first philosophy. In many ways, the 240’s design reflected an era where crashworthiness was a matter of brute strength and mechanical simplicity rather than electronic sophistication.

Another remarkable aspect of the 240 is its ability to survive crashes with minimal cabin deformation, especially in frontal and side impacts. The thick steel doors, heavy pillars, and reinforced floor pan contributed to a passenger compartment that remained intact even in high-speed crashes.

For example, side-impact tests from the era consistently showed better results for the 240 than many contemporaries due to its reinforced side structures.

This robust construction also contributed to excellent rollover resistance, a critical factor for family cars of its time. Despite lacking airbags and advanced electronics, the 240’s design prioritized physical protection first and foremost, leading to a stellar safety record.

In comparison, newer Volvos, while packed with airbags, electronic stability programs, and collision mitigation systems, sometimes do not fare as well structurally in certain crashes. The transition to lighter materials like aluminum and composites to meet modern efficiency standards has introduced new challenges.

Thinner panels and complex multi-material joints can behave unpredictably under crash stress, potentially compromising the rigid safety cage’s integrity.

While newer Volvos benefit from cutting-edge sensor suites and active safety tech, these systems are vulnerable to failure or limitations in edge cases, whereas the old-school strength of the 240’s steel body was a passive, always-present shield.

Finally, the Volvo 240 is revered by enthusiasts and safety experts alike for its “built like a tank” reputation. This sturdiness was not just marketing hyperbole but an engineering achievement that prioritized occupant survival above all else.

Even decades after production ceased, the 240’s safety performance in crash tests and real-world accidents remains a high benchmark for durability and occupant protection.

It exemplifies how older automotive design philosophies, focusing on mass, steel quality, and structural simplicity, sometimes offer better protection than modern lightweight, tech-heavy vehicles.

3. Toyota Land Cruiser 80 Series (1990-1997)

The Toyota Land Cruiser 80 series represents a pinnacle of traditional SUV engineering, with a robust body-on-frame chassis that emphasizes durability, off-road capability, and occupant protection.

This generation was built during a time when SUVs were designed to be rugged, go-anywhere vehicles with heavy steel frames capable of enduring extreme stresses and impacts.

The ladder frame construction allowed the chassis to absorb collision energy effectively while minimizing deformation of the occupant cabin.

This is crucial in off-road environments where rollovers and impacts with obstacles are common. The Land Cruiser 80 also featured thick steel reinforcements in key areas like the A and B pillars, as well as large crumple zones designed to absorb frontal collision energy.

One of the 80 series’ defining safety characteristics was its relatively low center of gravity compared to later SUVs, which helped improve rollover resistance. Coupled with the heavy steel frame and suspension designed for rugged terrains, this vehicle was less prone to tipping during sharp maneuvers or uneven ground.

In contrast, many modern SUVs sacrifice these characteristics for lower weight and better fuel economy, often leading to higher rollover risks.

The Land Cruiser 80’s weight itself, often exceeding 5,000 pounds, was a significant factor in its safety performance; its mass could absorb and dissipate collision energy more effectively than many lighter, newer vehicles.

Compared to modern Land Cruisers, which increasingly rely on unibody construction, aluminum components, and electronic safety systems, the 80 series favored a straightforward, mechanical approach to safety.

While newer models have introduced multiple airbags, traction control, and collision avoidance systems, the fundamental structural protection offered by the old ladder frame is difficult to replicate in lighter, more aerodynamic designs.

In crash scenarios involving heavy impact or rollovers, the 80’s rugged design still holds advantages in occupant compartment integrity and resistance to deformation.

Lastly, the Land Cruiser 80’s legacy in safety is bolstered by its real-world track record among off-road enthusiasts, humanitarian organizations, and military users worldwide.

These vehicles are often praised for their ability to protect occupants in harsh, unpredictable environments where crashes are more severe and complex than typical urban accidents.

This enduring reputation demonstrates that heavier, mechanically simple vehicles built with a focus on structural durability can outperform many modern SUVs when it comes to crash survivability.

