Motorsports often feel like a world separate from everyday driving. The screaming engines, the brutal acceleration, and the constant maintenance might seem like something only reserved for racetracks and professional garages.

But sometimes, what starts as a race-bred machine ends up under the hood of a production car that you can drive to work or take on a grocery run. Not every engine developed for motorsports manages to survive the real world of traffic lights, potholes, and oil change schedules. That’s why when one does, it leaves a mark, not only on gearheads but also on the automotive industry as a whole.

Throughout automotive history, some engines that were originally developed for racing purposes found themselves in daily-driven vehicles and managed to provide not only performance but also dependability. This intersection of motorsports technology and road-going practicality is where the real engineering magic happens.

These engines needed to be more than just powerful; they had to be reliable, easy to maintain, and versatile enough to adapt from a controlled race environment to the unpredictability of civilian roads. In these cases, engineers struck a balance between raw performance and long-term use.

There are countless examples of powerful engines in road cars, but not all of them carry motorsports DNA. The ones that do often carry a price tag or a reputation for needing high-level maintenance, but a select few engines managed to bring performance credibility without sacrificing reliability.

These engines became the heart of dependable cars that could be driven daily, serviced at regular intervals, and still put a smile on the driver’s face every time the throttle was touched.

This article highlights nine engines that were born in motorsports or had heavy racing influence, yet proved to be trustworthy in daily-driven cars. These are engines that didn’t need a pit crew to stay healthy, and their impact continues to be felt among enthusiasts and engineers alike.

Also Read: 12 Cars That Keep Their Value at High Mileage

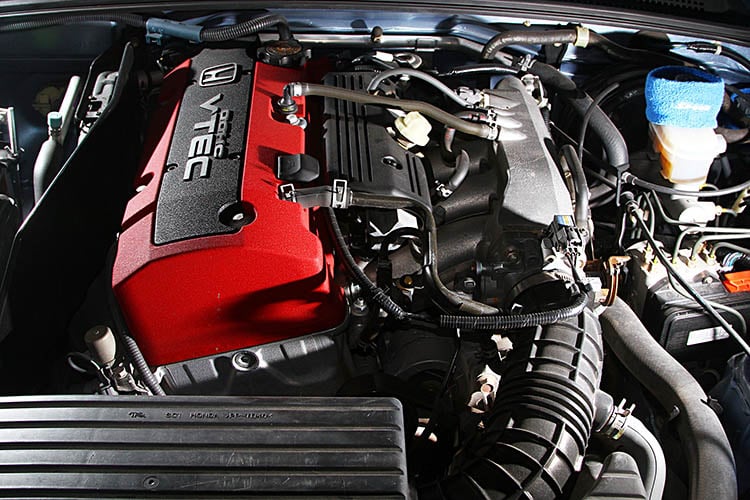

1. Honda F20C – The S2000’s High-Revving Heart

The F20C engine is often remembered for its ability to rev beyond 9,000 RPM, but what truly makes it special is how it manages to do so while remaining incredibly reliable. Originally developed for the Honda S2000, this engine took cues from Honda’s experience in Formula One and other forms of motorsport.

Unlike many high-performance engines that demand constant attention, the F20C earned a reputation for lasting well over 200,000 miles with proper maintenance. It’s a power plant that thrives on being pushed but doesn’t punish the owner for everyday use.

One of the reasons the F20C worked so well in a daily-driving context was its solid engineering. With a forged crankshaft, lightweight internals, and a block designed for high rigidity, the engine was built to handle extreme stress without breaking a sweat.

Honda’s VTEC system added a layer of versatility that made the car livable at low RPMs while offering thrilling performance in the upper rev range. The engine delivered a respectable 240 horsepower from just 2.0 liters, a feat that remained unmatched naturally aspirated for years.

In a world where high-performance engines often come with reliability concerns, the F20C was an outlier. Owners have driven these engines across continents, used them for weekend track days, and even turbocharged them without catastrophic failures.

