Valve burning is a frustrating and costly engine issue that can lead to significant performance problems, increased emissions, and eventually a complete engine rebuild if left unchecked.

While all internal combustion engines are subject to wear over time, some are known for being more durable when it comes to valve health, while others have a reputation for frequent valve burning, either due to poor design choices, materials, or operating conditions.

Understanding why some engines tend to avoid valve problems while others suffer from them regularly can help car owners, mechanics, and enthusiasts make smarter decisions regarding maintenance, engine choice, or modifications.

Engines rely on proper sealing between the valves and valve seats to maintain combustion efficiency. When a valve burns, typically the exhaust valve, it is often due to excessive heat, poor seating, or improper air-fuel mixture.

Over time, this causes the valve to lose its ability to seal properly, leading to compression loss, misfires, and eventually serious engine damage.

Manufacturers sometimes make design compromises in the name of performance or cost, which can leave an engine more vulnerable to this type of damage.

On the other hand, some engines are built with longevity in mind, with stronger materials, better cooling strategies, or more conservative tuning, which helps them stay out of trouble.

This article will look at five engines that are widely regarded for their resistance to valve-burning issues, followed by five engines that are known for being more susceptible.

While individual experiences will vary depending on maintenance, operating conditions, and even luck, these trends are based on broader patterns recognized by experienced mechanics, engine builders, and automotive communities.

It’s not just about reputation; valve longevity often comes down to a combination of metallurgy, engine geometry, fuel mixture control, and thermal management. Engines with robust valve materials, better heat dissipation, and conservative tuning often escape valve-related failures.

On the flip side, high-strung performance engines or poorly engineered models may be far more likely to suffer from premature valve wear or burning. Let’s look at which engines stand out on either side of the spectrum.

Also Read: 10 Compact SUVs That Survive Harsh Winters Offering Durability

Engines That Rarely Burn Valves

1. Toyota 22R/22RE

The Toyota 22R and its fuel-injected variant, the 22RE, have built a legendary reputation for reliability and mechanical toughness. These engines were common in Toyota trucks and 4Runners during the 1980s and early 1990s.

One of the key reasons they are unlikely to suffer from burnt valves is their relatively low power output combined with overbuilt components.

The engine is under-stressed, meaning it rarely operates at temperatures or pressures that might accelerate valve damage. Its conservative compression ratio and simple, carbureted or early fuel injection systems ensure that the air-fuel mixture remains consistent and not overly lean, which is a common cause of hot exhaust gases and burned valves.

Another strength of the 22R is its robust valve train design. The use of solid valve lifters and straightforward rocker arms means that valve clearance can be easily maintained with routine adjustments. Valve lash that is too tight can cause valves not to seat properly, leading to burning.

With regular attention, this issue is almost entirely avoidable. Additionally, the materials used in both the valves and seats are extremely durable, capable of enduring years of hard use without showing signs of degradation.

Cooling is another factor that contributes to the 22R’s valve health. These engines are known for their effective and simple cooling systems. They don’t typically run hot, and heat is one of the biggest enemies of exhaust valves.

By keeping internal temperatures in check, the 22R avoids the high thermal stresses that lead to valve issues. As a result, many examples are still on the road today with hundreds of thousands of miles and no valve-related failures.

Even when pushed hard off-road or used in work environments, the 22R holds up. It’s not uncommon to see these engines neglected in terms of oil changes or subjected to poor-quality fuel and still manage to keep their valves intact. Toyota’s engineering focus on durability, rather than outright performance, paid off in this engine’s long-term reliability.

2. Honda K20/K24 Series

Honda’s K-series engines, particularly the K20 and K24 variants, are known not only for their high-revving nature and performance potential but also for their strong reliability, especially when it comes to the valve train. Despite operating at high RPMs, these engines rarely suffer from burnt valves when maintained properly.

This is due in part to the use of high-quality materials in the valves and seats, as well as Honda’s precise machining standards. Their variable valve timing (VTEC) system also helps optimize engine performance without excessive stress on the components.

