Engines are the heart of any vehicle, and the head gasket plays a critical role in maintaining their integrity and performance. Acting as a seal between the engine block and cylinder head, the head gasket prevents coolant, oil, and combustion gases from mixing.

When functioning properly, it ensures smooth engine operation and longevity. However, head gaskets are often one of the most vulnerable components under stress, and their failure can lead to costly repairs or even complete engine failure.

Different engines show remarkable variation in how well their head gaskets hold up over time. Some engines develop a reputation for enduring hundreds of thousands of miles with their original gasket intact, while others are notorious for premature gasket failure.

This discrepancy is driven by a range of factors, including engine design, materials used, cooling system efficiency, manufacturing tolerances, and operating conditions.

Understanding which engines tend to outlive their head gaskets versus those that often experience early gasket failure provides valuable insight into the complexities of engine durability. It also highlights the importance of proper maintenance, engineering choices, and sometimes the inherent limitations of certain designs.

For car enthusiasts, mechanics, and everyday drivers alike, knowing the strengths and weaknesses of particular engines can guide purchasing decisions, maintenance practices, and modifications.

On one side, engines like Toyota’s 2JZ-GTE and Honda’s K-series are celebrated for their robust construction and gasket longevity. These powerplants feature strong blocks, precision-machined heads, multi-layer steel gaskets, and efficient cooling systems, all working together to resist the stresses that typically lead to head gasket failure.

Their ability to withstand high mileage and even significant performance upgrades without gasket issues speaks to thoughtful engineering and quality manufacturing.

On the other hand, some engines show a higher propensity for gasket problems, often due to design compromises or materials that do not adequately manage heat and pressure over time.

Turbocharged Subaru EJ25s, early Mini Cooper S engines, and certain Chrysler V6s illustrate the pitfalls of insufficient gasket clamping, poor coolant flow, or thermal expansion mismatch. These engines often face premature gasket blowouts, leading to headaches for owners and repair shops alike.

This article will cover five engines known for outliving their head gaskets, highlighting what makes them resilient, and five engines that are prone to early gasket failure, examining the reasons behind their weaknesses. Through this comparison, the goal is to provide a clearer understanding of the technical and practical factors that influence head gasket durability.

While no engine is completely immune to gasket problems, and proper maintenance always plays a significant role, the inherent design and manufacturing choices can drastically influence outcomes. Recognizing these differences helps prepare owners to manage expectations, take preventative steps, and make informed decisions whether purchasing, tuning, or maintaining a vehicle.

By exploring these contrasting examples, we can appreciate how engineering advances, materials science, and design philosophy impact engine reliability and longevity, especially when it comes to one of the most critical seals in an internal combustion engine — the head gasket.

Also Read: 9 Basic Things That Kill a Ford GT Too Early

5 Engines That Outlive Their Head Gaskets

1. Toyota 2JZ-GTE (Inline-6)

The Toyota 2JZ-GTE engine is often regarded as one of the most durable and reliable performance engines ever made. Beyond its reputation for high power potential, the 2JZ-GTE stands out because its head gasket rarely becomes a weak link. The engine block is cast iron, known for its rigidity and resistance to warping, which provides a stable base for the head gasket to seal against.

The cylinder head is made of aluminum, but Toyota uses advanced manufacturing processes to ensure flat mating surfaces. This combination helps prevent the head gasket from failing due to uneven compression or thermal expansion.

One critical element in the 2JZ-GTE’s durability is its cooling system. Toyota designed it to circulate coolant efficiently through the block and head, removing excess heat quickly and preventing hot spots.

Since thermal stress is one of the leading causes of head gasket failure, the even heat distribution helps the gasket maintain its seal under demanding conditions. This is especially important for turbocharged variants, where the combustion chamber sees higher temperatures and pressures.

Another factor contributing to the gasket’s longevity is the head bolt design and torque specification. Toyota uses a robust pattern and a torque sequence that ensures the head gasket is compressed evenly, reducing the chances of blowouts or leaks.

This design is proven to hold even after high mileage and when subjected to the stresses of performance upgrades. It also means the engine tolerates occasional heat cycling better than many others.

