Not every small engine is built the same. Some are rugged machines that keep going even when they’re mistreated, ignored, or run under less-than-ideal conditions.

Others are far more sensitive, requiring consistent maintenance, proper fuel, timely oil changes, and careful storage. Whether you’re dealing with a generator, a lawnmower, a pressure washer, or a small dirt bike, the type of engine it uses can mean the difference between reliable performance and a frustrating breakdown when you need it most.

Neglect is a common reality for many types of small equipment. Life gets busy, and checking the oil or cleaning the air filter becomes less urgent, until the machine refuses to start.

Some engines are forgiving. They’ll sputter, chug, and cough their way back to life even after sitting unused for a year in a damp shed with old fuel in the tank. Others are built to tighter tolerances or rely on more sensitive systems, and if you don’t take care of them, they fail fast.

This article compares five engines that are known for their ability to take abuse and still work, against five that are far more likely to break down when not cared for properly. These examples are pulled from a variety of industries and equipment types but share one common trait: reputation.

Whether it’s a widely respected Honda engine that runs after years of neglect, or a high-performance but finicky design that breaks down without perfect care, the experiences of everyday users, mechanics, and small engine experts paint a clear picture of which engines you can trust when maintenance isn’t perfect.

Let’s go through five of the toughest small engines that can survive long periods of neglect without major issues, followed by five that struggle when not maintained properly. Keep in mind, even the most durable engine can fail if it’s ignored long enough. But some just have more fight in them.

Also Read: 10 Bikes That Were Supposed to Be Recalled but Never Were

Engines That Survive Neglect

1. Honda GX Series

The Honda GX series has built a reputation over decades as one of the most durable and reliable small engines on the market. Found in pressure washers, water pumps, cement mixers, generators, and commercial mowers, the GX series is designed to run under harsh conditions.

Even when users forget oil changes or leave fuel sitting for months, these engines often fire up with minimal effort. Their forgiving nature makes them a favorite among rental companies and professionals who demand dependability.

Much of the GX series’ reliability comes from its engineering simplicity and high-quality materials. These engines are air-cooled, use overhead valves, and are designed with loose enough tolerances to handle some abuse without locking up.

Their cast iron cylinder sleeves and ball-bearing-supported crankshafts contribute to long-term durability, even when they’re not pampered. Mechanics often praise their ability to survive fuel degradation, carbon buildup, and occasional oil starvation without catastrophic failure.

In terms of real-world use, there are countless stories of GX engines starting after sitting untouched for years. People have pulled old tillers or pumps from barns and sheds and been amazed when the engine runs with just fresh gas and a few pulls. This reliability has earned Honda a loyal following and has contributed to the resale value of equipment powered by GX engines.

Even though these engines are incredibly durable, they’re not indestructible. Long-term neglect will eventually wear them down, especially if the oil is never changed or the air filter is completely clogged. However, compared to many of their competitors, the GX engines give you a much longer leash before things go seriously wrong.

2. Briggs & Stratton 550EX Series

Briggs & Stratton engines have a mixed reputation, but the 550EX Series is among their most forgiving. Commonly found on walk-behind lawnmowers, this engine is known for its “ReadyStart” feature and ease of use. It’s not built for performance, but for simplicity and survival. This makes it a decent choice for homeowners who don’t always remember to drain the fuel or change the oil on schedule.

The 550EX can tolerate some pretty bad treatment. Old fuel, skipped oil changes, and dirty filters don’t knock it out immediately. Many users report leaving gas in the tank over the winter and still getting the mower started in spring with just a few pulls. It’s not fancy, but it’s functional. The plastic carburetor design, while controversial, actually helps resist corrosion in humid storage conditions. Plus, fewer parts can go wrong.

This engine doesn’t produce much torque and won’t impress anyone with its power, but it has enough grit to keep going when better-built engines might seize up. For typical suburban lawn care, it can survive years of rough handling. It helps that replacement parts are cheap and widely available, so even if something does break, it’s easy to get back up and running.

Its longevity depends on light use. If this engine were put to daily commercial mowing use and ignored, it wouldn’t last long. But for seasonal residential work with little maintenance, the 550EX punches above its weight. As long as the blade stays sharp and there are no major fuel system clogs, it can last far longer than expected.