The aluminum cylinder heads are well-designed for efficient cooling, and Honda uses sodium-filled exhaust valves in some K-series variants, which helps draw heat away from the valve face and into the stem, where it can be dissipated.

This results in lower temperatures at the point of contact between the valve and the seat, reducing the risk of burning. Even under heavy use, including track days or spirited driving, these valves tend to stay within safe temperature ranges if the cooling system is maintained.

A feature of these engines is their ability to maintain tight control over air-fuel mixture and ignition timing. The electronic engine management systems used in these engines are extremely precise, preventing lean conditions that can lead to hot combustion and valve damage. This means even under aggressive driving, the engine maintains safe operating conditions.

The K20/K24’s resistance to valve issues is one reason why it’s become such a favorite in the engine swap community. It’s common to see these engines used in everything from lightweight sports cars to go-karts and off-road rigs. Their combination of performance and durability, especially in the valve area, makes them a top choice for tuners and enthusiasts alike.

3. Chevrolet Small Block (Gen I & Gen II)

The Chevrolet small-block V8, particularly the earlier Gen I and Gen II versions, has a long-standing reputation for durability and low maintenance needs. One area where it performs exceptionally well is valve life.

In stock or mildly tuned configurations, these engines rarely suffer from burnt valves, thanks to their relatively low compression ratios, conservative cam profiles, and robust valve materials. They were built to run on lower-octane fuel and under heavy loads, making them perfect for trucks, muscle cars, and even marine applications.

One of the main advantages of the small-block design is the availability of quality components. Whether you’re using factory GM parts or aftermarket upgrades, high-quality valves and hardened seats are easy to come by.

The original cast iron heads used in many early small blocks are extremely durable and handle thermal cycling well, minimizing the chances of warping or improper valve seating.

The simplicity of the valve train also works in its favor. These engines use hydraulic lifters that self-adjust to a degree, ensuring proper valve clearance over time.

As long as oil quality is maintained, the lifters help reduce wear and keep the valves functioning correctly. Furthermore, the pushrod design is inherently forgiving when it comes to valve timing and operation, adding an extra layer of mechanical tolerance.

While heavily modified or turbocharged small blocks may suffer from burnt valves over time due to increased heat and stress, stock versions used in pickups and older sedans often go well over 200,000 miles without valve trouble.

Regular oil changes, proper ignition timing, and cooling system maintenance are typically all that’s needed to keep valve health intact in these engines.

4. BMW M54 Inline-6

BMW’s M54 engine, found in models like the E46 3 Series and E39 5 Series from the early 2000s, is known for its smooth power delivery and long service life. It also happens to be an engine that rarely suffers from burnt valves when maintained properly.

This is impressive considering the engine’s aluminum block and relatively high operating temperatures, both of which can present challenges in lesser designs. The M54 uses strong valve materials and precision-engineered seats that resist wear and heat damage over time.

One of the keys to the M54’s valve health is its advanced engine management system, which carefully controls air-fuel ratios and ignition timing to prevent knock and maintain ideal combustion temperatures.

The use of wideband oxygen sensors helps ensure the engine doesn’t run too lean, which is a primary cause of hot combustion gases and subsequent valve burning.

Additionally, the dual VANOS variable valve timing system adjusts valve timing based on RPM and load to further optimize combustion conditions.

The cooling system, while sometimes prone to issues with components like the expansion tank or water pump, is well-engineered when functioning correctly.

It does a good job of keeping the engine temperature stable, which prevents hot spots in the cylinder head that can lead to valve issues. Some owners have taken these engines past 250,000 miles with original valves still performing flawlessly.

Another benefit is the engine’s smoothness. The inline-6 layout is naturally balanced, and this lack of vibration means less mechanical stress on the valve train.

With proper oil changes, the hydraulic lifters maintain valve lash well, reducing the chances of improper valve seating. For those who perform regular cooling system overhauls and avoid extended overheating events, the M54 proves to be a strong, long-lived engine with rare occurrences of valve burning.

