The Chevy Tracker, known for its compact size, rugged build, and versatility, is one of those vehicles that can last for decades if given the right care. Whether it’s being used for daily commutes, weekend camping trips, or hauling light gear, a well-maintained Tracker can continue to deliver reliable performance long after newer vehicles have come and gone.

Many owners appreciate its simple mechanical design and its straightforward maintenance requirements. However, like any vehicle, it needs consistent attention and care to run at its best. Fortunately, you don’t have to be a certified mechanic to keep your Tracker performing well. With just a little time and effort, there are simple steps you can take to make sure it stays reliable and efficient on the road.

These easy wins don’t require specialty tools or a deep background in automotive work. In fact, most of them can be done right in your driveway or garage with only basic tools and supplies. Regular maintenance isn’t just about preventing breakdowns; it’s about preserving performance, maximizing fuel efficiency, and keeping future repair bills manageable.

Overlooking small things can lead to bigger problems, but staying on top of basic tasks helps avoid surprises down the line. When you take a little time to monitor your Tracker’s vital systems and make some smart choices, the results pay off both in the short term and over the life of the vehicle.

This article covers ten straightforward yet highly effective maintenance habits that can help you extend the life of your Chevy Tracker. From oil changes and tire pressure checks to looking after the cooling system and keeping the undercarriage clean, each section focuses on something practical and accessible.

These are habits anyone can form, even if they’re not especially into cars. And they’re not just for those trying to stretch every last mile out of their Tracker; they’re just as useful for someone who wants to keep their ride in top shape simply because they enjoy driving it. Whether yours is a daily driver or a part-time trail buddy, keeping it running smoothly is easier than you might think.

Also Read: 5 Infotainment Units With Reliable Software vs. 5 That Are Glitchy

1. Stick to a Consistent Oil Change Schedule

Motor oil plays one of the most critical roles in engine health. It lubricates moving parts, helps reduce heat buildup, and protects internal components from wear. For a Chevy Tracker, keeping fresh oil in the engine is one of the simplest ways to extend its life and ensure smooth operation.

While manufacturers might suggest intervals between 3,000 and 5,000 miles, depending on the engine model and oil type, sticking to the shorter end of the spectrum is a good idea for older vehicles or those used under harsher conditions. Clean oil helps reduce sludge buildup, which is especially important for high-mileage engines that have seen years of wear.

Using the correct grade of oil is also key. The Tracker’s engine will run better with oil that matches its design and age. Older engines may benefit from high-mileage oils that include conditioners to protect seals and reduce leaks.

Synthetic oil can offer added protection and better performance in extreme temperatures, but regular conventional oil still does a fine job when changed often. Regardless of type, fresh oil always performs better than dirty oil. That alone should be motivation enough to make oil changes a regular habit.

Oil filters shouldn’t be ignored either. Every oil change should include a new filter, as it’s what keeps the oil clean between changes. A clogged or dirty filter can allow debris to circulate through the engine, causing wear and reducing efficiency.

Filters are inexpensive and easy to replace, making them one of the best low-cost maintenance choices available. Investing five extra minutes during an oil change to swap out the filter is a simple step with major benefits.

Lastly, it helps to keep a log of your oil changes, even if you do the work yourself. Write down the date, mileage, and type of oil used. Not only does this help you stay on schedule, but it can also come in handy if you’re ever troubleshooting engine performance issues. Consistency here builds a strong foundation for engine longevity.

2. Monitor and Maintain Proper Tire Pressure

Tires have a bigger impact on your Tracker’s performance than most people realize. Properly inflated tires ensure good traction, better fuel economy, and a smoother ride. When tire pressure drops below the recommended level, the vehicle becomes harder to control, and the tires wear out faster. It also puts additional stress on the suspension and steering components. Even just a few pounds per square inch under can make a noticeable difference.

Checking tire pressure regularly is an easy win. A simple tire gauge can be kept in your glovebox or garage and used every couple of weeks or before long trips. Each tire may lose pressure at a different rate, especially if there’s a slow leak or if weather conditions are changing. Cold temperatures, for instance, can cause pressure to drop by 1 PSI for every 10 degrees Fahrenheit. In summer, overinflation from heat can be a concern as well.

Always refer to the recommended tire pressure listed inside the driver’s side door jamb or in the owner’s manual, not the maximum PSI printed on the tire itself. This number is what the vehicle was designed for, ensuring the best balance between ride comfort, safety, and efficiency. Driving with even one underinflated tire can increase the risk of a blowout, especially during highway speeds or hot weather.