3. Kohler 7000 Series

Kohler’s 7000 Series engines are used in many riding mowers and zero-turns. Known for their balance of performance and durability, these V-twin engines can run surprisingly well even when neglected. While they appreciate clean oil and regular filter changes, they don’t immediately punish you when you fall behind on maintenance. That gives them an edge in homes or small businesses where perfect care isn’t always realistic.

One reason the 7000 Series holds up is due to its solid internal components. The full-pressure lubrication system with a spin-on oil filter adds a layer of protection that many lower-end engines lack. Even when the oil gets dirty, it’s still being pushed through the system efficiently. These engines also have cast iron cylinder liners and dual-seal air filters, which help protect against internal wear when conditions aren’t perfect.

A lot of casual users don’t check or change oil as often as they should, and the 7000 Series keeps going anyway. Reports of these engines crossing 500 hours with inconsistent maintenance aren’t uncommon. They do especially well in moderate climates where cold starts and extreme heat don’t stress the engine as much. Despite their relatively high compression ratio, they handle ethanol fuel better than some of their competitors too.

They’re not bulletproof. If left sitting with old gas, the carburetor can clog, and if completely oil-starved, the internal damage is inevitable. But the engine often gives warning signs before failure, such as harder starts or noisier operation. That gives owners a chance to catch up on care before the engine gives out. As far as mid-range riding mower engines go, the Kohler 7000 Series is among the more tolerant.

4. Subaru EA190V

Though Subaru no longer makes small engines, the EA190V earned a reputation during its production run as one of the toughest small vertical shaft engines. It was used in high-end residential pressure washers and mowers and was built with better internals than most competitors in its class. Even with long storage periods, stale gas, or inconsistent oil changes, it often continued to run well.

A key factor in its durability was the chain-driven overhead cam design. This layout helped reduce wear and improve timing reliability over time. It also had a cast iron cylinder sleeve and a robust crankshaft, features not always found in small residential-grade engines. These made it more resistant to heat damage and long-term wear, even when oil quality suffered.

This engine also ran smoother and quieter than many others in the same size range. That may not sound like it contributes to durability, but smoother operation often means less vibration and stress on seals, gaskets, and fasteners. Many users noticed that even after years of spotty care, the engine didn’t leak oil or lose compression. That’s a strong indicator of a well-sealed design.

Because it’s no longer in production, parts can be harder to find. But those who still have EA190V engines often report excellent performance despite years of neglect. They may not be flashy or well-known today, but they earned their place on the list through stubborn resilience in tough conditions.

5. Tecumseh HM80 (Older Models)

Tecumseh engines fell out of favor before the company stopped producing engines altogether, but the old HM80 series from the 80s and 90s is a standout in terms of neglect tolerance. These cast iron block engines were used in snowblowers, tillers, and other heavy-duty tools, and they were built to last. They’re not efficient or quiet by modern standards, but they take punishment better than many modern engines.

The HM80 was a simple flathead engine with very few moving parts. Its simplicity is part of what makes it so tough. The fewer parts you have, the fewer things there are to go wrong when the engine isn’t maintained well. Old-school carburetors could be cleaned easily, and the ignition systems were robust enough to spark after long periods of inactivity.

Another strength was the engine’s use of thick materials. The castings were heavy, the crankshafts were strong, and the construction was overbuilt. These engines didn’t have to run perfectly to keep going. As long as there was some spark and fuel, they usually ran. Even with old gas, bad spark plugs, or dirty filters, they often managed to start.

They’re getting rarer now, but people who still use them often swear by their durability. You can find 30-year-old snowblowers with original HM80s that start up every winter with minimal prep. It’s a dying breed of engine, but one that earned its reputation the hard way, by refusing to quit.

Engines That Can’t Handle Neglect

1. Kohler Courage Series

The Kohler Courage Series is widely known in the lawn and garden community, not always for the best reasons. While it looks solid on paper and can perform well under optimal conditions, its long-term reliability suffers greatly when basic maintenance isn’t followed closely.

