Some machines are built to last, but a few go far beyond expectations. In the automotive world, an engine isn’t just a mechanical heart, it’s a legacy forged through durability, engineering excellence, and real-world resilience.

While most engines fade away with time, a handful keep going, generation after generation, often still performing today just as they did when first fired up decades ago.

These engines have earned legendary status not just because they’re reliable, but because they represent a rare combination of endurance, simplicity, and strong engineering.

Whether found in garages, junkyards, farms, or daily drivers, these powerplants are still chugging along, proving that good design can stand the test of time.

Many of these engines hail from a time when vehicles were built with fewer electronics and more metal.

This simplicity plays a huge role in their longevity. Instead of complex electronics and sensors that can fail, they rely on straightforward mechanical systems that are easier to maintain and less likely to suffer from age-related failures.

Owners often praise them for being easy to work on with basic tools, which helps extend their life even further.

It’s not uncommon to hear stories of these engines reaching half a million miles or more, still starting up each morning with minimal fuss. In some cases, they’ve even outlived the cars or trucks they were originally installed in.

Another common trait among these long-lasting engines is their widespread use. The more units produced, the more knowledge and parts exist to support them. These engines became legends partly because so many people used and maintained them, building a wealth of collective experience.

Their presence in work trucks, military vehicles, taxis, or agricultural machinery gave them real-world tests across the globe in conditions that would destroy lesser designs. That legacy of reliability became part of their identity. These aren’t engines that people only admire, they’re engines people trust.

The ten engines on this list didn’t get here through luck or marketing. They’ve been in countless vehicles, endured abuse, and still get the job done.

Whether it’s an inline-four buzzing through city streets, a diesel workhorse hauling loads up mountain passes, or a V8 growling in a garage on Sunday mornings, each of these engines is a monument to long-lasting engineering.

Here are ten legendary engines that are still running strong, decades after they were first introduced.

Also read: 8 Biggest Mistakes That Kill a Dodge Durango Fast

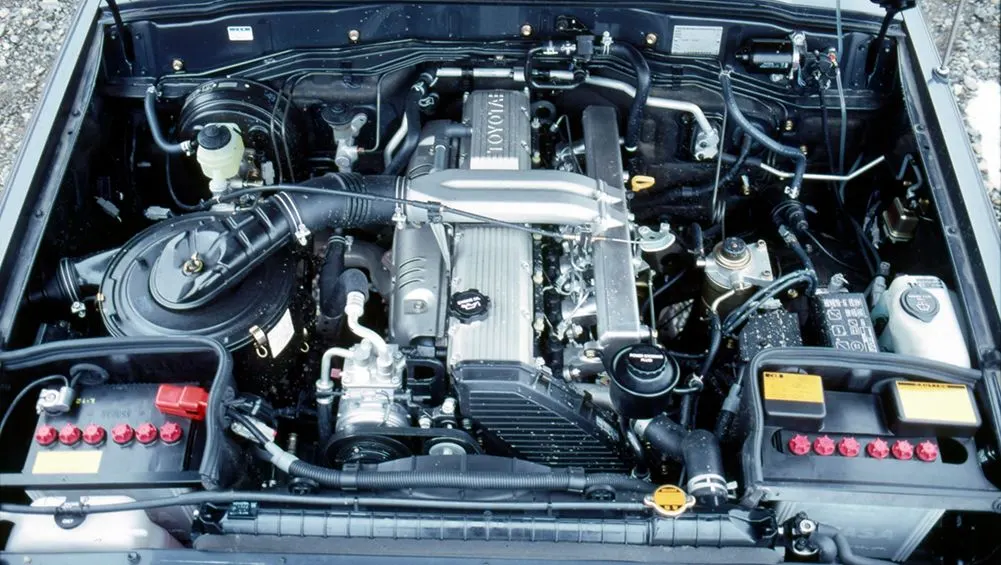

1. Toyota 22R/22RE

The Toyota 22R and its fuel-injected sibling, the 22RE, built a reputation for durability that few engines can match. First introduced in the early 1980s, these inline-four engines were designed for utility and longevity rather than speed or refinement.

They appeared in a variety of Toyota vehicles, including the Hilux, 4Runner, and Celica. The 22R series became especially loved by off-road enthusiasts and people living in rugged, rural areas.