Owners and tuners have shown that the 2JZ-GTE’s head gasket can handle extreme modifications without failure. From high horsepower drag cars to street-driven builds, this engine’s gasket rarely becomes the limiting factor. When maintained properly, it consistently surpasses 200,000 miles with its original gasket intact, underscoring the engine’s reputation for reliability and resilience.

2. Honda K-Series (K20, K24)

The Honda K-Series engines, particularly the K20 and K24 variants, are celebrated not only for their performance but also for their well-engineered durability.

One reason the head gaskets in these engines last so long is the use of modern multi-layer steel (MLS) gaskets. MLS gaskets are superior to older composite gaskets because they are made from several thin layers of steel that can expand and contract with the engine, maintaining a tight seal despite thermal cycling and pressure changes.

The K-series engines benefit from precision manufacturing and attention to detail. Honda engineers machine the block and cylinder head surfaces to extremely tight tolerances, ensuring the gasket has a perfectly flat surface to seal against. This minimizes the chance of small gaps or warping that can cause leaks.

Additionally, the K-series engines are designed with a relatively compact combustion chamber and well-balanced combustion dynamics, which reduce localized pressure spikes that stress the gasket.

Cooling plays a crucial role in protecting the gasket, and Honda’s cooling system for these engines is efficient and well-designed. Coolant flow is optimized to maintain consistent temperatures, preventing hotspots and thermal stress. The combination of high-quality gaskets and stable operating temperatures results in engines that can routinely reach 150,000 miles or more without gasket-related issues.

Beyond stock durability, the K-series engines are also popular platforms for performance tuning, including turbocharging and supercharging. Thanks to their robust gasket design and material quality, many tuners report that the head gaskets survive substantial power increases, provided the engine is properly maintained and cooling is upgraded.