5. Ford Modular V8 (4.6L and 5.4L SOHC/DOHC)

The Ford Modular engine family, especially the 4.6L and 5.4L variants found in many Ford and Lincoln vehicles from the mid-1990s through the 2010s, has proven to be very reliable in terms of valve longevity.

These engines utilize a modern overhead camshaft design and were engineered with durability as a core priority, especially in applications like police vehicles, fleet trucks, and work vans.

The valve materials are generally high-quality stainless steel or similar alloys, and when paired with properly hardened seats, the chances of burning a valve are quite low under normal use.

Even in heavy-duty applications like towing or hauling, these engines often continue running smoothly for hundreds of thousands of miles without needing a valve job.

A big factor in the long life of the Modular’s valve train is the engine’s conservative nature. These engines are not high-revving performance monsters in their stock form. Instead, they are tuned for torque and reliability, with compression ratios that help keep combustion temperatures manageable.

The fuel and ignition systems, controlled by robust engine management computers, ensure that the engine runs within safe thermal margins.

Even under load, the engine avoids the extremely lean conditions or pre-ignition that typically lead to excessive exhaust gas temperatures and valve damage. Their exhaust systems are also designed to allow efficient gas flow without unnecessary backpressure, which reduces stress on the exhaust valves.

Hydraulic lash adjusters in the Modular engines also contribute to their valve reliability. These components help maintain proper valve clearance automatically, eliminating the need for periodic valve lash adjustments. Improper valve clearance is a common cause of valve burning, as it prevents the valve from fully seating, especially when hot.

The fact that the Modular engines maintain consistent lash through their service life significantly lowers the risk of valve failures. These engines have been widely used in everything from the Mustang GT to the Crown Victoria and even the F-150, showing how adaptable and durable they are across a wide range of uses.

Many drivers have pushed their Modular V8s to 300,000 miles or more without any major engine work, and when valve issues do occur, they are often due to neglect or severe overheating, not inherent design flaws.

As long as oil changes and cooling system maintenance are done on schedule, the Modular series remains one of the better long-term engine choices for those who want to avoid valve-related failures. It may not be the flashiest engine, but it’s consistently dependable, which is why it rounds out the list of engines that rarely burn valves.