This series, used in many mid-range residential riding mowers, seems to be built with tighter tolerances and fewer safety margins compared to more robust engines. Unfortunately, that means there’s much less room for error when things like oil, fuel, and cooling systems are ignored.

One of the most common and frustrating problems tied to this engine involves oil leaks from the crankcase due to head gasket or crankcase cover failures. When that happens, it often leads to low oil levels, unnoticed by users until the engine begins knocking or shuts down completely.

The Courage Series lacks a low-oil shutdown sensor on many of its variants, so the engine can continue to run itself dry. If caught early, the damage might be limited, but in many cases, owners don’t realize something’s wrong until the engine is beyond repair.

Cooling is another weak point. The Courage tends to run hot, and the cooling fins require regular cleaning to maintain proper airflow. If these fins become clogged with grass clippings or dirt, the engine quickly overheats, often resulting in warped valves, blown gaskets, or piston scoring.

A surprising number of failures are traced back to poor airflow and poor oil condition working together to ruin the engine from within. If it were built with slightly more robust cooling and better protection against overheating, it might have survived neglect better, but it simply wasn’t designed with that margin.

Fuel quality issues can also take their toll. Stale gas can gum up the carburetor easily, and this engine’s carb isn’t known for being easy to clean or rebuild. Because many users don’t run their equipment dry or use stabilizer before storage, springtime starting becomes a headache.

Once you combine all of these weaknesses, the picture becomes clear: this is an engine that can perform well with routine care, but it doesn’t handle laziness or long periods of inattention gracefully. It’s simply not a good match for neglectful owners.

2. Toro Timemaster 223cc (Briggs Engine)

The 223cc engine used in the Toro Timemaster mower was specifically built to run a large 30-inch dual-blade cutting system while staying compact and lightweight. However, this comes with compromises in both build quality and durability.

Because this engine works harder than your average push mower engine, it requires close attention to oil levels and maintenance schedules. Unfortunately, many homeowners don’t realize how much strain this engine is under and treat it like any ordinary mower. That’s when the trouble begins.

One of the biggest complaints about this engine is its tendency to burn oil faster than expected. When operated in hot weather or under heavy grass load, it consumes oil at a noticeable rate. Without an oil filter or a pressure lubrication system, the internal components rely entirely on splash lubrication.

If oil levels get low, which they often do unnoticed, wear increases quickly. Some users experience engine failure in under 100 hours simply because they didn’t check the dipstick every few uses. It’s a design that punishes inattention.

The carburetor is another vulnerable part. This engine is extremely sensitive to ethanol-blended fuels, which can cause varnish and corrosion if the fuel is left sitting too long. Even a couple of months in a humid shed without fuel stabilizer can lead to clogs that prevent the engine from starting.

The average homeowner, who may not winterize the mower or clean the fuel system, is likely to run into this issue by the second or third season. Cleaning the carb isn’t always easy for casual users, so the mower often ends up in the repair shop or on the curb.

Beyond the mechanical vulnerabilities, the fact that this engine is often placed in a premium-priced mower creates mismatched expectations. People assume that because the Timemaster is more expensive, its engine will last like a commercial unit. But that’s not the case. This engine isn’t designed for abuse, high hours, or long mowing sessions without breaks.

It’s fine-tuned for a specific purpose but lacks the durability and tolerance of a commercial-grade motor. If you don’t keep up with oil checks, clean the air filter regularly, and run clean, stabilized fuel, this engine simply doesn’t last long.

3. Generac OHV Portable Generator Engines

Generac’s OHV engines, found in many of their home backup and portable generator models, often seem appealing thanks to competitive pricing and attractive features. But their performance under neglect tells a different story.

While they can start reliably when new and maintained well, these engines suffer significantly once you start skipping steps like draining old fuel or changing oil after each use. Unfortunately, most users store generators for long periods without proper preparation, which leads to a very common outcome: failure to start when they’re needed most.

Fuel system problems top the list. These engines have basic carburetors that don’t tolerate ethanol-based fuel very well. The jets and passages inside are narrow, and when exposed to stale gas, they gum up quickly. Some users report needing carburetor cleaning or replacement after just a few months of idle time.

