The GMC Sierra HD is built to take on heavy-duty tasks. Whether it’s hauling heavy trailers, carrying loads of materials, or enduring long hours on construction sites, it has earned a solid reputation for durability and strength. However, even the toughest truck won’t stay reliable forever without regular attention.

Just like any workhorse, it needs ongoing care to keep delivering peak performance. Owning a truck like the Sierra HD is not just about buying power up front; it’s about maintaining that power year after year, job after job.

Many owners make the mistake of believing that because the truck is heavy-duty, it doesn’t need the same level of detailed maintenance. That’s not only wrong but also potentially expensive.

The key to keeping your Sierra HD dependable for the long haul isn’t complicated. It comes down to a consistent approach with specific areas of maintenance. Neglect can creep up slowly. A little oil sludge here, some brake wear there, or an aging transmission can add up to major downtime or costly repairs.

But with the right habits and a few timely fixes, many of the common issues can be avoided or resolved before they lead to real trouble. The goal isn’t perfection, it’s preservation.

The list below covers ten of the most effective fixes and upkeep strategies that can keep your Sierra HD running like new for decades. These aren’t magic tricks or unnecessary upgrades. They’re practical, proven methods that focus on parts of the truck most likely to wear down under hard use.

Think of these as a maintenance blueprint designed not just to fix problems, but to prevent them. By putting a little effort into these key areas, you can make sure your Sierra HD stays ready to work every time you turn the key.

Also Read: 9 Tricks That Keep a Lexus RX Cabin Comfortable for 15 Years

1. Regular Fluid Maintenance

Engine oil, transmission fluid, coolant, brake fluid, and power steering fluid all play critical roles in the GMC Sierra HD’s performance. These fluids lubricate moving parts, manage temperatures, and support hydraulic systems.

If any one of these becomes dirty or low, it can cause serious internal damage that’s often avoidable. Owners sometimes underestimate how quickly fluid can degrade, especially under heavy workloads. That’s why sticking to a strict fluid replacement schedule is one of the smartest habits you can form.

Oil changes are essential. Don’t stretch them too far just because the truck is rated for hard use. Frequent towing or high-mileage use means oil breaks down faster, and dirty oil leads to sludge that harms internal engine components.

Using a high-quality synthetic oil helps, but it’s not a substitute for regular replacement. The same applies to the transmission. Clean transmission fluid ensures smooth shifts and prevents premature wear on gears and solenoids. This is especially important if the truck regularly hauls weighty loads.

Coolant is another area that often gets ignored until it becomes a problem. Over time, coolant loses its effectiveness and can even become corrosive. This can damage radiators, heater cores, and the water pump. Regular flushes can extend the life of the cooling system by years.

Brake fluid is also critical, especially if you’re regularly descending hills or hauling cargo. Moisture can build up in brake fluid, leading to a soft pedal feel and decreased braking power.

Finally, don’t overlook power steering fluid. It often lasts a long time, but when it starts to break down, it can lead to noisy steering and, eventually, a failing power steering pump.

The rule here is simple: inspect fluids often, replace them on time, and use the recommended grades. Keeping fluids fresh is one of the cheapest and most effective ways to preserve the life of your Sierra HD.

2. Address Rust Before It Spreads

Rust can slowly eat away at your Sierra HD if left unchecked. Even though modern trucks use rust-resistant materials and coatings, they’re not immune.

Salt, water, and mud can build up in the undercarriage, wheel wells, and corners of the frame, especially if the truck is used in snowy or coastal areas. Once rust starts, it rarely stops without intervention. The good news is, early signs of rust can be treated before they compromise the structure of the vehicle.

Start with regular visual inspections. Get into the habit of checking underneath the truck, around the bed, and in areas where metal meets metal. Bubbling paint, flaking undercoating, or orange-colored dust are early warning signs. If caught soon enough, rust can often be removed with a wire brush and treated with a rust converter.

After that, applying a protective coating helps prevent it from returning. Simple steps like washing the undercarriage after winter can go a long way in preventing buildup.

Pay close attention to the frame rails and suspension components. These are load-bearing parts that can’t afford to lose strength. Surface rust might seem harmless at first, but when it starts eating through brackets or welds, it becomes a serious safety issue.

Rust on brake lines or fuel lines is also a problem waiting to happen. Once compromised, those lines can fail under pressure, potentially leading to catastrophic consequences.

There are professional rustproofing services available, and while they’re not cheap, they’re often worth the investment for those who plan to keep the truck long-term.

