Turbocharging technology has revolutionized the automotive industry by delivering higher power outputs from smaller displacement engines, boosting fuel efficiency, and improving emissions performance. However, turbochargers add complexity to engine design, and their reliability can vary widely depending on the underlying engine architecture, manufacturing quality, and how the vehicle is driven and maintained.

While some turbocharged engines boast remarkable longevity where both the engine and turbochargers endure high mileage with minimal issues, others face frustrating early turbo failures that may cost owners thousands in repairs or force early replacements.

Understanding why some engines support long-lasting turbo operation while others struggle with early turbo failure is crucial for enthusiasts, mechanics, and prospective buyers alike.

Many factors contribute to the lifespan of turbocharged engines and their turbos. First is the mechanical strength and design of the engine itself: components like the block, pistons, connecting rods, and crankshaft need to handle the added stresses and heat generated by forced induction.

Engines that are robustly built with forged internals, reinforced blocks, and optimized cooling paths typically provide a better foundation for reliable turbo operation. Another key aspect is the turbo system’s design, including oil and coolant lines, bearing types, and the size and flow characteristics of the turbochargers themselves. Proper lubrication and thermal management prevent premature turbo wear and failure.

Additionally, the vehicle’s tuning and software calibration have significant effects on turbo longevity. Overly aggressive boost levels, insufficient warm-up or cool-down procedures, and inadequate oil change intervals increase wear on turbo components.

The quality of maintenance, including the use of the correct synthetic oils, timely oil and filter changes, and periodic inspections, plays a pivotal role in extending turbo life. Driving habits such as allowing the turbo to spool properly before aggressive throttle application, and letting the engine idle to cool the turbo after spirited driving, also influence durability.

This article highlights ten engines that demonstrate contrasting turbocharger reliability. Five engines are celebrated for their ability to outlast their turbos, often reaching high mileages without turbo-related failures. These engines combine strong mechanical designs, effective cooling, and thoughtful turbo integration to support long-lasting performance.

On the other hand, five engines have gained reputations for premature turbo failures, often caused by design compromises, inadequate cooling or oiling, or sensitivity to common maintenance oversights. Through this comparison, the underlying reasons behind turbo longevity and failure become clearer, providing insight into how automakers’ engineering choices impact real-world reliability.

Also Read: 5 Honda Sedans That Rarely Break vs 5 That Constantly Do

1. Toyota 2JZ-GTE

The Toyota 2JZ-GTE engine has earned a near-mythical reputation in the automotive world not just for its tuning potential but also for its exceptional reliability, especially when paired with its stock twin-turbo setup. Designed in the 1990s, the 2JZ-GTE is a 3.0-liter inline-six engine with a cast-iron block, forged steel crankshaft, and forged pistons, features that provide a robust foundation capable of withstanding high levels of stress and boost pressures.

One of the reasons the 2JZ-GTE’s turbochargers outlast many others is the mechanical strength of the engine itself, which is able to absorb the extra forces from forced induction without compromising internal integrity. The block’s rigidity helps maintain proper alignment and prevents failures that can cascade to turbo issues.

Beyond mechanical strength, the 2JZ-GTE benefits from well-designed cooling and lubrication systems. The twin-turbo setup is water-cooled and oil-lubricated, with dedicated oil supply lines ensuring that the turbo bearings receive consistent, clean lubrication.

This is critical because turbos spin at extremely high speeds and generate tremendous heat. Without proper cooling and lubrication, the bearings and seals can degrade quickly, leading to early failure. Toyota’s engineers designed the cooling system to maintain stable operating temperatures, even under sustained high boost and prolonged driving conditions. This thoughtful design minimizes heat soak and keeps the turbo components in a safe temperature range.

In real-world use, many stock 2JZ-GTE engines with their original turbos have been known to surpass 200,000 miles without major turbo problems. This is especially impressive considering the engine’s popularity in tuning circles, where many owners push the stock turbos beyond their factory power ratings.

The turbos themselves are built for durability rather than just maximum airflow, striking a balance between performance and longevity. The stock turbos spool relatively quickly and maintain efficiency without needing immediate replacement or upgrade under normal driving conditions. This reliability comes from Toyota’s conservative engineering approach, favoring durability over extreme performance limits in the factory setup.