4. Mercedes-Benz W124 (1984-1995)

The Mercedes-Benz W124 series is often heralded as one of the safest vehicles of its time, setting benchmarks for automotive safety engineering in the 1980s and early 1990s.

This generation incorporated innovative features such as rigid passenger safety cages, front and rear crumple zones designed to absorb impact energy, and one of the earliest uses of airbags and anti-lock braking systems as standard or optional features.

The W124’s structural design was revolutionary in how it managed crash energy: the rigid cabin frame remained intact while front and rear sections crumpled progressively, protecting occupants from sudden deceleration forces.

One of the W124’s standout safety attributes was its over-engineered steel construction. Unlike modern cars that focus on lightweight materials to improve efficiency, the W124 featured thick steel pillars and reinforced doors that significantly increased torsional rigidity and crashworthiness.

This approach led to an exceptionally strong safety cage that limited passenger compartment deformation even in severe frontal and side impacts. The design philosophy emphasized passive safety — the vehicle’s physical capacity to protect occupants even before electronic safety systems came into play.

Modern Mercedes models have moved toward lighter, more complex body designs incorporating aluminum and composite materials, which provide weight savings but introduce different failure modes in collisions.

While modern cars benefit from advanced electronic safety features like adaptive cruise control, collision avoidance, and numerous airbags, these systems are dependent on sensor accuracy and software reliability. The W124’s safety, however, was inherent in its structure — a physical, mechanical safeguard less susceptible to electronic failure.

Moreover, the W124’s safety legacy is supported by decades of real-world crash data demonstrating its occupant protection superiority. The vehicle’s ability to protect passengers in high-speed collisions remains impressive by today’s standards, underscoring the enduring value of strong, simple mechanical engineering.

Enthusiasts and safety experts often praise the W124 as an example of safety design where robustness and quality of materials were paramount, resulting in a vehicle that could withstand impacts that might seriously compromise modern, lighter cars.

5. Honda Accord (Early 1990s Models)

The early 1990s Honda Accord models, especially those from 1990 to 1993, represent a time when Honda combined solid structural design with emerging safety technology to produce vehicles that were notably safe for their class.

The Accords of this era featured a unibody construction with extensive use of high-strength steel in critical areas such as door beams, pillars, and the floor pan.

This focus on structural integrity meant the cars could withstand frontal and side impacts with minimal cabin intrusion. Unlike many contemporary cars that prioritized styling over substance, the early 90s Accords struck a balance between design and crashworthiness.

One important aspect of the safety advantage of these older Accords was their mass and weight distribution. They were heavier than many newer compact sedans, which improved crash performance by providing more inertia to resist sudden changes in velocity during collisions.

The crumple zones were well-engineered to deform progressively, absorbing impact energy without transferring excessive forces to occupants. Additionally, Honda was among the early adopters of dual airbags in this generation, offering enhanced protection at a time when airbags were not yet ubiquitous.

In recent generations, the Accord has evolved significantly, shedding weight and adopting aerodynamic shapes to meet fuel economy regulations and consumer preferences.

While these changes have improved efficiency and added advanced safety technologies such as lane-keeping assist, adaptive cruise control, and automatic emergency braking, the structural aspects have become more complex and lighter.

Thinner body panels, increased use of aluminum, and weight-saving techniques sometimes result in increased intrusion during severe crashes, as newer structures rely heavily on controlled deformation zones that may fail under extreme conditions.

Crash statistics and insurance data occasionally reveal that early 90s Accords perform as well or better than newer models in certain crash types, particularly side impacts and rollovers. The older model’s simpler, heavier, and sturdier bodywork provides reliable protection even when electronic systems are absent or malfunctioning.

This highlights an important lesson in automotive safety: technology supplements but does not replace the need for a fundamentally sound and robust structural design.