Its reliability made it a favorite among those who needed a simple, trustworthy powerplant to get through tough terrain or long distances without worry.

Part of what makes the 22R so tough is its conservative engineering. It uses a cast iron block, a timing chain instead of a belt, and basic carburetion or fuel injection. There’s nothing exotic or particularly delicate about the setup, which makes it extremely tolerant of poor maintenance.

These engines have been known to run even when neglected, and they often respond well to rebuilds if things ever go wrong. Some owners even report starting them up after sitting idle for years, with just some fresh oil and fuel.

Because so many of these engines were produced, replacement parts are still widely available even decades later. This has helped extend their lives further, since any worn component can be swapped out without much hassle.

Toyota designed them with enough internal strength that minor upgrades or increased power demands usually don’t push them past their limits.

As a result, they’re often used in project vehicles, off-road builds, or even generator swaps. The 22R has proven that it doesn’t need high horsepower numbers to earn respect.

It’s not unusual to see a 22R with well over 300,000 miles, still being used as a daily driver. Even in parts of the world where roads are unreliable or fuel quality is poor, these engines keep working.

That says more about their core design than any performance metric ever could. They’re not flashy, but they are dependable, and that’s exactly why they’re still running today.

2. Mercedes-Benz OM617

The OM617 is a five-cylinder diesel engine that powered many Mercedes-Benz vehicles during the late 1970s and 1980s. This engine earned legendary status for its sheer durability, often found in the W123 chassis diesel sedans and wagons.

It was not uncommon to see these engines with mileages well above 500,000, and some even crossing the million-mile mark with their original bottom ends intact. Designed during a time when Mercedes prioritized engineering above cost, the OM617 is a symbol of overbuilt reliability.

Diesel engines, by nature, are built tougher than their gasoline counterparts, and the OM617 is no exception. It features a cast iron block and head, and its internals are designed to handle the high compression ratios required for diesel combustion.

Mercedes engineers also designed it with the goal of low maintenance, making it appealing to taxi drivers and fleet owners. Its relatively low power output meant that the engine rarely operated under stress, further prolonging its life.

Another reason for the OM617’s lasting power is its simplicity. It uses mechanical fuel injection, which eliminates the need for complex sensors or ECUs.

As long as there’s fuel, air, and compression, it will run. This makes the engine incredibly resilient in remote areas or regions with poor infrastructure.

Many units are still in use in Africa and South America, powering everything from vehicles to stationary equipment. It’s not uncommon for an OM617-powered Mercedes to be handed down through generations.

Even today, the engine has a devoted following. Enthusiasts appreciate it not just for its longevity, but for its unique sound and character.

Some have even swapped these engines into other vehicles or used them in alternative fuel experiments due to their mechanical injection. The OM617 might not be quick or quiet by modern standards, but it keeps going where others fail, and that’s why it remains legendary.

3. Chevrolet Small Block V8 (Gen I)

The original Chevrolet Small Block V8 first appeared in 1955 and continued production in various forms for decades. It became one of the most mass-produced and recognizable engines in the world.

Found in everything from Corvettes to pickup trucks, this engine formed the backbone of American performance and workhorse vehicles.

Its longevity isn’t just about the design; it’s about the culture and ecosystem that grew around it. Mechanics, tuners, racers, and weekend builders all had a hand in keeping the small block relevant for generations.

One reason the Small Block V8 became so iconic is its modularity. The basic engine architecture was so flexible that it could be adapted for a wide range of applications, from daily drivers to drag racers.

Over time, GM continued to refine the engine, offering improved components and increased displacement, all while keeping the basic design intact. Its pushrod, two-valve layout may seem outdated today, but it was part of what made it so easy to work on and upgrade.

Because of the huge number of units produced, parts are still readily available. Aftermarket support is nearly endless. Whether you’re rebuilding an original or creating a high-performance monster, the Small Block platform provides a solid foundation.

The availability of parts and knowledge keeps these engines running strong, even decades after their original installation. Plenty of old trucks and cars with 200,000+ miles are still out there, firing up every morning.

Some of these engines have been passed down between vehicles, swapped from one project to another. They’re often found in hot rods, custom builds, and restoration projects, showing their continued relevance.

It’s not just nostalgia keeping the small block alive, it’s the fact that it still works, and works well. That kind of lasting utility is what makes it more than just a product of its time.