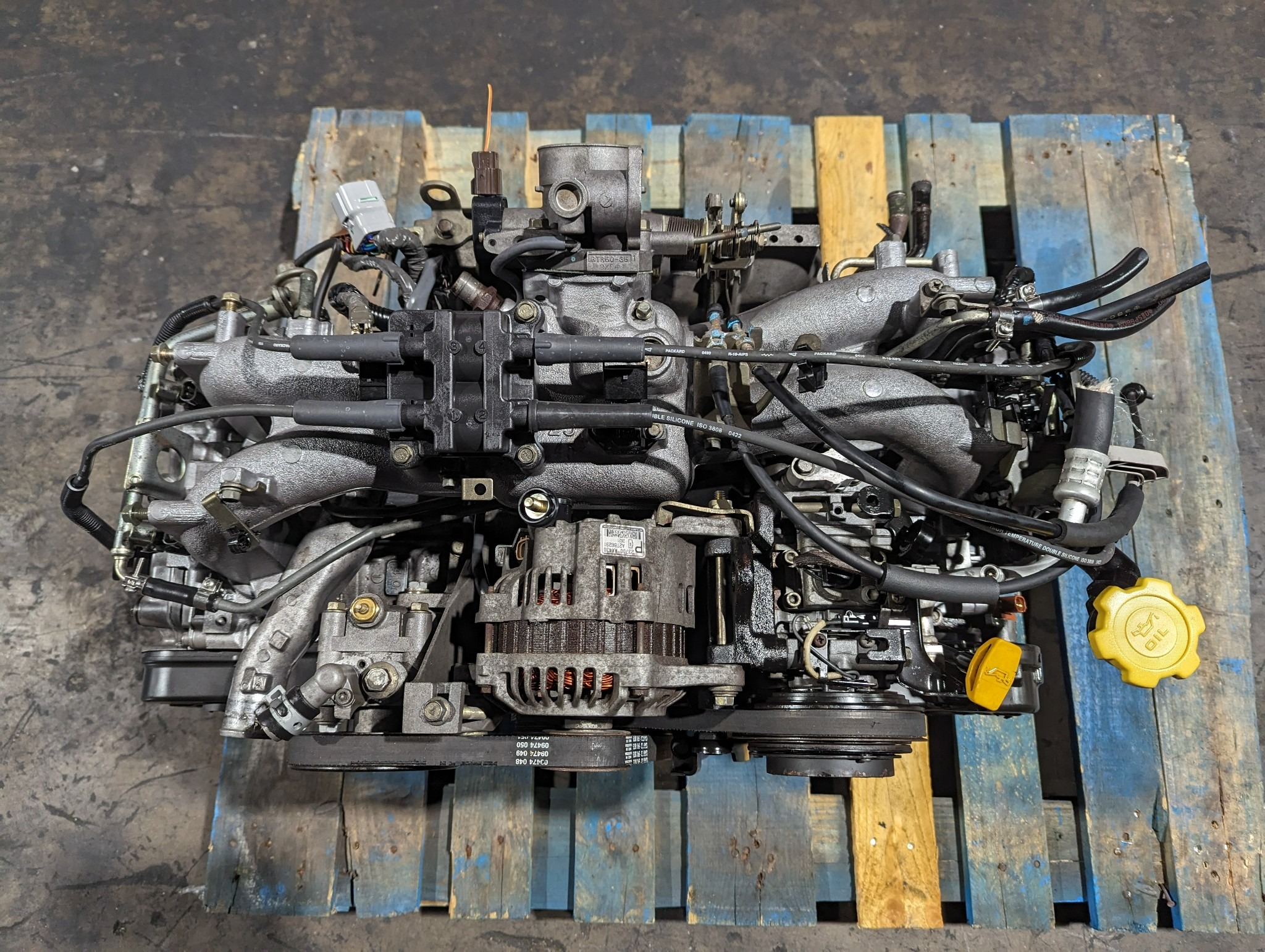

3. Subaru EJ25 (naturally aspirated versions)

Subaru’s EJ25 naturally aspirated engine is a good example of how an engine’s design can positively affect the longevity of the head gasket. The boxer layout is unique in the automotive world, with horizontally opposed cylinders that spread heat more evenly compared to inline or V engines. This layout prevents concentrated heat in one area, which often contributes to gasket failure.

The EJ25 engine uses aluminum heads with iron cylinder liners, a combination that balances weight and strength. Subaru’s engineers addressed early EJ series head gasket issues by improving gasket materials and introducing better clamping methods in later iterations.

The naturally aspirated versions of the EJ25 benefit from these improvements, and many examples have logged high mileage without requiring head gasket repairs. Cooling system improvements also played a role. The coolant passages were designed to flow efficiently around the combustion chambers, preventing hotspots.

In addition, Subaru incorporated reinforced multi-layer steel gaskets, which handle the stresses of expansion and contraction better than earlier composite types. This results in gaskets that are less prone to cracking or failure over time.

Routine maintenance and avoiding engine overheating are critical to keeping the head gasket intact, but the naturally aspirated EJ25’s design inherently supports long gasket life. Drivers who maintain proper coolant levels and avoid harsh driving conditions can expect these engines to easily surpass 200,000 miles on original head gaskets.

4. Ford 5.0 Coyote V8

The Ford 5.0 Coyote V8 has been a benchmark in modern naturally aspirated performance engines since its introduction in 2011.

One reason it maintains such reliability, especially concerning the head gasket, is its use of multi-layer steel gaskets combined with a sophisticated head bolt design. Ford engineers implemented torque-to-yield head bolts that stretch slightly when tightened, creating a consistent and reliable clamping force that resists gasket leaks.

The engine uses an aluminum block and heads, but with a high level of engineering precision that results in flat mating surfaces and minimal warping. The combustion chambers are designed to promote even pressure distribution, which reduces the risk of localized gasket failure. Furthermore, the Coyote’s advanced cooling system features optimized coolant flow paths that rapidly remove heat, keeping operating temperatures within safe limits.

Another factor is the durability of the materials used in the gasket itself. The MLS gasket material in the Coyote engine can endure thermal expansion and contraction far better than older gaskets. This resilience is especially valuable in a high-performance V8 where heat and pressure cycles are more intense than in smaller engines.