The community’s experience also highlights the importance of maintenance and driving habits. Regular oil changes using high-quality synthetic oil, proper warm-up and cool-down periods, and attentive cooling system upkeep all contribute to maintaining turbo health.

Many enthusiasts who respect these practices find that their 2JZ-GTE turbos continue performing well far beyond typical expectations. This engine-turbo pairing is a benchmark for how thorough engineering, mechanical strength, and effective thermal management can combine to produce turbocharged powertrains that stand the test of time.

2. Ford 6.7L Power Stroke Diesel

The Ford 6.7L Power Stroke diesel engine is a workhorse designed for heavy-duty truck applications, where durability and longevity are paramount. Unlike many gasoline engines, diesels generally operate at lower RPMs and generate torque differently, which often translates into less mechanical stress on turbochargers.

The 6.7L Power Stroke’s design incorporates a variable geometry turbocharger (VGT) that adapts to changing exhaust gas flow, enhancing efficiency and performance while managing turbo speed and heat more effectively than fixed geometry designs. This adaptability helps reduce stress on the turbo bearings and seals.

What truly sets the 6.7L Power Stroke apart is its comprehensive cooling and oiling system for the turbo. The turbocharger is water-cooled, which rapidly dissipates heat from the turbine housing, preventing excessive thermal loads. Combined with a robust oil cooling circuit and high-quality filtration, the turbo bearings are kept well lubricated with clean, cool oil.

This prevents bearing fatigue and the oil coking that frequently causes premature turbo failure. The engine block itself is heavy-duty cast iron, built to handle the substantial pressures and temperatures of turbocharging in a diesel context.

Additionally, the 6.7L Power Stroke is designed to perform under extreme conditions, including high payloads, towing, and long highway runs. Ford calibrates the turbo boost levels carefully to maintain reliability, favoring steady, controlled boost over sudden spikes that can lead to failure.

This, along with a well-engineered exhaust gas recirculation system and intercooling, keeps temperatures in check and prevents stress accumulation in the turbo system. Reports from fleet owners and private users alike show that these engines can surpass 200,000 miles on original turbochargers without issue, a testament to their durability.

From a maintenance perspective, these turbos benefit greatly from regular oil changes with high-grade diesel oil, cooling system upkeep, and following proper operating procedures. Diesel engines’ long service intervals and robust build quality contribute to the 6.7L Power Stroke’s reputation as one of the longest-lasting turbocharged engines available.

The combination of advanced turbo technology, thorough cooling, and strong mechanical components makes this diesel powerplant a prime example of turbo durability in demanding applications.