Fuel left in the lines over winter is especially damaging, and when generators are stored with gas in the tank for extended periods, spring startup becomes nearly impossible without repairs. It’s a major flaw for a product meant to be used in emergencies.

Oil is another pain point. These engines typically rely on splash lubrication and lack robust filtration systems. Because generators often run for long periods once turned on, sometimes for hours or days at a time, oil degradation happens quickly. If the oil is not changed after every long runtime, sludge builds up, and wear on the internal parts accelerates.

Many models don’t make oil changes very convenient, which encourages owners to delay or skip them entirely. Once that happens, piston rings wear faster, valve components suffer, and compression drops off quickly.

Cooling is the final vulnerability. These engines need good airflow to prevent overheating, but they’re often stored in dusty sheds or garages and run outdoors without cleaning the vents. Over time, dirt and dust build up, reducing airflow and raising operating temperatures.

Add in poor oil and old fuel, and the engine’s lifespan shrinks dramatically. For a backup generator, that kind of fragility is disappointing. These units are meant to provide peace of mind, but they only do so when cared for meticulously. Neglect them, and they’ll let you down.

4. Chinese Clone Engines (Cheap 2-Stroke Models)

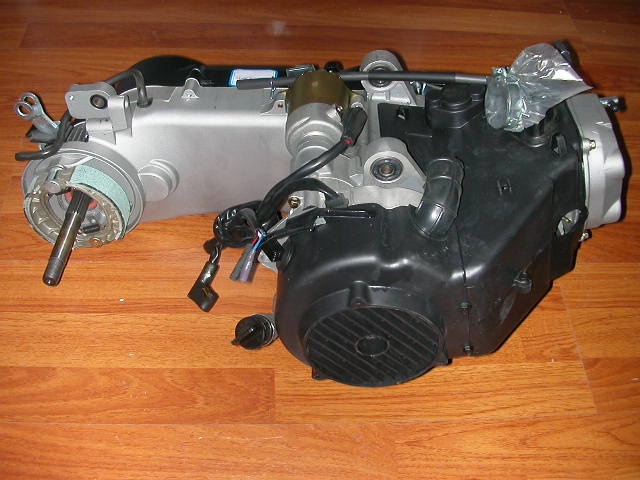

There’s been a flood of low-cost 2-stroke engines from lesser-known Chinese manufacturers on the market over the last decade. They appear in chainsaws, augers, blowers, and even mini dirt bikes. Their main appeal is the extremely low price. However, that price comes at a cost. These engines are often produced with inconsistent quality standards, and they are highly sensitive to misuse or neglect. Even a short period of improper storage or operation can lead to failure.

The most common issue is with the fuel system. These engines typically include very low-quality carburetors, often made of plastic or low-grade aluminum that corrode easily. When left with fuel inside, especially ethanol-blended gas, the carb components break down or get gummed up fast.

Gaskets swell, jets clog, and the needle valves stick. Trying to start one of these engines after even a couple of months of sitting often results in nothing but frustration. Unlike higher-end engines, which sometimes tolerate bad gas for a while, these engines stop working quickly.

The engines are also unforgiving when it comes to fuel-oil mix ratios. Most require a precise 40:1 or 50:1 ratio, and running them too lean, even briefly, can result in scoring the cylinder walls or seizing the piston. Some users premix improperly or use stale 2-stroke oil, both of which lead to lubrication failure. Once damage like this occurs, the engine is usually not worth repairing. Replacement parts are either unavailable or just as poor quality as the originals. In many cases, it’s cheaper to toss the engine than fix it.

Another issue is long-term durability. Even when these engines run well for a while, their bearings, crankshafts, and ignition modules are usually made with cost-cutting materials that don’t hold up. Vibration often loosens fasteners, the muffler screens clog quickly, and spark plug quality varies widely.

If you miss routine care even slightly, like failing to clean the air filter or allowing carbon buildup, the engine performance drops off sharply. These engines are built to a price, not a standard, and neglect pushes them over the edge fast.

5. Predator 212cc (Modified or Abused Units)

The Predator 212cc engine is a favorite in the DIY and hobby community due to its affordability and surprisingly good performance right out of the box. It’s often used in go-karts, minibikes, log splitters, and even racing projects. When run stock and maintained decently, it holds up surprisingly well. But the problems begin when users start modifying the engine or run it hard without any regular maintenance. Its popularity in these circles leads to more abuse than it was ever designed to handle.

