Car owners and mechanics alike have often learned the hard way how costly and frustrating a blown head gasket can be. It’s not just the part itself that makes it such a headache. It’s the labor, the downtime, and the looming risk of more significant damage if it goes unnoticed.

Engines that suffer from frequent head gasket failures tend to develop reputations that follow them for years. Some engines can barely go 100,000 miles before the issue becomes inevitable. However, not all engines are built the same. A few have managed to build a legacy of being exceptionally resistant to this kind of failure.

The integrity of a head gasket comes down to a combination of design, materials, cooling efficiency, and head bolt clamping force. If an engine is designed with consistent thermal expansion, solid casting, and reliable torque retention, the odds of blowing a head gasket drop dramatically.

Engineers who focus on these areas tend to produce engines that last much longer without developing head sealing problems. In practice, these engines can go hundreds of thousands of miles with nothing more than basic maintenance, often outlasting the vehicles they’re installed in.

This list doesn’t aim to point out the highest-horsepower or most technologically advanced engines. Instead, it highlights engines that have built a reputation for keeping their head gaskets intact, regardless of how many years or miles pass.

Whether used in family sedans, trucks, or performance applications, these engines have a track record of reliability that is hard to argue with. Owners trust them, mechanics recommend them, and many are still on the road today doing exactly what they were designed to do.

Also Read: 10 Cars Mechanics Call Unkillable Even After Long Service History

1. Toyota 2JZ-GE

The Toyota 2JZ-GE, the naturally aspirated sibling of the legendary 2JZ-GTE, earned its reputation through durability more than raw power. Built with a strong cast iron block and a well-designed aluminum head, the 2JZ-GE is known to run smoothly past 300,000 miles without major issues.

One key to its longevity is the high-quality head gasket material used from the factory, which holds up under stress and heat over time. Combined with robust head bolts and excellent cooling flow, the engine avoids the warping and pressure imbalances that often lead to failure in other designs.

Another aspect that keeps this engine from blowing head gaskets is its conservative tuning. While tuners often increase boost on the turbocharged variant, the 2JZ-GE remains naturally aspirated and runs at safe temperatures and pressures. That factory restraint helps extend gasket life significantly.

The smooth power delivery and balanced internals reduce sudden thermal spikes, which are common culprits behind gasket breakdowns. It’s not flashy, but that reliability makes it a favorite among those who prioritize endurance over excitement.

Toyota’s engineering in the ’90s focused on long-term serviceability. The 2JZ block has deep threads for the head bolts, which means clamping force stays consistent even after decades. Many engines lose head gasket sealing simply because bolt tension reduces over time or due to thermal cycling.

The 2JZ avoids that with a design that emphasizes material stability and mechanical integrity. It’s not just the block; the head design also avoids hotspots that could trigger warping, which is where many aluminum heads fail.

There are numerous reports of 2JZ-GE engines with over 400,000 miles that have never needed head work. Regular maintenance like coolant changes and oil services helps, but even when neglected, these engines often hold together better than others. For those who just want an engine that won’t leave them stranded or facing a major rebuild, the 2JZ-GE delivers consistency and peace of mind.