4. Jeep 4.0L Inline-Six

The Jeep 4.0-liter inline-six, commonly known as the AMC 242, is one of the most beloved straight-six engines ever made.

Introduced in 1986 and running strong through 2006, this engine powered a range of Jeep vehicles, including the Cherokee (XJ), Grand Cherokee (ZJ), and Wrangler (YJ and TJ).

Its longevity is the stuff of legends, with many examples pushing well past 300,000 miles with only routine maintenance.

This engine was not about cutting-edge performance or fuel economy; it was about unbreakable utility. And for off-roaders, overlanders, and daily drivers alike, that’s exactly what made it unforgettable.

The design of the 4.0L engine was simple and robust. It used a cast iron block and head, traditional overhead valve architecture, and was tuned more for torque than high RPM power.

This made it particularly well-suited for off-roading, where low-end grunt is more important than peak horsepower.

Unlike modern engines that rely heavily on electronics, the 4.0 used straightforward systems that were easy to diagnose and repair. Even the fuel injection system, introduced in the early ’90s, was reliable and rarely caused problems if maintained properly.

One of the biggest reasons the 4.0 earned its bulletproof reputation was the way it handled abuse. These engines were often found in vehicles that were subjected to the worst conditions imaginable: mud, rocks, dust, water crossings, and steep inclines.

Yet, with proper oil changes and some cooling system upkeep, they just kept running. They didn’t need specialty tools or complicated procedures to fix.

Many owners report that their Jeep engines outlast the body or frame of the vehicle. Even when they did fail, rebuilding them was relatively cheap and straightforward.

The community surrounding Jeep vehicles also contributed to the engine’s legacy. Countless online forums, YouTube channels, and off-road clubs passed down knowledge on how to maintain, repair, and upgrade the 4.0.

This communal knowledge base helped owners keep these engines going far longer than the automaker probably intended.

Today, it’s not uncommon to find old Cherokees or Wranglers with the original 4.0 still ticking along, even after 30 years of service. The fact that so many are still in use today is a testament not only to the design but to the passion of those who kept them running.

5. Ford 300 Inline-Six

The Ford 300 inline-six is another workhorse engine that has built a reputation for durability across decades of use.

Found in Ford trucks from the 1960s through the mid-1990s, this 4.9-liter straight-six became a favorite among farmers, tradesmen, and fleet operators.

It wasn’t flashy or fast, but it was a torque-heavy brute that could handle heavy loads day in and day out. Like the Jeep 4.0, the Ford 300 was built with simplicity and strength in mind, favoring longevity over innovation. It wasn’t uncommon to see these engines go over 400,000 miles without a rebuild.

What made the 300 special was its overbuilt nature. The engine had a forged crankshaft in many configurations, a tall-deck cast iron block, and relatively low compression. This meant it was under-stressed, even when hauling loads or pulling trailers.

It had plenty of low-end torque, which made it perfect for industrial work, snow plowing, and towing. Its long-stroke design gave it a distinct feel, and many drivers appreciated how it delivered power at low RPMs without needing to wind it out.

Maintenance on the 300 was as simple as it gets. Basic tools, routine oil changes, and occasional carburetor adjustments were enough to keep it going. Its ignition system, while updated over the years, remained easy to troubleshoot.

Whether you were in a rural garage or stuck on a roadside, chances were you could find someone who had worked on one of these engines. Ford sold millions of them, so there was always a parts store nearby with what you needed. And if it did need a rebuild, the cost was relatively low because of the abundance of parts and straightforward engineering.

Today, the 300 is still cherished by collectors and users alike. Some classic truck enthusiasts go out of their way to find a 300-powered F-series, believing it to be more dependable than even newer engine options.

In agriculture, you can still find old trucks or equipment powered by this engine doing daily work. It might not have the name recognition of a V8, but among those who used them in real-world conditions, the Ford 300 is nearly unmatched in trustworthiness.

6. Honda B-Series (B16/B18)

Honda’s B-series engines, particularly the B16 and B18 variants, are icons of the 1990s and early 2000s performance scene, but what makes them legendary is not just their rev-happy personality; it’s how long they last.

These dual-overhead cam, naturally aspirated four-cylinder engines gained fame in the Civic, Integra, and CRX platforms.