5 Cars Where Newer Models Regressed in Safety

1. Subaru Outback (Early 2000s vs. Recent Models)

The Subaru Outback has long been celebrated as a reliable and safe vehicle, particularly in its early 2000s iterations when it combined solid engineering with proven safety principles. Early Outbacks boasted robust unibody frames, thick steel reinforcements, and straightforward mechanical designs that contributed to strong crash performance.

The weight of these vehicles was balanced well with an emphasis on ruggedness, stability, and durability, especially given Subaru’s focus on all-wheel-drive capability that helped in slippery conditions.

The Outback’s structural integrity was a significant factor in its ability to protect occupants in frontal and side impacts, with well-engineered crumple zones and strong safety cages ensuring minimal intrusion into passenger space. These vehicles also had a reputation for excellent roof strength, an essential attribute given the SUV-like design that exposes occupants to rollover risks.

However, in more recent years, Subaru has shifted to lighter materials and more complex body constructions to improve fuel efficiency and meet stringent emissions regulations.

While newer models are packed with driver-assistance technologies like EyeSight driver assist, adaptive cruise control, and automatic emergency braking, their fundamental structural design has seen some compromises.

Reports from crash tests and consumer feedback indicate that the newer Outbacks show increased intrusion in certain side-impact collisions, partly due to thinner body panels and lighter reinforcements.

This regression is problematic because physical structural integrity remains the last line of defense when electronic systems fail or are overwhelmed in real-world crashes. Moreover, some recent models have exhibited slightly worse rollover resistance compared to their heavier predecessors, raising concerns about stability under emergency maneuvers.

Another point to consider is the increased complexity of modern Outbacks, which, while technologically advanced, introduces potential points of failure.

The reliance on electronic stability systems and multiple airbags can sometimes give a false sense of security; these systems require sensors and software that can malfunction or be less effective in unusual crash scenarios.

In contrast, the older Outbacks’ safety relied more on physical strength and simple, proven mechanical systems that were inherently reliable and less prone to failure during a collision.

This shift highlights the trade-off between modern efficiency and traditional robustness, where lighter, tech-heavy vehicles sometimes pay a safety price in fundamental crash protection.

Furthermore, Subaru’s commitment to active safety features sometimes masks the reality that the underlying crashworthiness of the vehicle’s structure is not as strong as it once was.

Insurance Institute for Highway Safety (IIHS) ratings and real-world crash data have occasionally shown that newer Outbacks, despite having all the latest safety tech, perform worse in certain severe crash scenarios than their older counterparts.

This disconnect between electronic safety aids and physical crash protection underscores an industry-wide challenge: balancing the push for lighter, more efficient cars with the uncompromising need for occupant safety.

Subaru’s Outback exemplifies this tension, demonstrating that technological progress does not always translate to improved physical protection.

2. Ford Explorer (1995-2000 vs. Post-2015 Models)

The Ford Explorer of the late 1990s is a case study in early SUV safety. These models featured body-on-frame construction, heavy steel reinforcements, and relatively simple mechanical systems that contributed to good crashworthiness.

At the time, Ford focused on building a rugged, durable SUV capable of surviving rough driving conditions, with structural integrity prioritized to protect occupants from intrusion during collisions.

This was especially important given the Explorer’s popularity as a family vehicle and off-road capable SUV. The 1995-2000 Explorer models had substantial mass and strong safety cages that effectively absorbed and redirected crash energy, giving them a solid reputation in frontal and side-impact crash tests of the era.

In contrast, the Explorer’s post-2015 redesign, which transitioned to a unibody chassis and increased use of aluminum and composites, marked a significant departure from these safety fundamentals.

While the newer Explorer gained improved handling, fuel economy, and a suite of advanced driver-assistance systems (ADAS), its structural safety has sometimes suffered.

Unibody construction offers weight savings but demands extremely precise engineering of crumple zones and reinforcements. Unfortunately, certain crash tests have revealed that the newer Explorers exhibit more cabin deformation in side impacts and reduced roof strength compared to older models.

This regression raises questions about whether the push for lighter, more aerodynamic designs has compromised the fundamental physical safety of the vehicle.