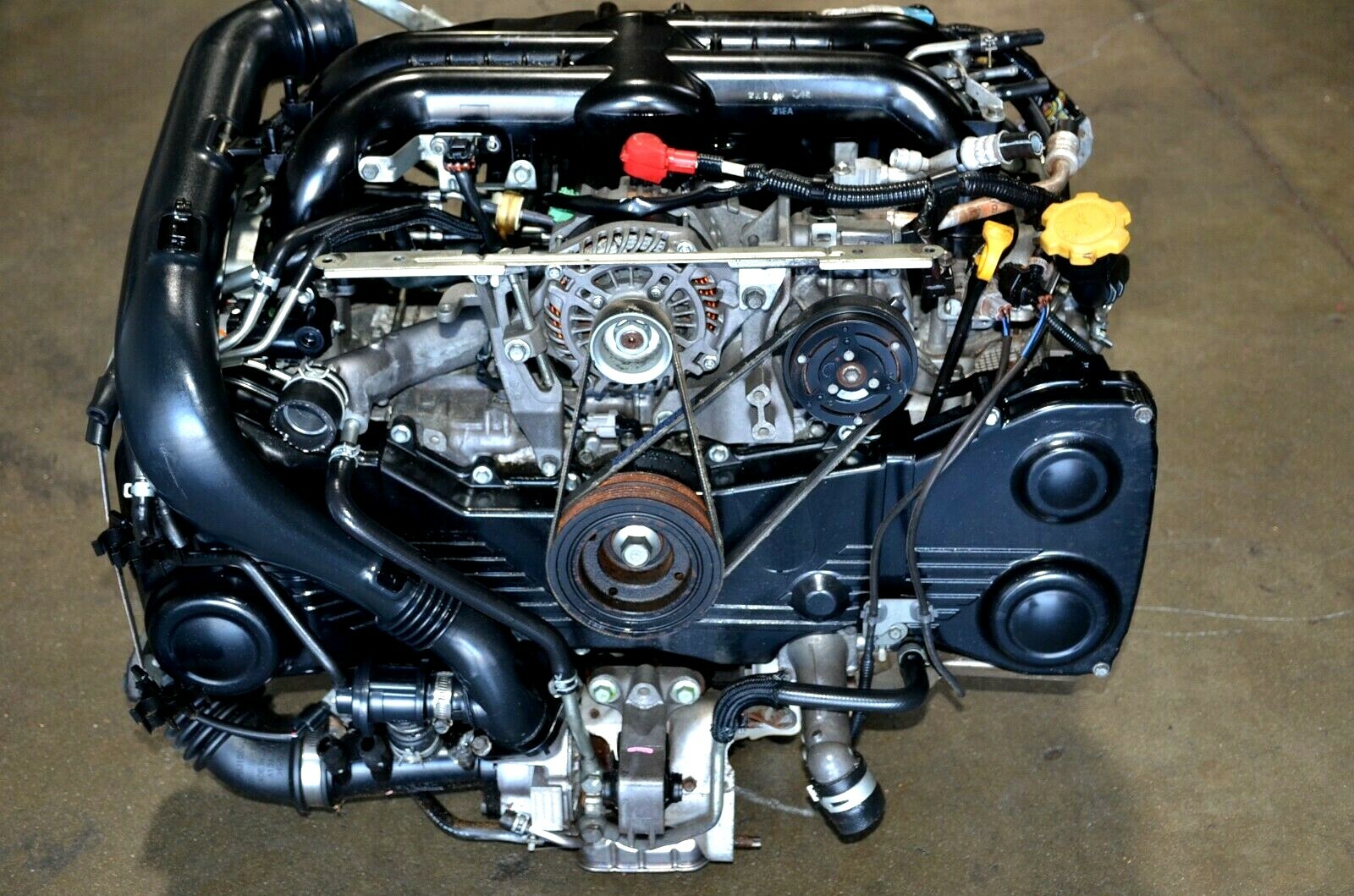

3. Subaru EJ25 Turbo (WRX/STI)

The Subaru EJ25 turbocharged engine is another example of an engine-turbo pairing known for longevity when cared for correctly. The EJ25 is a 2.5-liter horizontally opposed four-cylinder engine widely used in the WRX and STI models. Its boxer layout inherently provides a low center of gravity and improved balance, but it also influences the turbocharging setup.

The turbocharger on this engine is typically a single turbo mounted close to the exhaust manifold for quick spool times and efficient response. This compact packaging, combined with a water-cooled turbo bearing system, helps manage the extreme heat generated during boost.

The EJ25’s integrated cooling system delivers coolant directly to the turbo housing, which plays a significant role in maintaining consistent temperatures and preventing overheating. Oil lubrication is similarly prioritized, with dedicated oil feed and return lines ensuring a continuous flow of fresh, clean oil to the turbo bearings.

Preventing oil starvation and heat buildup reduces the risk of coking and bearing failure, two of the most common causes of turbo damage. Subaru’s design also includes an intercooler system that keeps intake air temperatures low, further protecting the turbo and engine components.

Factory boost levels on the EJ25 are relatively moderate compared to aftermarket tuned versions, reducing the mechanical and thermal stresses on the turbocharger.

When owners adhere to regular maintenance intervals, including frequent oil changes with the correct synthetic oils, and avoid harsh cold starts or immediate shutdowns after spirited driving, turbo longevity is often excellent. The engine’s robust construction, with a strong block and well-engineered internals, complements the turbo’s durability, allowing many WRX and STI owners to experience trouble-free turbo operation well past 100,000 miles.