Applying a yearly undercoat, especially if you drive in salty conditions, helps protect vulnerable areas. Remember, rust repair is far more expensive than rust prevention. Deal with rust early, and your Sierra HD will keep its strength and structure for the long haul.

3. Replace Worn Suspension Components

The suspension system on the Sierra HD takes a real beating. Whether it’s rough job sites, pothole-ridden roads, or the constant weight of trailers and loads, suspension parts don’t last forever.

The bushings, ball joints, shocks, and control arms all play a vital role in how the truck handles and how well it carries weight. Once these parts begin to wear out, you’ll notice changes in ride comfort, steering control, and even tire wear.

Shocks and struts are often the first components to go soft. When that happens, you’ll feel the truck bouncing more than usual, especially on uneven surfaces. This not only affects comfort but also impacts how well the truck keeps all four wheels planted during towing.

If you’ve noticed increased swaying or nose-diving under braking, chances are the suspension needs attention. Replacing shocks with heavy-duty or upgraded aftermarket versions can provide better stability for hauling.

Ball joints and bushings wear down over time, particularly with constant turning under load or rough terrain driving. Worn ball joints can lead to play in the steering and uneven tire wear, and if one fails, it can even cause a wheel to detach.

Suspension bushings also break down with age, resulting in clunks, rattles, and general instability. Keeping these components fresh helps ensure the Sierra HD stays responsive and reliable on the road or job site.

Another area to watch is the leaf springs in the rear. These carry a huge portion of the truck’s working load and are often under strain. Cracks, sagging, or broken leaves indicate it’s time for replacement. Sometimes, upgrading to helper springs or airbags can provide extra support for trucks used in consistent heavy-duty environments.

Don’t wait for a failure to act. Staying ahead of suspension wear keeps your truck safer and prevents damage to other systems like tires and drivetrain components.

4. Upgrade and Maintain the Braking System

A heavy-duty truck like the GMC Sierra HD needs a braking system that matches its size and capability. Brakes are often one of the most stressed systems on the truck, especially when towing or hauling loads.

Over time, factory brake components may wear faster than expected under heavy use. The key to keeping your truck safe and responsive is not only regular maintenance but sometimes a complete upgrade of the braking system for more demanding tasks.

Rotors and pads are wear items and should be inspected regularly. If you hear squealing, grinding, or feel a pulsing in the pedal, it’s time to replace them.

But instead of always using standard replacements, consider heavy-duty brake pads and slotted rotors, which handle heat better and offer more consistent stopping power. This can make a noticeable difference when you’re towing downhill or braking repeatedly in traffic with a full load.

Brake fluid often gets overlooked, but it’s essential for maintaining brake performance. Over time, it absorbs moisture, which lowers its boiling point and can cause fade during hard braking. A simple flush every two to three years ensures your brakes stay responsive.

Check the lines as well, rubber lines can degrade, and metal lines can rust, especially in areas where salt is common in winter. Replacing old lines with stainless steel options improves both safety and longevity.

Another upgrade worth considering is a larger brake kit. Some owners who use their Sierra HDs for extreme tasks opt for bigger rotors and calipers to increase stopping power. While more expensive, it adds a level of safety that standard setups may not offer.

Don’t forget about the parking brake either, it plays an important role in holding the truck steady when parked on an incline or during hitching. Keeping the entire braking system in top condition isn’t just about comfort. It’s about safety, control, and protecting your investment.

5. Maintain the Transmission

The transmission in a GMC Sierra HD works harder than most. It’s tasked with transferring power from a high-torque diesel or gas engine to the wheels under immense stress, often while pulling trailers, climbing grades, or crawling through job sites.

It’s no exaggeration to say that a poorly maintained transmission can bring even the strongest truck to a grinding halt. To avoid major issues and preserve performance, a strict maintenance schedule, along with timely fixes, is essential.

One of the most important steps in transmission care is fluid maintenance. Transmission fluid doesn’t just lubricate, it also cools the system and provides hydraulic pressure for gear shifts. Over time, heat, metal shavings, and friction material from the clutches can contaminate the fluid.

This results in harsh shifting, slipping, or delayed engagement. Sierra HD owners should follow service intervals, especially if they tow often. Flushing the fluid and replacing the filter (if applicable) can extend the lifespan of both the transmission and torque converter.

It’s also critical to monitor how the truck shifts under load. Early signs of transmission wear include rough or delayed shifting, surging, or high RPMs before gear engagement.

These symptoms should never be ignored. Software updates for the transmission control module are sometimes issued by GMC to improve shifting logic and longevity. Getting the truck scanned at a dealership or using a quality diagnostic tool can reveal early issues that don’t always trigger warning lights.