In addition to air pressure, take a moment to look at tread wear. Uneven wear patterns might suggest an alignment issue or worn suspension parts. Rotating the tires every 6,000 to 8,000 miles can help them wear evenly, extending their life. A small amount of effort here goes a long way in keeping your Tracker safe and running smoothly.

3. Keep the Cooling System in Check

Overheating is a major risk for older vehicles, and the cooling system in a Chevy Tracker plays a central role in keeping the engine temperature stable. The system includes the radiator, thermostat, water pump, hoses, and coolant itself. Each of these parts must function correctly to prevent the engine from running too hot. Heat is the enemy of metal parts under the hood, and once a vehicle starts to overheat regularly, damage can add up quickly.

One simple habit that can protect your engine is checking coolant levels regularly. Low coolant can lead to overheating even if every other part of the system is working properly. Always check when the engine is cool to avoid burns, and make sure the coolant reservoir is filled to the correct mark. If levels drop frequently, there may be a leak somewhere in the system that needs to be addressed right away.

Flushing the coolant system every couple of years is another smart step. Old coolant loses its ability to regulate temperature and can start to corrode internal components. A full flush removes rust, scale, and debris that might otherwise block passages or reduce circulation. It also gives you a chance to inspect hoses and clamps, which can dry out and crack over time.

The radiator cap and thermostat are small parts with big roles. A weak radiator cap can let pressure escape, while a sticky thermostat can prevent proper coolant flow. Neither is it expensive or difficult to replace. Spending a few minutes inspecting the cooling system twice a year can prevent one of the most damaging and expensive problems an older vehicle can face.

4. Replace Spark Plugs and Wires at Regular Intervals

The ignition system may seem like a behind-the-scenes player, but it’s a major part of how smoothly your engine runs. Spark plugs ignite the fuel-air mixture inside each cylinder, and if they’re worn out or fouled, your Tracker can start misfiring, stalling, or losing power. Replacing spark plugs on time helps ensure complete combustion, smoother acceleration, and better fuel efficiency.

Many people forget to replace spark plug wires, but they’re just as important. Worn wires can cause weak or inconsistent sparks, leading to poor engine performance and even triggering the check engine light. Over time, the rubber insulation on the wires can degrade, leading to arcing or misfires. A full ignition tune-up includes both plugs and wires, and it’s one of the more satisfying DIY jobs for a Tracker owner.

The interval for changing spark plugs depends on the type used. Standard copper plugs might need changing every 30,000 miles, while platinum or iridium versions can last over 60,000 miles. That said, it’s a good idea to check them more frequently if the vehicle is older or if you notice symptoms like rough idling, hesitation, or a drop in fuel economy. Visual inspection of the plugs can also reveal deeper problems, like oil fouling or overheating.

When doing this maintenance, use the correct plug gap and torque settings. Getting this wrong can cause performance issues or even engine damage. Always refer to the service manual or a trusted source for specs. While it might take a bit of patience, changing plugs and wires can refresh your Tracker’s engine and restore lost performance.

Also Read: 5 Infotainment Units With Reliable Software vs. 5 That Are Glitchy

5. Change the Transmission Fluid Before It’s Too Late

Transmission issues are often expensive and frustrating to fix, but the good news is that they’re usually preventable with regular fluid changes. The Chevy Tracker, like many compact SUVs, depends on its transmission fluid to cool and lubricate internal components.

Over time, the fluid breaks down due to heat and friction, losing its protective qualities. When fluid is neglected, it becomes dark, dirty, and full of debris that can lead to sluggish shifting, slipping gears, or complete failure. The best strategy is to treat transmission fluid like engine oil, something that needs routine attention rather than something you “set and forget.”

Many Tracker owners mistakenly believe that transmission fluid should only be changed when there’s a noticeable problem, but waiting that long can cause irreversible damage. A better approach is to change it based on mileage and usage patterns.

For automatic transmissions, a good interval is around every 30,000 to 40,000 miles, though this can vary depending on whether the vehicle is used for towing, off-roading, or lots of stop-and-go driving. Manual transmissions also benefit from fresh fluid, though their intervals tend to be longer. If the Tracker is older or high mileage, a fluid and filter change can make a significant difference in how smoothly it shifts.

It’s also important to use the correct type of transmission fluid. Using the wrong kind can cause serious issues. Always double-check the specifications listed in your Tracker’s manual. Some fluids are designed specifically for General Motors transmissions and have unique friction properties.

A high-quality fluid helps with temperature regulation and prevents premature wear on the clutch packs, valves, and seals inside the unit. If you’re flushing the system yourself, take your time and make sure all the old fluid is properly drained. Also, if your Tracker has a transmission filter, don’t skip it, changing the fluid without replacing the filter is like changing your oil and leaving the old oil filter in place.