One of the most common points of failure comes from removing or bypassing the governor. Many users want more speed and higher RPMs, so they eliminate the factory-governed RPM limiters. While this can push performance higher temporarily, it significantly increases stress on the connecting rod, flywheel, and crankshaft.

If users don’t upgrade these components along with removing the governor, they risk catastrophic failure. In many cases, the rod snaps or the engine throws a valve. It’s a predictable outcome when performance upgrades outpace maintenance and component strength.

Oil neglect is another killer. The Predator 212 uses splash lubrication, and it’s very sensitive to oil level. Many users forget to check oil before long rides or use it in off-angle positions, like on rough terrain, which further limits oil flow. Low oil leads to premature wear, especially on the camshaft and lifters. Because it’s a horizontal shaft engine used in fast-moving machines, it also runs hot, and the oil degrades faster than most realize. Dirty or low oil means failure is only a matter of time.

While the stock engine can handle casual abuse for a while, neglecting to clean the air filter, letting carbon build up on the head, or ignoring valve lash adjustment causes problems fairly quickly. The popularity of cheap aftermarket parts compounds the issue.

Many users swap in parts of questionable quality without properly tuning the engine, leading to imbalance, overheating, and early failure. In short, the Predator 212 can be a workhorse when maintained and respected. But when it’s neglected or pushed too far without supporting upgrades, it breaks down fast, usually in spectacular fashion.

Also Read: 5 Signs Your Bike Needs a Suspension Overhaul

When it comes to small engines, longevity is not always about brand name or engine size; it’s often about how well an engine tolerates real-world use. In many cases, that means forgiving owners who forget to change the oil, use stale fuel, or store machines improperly. Some engines are built with enough mechanical cushion to handle that kind of neglect for years, while others need careful, consistent upkeep just to make it through a single season.

The engines that survive abuse usually share a few key traits. They tend to be overbuilt, with heavier materials, looser tolerances, and simpler internal designs. They often rely on splash lubrication but have strong bottom-end components that resist wear even when oil gets low or dirty.

Engines like the Honda GX series, older Tecumseh models, and the Kohler 7000 line don’t need perfect conditions to keep running. They can sit for months, be run on less-than-fresh fuel, and still fire up with minimal fuss. For homeowners, renters, or anyone who doesn’t have time to baby their machines, these engines are a safer bet.

By contrast, engines that don’t tolerate neglect tend to be designed with tighter tolerances, weaker materials, or in some cases, with unrealistic assumptions about how carefully they’ll be maintained. Kohler’s Courage series and the Briggs engine used in the Toro Timemaster both suffer when routine care is skipped.

They burn oil faster than expected, overheat more easily, and have components that don’t hold up when stressed. And then there are the cheap two-stroke clones and low-cost generator engines that work okay when new but fall apart quickly under the kind of storage and maintenance lapses that are common in real life.

Another important distinction is how forgiving an engine is after neglect has occurred. Some engines will warn you with hard starts, increased noise, or loss of power. Others just seize up or blow out major components with little warning. This matters because the ability to recover from neglect is a huge part of what makes an engine practical. If you can’t start your generator during an outage because of bad fuel, or your mower blows a head gasket because you skipped one oil change, that engine has failed its real job.

Choosing the right small engine depends heavily on your habits. If you’re meticulous with maintenance and enjoy tuning and servicing your machines, you can probably get away with using more sensitive engines and getting good results.

But if you’re the type to forget fuel stabilizer or let your mower sit through the winter with gas in the tank, it’s much smarter to pick an engine with a proven track record of resilience. It’s not about finding something that lasts forever, just something that lasts long enough to be useful, even when life gets in the way.

Durability under neglect isn’t just a mechanical feature; it’s a practical one. It means fewer repairs, fewer ruined weekends, and more time getting the job done. For most people, that’s what counts. Knowing which engines can take a beating and which ones demand constant attention makes all the difference when it comes to buying equipment that actually works when you need it.