The key was not just in the materials used, but in the level of precision Honda brought to the engine’s development. Everything from oiling to cooling was overbuilt relative to what a daily driver would typically need, and that extra headroom translated into long-term dependability.

Despite its motorsports pedigree, the F20C didn’t require exotic fluids, specialized tools, or a technician trained by race teams. Routine oil changes, proper warm-up before spirited driving, and regular servicing were usually enough to keep this engine happy. For an engine that screamed like a race car, the fact that it could go about its business without major issues made it one of the most beloved motorsports-derived engines ever installed in a road car.

2. Toyota 3S-GTE – Turbocharged Durability

The 3S-GTE is a turbocharged inline-four that Toyota developed with rally racing in mind. It powered the Celica GT-Four, which saw success in World Rally Championship competition, and later made its way into other vehicles like the Toyota MR2 Turbo.

While the engine was built to handle the abuse of rally stages filled with jumps, gravel, and extreme conditions, it turned out to be just as competent on city streets and highways. This engine blended ruggedness with enough performance to make daily driving genuinely enjoyable.

One of the standout features of the 3S-GTE was its stout iron block, which made it a strong foundation for both stock reliability and aftermarket tuning. The closed-deck design allowed the engine to handle boost pressures that would have destroyed less robust setups.

Even though the engine was capable of high horsepower when modified, in factory form it was tuned to be both powerful and manageable, making it a comfortable fit for a daily-driven vehicle. Its ability to take abuse and still run smoothly earned it a loyal following among Toyota enthusiasts.

The turbocharger setup and fuel system were also designed with longevity in mind. The early generations of the engine featured a water-to-air intercooler to keep intake temperatures down, which helped preserve engine components over time. Later versions improved on this with more modern technologies, but the core durability remained.

Many examples of the 3S-GTE have crossed well over 150,000 miles while still holding factory compression numbers. That kind of durability is rare in turbocharged motorsport-derived engines.

Drivers who owned cars with the 3S-GTE appreciated how the engine could be driven hard when needed but also settle into a docile, fuel-efficient rhythm when used for commuting. Regular maintenance and good quality fluids were usually all it took to keep the engine in top shape. Its success on the rally stage might have brought it fame, but its performance on the road made it a lasting favorite for anyone who wanted motorsports performance without constant wrenching.

3. BMW S54 – Precision and Power in Harmony

The BMW S54 engine, most famously found in the E46 M3, is a naturally aspirated inline-six that drew directly from BMW’s motorsport heritage. While it didn’t have a direct one-to-one transfer from a racing engine, the technology and philosophy behind its construction were deeply influenced by BMW’s involvement in touring car championships and Formula One.

This engine delivered an engaging driving experience thanks to its linear powerband, high-revving nature, and responsive throttle. Yet, it also managed to establish a reputation for everyday usability when properly maintained.

A key aspect of the S54’s reliability was its solid mechanical foundation. It featured forged pistons, a lightweight crankshaft, individual throttle bodies, and an advanced VANOS variable valve timing system.

While some of these technologies increased complexity, they also allowed the engine to perform exceptionally well across a wide RPM range. Despite being pushed hard by spirited drivers, the engine showed remarkable endurance when serviced regularly. It was not uncommon to see well-maintained examples approaching or surpassing 200,000 miles.

One challenge with the S54 was that it demanded responsible ownership. Neglecting maintenance intervals or using subpar oil could lead to problems, particularly with the VANOS system or rod bearings. However, for owners who took care of the engine, it responded with unwavering performance.

The key was understanding that while the engine was born from motorsport ideals, it was also engineered with street reliability in mind. With high-quality fluids, routine inspection, and cooling system upkeep, the S54 proved to be a trustworthy daily companion.

This engine made the E46 M3 one of the most revered performance cars of its time. It offered both the edge of motorsports and the predictability needed for daily driving. Whether carving through back roads or cruising on a highway, the S54 delivered consistency and excitement in equal measure. Its longevity and versatility are why it remains a favorite among enthusiasts and why it earns a place on this list.