Also Read: 12 Vehicles That Stay Reliable Even With Multiple Owners

Engines That Commonly Burn Valves

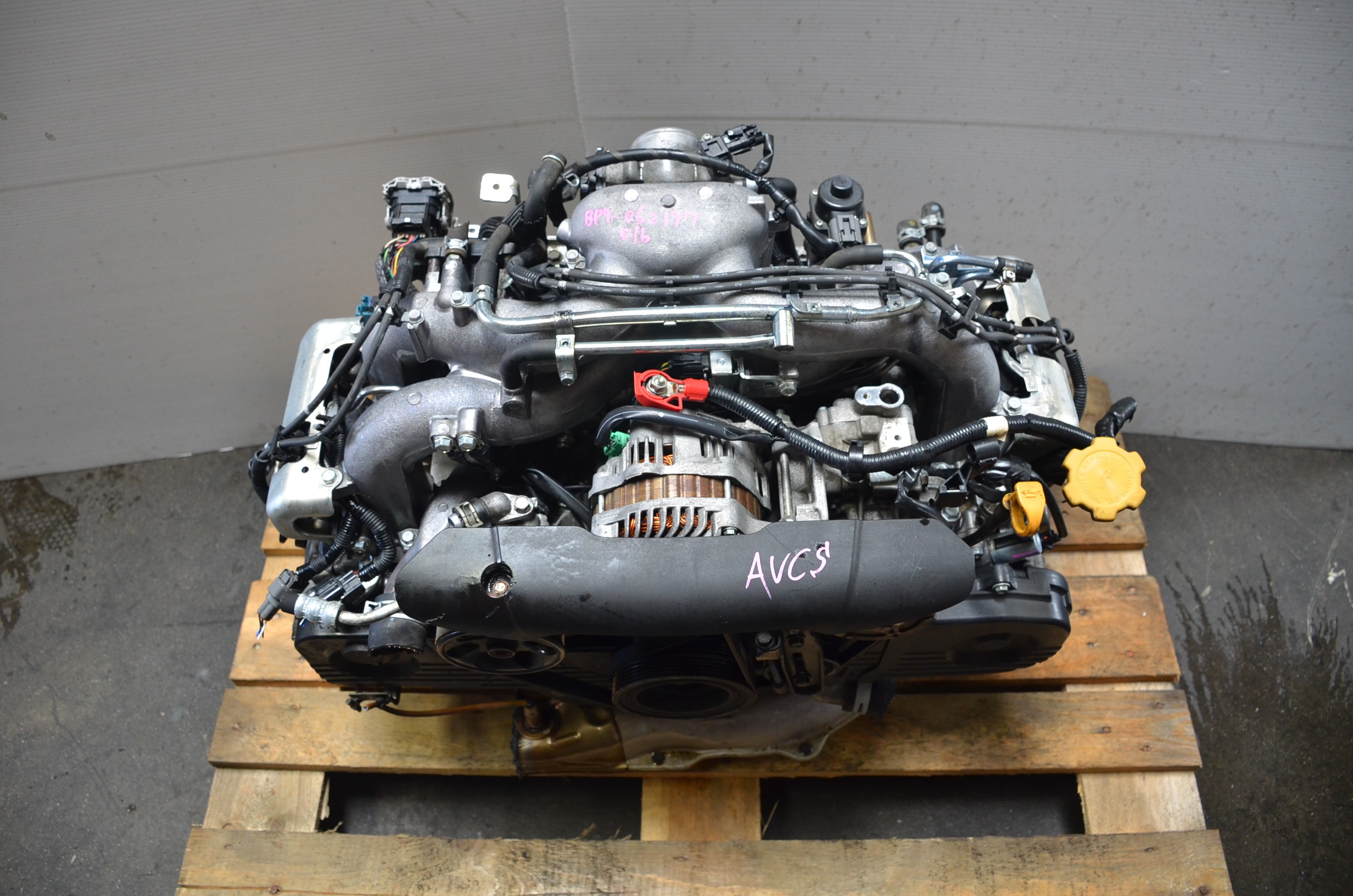

1. Subaru EJ25

The Subaru EJ25 engine, used extensively in models like the Forester, Outback, and WRX from the late 1990s through the 2010s, is notorious for a few issues, and valve burning is among them.

While Subaru engines are loved for their boxer layout and all-wheel-drive compatibility, the EJ25’s horizontally opposed design comes with unique thermal challenges.

Because the cylinders are laid flat and the exhaust valves sit on the lower side of the combustion chamber, they are subjected to more heat buildup than in upright engine configurations. Over time, this can lead to localized hot spots that degrade the valve face and seat, especially if the engine is not well-maintained.

Another factor contributing to valve problems in the EJ25 is the engine’s tendency to run lean under certain driving conditions. The combination of aggressive ignition timing, emissions tuning, and weak head gaskets can lead to overheating or detonation.

If a driver continues to operate the vehicle with failing head gaskets or an unbalanced air-fuel mixture, the exhaust valves often suffer first.

Unlike some of Subaru’s turbocharged engines that use sodium-filled valves or stronger metallurgy, the naturally aspirated EJ25 variants rely on more basic valve materials that don’t hold up as well under repeated thermal cycling.

This results in frequent occurrences of burned valves, especially in cylinder number four, which is known to run hotter than the others due to cooling imbalance.

Complicating matters is the valve lash adjustment system in earlier EJ engines, which often goes unchecked. If valve clearances tighten over time and the valves aren’t allowed to fully seat, they lose contact with the cylinder head, allowing them to overheat and accelerate wear.

Many Subaru owners are unaware that periodic valve lash inspections are necessary, particularly on models with solid lifters. Without this attention, the risk of valve burning goes up significantly. On high-mileage engines, this often manifests as a misfire, rough idle, or loss of power, with compression tests confirming burnt exhaust valves.