Transmission fluid maintenance may not have the immediate feel of a performance upgrade, but it’s one of the smartest investments you can make. A neglected transmission often means the end of a vehicle for many owners because repairs can quickly exceed the value of the car.

But keeping the fluid clean and fresh buys you thousands of extra miles of reliable service. It’s one of those tasks that feels minor until you experience what happens when it’s ignored. Take care of the transmission, and your Tracker will return the favor.

6. Don’t Ignore the Undercarriage and Frame

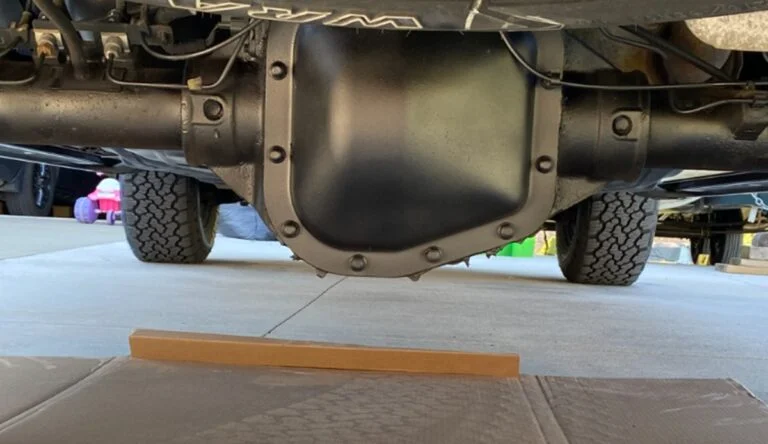

Most maintenance advice focuses on what’s under the hood, but underneath your Tracker is another story that often gets overlooked. The undercarriage is exposed to everything from road salt and mud to gravel, standing water, and rust-causing moisture.

Over time, the frame and suspension components can start to corrode, weakening structural integrity and causing mounting points to fail. In regions with harsh winters or coastal areas with salty air, this process can happen alarmingly fast. Just because you don’t see it doesn’t mean it’s not happening. A clean and rust-free undercarriage keeps your Tracker safe and roadworthy for years to come.

One of the easiest habits to form is giving the underside of your vehicle a rinse every few weeks, especially during winter or after driving on salty or muddy roads. A regular garden hose or car wash wand works well for this task. Focus on spraying out wheel wells, rocker panels, and the lower frame.

Many owners only realize the importance of this when they fail an inspection or discover a hole in the floorboard. Dirt, sand, and salt can build up in tight areas and stay damp, creating the perfect environment for rust to form and spread. Cleaning it out regularly makes a huge difference.

It’s also a good idea to inspect the undercarriage at least twice a year. Look for flaking rust, soft spots, or areas where metal appears bubbled or blistered. These are early warning signs that corrosion is forming underneath the surface. Applying a rust-inhibiting spray or undercoating can provide another layer of protection.

While professional rustproofing treatments are available, even a DIY application of rubberized undercoat spray can delay the advance of corrosion. Be sure not to coat over rust without addressing it first, as this can trap moisture and make things worse over time.

Fixing rust early is far cheaper and easier than repairing a rotted-out frame later on. Whether you do off-road driving or just daily errands, keeping the underside of your Tracker protected is a smart, long-term move. A solid undercarriage doesn’t just help with safety, it also ensures suspension components, fuel lines, brake lines, and exhaust parts stay in good shape. It’s a maintenance task that often gets skipped but pays big rewards down the road.

7. Replace the Air Filter for Better Efficiency

The air filter is one of those parts that plays a silent but vital role in your Tracker’s engine performance. It ensures that the air entering the engine is free of dust, pollen, and road debris. Clean air is essential for proper combustion, and when the filter becomes clogged, the engine has to work harder to draw air in.

This leads to reduced fuel economy, sluggish acceleration, and even engine strain over time. Fortunately, replacing the air filter is one of the quickest and cheapest maintenance tasks you can perform, and it can have an immediate impact on how smoothly your Tracker runs.

For most Chevy Trackers, the air filter is easily accessible in a plastic box near the front or side of the engine bay. Opening this box takes just a few minutes, and swapping out the old filter for a new one is usually tool-free.

You should inspect the filter every 10,000 to 15,000 miles, though dusty environments like gravel roads or desert areas may require more frequent checks. A dirty air filter will often look gray or black and may feel clogged with grit when tapped. If you’re unsure, replacing it preemptively is rarely a waste.