Owners of the Coyote V8 often report excellent longevity even with aggressive driving and aftermarket power modifications. The engine’s strong block, robust gasket design, and careful engineering make it a dependable choice where head gasket longevity is concerned, often surpassing 150,000 miles or more with stock components.

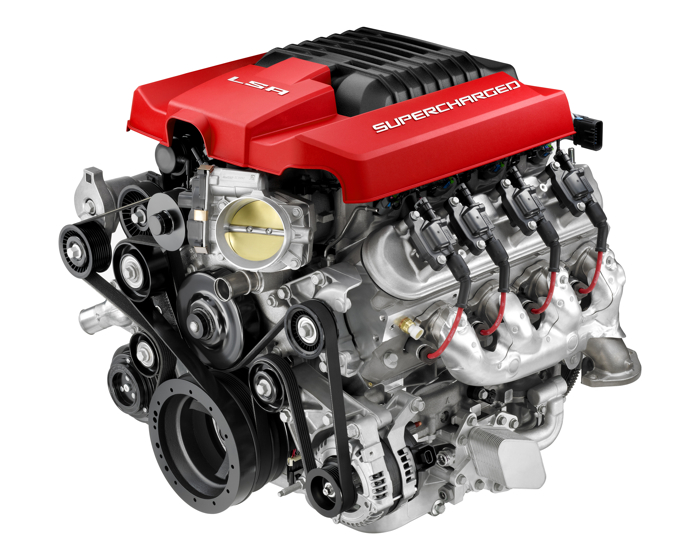

5. Chevrolet LS Series V8 (LS1, LS3, etc.)

The Chevrolet LS family of V8 engines is widely praised for its robustness and reliability, with head gasket durability being a aspect. The LS engines use cast aluminum blocks with iron cylinder liners, which provide structural integrity and reduce cylinder distortion. This rigidity is vital for maintaining a solid seal with the head gasket over long periods and high mileage.

GM uses multi-layer steel head gaskets in these engines, which are well suited to the thermal and pressure demands of V8 combustion. The gasket material, combined with carefully machined and flat surfaces on the heads and block, ensures consistent compression and minimal leakage risk. The head bolt pattern is designed to distribute clamping force evenly, reducing the chance of warping and gasket blowout.

The cooling system in LS engines is another important factor for gasket longevity. Efficient coolant flow prevents overheating and reduces thermal gradients across the cylinder head, which can otherwise cause gasket damage. Many LS engine owners have driven over 200,000 miles with original gaskets intact, demonstrating the reliability of the design.

The LS series’ versatility and strength make it a favorite for performance and endurance builds alike. Its head gasket system can handle increased power from forced induction or higher RPMs without succumbing to premature failure, making it one of the most durable engines in its class.