Although the EJ25 has some great qualities, especially in off-road or snow-bound applications, it remains a cautionary tale when it comes to valve longevity.

Preventive maintenance and early detection of cooling system or gasket issues are essential. Without that, valve burning becomes a recurring issue for these engines, making them one of the more problematic when it comes to exhaust valve durability.

2. Chrysler 2.7L V6

Chrysler’s 2.7L V6 engine, found in vehicles such as the Dodge Intrepid, Chrysler Sebring, and Dodge Stratus during the early 2000s, has long been plagued by reliability issues, with burned valves being one of several chronic problems.

The engine design was ambitious, aiming for lightweight construction and efficient power delivery, but the execution fell short in key areas.

The most prominent problem stems from oil sludge buildup, which affects valve operation indirectly but severely. Poor oil flow and overheating lead to sticking valves, increased valve temperatures, and eventual burning.

As the valves are starved of lubrication and the seats wear prematurely, it becomes increasingly difficult for them to seal properly.

A poorly designed cooling system adds to the problem. The engine is known for running hot, and the water pump, which is located inside the engine, is prone to failure. When the pump leaks or fails, it can cause rapid overheating, further degrading the valve seats and faces.

The thermal stress this engine experiences, particularly during stop-and-go traffic or in hotter climates, creates a perfect scenario for valve damage. Once valves begin to leak or fail to seat correctly due to wear or deformation, combustion gasses begin to escape, further heating the surrounding material and causing burning on the valve edges.

Another issue with the 2.7L is the design of the cylinder heads. The heads themselves don’t dissipate heat effectively, especially around the exhaust valve areas. Combined with the engine’s relatively small oil capacity and long service intervals encouraged by early marketing, many owners unknowingly pushed their engines into failure territory.

Burned valves usually show up after 80,000 to 120,000 miles, but they can appear much earlier if oil changes are skipped or the engine is exposed to extreme conditions. Misfires, poor fuel economy, and a loss of compression are all signs that this engine is already deep into valve trouble.

It’s no surprise that the 2.7L has developed a poor reputation among used car buyers and mechanics. Many professionals will flat-out refuse to work on one due to the difficulty of repairs and high likelihood of recurring problems.

While some owners managed to get decent service life with meticulous maintenance, the reality is that this engine is structurally weak in several areas, with valve burning being a predictable outcome in its later life.