While the EJ25 has faced some well-known issues, such as head gasket failures in earlier models, the turbochargers themselves generally have strong reliability. The key to long life is proper maintenance and mindful driving habits. The Subaru EJ25 turbo system illustrates how combining effective cooling, lubrication, and solid engine architecture can yield a turbocharged package that withstands years of spirited use without premature failures.

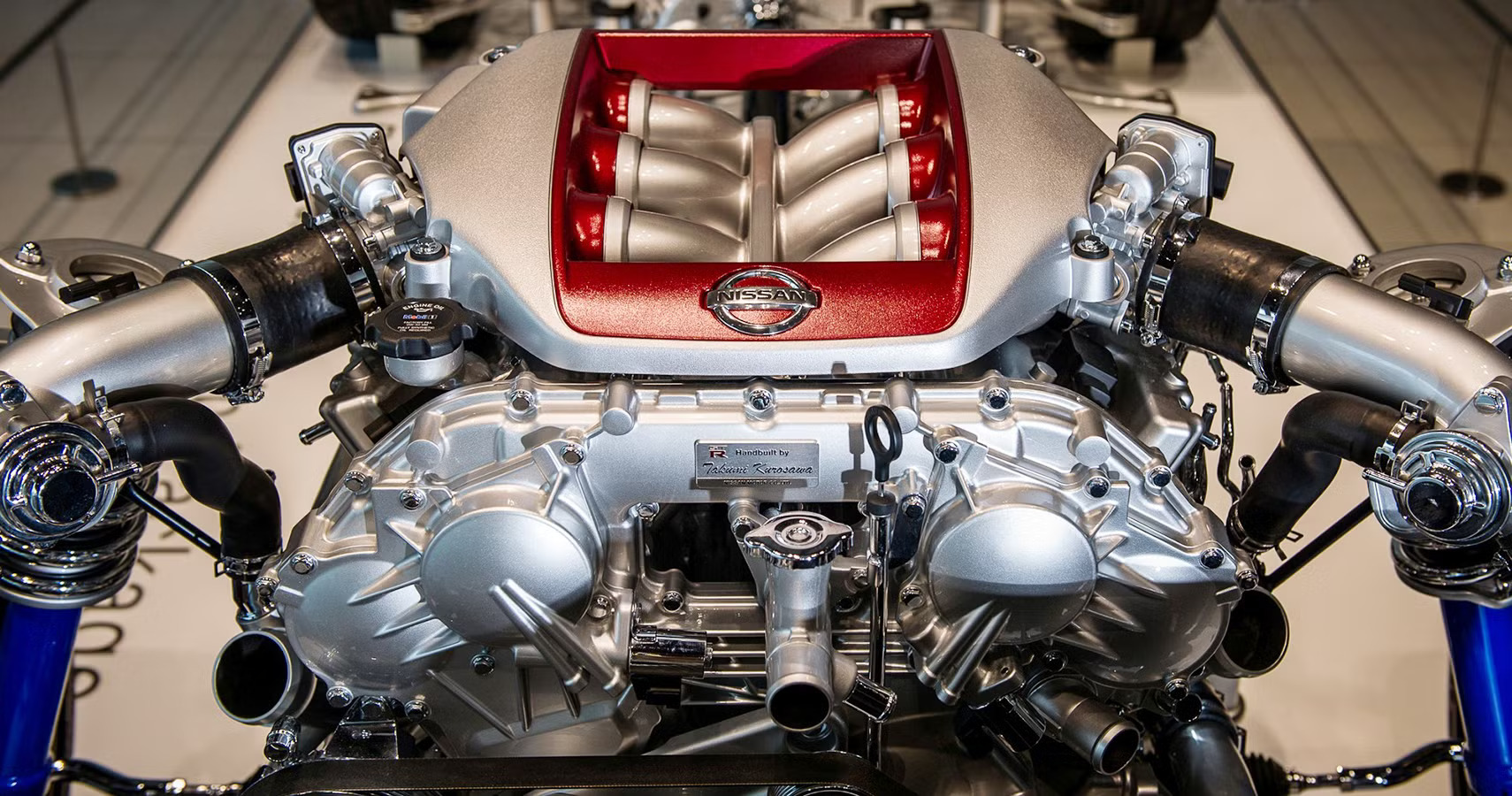

4. Nissan VR38DETT (GT-R)

The Nissan VR38DETT engine is an engineering masterpiece that balances enormous power output with a surprising degree of reliability, especially considering the extreme conditions under which the turbos operate.