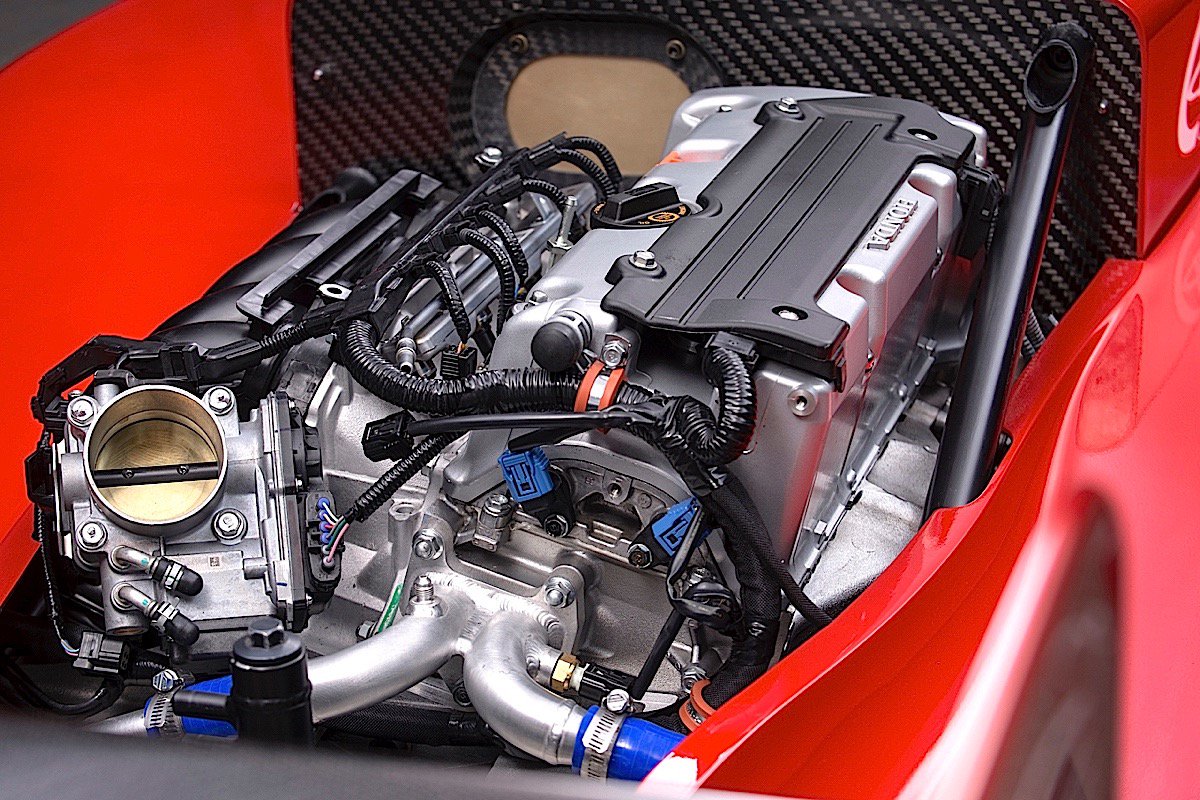

2. Honda K24

The Honda K24 series, especially in its earlier forms, built a reputation for being nearly unbreakable under normal use. Known for powering everything from Accords to CR-Vs and even performance versions in the Acura lineup, the K24 can handle high mileage with ease.

One of the secrets behind its resistance to head gasket issues lies in its aluminum block and head pairing. Honda made sure thermal expansion between the two components was closely matched, reducing stress on the head gasket seal during warm-up and cooldown cycles.

Another key factor is the use of multi-layer steel (MLS) head gaskets in most versions of the K24. These gaskets provide a reliable seal even when subjected to modest pressure increases. MLS gaskets are more resistant to failure from overheating and pressure spikes, making them a popular choice in motorsport as well as everyday driving.

Combined with solid head bolt torque specs and a high-quality casting process, these engines are well protected against failure points that often plague other aluminum motors.

Cooling efficiency also plays a role in the K24’s durability. The engine has a well-routed coolant path and a thermostatically controlled cooling system that avoids rapid heat buildup. Many engines blow head gaskets when heat pockets form around the combustion chamber, causing localized warping and stress.

The K24’s coolant design avoids those hotspots and maintains even temperatures across the head. That stable environment gives the gasket a much better chance of surviving long-term use without degradation.

It’s also worth noting how the K24 manages oil control and detonation, which are indirect factors in head gasket failure. By avoiding high knock levels and keeping oil away from the gasket surface, Honda further ensured that this engine could withstand decades of use. For enthusiasts and daily drivers alike, the K24 remains a prime example of how good design and manufacturing discipline can result in an engine that rarely, if ever, needs its head gasket replaced.

3. Ford 300 Inline-6

The Ford 300 cubic-inch inline-six is often hailed as one of the toughest engines ever built in America. Introduced in the 1960s and used well into the 1990s, it gained a cult following among truck owners and fleet managers for its brutal simplicity and mechanical toughness.

One of its standout features is the heavy-duty cast iron block and head combination, which essentially removes the threat of head warping, one of the leading causes of gasket failure.

Because both the block and head are made from cast iron, the Ford 300 heats up and cools down at the same rate. That uniformity greatly reduces the stress on the head gasket, which often fails in engines where the head expands faster than the block.

Add to that the engine’s low compression ratios and low redline, and you have a setup that avoids generating the excessive heat and pressure that typically destroy head gaskets. It’s the kind of engine that runs cool even under load.