Known for VTEC kicking in at high RPMs, they offered performance that rivaled larger engines while still maintaining the efficiency and reliability Honda was known for. Despite being driven hard by enthusiasts, many of these engines are still running today, often with very high mileage.

What made the B-series stand out was its blend of engineering precision and real-world usability. Built with forged internals in many versions, high-flow heads, and precision machining, they were overbuilt for the relatively low power numbers they produced.

This over-engineering meant they could handle spirited driving and high-revving operation without complaint.

VTEC, Honda’s variable valve timing system, allowed the engine to perform well both in city driving and on the track. Despite being thrashed by countless owners, the engines rarely failed due to mechanical issues.

Another strength of the B-series was its swap-friendly nature. Because of the modularity and compatibility across Honda platforms, it became a staple in the tuner world.

This popularity meant there was a massive community keeping the engines alive, with guides, aftermarket parts, and performance upgrades readily available.

Even people unfamiliar with working on engines often cut their teeth on a B-series build. Its simplicity compared to newer turbocharged engines made it more approachable, while still delivering real performance.

It’s common today to see B-series engines still powering old Civics and Integras with over 250,000 miles. Some of these engines are still used for racing, showcasing their strength and resilience. Even more are found in daily drivers, making their way through city traffic or weekend cruises without issue.

The B-series earned its place in history not just because it was fast for its size, but because it proved itself reliable under stress, abuse, and time.

7. Cummins 5.9L 12-Valve Diesel

The Cummins 5.9L 12-valve inline-six diesel engine is a powerhouse known for its longevity and unkillable nature. Introduced in Dodge Ram trucks in 1989, it brought heavy-duty diesel performance to light trucks in a way that hadn’t been done before.

With its mechanical fuel injection system, cast iron construction, and tractor-like torque output, it quickly gained a cult following.

These engines are still used today in everything from daily drivers to off-road rigs, RV conversions, and even generators. It’s not unusual for them to surpass 500,000 miles with little more than routine care.

One of the major strengths of the 12-valve Cummins is its simplicity. It uses a Bosch P7100 mechanical injection pump, which is considered one of the most durable and tunable fuel delivery systems ever made.

No electronics are controlling the injection process, making it highly reliable and easy to troubleshoot.

The engine block and internals are built to commercial-grade standards, essentially borrowing from the company’s experience building engines for industrial equipment. This made the engine far stronger than it needed to be for light-duty truck use.

Beyond its internal strength, the engine also benefits from a design that’s easy to work on. Accessibility is good, parts are widely available, and there’s a massive aftermarket and support community. Owners frequently modify them for more power, and the engine takes it in stride.

It’s common to see upgraded turbochargers, fuel pumps, and even propane injection used to increase power output, yet many of these modifications don’t compromise long-term durability.

The engine’s low RPM operating range and heavy-duty components help keep stress levels low, even under increased loads. Even though production of the 12-valve ended in the late 1990s, thousands of them are still on the road today.

Some are swapped into other vehicles due to their reputation for dependability. Others are maintained in their original trucks, often serving as workhorses on farms or in fleets.

Their mechanical nature and overbuilt construction mean they can often be restored and rebuilt easily, keeping them alive for decades after most other engines from their era have been retired. It’s not hype, the 12-valve Cummins really is as tough as they say.