4. Porsche M96/76 – From Race Track to Road Trip

The M96/76 engine is a flat-six powerplant that found a home in the 996-generation Porsche 911 GT3. It was based on technology used in Porsche’s racing efforts, particularly the Le Mans-winning GT1 car.

Unlike the standard M96 engine used in base models, the M96/76 was hand-assembled and designed with high-performance track usage in mind. What made this engine particularly was how it brought race-ready architecture to a production car without sacrificing street usability or reliability.

One major factor contributing to its dependability was its dry-sump lubrication system, which ensured consistent oil delivery under hard cornering and high RPMs. This technology, directly lifted from racing, also helped extend engine life by preventing oil starvation, a common failure point in high-performance engines.

Combined with high-quality materials and a simplified valvetrain compared to more complex systems, the M96/76 struck a smart balance between performance engineering and long-term robustness.

Unlike many high-performance engines, the M96/76 didn’t suffer from chronic design issues. While the standard M96 engines had well-known problems like IMS bearing failures, the GT3’s version was built differently and avoided those pitfalls. Owners found that, with regular maintenance, the engine was capable of racking up serious mileage while still retaining its sharp throttle response and strong mid-range power. It was as at home on a 10-hour road trip as it was on a racetrack.

The engine also earned respect for its resilience under track conditions. Many GT3s with this engine saw repeated track days and endurance events without major mechanical failures. It wasn’t uncommon for owners to do oil changes at trackside, drive hundreds of miles home, and then use the car for commuting during the week.

That kind of flexibility is rare in motorsport-influenced engines, which often require more attention and rebuilds after extensive use. Porsche’s ability to design an engine that could handle the abuse of hot laps and still idle smoothly in traffic set a new standard for dual-purpose vehicles.

What added to the appeal of the M96/76 was its mechanical simplicity compared to other modern engines of its time. While newer performance engines leaned into turbocharging and increasingly complex electronics, the M96/76 relied more on naturally aspirated performance and mechanical purity.

Fewer systems could fail, and that meant less to worry about during ownership. The throttle response, engine braking, and engagement felt raw, yet the engine proved that performance didn’t always have to come with a compromise in reliability.

Many GT3s equipped with the M96/76 engine are still on the road today, with some examples surpassing 150,000 miles while retaining good compression and oil pressure. Porsche collectors and enthusiasts often seek out these early GT3s not only for their analog driving feel but also for the engine’s reputation.

It became clear over time that this engine was built to last, even if its primary mission was performance. The long-term success of the M96/76 helped solidify the GT3’s legacy as a car that could deliver both emotion and endurance.