Some owners opt for aftermarket performance air filters, which claim to improve horsepower or throttle response. While these can offer marginal gains, they require regular cleaning and oiling, and not everyone wants that extra upkeep. For most drivers, a good-quality paper filter changed on schedule is the best balance of convenience and performance. It’s also more forgiving if forgotten for a while. What matters most is making sure that airflow is never restricted.

An efficient engine burns fuel more cleanly and runs cooler. Clean air promotes better combustion and smoother idling. Especially in older vehicles like the Tracker, maintaining simple components like the air filter goes a long way in preventing bigger issues. It might not be flashy, but it’s a solid win in keeping your Tracker running strong.

8. Inspect and Maintain the Brake System

Brakes are one of the most critical safety systems in your vehicle, and they deserve regular attention. For a Chevy Tracker, especially one used for outdoor adventures or older daily use, brakes can wear faster than expected. Regularly inspecting the brake pads, rotors, fluid, and lines ensures that your stopping power remains sharp.

Brake pads wear down over time, and if ignored long enough, they’ll start to grind against the rotors, leading to expensive repairs. By checking them every oil change or every 5,000 miles, you can spot wear before it becomes a problem.

Many owners assume they’ll know when brake pads are low because of the squealing noise, but not all brakes make noise when worn. In fact, some pads have wear indicators while others do not. If you notice longer stopping distances, a soft pedal, or pulsating while braking, it’s worth taking a look. Rotors should also be inspected for grooves or warping, especially if you’ve driven through a lot of water, mud, or salt. A warped rotor can cause vibrations through the steering wheel and reduce brake effectiveness.

Brake fluid is another overlooked component. Over time, it absorbs moisture from the air, which reduces its boiling point and can lead to brake fade during heavy use. This is especially important in older vehicles where seals might not be as tight.

Flushing and replacing brake fluid every 2–3 years helps maintain proper hydraulic pressure and protects the internal components of the master cylinder and calipers. You should never wait until the fluid looks dark brown or black, it should be light yellow or amber when fresh.

Regular brake inspections are easy to perform if you have a jack and a basic set of tools. Pulling the wheels off and checking pad thickness and rotor condition takes less than an hour and can prevent a much bigger bill later on. Your Tracker’s ability to stop effectively is just as important as its ability to go. Taking the time to keep brakes in good shape is one of the best habits any owner can form.

9. Watch for Vacuum Leaks and Sensor Failures

As the Tracker ages, rubber components like vacuum lines and intake hoses can dry out and crack. These tiny leaks might not seem like a big deal, but they can wreak havoc on engine performance.

A vacuum leak allows unmetered air to enter the system, which throws off the air-fuel ratio and causes rough idling, hesitation, or a high-pitched whistling sound. Many Tracker owners have spent hours chasing strange engine behavior only to find a brittle hose or loose clamp was to blame.

A good way to catch these issues early is through periodic inspection. With the engine running, you can listen closely for hissing sounds around the intake manifold, throttle body, and vacuum lines. Lightly spraying areas with carb cleaner and listening for changes in idle speed can help pinpoint leaks.

If you suspect a vacuum issue but can’t find it, a smoke test by a mechanic is a quick and effective method. Preventing these leaks keeps your Tracker running efficiently and prevents costly misdiagnosis.

Beyond vacuum lines, aging sensors can also affect driveability. The oxygen sensor, throttle position sensor, and mass airflow sensor are all key to how your engine runs. When they start to fail, they may not always trigger a check engine light right away. Instead, they cause rough starts, poor fuel economy, or inconsistent power delivery.

Using an OBD-II scanner periodically helps catch these issues before they become more serious. You can even buy a basic scanner and check codes at home without needing a shop visit.

Replacing these components isn’t usually difficult, and most are accessible without needing to remove major parts. Swapping a faulty sensor for a new one can reset the engine’s behavior and restore lost performance. Being proactive with inspections and repairs keeps your Tracker running like it should and avoids the slow decline that often happens with aging electronics.