This 3.8-liter twin-turbocharged V6 engine, found in the Nissan GT-R, features an aluminum block with forged pistons and a high-strength crankshaft designed to handle aggressive driving and high boost pressures. The turbos themselves are water-cooled and oil-lubricated, with dedicated coolant circuits that rapidly dissipate heat from the turbine housings, an essential factor given the engine’s ability to produce over 500 horsepower in stock form.

One of the standout design features of the VR38DETT is its comprehensive thermal management system. The turbos run at extremely high speeds, and exhaust gases reach very high temperatures.

Nissan’s engineers designed the turbocharger housings and oiling systems to ensure rapid cooling and reliable lubrication, significantly reducing the risk of heat-related bearing failure. The engine also uses an efficient intercooler system that lowers intake air temperature, preventing heat soak and helping the turbo maintain performance and durability under load.

Nissan carefully calibrated the VR38DETT’s boost levels and turbo spool characteristics to avoid excessive stress on the turbochargers. Although the engine can be tuned for much higher power outputs, the factory setup favors reliability, ensuring that turbos can operate safely for extended periods.

Many GT-R owners report their turbos lasting well beyond 100,000 miles with proper maintenance, including regular oil changes, coolant flushes, and avoiding harsh shutdowns immediately after spirited driving.

The VR38DETT exemplifies how high-performance turbocharged engines can be engineered to handle intense heat and mechanical loads while maintaining turbo longevity. Its combination of advanced materials, effective cooling, and balanced tuning creates a package where turbos not only survive but thrive, making it a benchmark for turbo durability in the high-performance segment.

5. Volkswagen/Audi 2.0T TSI EA888 Gen 3

The Volkswagen Group’s EA888 Gen 3 2.0T TSI engine is an evolution in turbocharged engine design that significantly improved turbocharger reliability compared to earlier generations. This 2.0-liter inline-four engine is widely used across VW and Audi vehicles, praised for its blend of efficiency, power, and durability. Key to its turbo longevity are the design improvements in cooling, lubrication, and turbocharger construction introduced in the third generation.

The EA888 Gen 3 uses a water-cooled turbocharger to manage the high heat generated during boost. Effective cooling is crucial to prevent the turbo from overheating and damaging its internal seals and bearings.

Volkswagen improved oil flow pathways, including the use of a more efficient oil pump and cleaner oil delivery routes, to ensure consistent lubrication under various operating conditions. These refinements help reduce wear on turbo components and prevent common failures seen in earlier turbo designs.

Owners and mechanics report that the Gen 3 EA888 turbos last well beyond 150,000 miles when maintenance guidelines are followed. Regular oil changes with the correct synthetic oil, prompt replacement of oil filters, and maintaining the cooling system help maintain the turbo’s health. The engine’s moderate factory boost levels, combined with a well-tuned intake and exhaust system, avoid pushing the turbocharger beyond its durability limits in stock form.

This engine demonstrates how iterative design improvements, particularly in thermal management and lubrication, can transform turbo reliability. The EA888 Gen 3’s turbo system strikes a balance between performance and longevity, making it a preferred choice for drivers seeking a turbocharged engine that can deliver spirited driving while lasting the long haul.

Also Read: 5 Nissan Maxima Years You Can Keep vs 5 That Won’t Last

5 Engines That Blow Early

1. Volkswagen 1.8T (Early Models)

The early Volkswagen 1.8T engine, while celebrated for its smooth power delivery and tunability, has a reputation for turbocharger issues that can arise relatively early in its lifespan. This engine, introduced in the late 1990s and early 2000s, uses a turbo design that, although innovative for its time, is prone to problems related to oil supply and heat management.