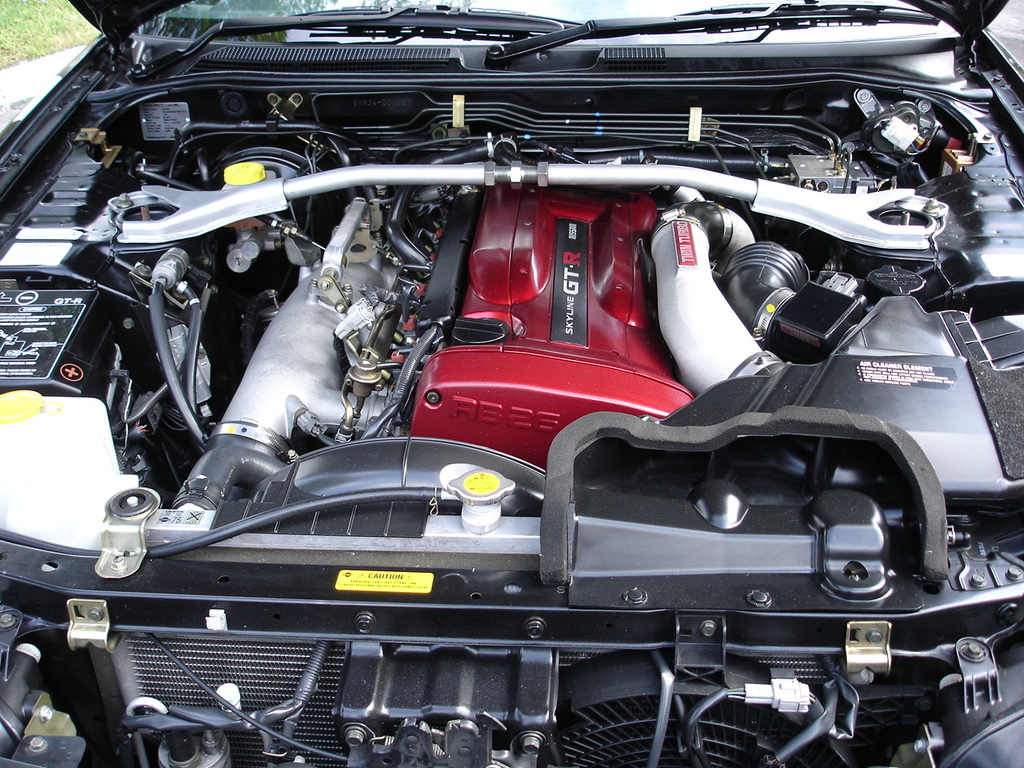

5. Nissan RB26DETT – Skyline’s Iron-Clad Icon

The RB26DETT engine is one of the most iconic motorsport-derived engines ever to make its way into a production car. Originally developed for Group A racing, this twin-turbocharged inline-six powered the Nissan Skyline GT-R from the late 1980s through the early 2000s.

Its design was heavily influenced by endurance and touring car racing, with a focus on strength, balance, and the ability to sustain high power levels under demanding conditions. What shocked many was not just its performance but how long these engines could run with minimal issues when properly cared for.

One of the most impressive aspects of the RB26DETT is its overbuilt nature. The engine used a closed-deck iron block, a forged crankshaft, and robust internals that were designed to take abuse.

While it officially produced around 276 horsepower due to Japan’s “gentleman’s agreement,” it was widely known to be underrated from the factory. With minimal modifications, the engine could easily handle 400-500 horsepower without any internal changes, and even stock versions were capable of lasting over 200,000 kilometers if maintained regularly.

The key to its reliability wasn’t just in the components, but also in the way the engine delivered power. The RB26 had a relatively flat torque curve and a smooth revving nature that put less strain on internal parts compared to more aggressive setups.

The twin-turbo system, while dated by modern standards, was well matched to the engine’s characteristics and provided solid performance without being peaky or unpredictable. This allowed drivers to enjoy the engine daily, whether on a spirited backroad drive or during a simple grocery run.

Although the RB26DETT wasn’t known for being the easiest engine to work on due to its tight engine bay packaging, it was not inherently fragile or unreliable. Regular oil changes, quality fuel, and proper cooling were enough to keep the engine running strong for years.

Many enthusiasts still import and daily-drive these engines today, and their resilience has become a key part of the RB legend. It was an engine that lived up to its racing roots but never lost touch with the needs of everyday drivers.