Another factor contributing to the newer Explorer’s safety regression is the increased reliance on electronic aids such as lane-keeping assist and blind-spot monitoring.

While these systems are undoubtedly helpful in preventing accidents, their effectiveness depends on flawless operation and cannot compensate if the vehicle’s structure itself is less capable of protecting occupants during a crash.

There have also been concerns regarding the new model’s rollover resistance, as the combination of lighter materials and higher center of gravity has sometimes resulted in less stable handling during evasive maneuvers.

This is particularly problematic given the SUV’s size and family-oriented usage, where rollover risk is a critical safety consideration.

Moreover, repair costs and long-term durability concerns arise with newer Explorers due to their complex construction and reliance on advanced electronics. Post-collision repairs may be more expensive and complicated, potentially leading to vehicles being repaired inadequately or written off more frequently.

In contrast, the older Explorers’ simpler, heavier frames were not only safer but also easier to inspect and repair properly after accidents, ensuring continued occupant protection over time.

The Ford Explorer’s evolution from a tough, protective vehicle into a lighter, tech-heavy SUV highlights broader industry challenges in balancing innovation with proven safety principles.

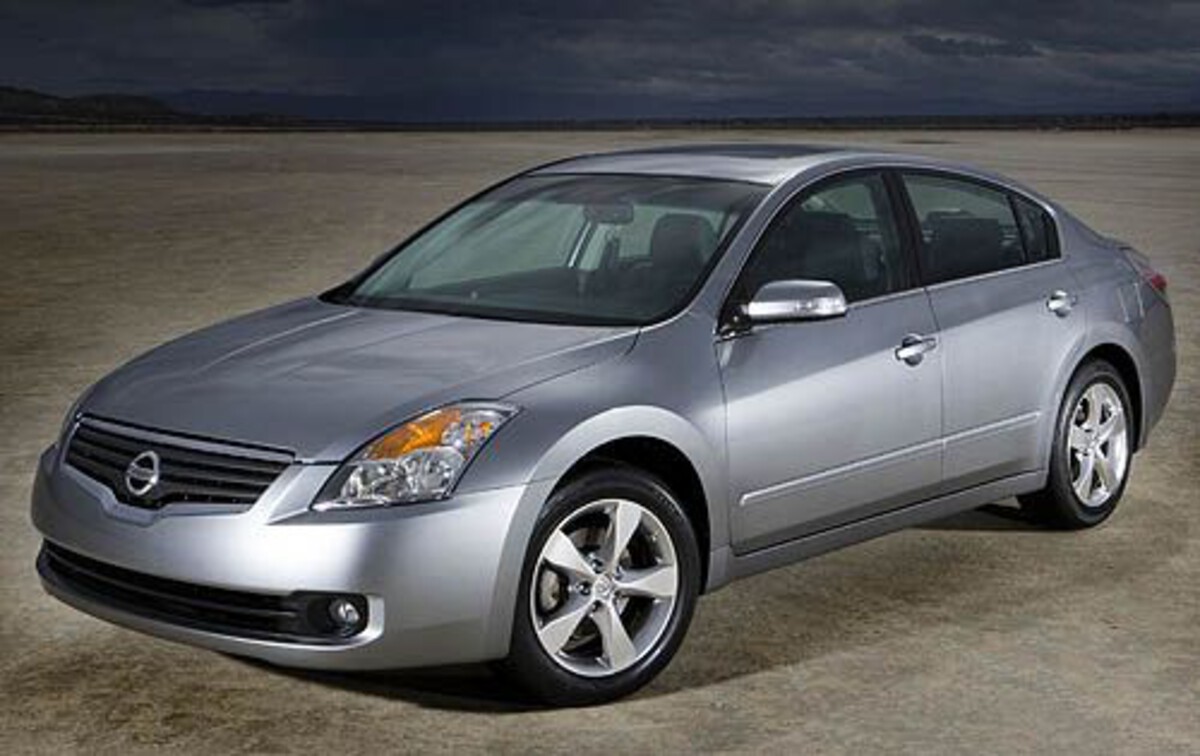

3. Nissan Altima (Early 2000s vs. Recent Models)

The early 2000s Nissan Altima was widely recognized as a solid midsize sedan with good crash protection thanks to its relatively heavy, steel-intensive construction.