5 Engines That Blow Their Head Gaskets Early

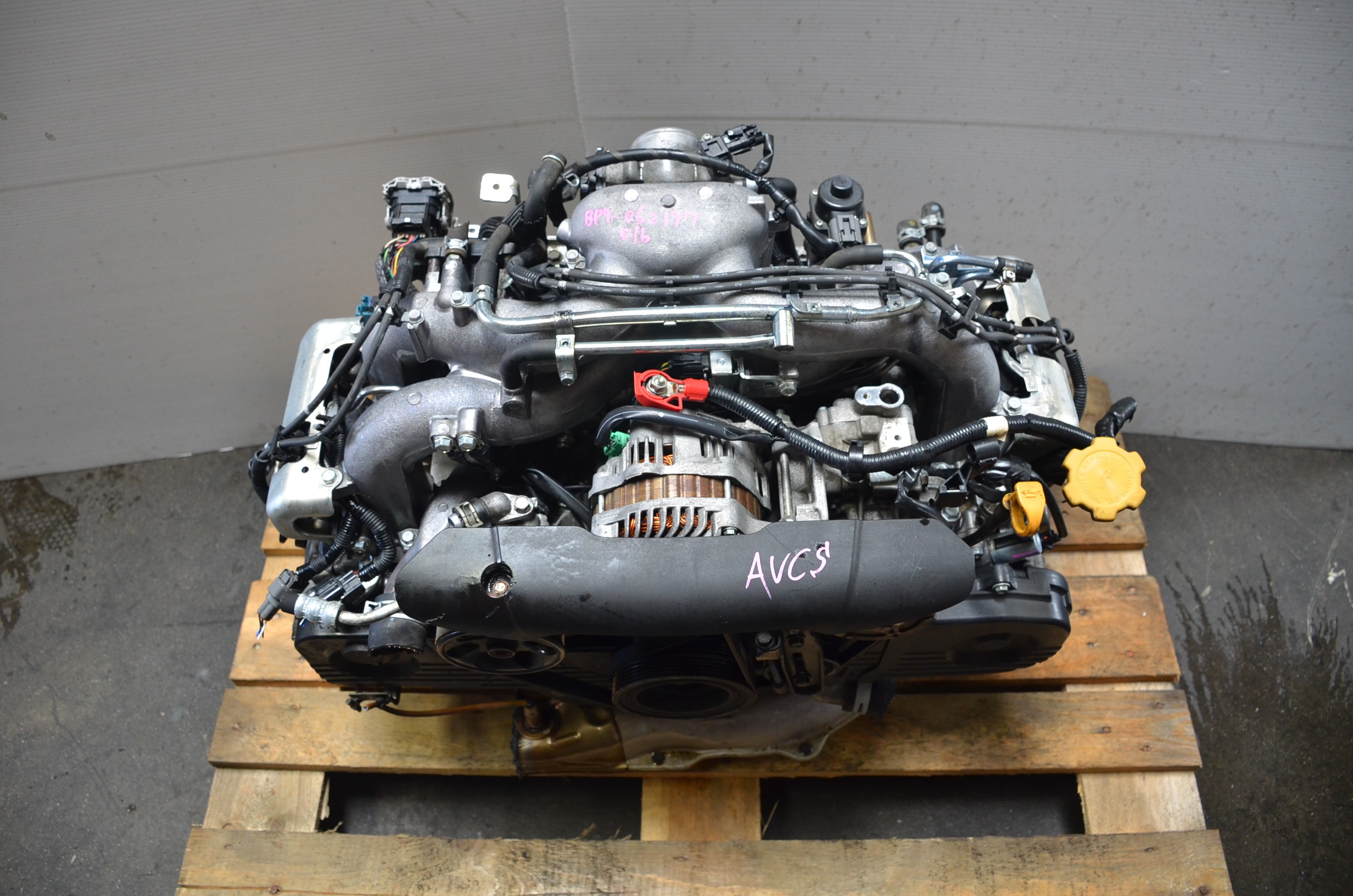

1. Subaru EJ25 (turbocharged versions)

The turbocharged versions of the Subaru EJ25 engine, particularly those found in WRX and STI models from the early 2000s, are infamous for premature head gasket failures. The added stress of forced induction means higher combustion pressures and increased thermal loads, which many early EJ25 designs struggled to accommodate.

The aluminum head and block combination, while light and efficient, tends to expand at different rates under heat. This differential expansion stresses the head gasket, making it vulnerable to leaks and eventual failure.

Subaru’s original gasket design for these turbocharged models often wasn’t robust enough to handle the increased power and heat without additional support. The stock MLS gaskets and head bolts sometimes lacked sufficient clamping force, and the torque specs could allow gradual loosening over time, further compromising the seal.

The problem was compounded when the engine was driven aggressively or subjected to prolonged high temperatures, common in spirited driving or track use.

Another issue contributing to early gasket failure in turbo EJ25 engines is the cooling system design. While Subaru improved coolant flow in later models, many early versions had inadequate circulation around critical areas of the head, leading to hotspots.

These hotspots cause localized warping of the head, which breaks the gasket seal. Moreover, head warpage causes uneven pressure distribution on the gasket, accelerating failure.

Owners often face expensive repairs due to the engine’s complexity and the labor-intensive nature of replacing head gaskets in boxer engines. Many enthusiasts upgrade to aftermarket head studs and improved gaskets to combat these weaknesses. Despite this, the turbo EJ25 remains a cautionary example of how early design limitations combined with high-performance demands can result in premature gasket failure.