For those regularly pushing their Sierra HD to its limits, installing a transmission cooler is a smart upgrade. Keeping temperatures down is one of the most effective ways to prevent breakdown. Overheated transmissions are the most common cause of failure in heavy-duty use.

With proper care, fresh fluid, accurate tuning, and cooling support, the transmission can last well into the hundreds of thousands of miles. Avoid the “drive it until it breaks” mentality, and your transmission will stay strong and reliable.

Also Read: 10 Pro Tips That Keep a Chevy HHR Reliable for Daily Driving

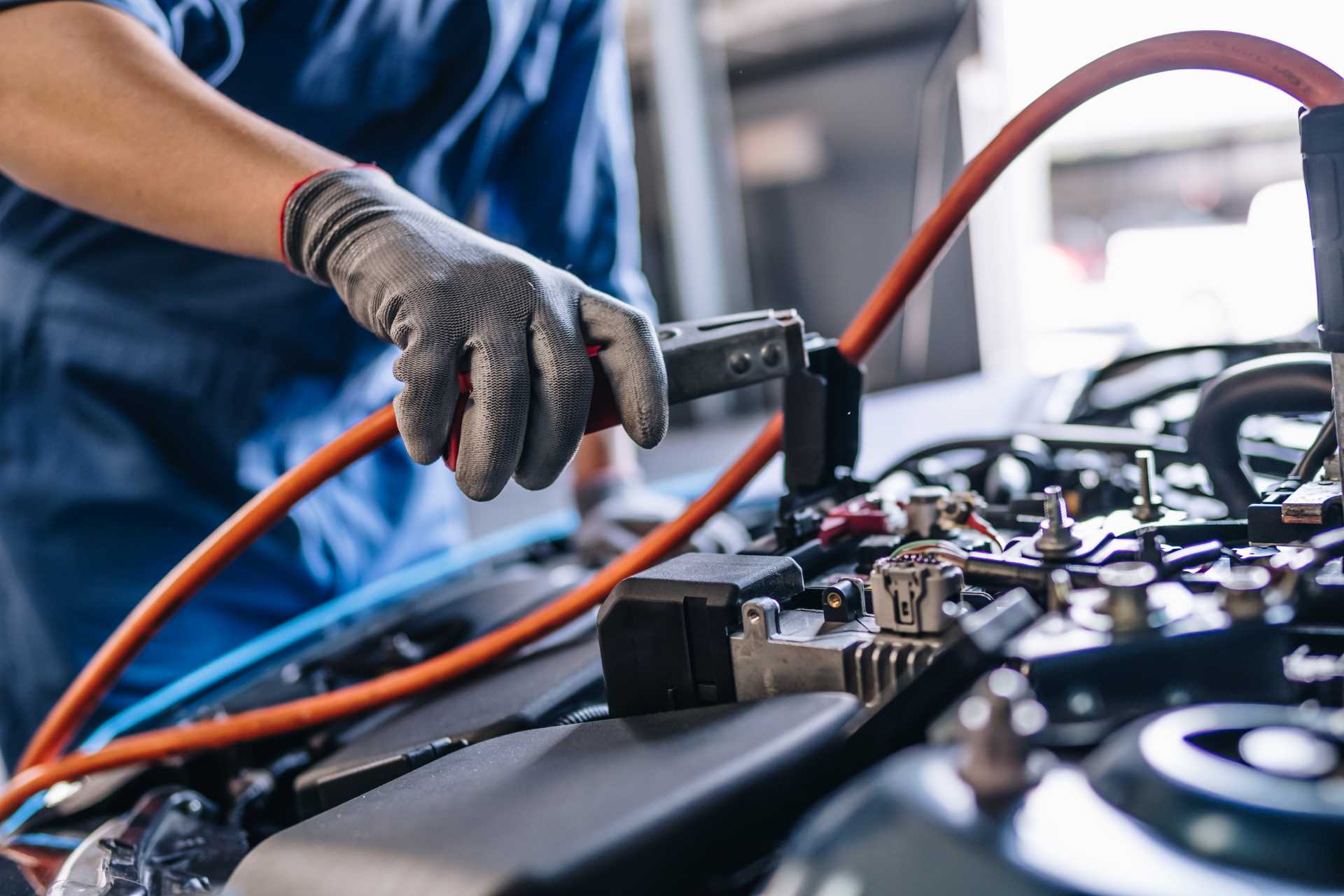

6. Keep Electrical Systems in Check

Electrical problems can quietly undermine the performance and reliability of a work truck. While the GMC Sierra HD is mechanically robust, its electrical systems are complex and integrated into every aspect of operation, from engine management and lighting to trailer brakes and infotainment.