Also Read: 12 Vehicles That Outlasted the Companies That Built Them

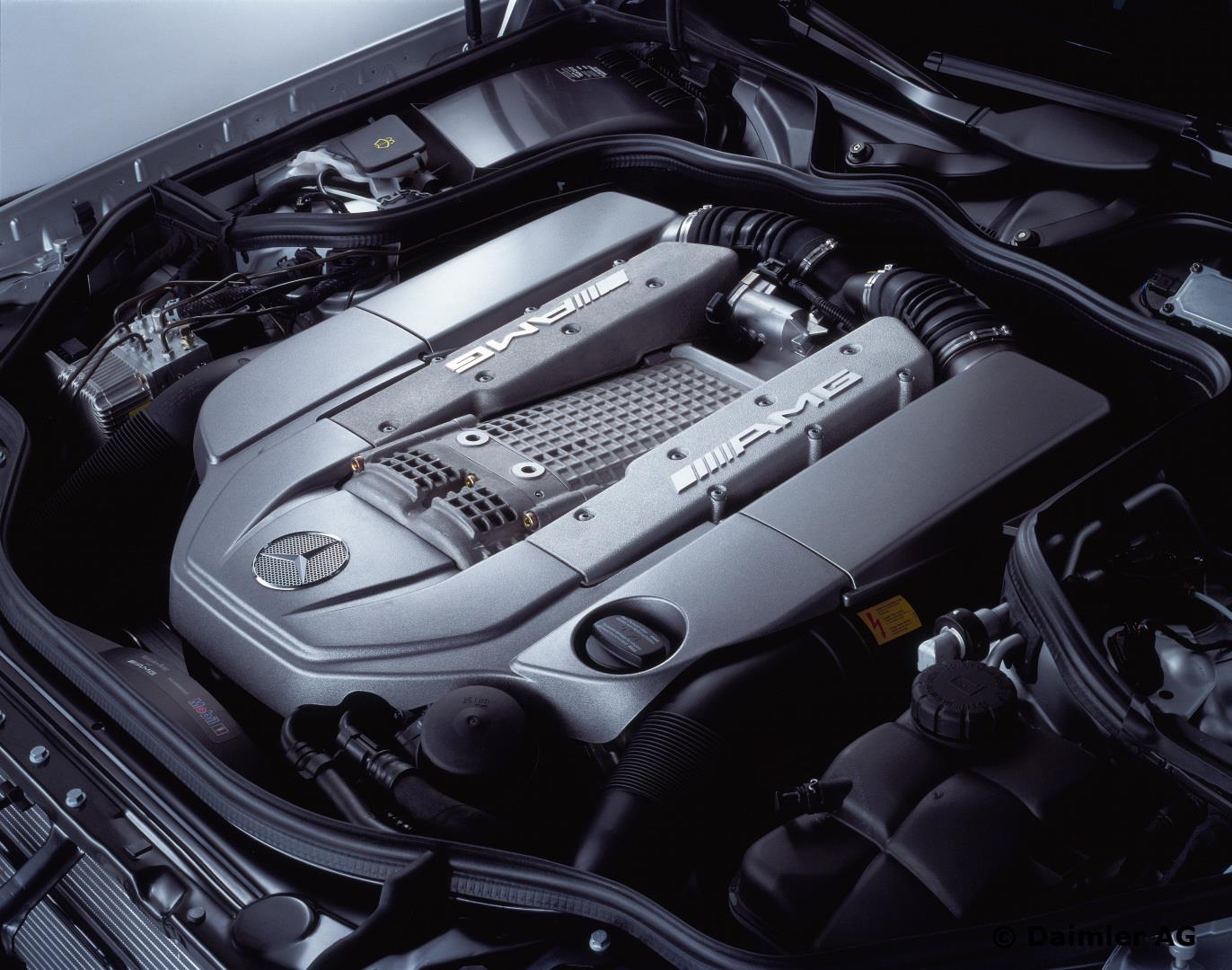

6. Mercedes-Benz M113K – Supercharged Longevity

The Mercedes-Benz M113K engine is a supercharged 5.4-liter V8 that powered several AMG models in the early to mid-2000s, including the E55 AMG and SL55 AMG. While it may not have been directly derived from a specific race program, its internal robustness and design philosophy stemmed from Mercedes’ long-standing involvement in endurance and touring car racing.

This engine stood out because it delivered massive torque and performance numbers while maintaining a reputation for being incredibly durable over high mileage.

Built on the naturally aspirated M113 architecture, the M113K added a twin-screw supercharger, intercooler, and upgraded internals to handle the increased stress. It produced 469 horsepower and over 500 lb-ft of torque, making AMG vehicles some of the fastest sedans of their time.

Despite the massive output, the engine didn’t suffer from the kind of heat soak or reliability concerns that plagued some other forced induction setups. Its conservative tuning and bulletproof bottom end made it more than capable of handling both spirited driving and long-distance cruising.

What really defined the M113K was how little drama it brought to ownership. Many high-performance engines demand specialized fluids, frequent valve adjustments, or expensive timing system replacements. The M113K, however, was content with standard synthetic oil changes and regular inspections.