2. Mini Cooper S R53 (early models)

The first-generation supercharged Mini Cooper S R53 is beloved for its peppy performance and unique style, but it suffers from a less-than-stellar reputation for head gasket reliability. The small 1.6-liter supercharged four-cylinder engine runs at high pressures and temperatures for its size, and the head gasket often becomes a weak link. Many owners experience head gasket failure at relatively low mileages compared to similar engines in other vehicles.

One major cause is the compact nature of the engine’s design. The limited surface area available for the head gasket means the seal has to withstand intense pressure over a smaller area, increasing the risk of failure. The aluminum head and block materials, while lightweight, also contribute to differential expansion issues. Without an exceptionally robust gasket and head bolt design, the seal can degrade prematurely.

The cooling system in the R53, although adequate for daily driving, can struggle in demanding conditions. Prolonged aggressive driving or high ambient temperatures often push the cooling system beyond its capacity.

This results in overheating, which is a leading factor in gasket failure. Heat causes the head to warp and the gasket to deteriorate, leading to leaks of coolant and oil, which often manifest as symptoms of head gasket failure.

Additionally, the head bolts and torque specs in the Mini R53 engine have been criticized for not maintaining sufficient clamping force over time. This loosening allows the gasket to lose compression and eventually fail.

Many owners choose to upgrade to stronger gaskets and use head studs during repairs to improve reliability. The R53 serves as a reminder that even a fun, sporty engine can have fundamental design flaws that affect longevity.

3. Nissan VQ35DE (early 2000s models)

The Nissan VQ35DE, found in the Nissan 350Z and other models, is a well-regarded engine in many respects but had problems with head gasket failures in its early 2000s variants.

This 3.5-liter V6 uses an aluminum cylinder head and block, which can experience issues with thermal expansion, leading to warping and gasket sealing problems. These early engines often suffer from coolant flow inefficiencies that cause hot spots in the cylinder head.

One of the key design weaknesses was the head bolt pattern and clamping method. The bolts sometimes failed to maintain the necessary pressure over the gasket surface, especially under high heat or performance stress.

The resulting loss of compression and coolant leaks were common symptoms. Owners often reported white smoke from the exhaust, overheating, and coolant loss, classic signs of head gasket failure.

The cooling system also had its shortcomings. Restrictions in coolant flow caused uneven temperature distribution, exacerbating head warping and gasket deterioration.

Over time, this led to failures often seen at lower mileages than expected for an engine of this caliber. Nissan eventually addressed some of these issues in later revisions, improving coolant passage design and gasket materials.

However, early VQ35DE owners frequently faced costly repairs. Preventative maintenance, such as monitoring coolant health and avoiding overheating, is critical for these engines. Without care, the head gasket failure can escalate to more severe engine damage, including cracked heads or blocks. The VQ35DE’s early problems highlight how even popular engines can struggle with gasket durability if design issues are present.

4. Volkswagen 1.8T (early models)

Volkswagen’s 1.8T engine, particularly the models produced between 1999 and 2001, is another example of an engine that commonly experiences early head gasket problems.

This turbocharged four-cylinder aluminum-block engine runs at high pressures and temperatures, placing significant demands on the head gasket. Early gasket designs in this engine were prone to degradation when exposed to prolonged heat and boost.

The aluminum head and block expand and contract differently with heat, which can cause warping over time. The original gaskets, often composite types before MLS became standard, had difficulty maintaining a proper seal under these conditions. This problem was worsened by the engine’s cooling system, which in some early models was prone to failure or inefficiency.

Many owners encountered head gasket failure symptoms such as coolant loss, overheating, and white smoke. Overheating was frequently linked to issues like faulty thermostats or water pumps, which, if left unchecked, accelerated gasket damage. The limited clamping force from the head bolts was also a factor, allowing the head to shift slightly and break the gasket seal.

Repairs for these failures tend to be expensive and labor-intensive. As a result, many owners invest in upgraded gaskets and stronger head studs during engine rebuilds to prevent recurrence. The 1.8T’s early issues serve as a lesson in the importance of matching gasket design to engine stress, particularly in turbocharged applications.