Over time, wear, corrosion, or poor connections can lead to a wide variety of headaches. Staying ahead of these issues means inspecting and maintaining electrical systems with the same discipline as you would with the engine or suspension.

Battery health is the starting point. A weak or aging battery can lead to starting issues, dim lights, or trouble with onboard electronics. Since the Sierra HD may sit for extended periods between jobs or be operated in extreme weather, the battery can degrade faster than expected.

Regular voltage checks and load testing are useful in catching early signs of failure. Keeping the terminals clean and connections tight ensures consistent performance. For added protection, especially in colder climates, a battery tender or warmer can help extend battery life.

Alternators and starters also wear out over time, especially with frequent engine starts or when powering auxiliary equipment like winches, lights, or plows. Symptoms like flickering lights, slow cranking, or strange gauge behavior often point to issues in the charging system.

Upgrading the alternator in trucks with heavy electrical demands is a common fix that pays off in the long run. As these systems degrade, they can also create cascading problems in sensors, modules, or onboard computers.

Wiring and connectors are particularly vulnerable in work trucks. Dust, vibration, and moisture can damage insulation or corrode pins. Trailer plugs, lighting connectors, and chassis harnesses should be inspected periodically. Electrical greases and proper dielectric protectants can help keep water and corrosion at bay.

Many frustrating electrical gremlins, like random warning lights or erratic behavior, trace back to simple wire issues. Staying vigilant with inspections and using quality replacement parts prevents downtime caused by hard-to-trace electrical faults.

7. Monitor and Upgrade the Cooling System

The cooling system on a heavy-duty truck plays a critical role, particularly under demanding workloads. The GMC Sierra HD, especially with a diesel engine, generates massive heat when pulling trailers or working in slow-moving environments.

A weak cooling system won’t just result in overheating; it can lead to warped cylinder heads, blown gaskets, or engine failure. This makes the cooling system one of the most vital, yet often ignored, components in long-term truck reliability.

Radiators, hoses, thermostats, and water pumps all wear down over time. Even though the coolant itself should be changed periodically, so too should the parts responsible for its circulation. Radiators can get clogged internally or externally with debris and corrosion.

A clogged radiator won’t cool properly even if the coolant is clean. It’s good practice to blow out debris from the front grille and condenser area regularly, especially during bug season or if working in dusty environments.

Coolant hoses may look fine on the outside while degrading internally. Over time, rubber breaks down due to constant heat cycles and pressure. A burst hose can cause instant overheating, leaving the truck stranded. Replacing aging hoses before failure is an easy and cost-effective fix.

Thermostats are another overlooked part. If they stick closed, they prevent coolant from flowing, leading to rapid overheating. If they stick open, the engine may run too cold, hurting fuel efficiency and emissions performance.

For trucks constantly under load, an upgraded cooling system may be necessary. High-capacity radiators, dual electric fans, and better thermostats are all common upgrades in performance or commercial builds. If you’re operating in hot climates or frequently towing, these upgrades provide peace of mind. It’s also essential to watch temperature gauges closely and respond to any changes, no matter how small.

Regular system pressure tests and coolant analysis help detect leaks or contamination before they cause trouble. Preventing overheating saves engines, and in a work truck, that means avoiding some of the most expensive repairs imaginable.

8. Replace and Rotate Tires Consistently

Tires are one of the most important parts of any vehicle, and on a heavy-duty work truck like the Sierra HD, they carry more weight and stress than most drivers ever encounter. Tire maintenance is about more than avoiding blowouts; it’s about ensuring proper handling, braking, fuel economy, and load distribution.

Despite being a wear item, tires are often neglected, especially when work schedules get busy. But poor tire maintenance can lead to serious safety issues and unexpected downtime.

Regular tire rotation is one of the simplest and most effective practices. Since the weight distribution and driving conditions are often uneven, especially when towing, front and rear tires wear at different rates. By rotating them every 5,000 to 7,000 miles, you ensure even wear and extend the life of the entire set.

Skipping this step results in cupping, feathering, or premature replacement of one or two tires, which can lead to mismatched traction and performance.

Tire pressure is another critical point. Underinflated tires generate excess heat, which not only reduces fuel economy but also increases the risk of sidewall failure. On the other hand, overinflated tires wear out the center tread faster and provide less grip.

Using a quality gauge and checking pressure regularly is key, especially during temperature swings. For trucks used in towing, using load-rated tires and adjusting pressure according to the load chart provided by the tire manufacturer ensures maximum safety and stability.