One of the primary issues is that the turbo’s oil feed and return lines can become clogged or restricted, especially if the engine oil is neglected or changed infrequently. The buildup of carbon deposits in the oil passages can starve the turbo bearings of lubrication, leading to accelerated wear and eventual failure.

The turbocharger itself is mounted in a tight space near the exhaust manifold, which subjects it to extreme heat and makes effective cooling a challenge.

In addition to lubrication problems, early 1.8T turbos are vulnerable to heat damage. The turbo housing and turbine wheel endure very high exhaust gas temperatures, which can cause warping of components and breakdown of seals over time.

The heat can also lead to coking, where oil burns and leaves deposits in the turbo’s oil passages, further restricting oil flow and causing the turbo to fail prematurely. Because the 1.8T was one of the earlier widespread turbocharged engines in mass-market vehicles, its thermal management system was less advanced than what’s found in modern turbocharged engines.

This makes the turbo more sensitive to driving habits such as frequent short trips or hard acceleration without proper warm-up and cool-down periods.

The engine’s turbo longevity is also affected by the factory boost levels, which, while not extreme, can sometimes be aggressive for the original turbo hardware if the vehicle has high mileage or has seen modifications.

Many owners report needing turbo replacements around 100,000 miles, although with careful maintenance and driving, the turbos can sometimes last longer. The key to extending the life of the 1.8T turbo is regular oil changes with high-quality synthetic oil, ensuring oil passages are clear, and giving the turbo time to cool down after spirited driving. Neglecting these can result in oil starvation and overheating, common causes of premature turbo failure.

Despite these issues, the 1.8T remains a popular and tunable engine, and many owners have successfully upgraded to more robust aftermarket turbos or improved cooling solutions to address early failures. However, in its stock form, the early 1.8T turbochargers are known to have a shorter lifespan compared to other engines on this list.

2. Mini Cooper S (R56) N14 Engine

The N14 engine found in the Mini Cooper S (2007-2010 models) has been notorious for turbocharger and engine reliability issues. The 1.6-liter turbocharged four-cylinder engine delivers impressive performance, but it has a reputation for early turbo failures caused by a combination of design shortcomings and maintenance challenges.

The turbocharger in the N14 is sensitive to oil supply issues, with oil starvation being one of the primary reasons for premature failure. This is compounded by the turbo’s location near the engine’s exhaust manifold, exposing it to very high temperatures and making proper cooling difficult.

Additionally, the N14 engine itself has a history of timing chain problems, which can indirectly affect turbo longevity. If the timing chain or related components fail, it can cause abrupt engine damage or misfires, resulting in abnormal turbo operation and increased stress.

The engine’s cooling system is also prone to problems, such as thermostat failures or coolant leaks, which reduce the system’s efficiency and cause the turbo and engine to run hotter than intended. These higher temperatures accelerate wear on turbo seals and bearings, often leading to oil leaks and turbo failure.

Turbo longevity on the N14 is further impacted by its oil change interval recommendations, which some owners find too long for such a high-stress turbocharged engine. Neglecting oil quality or using incorrect oil can accelerate the buildup of deposits and cause oil starvation to the turbo.

Many owners report needing to replace the turbocharger before the engine reaches 80,000 miles, with some failures occurring even earlier under harsh driving conditions or neglect. Cooling modifications and more frequent oil changes can help mitigate these issues, but the stock N14 turbo system is generally considered less robust than many competing engines.

Despite its shortcomings, the N14 engine has been improved upon in later Mini Cooper models, with newer engines featuring better turbo cooling and timing chain designs. However, the early N14 turbos remain a cautionary example of how design and maintenance issues can lead to early turbo failures in an otherwise fun-to-drive car.