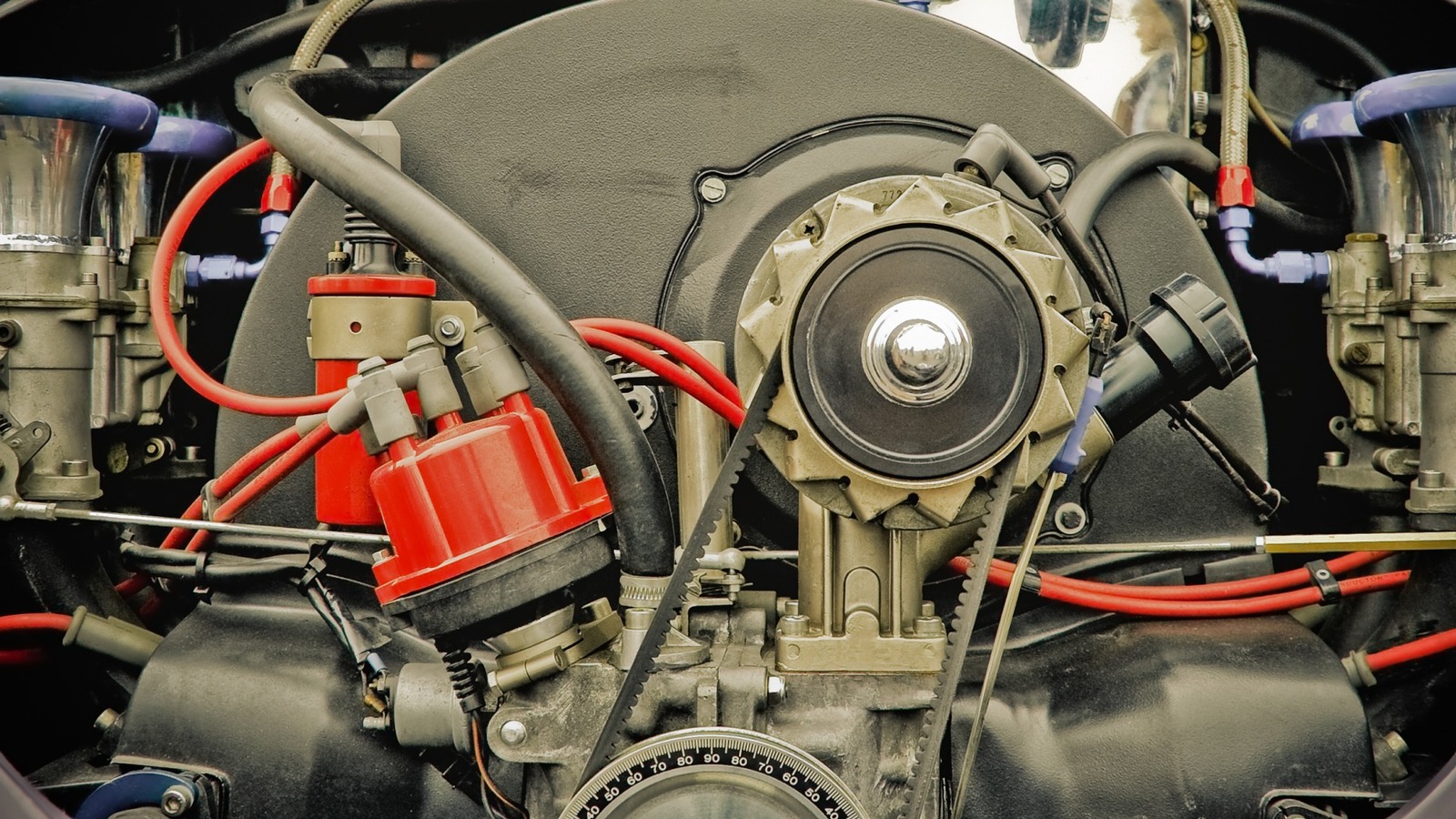

3. Air-Cooled Volkswagen Flat-4 (Beetle, Bus, Type 3)

The classic air-cooled Volkswagen flat-four engine, used in the Beetle, Bus, Karmann Ghia, and early Type 3 models, is one of the most iconic engine designs ever made. Its simplicity and accessibility made it a favorite for generations of drivers and backyard mechanics.

However, for all its charm and tunability, valve burning has always been a well-known weak point. The reason comes down to a combination of its air-cooled nature, poor thermal distribution, and early metallurgy that struggled with the demands of high-heat exhaust gases. In particular, the number three cylinder and its exhaust valve are infamous for burning out far sooner than the rest.

Air-cooled engines lack the controlled thermal regulation of liquid cooling systems. While this design reduces complexity and weight, it also means the engine is more prone to hot spots and uneven cooling.

In the VW flat-four, the cooling fan directs air across the cylinders, but airflow to the third cylinder is partially blocked by the oil cooler, leading to a significant heat imbalance.

As a result, the exhaust valve in that cylinder consistently runs hotter than the others. Over time, the constant high temperature and inadequate cooling cause the valve to become brittle and eventually fail, either through cracking or erosion. This is especially true in hotter climates or in vehicles that were driven hard on the highway.

Another contributing factor is the limited strength of the original valve materials and seats, especially in engines built before hardened exhaust valve seats became common. With the phase-out of leaded fuel in many countries, these engines were suddenly exposed to unleaded gasoline that offered less valve lubrication.

Lead acted as a cushion and coolant for the valve and seat contact area. Once it was removed, older VW engines that weren’t upgraded to hardened seats began to suffer accelerated valve wear. Without proper upgrades or meticulous tuning, the combination of weak metallurgy, high exhaust temperatures, and lean running conditions would eventually cause valves to burn.