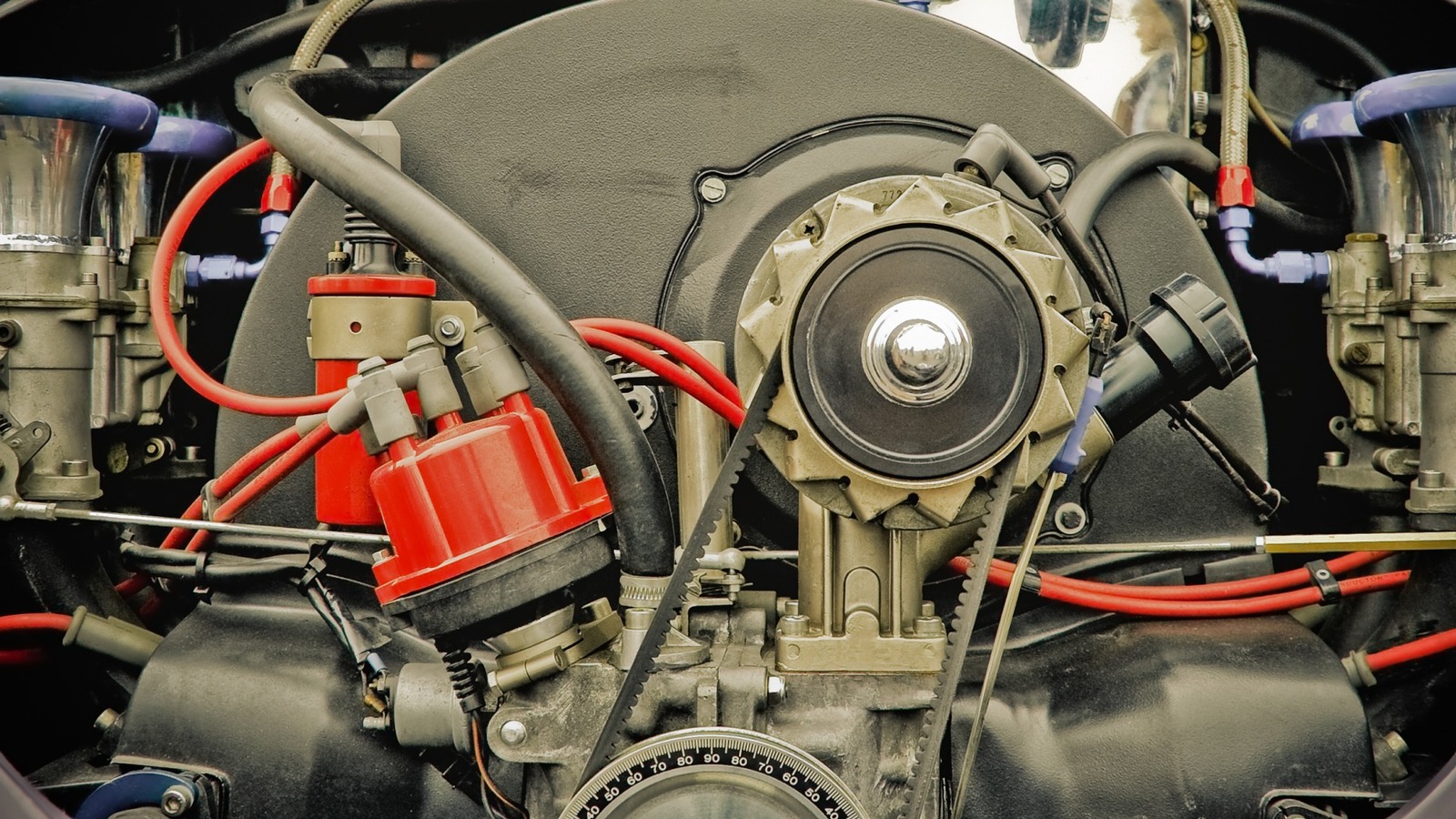

8. Volkswagen Air-Cooled Flat-Four (Beetle Engine)

Few engines have had the global impact and staying power of the Volkswagen air-cooled flat-four. Originally developed in the 1930s and reaching mass production in the post-war Beetle, this engine became a symbol of simplicity, efficiency, and reliability.

It powered millions of vehicles, not just the Beetle, but also the Type 2 Bus, Karmann Ghia, and a host of other VW models.

Even today, enthusiasts around the world continue to rebuild and drive these engines, keeping the spirit of the original Volkswagen alive. For many people, their first car had this engine, and in many cases, it’s still running somewhere.

The engine’s basic design contributed heavily to its longevity. Its air-cooled setup eliminated the need for a radiator, hoses, and a liquid cooling system, which reduced failure points. It used a horizontally opposed (flat-four) configuration, which kept the center of gravity low and made the engine very compact.

The engine block and heads were made of aluminum, helping with weight and heat dissipation. While early models made very little power, that simplicity was actually a virtue. The fewer parts an engine has, the fewer things there are to go wrong.

Maintenance on the VW flat-four was famously simple. With a few hand tools and a garage, an owner could adjust valves, change spark plugs, clean the carburetor, or even remove the engine entirely. Many people learned mechanical skills on this engine, and a whole generation of DIY culture grew around it.