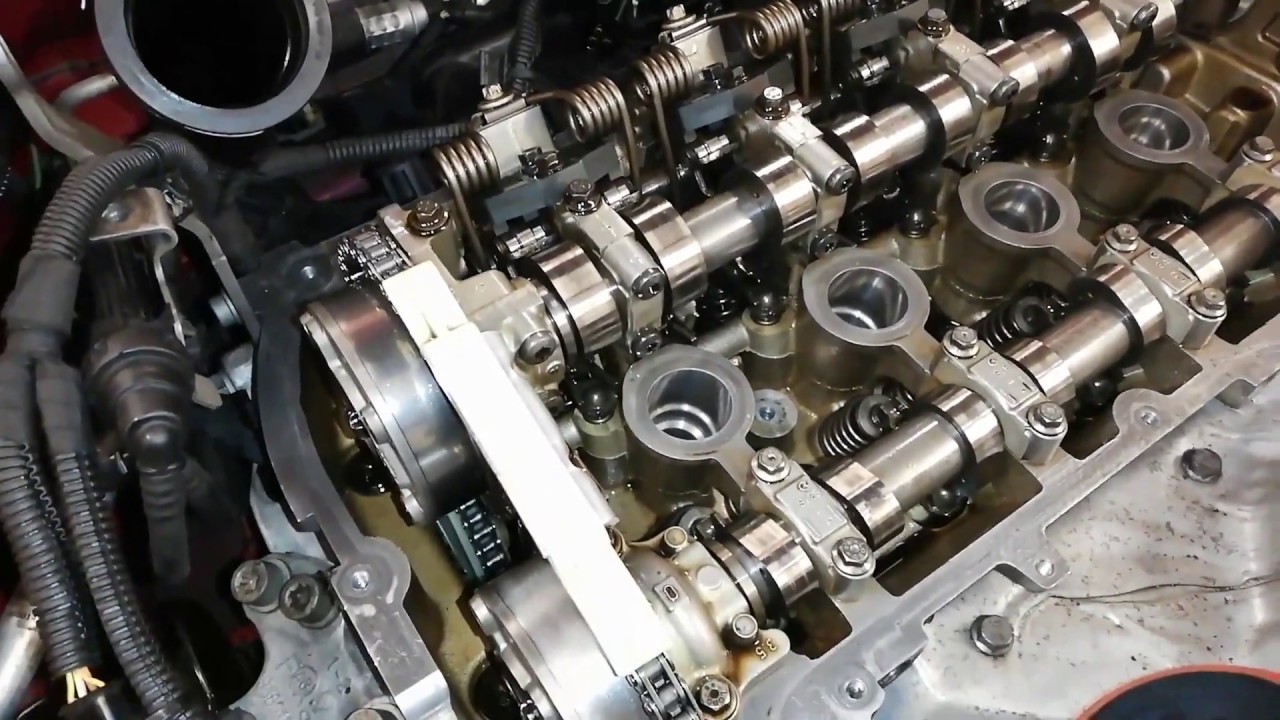

3. BMW N54 Engine

The BMW N54 engine, the first mass-produced twin-turbocharged inline-six from BMW, is widely praised for its performance but also infamous for early turbocharger problems. This 3.0-liter engine introduced direct injection and twin turbos to the brand’s lineup, delivering smooth and powerful acceleration.

However, the turbochargers used on the N54 have a well-documented tendency to fail prematurely, often requiring replacement between 60,000 and 100,000 miles. One of the core issues lies in the turbo’s high operating temperatures and the complex oil delivery system. Oil coking and carbon buildup in the turbo oil feed lines restrict proper lubrication, causing bearing wear and eventual turbo failure.

Thermal management in the N54 is a challenge due to the engine’s compact design and tightly packed turbo system. The turbos sit close to the exhaust manifolds, exposing them to extreme heat cycles that accelerate wear on seals and turbine wheels.

Furthermore, the water-cooling passages for the turbos can become clogged or corroded over time, reducing their effectiveness and increasing the risk of overheating. The engine’s high boost levels also place significant mechanical stress on the turbochargers, which are pushed close to their limits in stock form, especially when the car is driven aggressively or modified.

Owners of the N54 often report issues such as whining noises, smoke from the exhaust, and oil leaks as early signs of turbo failure. The cost of turbo replacement can be substantial, and the labor-intensive process makes it a frequent and costly maintenance item for this engine.

Preventive measures like frequent oil changes with high-quality synthetic oil, using fuel additives to clean injectors, and ensuring the cooling system is in good condition can help extend turbo life, but many still experience failures relatively early compared to other engines. The N54’s turbo durability challenges highlight the trade-off between cutting-edge performance technology and long-term reliability.