Alignment and balance also affect tire longevity. If your Sierra HD pulls to one side, has a crooked steering wheel, or shows uneven tread wear, chances are your alignment is off.

This can stem from hitting potholes, curbs, or general wear. Keeping the suspension aligned protects not just tires but also steering components and ride quality.

Balancing tires during installation or rotation helps avoid vibration that can wear out other parts prematurely. Good tire care means better traction, safer driving, and longer service intervals across the board.

9. Stay Ahead of Fuel System Problems

The fuel system in a GMC Sierra HD is responsible for much more than delivering power. It controls everything from emissions performance to throttle response, and even a minor issue in the fuel system can bring the truck’s performance to a crawl.

Whether you’re running diesel or gas, the fuel system needs regular attention to keep running clean, efficient, and responsive. Ignoring it opens the door to hard starts, clogged injectors, or even engine damage.

Fuel filters are the first line of defense. They trap dirt, water, and other contaminants before they reach the injectors. For diesel models, especially, water contamination is a major concern. Many modern diesel engines have water separators that need to be drained regularly.

Letting dirty fuel pass through the system can clog injectors, damage the high-pressure pump, or even trigger engine codes. Replacing the fuel filter on schedule is cheap insurance against major fuel system repairs.

Injectors also deserve attention. Over time, deposits can build up, affecting spray patterns and combustion efficiency. This leads to misfires, poor mileage, and smoky exhaust.

Using high-quality fuel, along with periodic injector cleaning (either via additives or professional service), helps prevent these issues. For trucks that idle often or sit unused between jobs, fuel stabilizers can protect the system from varnish buildup or condensation.

Fuel pumps eventually wear out too, especially when run dry or with poor-quality fuel. If your truck begins to stall under load, has a sluggish throttle, or makes a whining sound from the tank, the pump could be failing.

Catching this early can prevent a no-start condition. Upgrading the fuel lift pump on diesel models is a common practice among those who tow heavy or run performance tuners, as it helps maintain consistent fuel pressure and filter life.

10. Regularly Inspect the Drivetrain and Axles

The drivetrain of the GMC Sierra HD is where all the engine’s power gets translated into usable traction. From the transfer case to the driveshafts to the differentials and axles, each component plays a critical role in keeping the truck moving under load.

These systems operate under intense stress, especially in off-road conditions, during towing, or when hauling heavy payloads. Failing to inspect and maintain these parts can lead to expensive repairs and dangerous breakdowns, often with very little warning before failure occurs.

Differential maintenance is one area that often gets overlooked. Front and rear diffs should have their gear oil changed at intervals recommended by GMC, more frequently if the truck is used in high-stress environments or frequently encounters water crossings, mud, or dusty conditions.

Gear oil breaks down over time, and if it’s contaminated with moisture or metal particles, it can cause the ring and pinion gears to grind themselves into failure.

A noisy differential, especially during turning, is often a sign of wear or low fluid. Upgrading to synthetic gear oil is often a good idea for added heat resistance and longevity.

U-joints and driveshafts are equally important. These components handle constant rotation, torque load, and articulation over uneven terrain. If a U-joint begins to squeak, vibrate, or bind, it’s time for replacement.

A failed U-joint at highway speed can cause the driveshaft to detach, leading to severe vehicle damage and potentially dangerous road situations.

Greasable U-joints are ideal for work trucks, allowing for regular lubrication and increased lifespan. If your truck is lifted or modified, ensuring correct driveline angles is also important to avoid premature wear.

Axle seals, bearings, and CV joints (for 4WD models) should be visually inspected at every oil change. Leaks from the differential or hubs are red flags that point to worn seals or internal pressure issues. Ignoring these leaks can lead to fluid loss, contamination, and eventual component failure.

In trucks equipped with electronic locking differentials or limited-slip systems, using the correct friction modifiers and fluid types is essential to maintaining smooth operation.

Even subtle vibrations or hums from the drivetrain shouldn’t be ignored, they often signal the early stages of wear that can be corrected easily if caught early.

For owners who routinely push the Sierra HD to its limits, drivetrain upgrades can add durability and peace of mind. Chromoly axle shafts, heavy-duty differential covers, and upgraded bearings can provide a buffer against wear and improve the truck’s ability to survive abuse.

That said, routine inspection remains the most valuable habit. Catching a leak, loose bolt, or strange noise early can prevent a $100 problem from turning into a $2,000 repair. Like every system on the truck, the drivetrain rewards consistency. If it stays healthy, your GMC Sierra HD will keep pulling, hauling, and climbing for decades to come.