High-mileage examples with over 200,000 miles are not unusual, and many owners report that the engine outlasted the rest of the car. It was not only a powerhouse but also a workhorse, capable of handling city traffic, long road trips, and aggressive driving without skipping a beat.

Even when heavily modified, the M113K showed its resilience. Tuning shops regularly pushed these engines to 600 or even 700 horsepower with upgraded pulleys and cooling systems, all while retaining factory internals. That kind of overhead speaks to the confidence AMG had in the engine’s design.

For anyone who wanted motorsports-inspired performance without the headaches of frequent repairs, the M113K delivered a balance that few engines in its class could match.

7. Mazda 13B-REW – Rotary with Surprising Endurance

The Mazda 13B-REW engine is often misunderstood in discussions about reliability. As the first mass-produced sequential twin-turbo rotary engine, it powered the FD3S RX-7 and had a strong connection to motorsports, particularly through Mazda’s success at Le Mans and in IMSA racing.

While rotary engines have a reputation for requiring meticulous care, the 13B-REW, when maintained correctly, proved to be more dependable than commonly believed. It was an engine that rewarded the informed owner with exceptional performance and long-term usability.

The key challenge with the 13B-REW was its unique design. Unlike piston engines, rotary engines operate using spinning rotors, which require different lubrication and cooling considerations. Mazda implemented numerous features to improve reliability, such as oil injection systems to lubricate apex seals and water cooling channels through the rotors.

When these systems were kept in proper working order, the engine could run reliably for well over 100,000 miles, even with spirited use. Problems often arose not from poor engineering but from neglect or improper modifications.

Mazda tuned the engine conservatively from the factory, and while it produced only around 255 to 280 horsepower depending on the model year, it offered a smooth, linear power delivery that felt stronger than the numbers suggested.

The twin-turbo setup was complex, but its sequential nature meant that power came on gradually, reducing shock to the drivetrain and engine components. For drivers who took the time to learn how to operate the car properly, warming it up before revving high and staying on top of oil levels, the 13B-REW offered years of reliable service.

What made the 13B-REW special wasn’t just its racing roots or performance potential, but how livable it could be when cared for. The lightweight design and compact size made it ideal for a balanced chassis, and the lack of reciprocating mass allowed it to rev freely and quickly. While it demanded more involvement from its owner, those who respected its needs were rewarded with a motorsports-bred engine that could serve as a dependable companion for both the track and the street.

8. Ford Coyote V8 – Modern Muscle with Racing Roots

The Ford Coyote 5.0L V8, introduced in the 2011 Mustang GT, was inspired by Ford’s modular V8 platform but featured extensive upgrades that brought it closer to racing specifications.

With input from Ford’s performance divisions and lessons learned from racing programs like Grand-Am and NASCAR, the Coyote was engineered to deliver not just horsepower but also reliability under stress. It represented a shift in American V8 development, moving from sheer displacement toward high-revving performance and modern engineering techniques.

At the heart of the Coyote’s durability is its strong aluminum block with cross-bolted main caps, forged crankshaft, and high-flow cylinder heads. The use of twin independent variable cam timing (Ti-VCT) allowed the engine to optimize performance and fuel efficiency across a broad power band.

Despite revving to over 7,000 RPM, the engine proved remarkably durable, even under track conditions. Owners quickly discovered that the Coyote could take serious punishment on road courses, drag strips, and street driving without developing major issues.

Another aspect of the Coyote’s success was its adaptability. Ford released multiple versions of the engine, including the Boss 302 variant and later the Gen 3 version found in the Mustang GT and F-150. Each version retained the same core architecture but improved on components like oiling, cooling, and valve train durability.

This continuous refinement helped build the engine’s reputation as both a strong performer and a dependable workhorse. It was not uncommon to find daily-driven Coyotes with over 150,000 miles that had also seen regular track use.

For the enthusiast who wanted motorsports DNA without the cost or compromise of exotic parts, the Coyote offered a sweet spot. It brought modern performance and old-school reliability into one package.