Many air-cooled VW owners have learned to mitigate these issues by installing improved cylinder heads with hardened valve seats, converting to full-flow oil cooling systems, or rejetting carburetors to enrich the fuel mixture and lower combustion temperatures. But despite those efforts, even well-maintained engines can still fall victim to the heat-related stress that leads to valve failure.

Anyone restoring or driving one of these vehicles regularly should be prepared to inspect the valves periodically or build the top end to modern specifications to avoid repeating the mistakes of the past. While the engine is beloved for its design simplicity, valve burning remains an Achilles heel for the air-cooled VW flat-four.

4. GM 2.4L Ecotec (LE5, LAT, LEA)

General Motors’ 2.4L Ecotec engine, used in many Chevrolet, Pontiac, Saturn, and Buick models throughout the late 2000s and early 2010s, developed a reputation for frequent valve-related issues, especially in high-mileage vehicles.

Although the Ecotec family as a whole introduced some improvements in efficiency and weight reduction, the 2.4L version in particular struggled with several long-term reliability problems, with valve burning being a common one.

The issue is often linked to carbon buildup on the intake valves due to the engine’s direct injection system, which causes pre-ignition, lean operation, and higher exhaust temperatures. All of these conditions can contribute to burned exhaust valves over time.

Another challenge with the 2.4L Ecotec is the valve train design itself. While it uses hydraulic lifters, the timing chain and associated tensioners are prone to stretching or failing, which can cause valve timing to shift subtly.

A poorly timed exhaust valve can lead to insufficient seating, which in turn prevents heat from escaping through the valve seat and contributes to overheating the valve face.

In cases where timing is off even slightly, valves that should be cooling against the seat are instead left floating under combustion pressure. This significantly shortens their lifespan, especially when combined with lean fuel delivery.

The combination of mechanical, fuel system, and thermal challenges makes the 2.4L Ecotec particularly susceptible to valve burning by the 100,000-mile mark if maintenance isn’t kept up religiously. Some drivers were caught off guard, assuming regular oil changes would be enough.

However, this engine benefits from more proactive maintenance, such as valve cleaning, fuel system additives, and regular inspection of timing components.

Without that, it’s not uncommon to see burned valves by mid-life, leading to expensive top-end repairs or complete replacements. Despite being a modern design, it suffers from the kind of wear patterns that many older engines had, making it a frustrating experience for long-term ownership.

5. Toyota 3VZ-E

While Toyota has a generally strong reputation for reliability, the 3VZ-E V6 engine, used in Toyota trucks and 4Runners from the late 1980s to the mid-1990s, is an exception in terms of valve durability. This engine is known for its robust bottom end, but it has a well-documented issue with exhaust valves burning, particularly in the number six cylinder.

Part of the problem lies in the cooling system design. The rear cylinders of this engine do not get the same cooling efficiency as the front ones, leading to significantly hotter operating conditions at the back of the cylinder head.

This uneven temperature distribution places extra thermal stress on the exhaust valves in those cylinders, and over time, that heat leads to valve burning and compression loss.

Fuel quality and tuning also played a role. The 3VZ-E wasn’t the most refined in terms of air-fuel mixture control. It tended to run a bit lean under load, especially if there were issues with the fuel injectors, mass air flow sensor, or oxygen sensor.

A lean condition increases exhaust gas temperature dramatically, which is exactly the condition that exhaust valves hate.

By the time symptoms appear, such as poor idle, pinging, or failed emissions tests, the damage to the valve may already be done. The number six cylinder tends to fail first because it is farthest from the coolant inlet and sits at the end of the exhaust manifold, where heat can pool.

While some owners have gone well over 200,000 miles on their original 3VZ-E engines with proper care, the reality is that many have encountered burned valves between 125,000 and 175,000 miles, even with decent maintenance.

Unlike the 22RE, which shared Toyota’s reputation for durability, the 3VZ-E was more finicky and less forgiving. If valve lash was ignored or if overheating occurred even once, valve damage was likely. This is one of the few Toyota engines where top-end rebuilds are not considered rare, particularly in the rear bank of cylinders.