These models featured a rigid unibody frame that emphasized structural integrity and progressive crumple zones, which were well-designed to absorb frontal and side impact energy while maintaining passenger compartment integrity.

The Altima was designed during a period when automakers still prioritized weight and structural robustness alongside emerging safety features like airbags. Consequently, the early Altimas performed consistently well in crash tests and real-world accident survivability.

Fast forward to recent generations, and the Nissan Altima has undergone a significant transformation aimed at maximizing fuel efficiency and appealing to a younger, tech-savvy demographic. This involved extensive use of lighter materials, increased incorporation of aluminum, and a focus on sleek, aerodynamic styling.

While these changes brought improvements in fuel economy and driving dynamics, they have sometimes come at the expense of fundamental structural safety.

Crash tests have shown newer Altimas to experience greater intrusion in side impacts and less favorable outcomes in certain rollover scenarios. This regression is concerning given that many consumers assume newer always means safer, especially with the proliferation of advanced driver aids now standard on many trims.

Additionally, the modern Altima’s suite of electronic safety features, such as automatic emergency braking and lane departure warnings, depends heavily on sensors and cameras that may be vulnerable to failure or false positives in adverse conditions.

These systems, while beneficial, cannot physically protect occupants if the car’s structure collapses during a high-energy crash. The lighter body panels and complex crumple zones of the newer Altimas may deform unpredictably, reducing occupant protection and increasing the risk of injury in real-world collisions.

This structural regression highlights an often overlooked aspect of vehicle safety: no matter how advanced the technology, the physical integrity of the vehicle remains paramount.

Furthermore, consumer feedback and insurance data have sometimes indicated that newer Altimas have seen higher injury claims compared to earlier models, reinforcing concerns about their crashworthiness.

The trade-off between modern design priorities and structural safety is evident here, illustrating how the quest for lower emissions and better mileage can inadvertently compromise fundamental protections. Nissan’s Altima evolution exemplifies the difficult balance automakers face today, as they attempt to innovate while maintaining or improving vehicle safety.

4. Chevrolet Malibu (2000s vs. Recent Models)

The Chevrolet Malibu of the early to mid-2000s was built on a platform emphasizing structural robustness and occupant protection. These models featured thick steel safety cages, reinforced door beams, and well-engineered crumple zones that contributed to favorable crash test ratings for frontal and side impacts.

The Malibu was a popular family sedan that earned respect for its solid build quality and balanced safety design. The vehicle’s weight and structural design helped it manage crash energy effectively, limiting intrusion and maintaining occupant survival space even in higher-speed collisions.

In contrast, the recent generation of Malibu models, introduced after 2012 and especially post-2016, shifted heavily toward weight reduction strategies and modern aesthetics.

This included greater use of aluminum components, thinner sheet metal, and more complex structural joints designed to optimize crumple zone performance. While these advances help meet fuel economy and emissions targets, they have sometimes compromised the vehicle’s inherent crashworthiness.

Some crash tests and consumer reports have noted increased cabin intrusion and diminished roof strength compared to older Malibus. This has raised concerns about occupant protection in severe crashes, particularly side impacts and rollover scenarios.

Moreover, the newer Malibus incorporate a wide array of electronic safety features such as forward collision alerts and lane-keeping assist. Although these technologies provide valuable accident prevention capabilities, their effectiveness is limited by environmental conditions and system reliability.

When collisions do occur, the physical safety cage and structural integrity are the final defenses, and here, the newer Malibu may not perform as well as its predecessors. Additionally, repair complexity and costs have increased, potentially leading to longer vehicle downtime and a greater risk of inadequate repairs after collisions.