5. Chrysler 2.7L V6

The Chrysler 2.7L V6 engine, widely used in vehicles like the Dodge Intrepid and Chrysler Pacifica in the early 2000s, developed a poor reputation due to frequent head gasket and cooling system problems. Despite its aluminum block and heads designed for lightweight efficiency, the engine suffered from fundamental design flaws that impacted gasket longevity.

One major issue was poor coolant flow, which created hot spots that caused thermal distortion of the cylinder heads. This uneven heat distribution placed severe stress on the head gasket, leading to premature failure. The gasket material itself was often considered too thin and not robust enough to handle the engine’s thermal cycles, which further exacerbated the problem.

The head bolt pattern and clamping force were also insufficient to maintain a strong seal under these conditions. As a result, many engines developed coolant leaks and overheating problems relatively early in their lifespan, sometimes before 60,000 miles. These failures were often accompanied by symptoms like overheating, coolant loss, and white smoke from the exhaust.

Repair costs for the Chrysler 2.7L can be high, and many mechanics recommend preventative measures or even engine replacement due to the frequency and severity of gasket issues. The engine’s struggles underscore the importance of proper cooling system design and gasket material quality in ensuring head gasket durability.

Also Read: 9 Mistakes That Kill a Ford Mustang Mach-E Too Soon

Head gasket durability remains a defining factor in engine reliability and longevity. As we have seen, not all engines are created equal when it comes to how well their head gaskets perform under stress and over time

. The difference between engines that outlive their head gaskets and those that succumb early often comes down to a combination of design robustness, material quality, manufacturing precision, and effective thermal management.

Engines such as the Toyota 2JZ-GTE, Honda K-series, and Chevrolet LS family demonstrate how thoughtful engineering and superior materials contribute to gasket longevity.

These engines benefit from cast iron blocks or reinforced aluminum with iron liners, multi-layer steel gaskets that accommodate thermal expansion, carefully designed head bolt patterns for even clamping force, and cooling systems optimized to prevent hotspots.

This combination creates an environment where the head gasket can maintain a tight seal through high mileage and even significant performance modifications.

In contrast, engines that struggle with early head gasket failure often share common issues: aluminum heads and blocks that expand at different rates, insufficient clamping force from head bolts, inefficient cooling systems that create hotspots, and gasket materials that cannot withstand the thermal and mechanical stresses over time.

The Subaru turbocharged EJ25, early Mini Cooper S R53, and Chrysler 2.7L V6 all suffer from these design challenges, leading to costly repairs and reduced reliability.

Importantly, head gasket failure is not always solely a result of poor engineering. Maintenance habits, operating conditions, and aftermarket modifications can influence gasket life dramatically.

Overheating due to coolant leaks, blocked radiators, faulty thermostats, or aggressive driving will accelerate gasket wear on any engine. Similarly, using quality replacement gaskets and upgrading head studs during repairs can help extend gasket life, even on engines with known weaknesses.

The contrasting stories of these ten engines underscore the broader lessons in automotive design: longevity and reliability often come from balancing performance with durability, using the right materials, and applying engineering solutions that account for real-world stresses.

As engines become more complex with forced induction and emissions controls, maintaining gasket integrity remains a critical challenge.

For consumers and enthusiasts, knowledge is power. Understanding which engines are more prone to head gasket failure can inform vehicle choice, maintenance priorities, and the selection of aftermarket upgrades. Meanwhile, recognizing the engineering behind engines that outlive their gaskets offers appreciation for what goes into building long-lasting machines.

In summary, the head gasket’s fate hinges on multiple factors, with design and materials playing leading roles. Engines that integrate these elements well tend to defy gasket failure and keep running strong well beyond 200,000 miles.

Engines with less optimal designs often face gasket problems earlier, but careful maintenance and upgrades can mitigate many issues. Awareness of these differences can help owners prolong engine life and avoid the frustrations of premature gasket failure.

The head gasket may be a small component, but its impact on engine health and vehicle reliability is enormous. Whether an engine will outlast its head gasket or blow it early often tells a larger story about the balance between engineering ambition and practical longevity.