There was also a massive parts supply, both OEM and aftermarket, that ensured even engines from the 1950s could be kept on the road. And thanks to a massive global distribution, even people in remote areas could usually find help or replacement parts.

What really makes this engine legendary is how many are still around and operational. From vintage Beetles and Buses to custom sand rails and trikes, this engine continues to power vehicles well into the 21st century.

It has a loyal following, not because it’s powerful or efficient by modern standards, but because it has proven itself year after year.

In the right hands, with periodic care, this engine can run seemingly forever. It’s a mechanical icon that earned its reputation through real-world results, not just marketing or nostalgia.

9. BMW M30 Inline-Six

The BMW M30 inline-six engine, often referred to as the “Big Six,” was in production from the late 1960s until the early 1990s. It powered a range of BMWs, including the E3 sedans, E9 coupes, and the iconic E28 and E34 5 Series models.

With a cast iron block and aluminum head, this engine delivered smooth power and a refined feel while maintaining an exceptional degree of durability. The M30 is often cited as one of BMW’s most reliable engines, with many examples still running strong more than 30 years after they were built.

One of the M30’s defining traits was its balanced design. Unlike some performance engines that sacrificed longevity for higher output, the M30 hit a sweet spot between power, smoothness, and dependability. It used a single overhead cam design with a timing chain, which proved to be far more durable than rubber belts.

The engine could handle long stretches of high-speed driving, making it well-suited to the German autobahn and long-distance touring. Many units survived for hundreds of thousands of kilometers without major issues.

While the M30 was relatively complex compared to more utilitarian engines, it was still accessible for maintenance. Owners with a bit of mechanical knowledge could perform basic repairs and even full rebuilds.

The Bosch fuel injection systems used in later models were relatively simple by today’s standards, and BMW’s factory service manuals made working on the M30 manageable for skilled DIYers.

The fact that many of these engines were installed in luxury vehicles also meant they were often well-maintained, further extending their lifespan.

Today, the M30 continues to live on in both restored classics and engine-swapped builds. It remains a favorite among those who appreciate vintage BMW engineering. Despite the increasing age of the vehicles it powers, the engine is often the last thing to fail.

For those looking to buy an old BMW with a dependable motor, an M30-powered model is often a safe bet. It’s a quiet legend, less flashy than more modern BMW M engines, but just as respected in the eyes of those who value long-term performance and mechanical integrity.

10. Toyota 1HZ Diesel

The Toyota 1HZ is a 4.2-liter inline-six diesel engine that has become one of the most respected and trusted engines in the Land Cruiser family. Introduced in the early 1990s, it was not designed for high power, but rather for unmatched reliability in the world’s harshest conditions.

Found in models like the Land Cruiser 70 Series and 80 Series, the 1HZ quickly earned a reputation as a go-anywhere, do-anything powerplant.

From the Australian Outback to the African savannas, this engine continues to serve in places where breakdowns can be dangerous or even life-threatening.

Part of what makes the 1HZ so dependable is its conservative engineering. It uses a simple indirect-injection diesel system, naturally aspirated in most versions, and has minimal electronic components. It features a strong cast iron block and head, forged steel crankshaft, and robust internal components.

These choices might make the engine feel underpowered by modern standards, but they contribute directly to its ability to run for hundreds of thousands of miles with minimal issues. The engine is designed to operate in extreme heat, dusty conditions, and poor fuel quality.

Owners and mechanics alike praise the 1HZ for its straightforward maintenance and incredible tolerance for abuse. Oil changes, air filters, and routine checks are usually all that’s needed to keep it running well. Even when problems arise, the engine rarely suffers catastrophic failure.

Head gaskets and valve issues can occur over time, but these are usually manageable and expected in engines with such high service lives. When used for heavy-duty applications like towing, climbing, or long-distance expeditions, the 1HZ performs with calm confidence.

What really makes the 1HZ stand out is how many are still being used in critical roles. In remote regions with limited access to repair facilities, NGOs, government fleets, and commercial operators continue to rely on the 1HZ.

Its ability to function in extreme environments without needing specialized tools or electronic diagnostics makes it irreplaceable in many cases. It may not have the prestige of some high-performance engines, but among those who need their vehicle to start and run no matter what, the 1HZ is often the first choice.