The transition in Malibu’s design reflects a broader industry trend toward lighter, more technologically advanced vehicles at the cost of some structural solidity. This shift emphasizes the challenge automakers face in maintaining safety standards while adapting to regulatory and market pressures.

The Malibu example serves as a cautionary tale, reminding consumers and manufacturers alike that newer does not always mean safer, particularly when fundamental crashworthiness is compromised.

5. Volkswagen Passat (Early 2000s vs. Recent Models)

The Volkswagen Passat from the early 2000s earned praise for its strong structural design and solid build quality. These models featured a well-engineered safety cage constructed from thick steel and reinforced doors, pillars, and floor sections.

The Passat’s crashworthiness was evident in its good frontal, side, and rear impact ratings, reflecting a design philosophy that prioritized occupant protection through mechanical strength and integrity. The vehicle’s weight and balanced chassis contributed to stable handling and low rollover risk, further enhancing its safety credentials.

This era of Passats was a benchmark for midsize European sedans, combining durability with safety in a way that gave drivers confidence on the road.

However, the more recent Passat models, particularly those from the 2010s onward, have seen a marked shift toward lighter body constructions using aluminum and mixed materials.

The move toward weight reduction and fuel efficiency has introduced structural compromises, including thinner steel sections and more reliance on engineered deformation zones.

While these newer vehicles come loaded with advanced electronic safety systems like autonomous emergency braking and blind-spot monitoring, their physical crash protection has sometimes regressed.

Test results and accident data suggest that recent Passats may exhibit increased passenger compartment intrusion during side impacts and reduced roof strength, impacting occupant survivability in severe crashes.

The heavy dependence on electronic aids in the newer Passats also raises concerns about reliability under extreme conditions. Sensors and software systems may fail or become less effective in complex crash scenarios, leaving occupants reliant on the vehicle’s structural design to absorb impact forces.

When that structure is compromised due to weight-saving measures, the overall safety of the vehicle diminishes. Repair costs for newer Passats also tend to be higher, partly because of their complex construction and integrated safety systems, which may lead to prolonged vehicle downtime or incomplete repairs that affect post-accident safety.

Volkswagen’s Passat evolution illustrates the delicate balance between modern automotive demands and traditional safety principles. The progression toward lighter, more technologically advanced cars sometimes comes at the expense of proven structural strength and occupant protection.

The Passat’s journey from a solid, robust midsize sedan to a lighter, tech-dependent vehicle highlights the challenges automakers face in meeting evolving consumer expectations, regulatory requirements, and safety benchmarks, sometimes with unintended regressions in fundamental safety.

Also Read: 5 Cars with Solid Seat Structures vs 5 with Belt or Latch Failures

The evolution of automotive safety is a complex journey marked by remarkable technological advancements but also by challenges and trade-offs.

As we have seen, newer does not always mean safer. Older generations of vehicles like the Jeep Grand Cherokee, Volvo 240, and Toyota Land Cruiser often exhibit superior crashworthiness because of their heavier, more rigid structures and simpler mechanical designs that consistently protected occupants in severe collisions.

These cars serve as a reminder that physical robustness remains a cornerstone of safety, one that cannot be fully replaced by electronic systems alone.

Conversely, the cases of the Subaru Outback, Ford Explorer, and Nissan Altima show how modern priorities—lighter materials, aerodynamic styling, and advanced driver-assist technologies-can sometimes come at the expense of fundamental crash protection.

While these innovations contribute to accident avoidance and improved fuel economy, they occasionally result in increased cabin intrusion or reduced rollover resistance when collisions do occur. This tension illustrates the delicate balance automakers must strike between innovation and reliability.

Ultimately, safety in vehicles is about a holistic approach: strong, well-engineered structures complemented by reliable technology and thoughtful design.

The lessons from these contrasting examples emphasize the need for consumers to look beyond marketing claims and understand the full safety profile of a vehicle, including its crashworthiness and long-term durability.

For manufacturers and regulators, the challenge is clear—continuously push forward in innovation while preserving the essential mechanical integrity that has saved lives for decades. Only then can true progress in automotive safety be achieved.