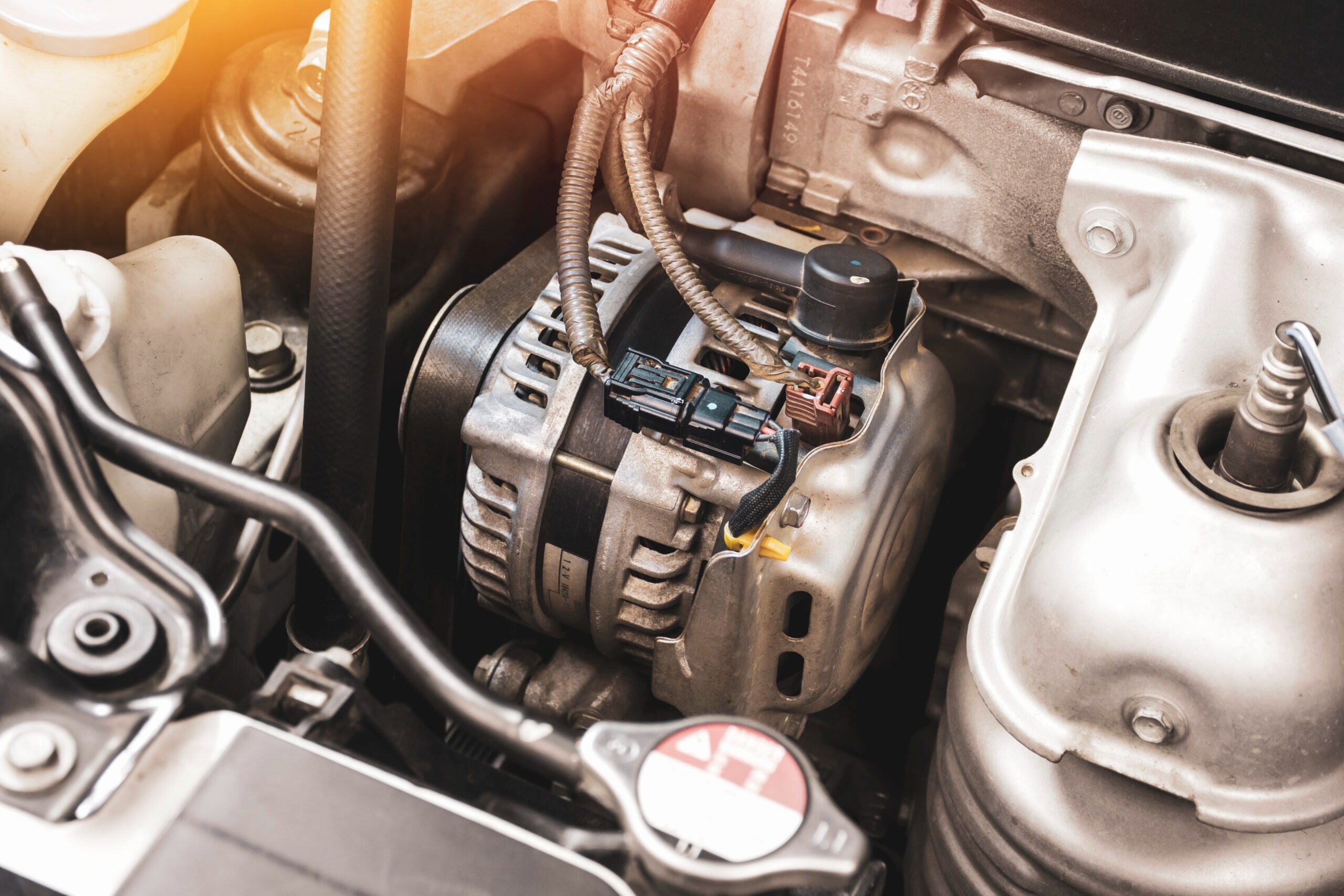

10. Keep the Battery and Grounds Clean

Last but not least, electrical issues can cause a lot of confusion, especially when they come and go randomly. The battery, cables, and ground connections are the starting point for everything electrical in your Tracker. Corroded terminals or loose grounds can lead to no-start situations, dim lights, slow cranking, or strange electrical behavior. Regularly checking and cleaning these connections is an easy way to prevent headaches.

Battery terminals often collect a white or blue-green crust that reduces conductivity. This corrosion can be cleaned using a simple mix of baking soda and water with a toothbrush or a wire brush. Once clean, applying a bit of dielectric grease or terminal protector spray helps keep corrosion from returning. Always make sure the clamps are tight and the battery is securely mounted to prevent movement that could loosen connections.

Ground wires are equally important. Over time, rust or wear at the grounding point (often where the negative battery cable attaches to the body or engine block) can cause poor conductivity. A weak ground can mimic symptoms of a failing alternator or starter. Checking that the ground wires are clean, tight, and free of rust ensures reliable operation of all your Tracker’s systems, from ignition to fuel injection.

It’s also wise to check the battery’s age. Most car batteries last between three and five years. If your battery is getting up there in age, consider testing it at an auto parts store for free. A failing battery may still hold a charge, but won’t perform well under load. Replacing it before it fails saves you from being stranded in a parking lot or driveway. Simple electrical checks keep your Tracker dependable and save you time and frustration.