Whether bolted into a Mustang, F-150, or a custom project car, it proved to be a reliable platform capable of handling both factory power and serious aftermarket upgrades. The Coyote’s blend of accessible power and day-to-day dependability made it one of the most successful motorsport-influenced engines in recent memory.

9. Ferrari F136 – Exotic Reliability from Maranello

When people hear “Ferrari engine,” the last thing they usually think about is long-term reliability. But the F136 engine series challenged that perception. Built in partnership with Maserati and used across multiple high-performance road cars, the F136 was a naturally aspirated V8 that showed surprising durability when maintained properly.

This engine found a home in cars like the Ferrari F430, California, and several Maserati models including the GranTurismo and Quattroporte. What set it apart was not only its motorsport-inspired performance but also its capability to handle the realities of daily driving.

The F136 was developed during a period when Ferrari was deeply involved in Formula 1, and its engineering reflected the lessons learned on the track. With a flat-plane crankshaft, high-revving characteristics, and meticulous attention to airflow and combustion efficiency, the engine delivered sharp throttle response and a uniquely aggressive exhaust note.

However, unlike many other exotic engines, it didn’t require a full teardown every 20,000 miles. When placed in a Maserati chassis, cars more often driven daily, it proved to be a V8 that could run strong past 100,000 miles if properly cared for.

Much of the engine’s reliability stemmed from its relatively simple yet robust construction. Ferrari resisted the trend toward forced induction at the time, relying instead on naturally aspirated power to reduce heat stress and complexity.

The timing chain system, dry-sump lubrication, and high-quality components meant fewer points of failure. Owners who stuck to routine service intervals, especially for oil changes and belt inspections, often found themselves with an engine that aged gracefully despite high mileage or spirited driving.

Another testament to the F136’s dependability is the number of Maserati and Ferrari models with this engine still being used daily, some even as family cars or long-distance cruisers. While the cost of parts and service remains high (as expected with Italian exotics), the engine itself rarely fails catastrophically without warning.

It brought a level of race-bred excitement to a more accessible tier of ownership and reminded the world that an engine doesn’t need to be fragile just because it comes from a brand known for race tracks and high-strung supercars.

10. Toyota 2ZZ-GE – Compact Engineering Done Right

The Toyota 2ZZ-GE may not have had the raw power of larger motorsport engines, but it delivered an impressive mix of performance, efficiency, and durability. Co-developed with Yamaha, and influenced by Toyota’s involvement in touring and GT racing, the 2ZZ was a high-revving 1.8-liter inline-four used in cars like the Celica GT-S, Lotus Elise, and Corolla XRS.

It featured variable valve timing with lift (VVTL-i), which gave it dual personalities, calm and economical at low RPMs, but exciting and aggressive once the cam profile switched over at higher revs. Despite its complex valve train, it proved to be a surprisingly tough engine.

The 2ZZ was designed to be revved hard. It could spin up to 8,200 RPM, a figure unheard of in most economy-based cars of the early 2000s. And yet, this wasn’t an engine that constantly blew up under spirited driving. In fact, many examples are still running strong with minimal issues, even after a decade or more of use. Its block was based on the reliable 1ZZ engine, but the 2ZZ received stronger internals, a unique head design by Yamaha, and higher flow capabilities that made it a true enthusiast’s engine.

What made the 2ZZ-GE stand out even more was how it maintained Toyota’s traditional reliability in a performance-focused package. The engine responded well to proper maintenance, mainly frequent oil changes and attention to timing chain condition, but it didn’t need anything extraordinary to survive.

It could handle daily commutes in stop-and-go traffic without any complaints, then spend weekends tearing up canyon roads or autocross courses. The versatility of the engine helped it find fans not just in sports car circles but also among practical-minded drivers who wanted something with a bit more edge.

Lotus’ decision to use the 2ZZ-GE in the Elise was perhaps the greatest vote of confidence in its capabilities. Known for their extreme performance standards and minimal weight, Lotus cars needed an engine that was both lightweight and durable.