Despite these concerns, the N54 remains a beloved engine among enthusiasts due to its performance potential and tunability. Many owners upgrade their turbos to more robust aftermarket units or reinforce oil and cooling systems to prevent early failures. However, as a stock turbocharged engine, the N54’s turbos are often considered among those prone to blow early without attentive care.

4. Mitsubishi 4G63T

The Mitsubishi 4G63T engine, famous for powering the Lancer Evolution models up to the Evo IX, has a mixed reputation when it comes to turbo longevity. While the engine itself is robust and can handle significant power increases, the stock turbochargers on some 4G63T variants are known to suffer from premature wear and failure.

One contributing factor is the turbo’s design, which, in certain versions, lacks advanced cooling features like water cooling. This causes the turbocharger to endure high exhaust gas temperatures that can break down the oil and damage bearings over time.

The oiling system on the 4G63T is generally adequate but requires careful maintenance to avoid clogging of the oil feed and return lines. Oil degradation and contamination can lead to insufficient lubrication, causing accelerated wear on the turbo bearings and seals.

Additionally, the turbo’s turbine wheel and housing design can make it susceptible to thermal stress and cracking if subjected to aggressive driving without proper cooldown. Heat soak, a condition where heat accumulates in the turbo components after driving hard, can cause the seals to harden and fail, leading to oil leaks and turbo damage.

Boost levels on the stock 4G63T turbos are relatively moderate, but the engine’s popularity among tuners means many owners push beyond the factory settings, increasing the risk of turbo failure if supporting upgrades and maintenance are not implemented.

The turbochargers tend to require replacement anywhere from 80,000 to 120,000 miles, depending on maintenance and driving style. Cooling modifications, upgraded oil lines, and improved lubricants are common upgrades to extend turbo life on this engine.

Despite these issues, the 4G63T remains an iconic engine for performance enthusiasts, and its turbos, while sometimes early to fail in stock form, can last much longer with proper care and modifications. Its reputation serves as a reminder that even strong engines require appropriate turbo cooling and lubrication to ensure the longevity of forced induction components.

5. Fiat 1.4L MultiAir Turbo

The Fiat 1.4L MultiAir turbocharged engine, used in various Fiat and Alfa Romeo models, offers a blend of small displacement efficiency and turbocharged power. However, this engine has developed a reputation for early turbocharger failures in some cases.

The turbo’s compact size and location close to the exhaust manifold expose it to high heat levels, which can degrade the oil and cause coking within the turbo oil feed system. This results in restricted oil flow, increased bearing wear, and premature turbo failure.

Additionally, the engine’s variable valve timing and MultiAir system add complexity to the powertrain, sometimes leading to maintenance challenges that indirectly affect turbo longevity.

The cooling system for the turbo is water-assisted, but its small size and the engine bay layout limit heat dissipation efficiency. Overheating can cause the turbo’s seals and bearings to degrade faster than expected, especially if the vehicle experiences frequent stop-and-go driving or short trips that prevent the turbo from reaching optimal operating temperatures.

Oil change intervals are crucial for the 1.4L MultiAir engine, as degraded oil increases the risk of carbon deposits forming in the turbo’s oil passages. Many owners report turbo failures occurring before 70,000 miles if maintenance has been neglected or if the engine has been driven hard without proper cooldown.

The turbocharger’s compact design also makes repairs more expensive and complex, sometimes requiring engine disassembly to access turbo components. This has contributed to the perception of the 1.4L MultiAir turbo as an engine prone to early turbo failure, particularly in vehicles that have not been meticulously maintained.

While the engine delivers good performance for its size, the turbo’s longevity depends heavily on proper oil and cooling system maintenance, as well as responsible driving habits.

Despite these challenges, the 1.4L MultiAir turbo continues to be used in various small cars due to its efficiency and power output. Fiat and Alfa Romeo have addressed some issues in later versions and through improved service recommendations. However, the early turbo failures experienced by some owners highlight the importance of turbo cooling and lubrication in maintaining the durability of modern small-displacement turbocharged engines.