The Ford 300 was also designed with long service intervals in mind. Used in vans, trucks, and industrial applications, it needed to run under load for hours without flinching.

The head bolt pattern and torque sequence are engineered for maximum retention, which prevents the kind of micro-movement between the head and block that can lead to gasket wear. These details may seem minor, but over hundreds of thousands of miles, they add up to real-world reliability.

Perhaps the most impressive thing is that many of these engines are still running today, often in older F-Series trucks or farm equipment.

Owners report hitting mileage well into the 300,000s without ever needing to pull the head. It may not have cutting-edge technology or lightweight materials, but what it lacks in flash it makes up for in toughness. For those who want something they can fix with a wrench and keep running forever, the Ford 300 has proven itself time and again.

4. Chevrolet LS-Series (Gen III & IV)

The Chevrolet LS engine family has become one of the most recognized and respected engine lines in the automotive world. Beyond its power potential and modular design, one of the lesser-discussed strengths of the LS platform is its strong reliability, especially when it comes to head gasket integrity.

Unlike older small-blocks that occasionally suffered from warping or coolant leakage, the LS-series was designed with modern materials, computer-aided engineering, and precise tolerances that virtually eliminated chronic gasket issues under normal conditions.

The result is an engine family that rarely requires head gasket replacement unless it’s been abused or poorly modified.

One key aspect of the LS engine’s reliability is the use of robust aluminum heads paired with strong head bolts that maintain proper torque and clamping pressure even under performance conditions. Many of these engines, including the LS1, LS3, and LQ4, were built to handle both daily driving and spirited use.

The MLS head gaskets used across the LS lineup are high-quality and resist deterioration under heat cycles. Combined with excellent head bolt design, in some cases using torque-to-yield bolts, the cylinder head remains firmly sealed against the block, even during heavy loads or slight overheating.

Cooling system design in the LS family also contributes to preventing head gasket failure. The water jackets in the block and heads are designed to reduce hot spots around the combustion chambers.

These areas are particularly vulnerable in many engines, but the LS platform avoids this with intelligent routing that cools all cylinders evenly.

Over time, this keeps the head and gasket materials from becoming compromised. The LS also features a crossflow cylinder head design that promotes temperature stability and minimizes the risk of sudden pressure spikes.

While many people associate LS engines with turbocharging and high-horsepower builds, the factory versions are incredibly resilient when left in their original state. Even modified, LS engines tend to tolerate increased pressure without blowing gaskets, provided the tune is safe and cooling is adequate.

Countless stories exist of LS-powered vehicles logging hundreds of thousands of miles without needing head gasket attention. Whether in a Silverado, Corvette, or an engine-swapped project car, the LS delivers not just power but a level of durability that keeps owners from dealing with head gasket problems year after year.

5. Mercedes-Benz OM617

The Mercedes-Benz OM617 diesel engine is legendary for its ruggedness, longevity, and sheer indifference to abuse. Manufactured primarily through the 1970s and 1980s, this 5-cylinder inline diesel engine powered vehicles such as the W123 and early G-Wagens.

Known to run for over half a million miles without major repairs, the OM617’s resilience includes excellent resistance to head gasket failure. It’s not just that it’s a diesel; it’s how Mercedes built it. The engine’s cast iron block and head contribute to a level of thermal stability that most modern engines can’t match.

What makes the OM617 stand out even among other cast iron engines is the level of overengineering Mercedes applied. The engine was designed at a time when long-distance durability mattered more than fuel economy or emissions. This meant beefier head bolts, thick gasket materials, and a conservative design that prioritized longevity.

The compression pressures in a diesel engine are much higher than in gasoline engines, yet the OM617 manages to maintain a perfect seal due to how well the head bolts retain torque and how evenly the head distributes that force across the block.

Another advantage of the OM617’s design is its cooling and lubrication systems. The cooling system was designed to handle high load scenarios like climbing steep European mountain roads or idling for long hours in traffic. It uses a large radiator, an effective fan clutch, and simple water flow paths that prevent overheating.

The oiling system is similarly robust, with a high-volume oil pump and efficient distribution to all critical areas. Since oil contamination and overheating are two of the biggest threats to head gasket longevity, the OM617’s ability to keep both in check allows the gasket to last essentially for the life of the engine.

In real-world use, it’s not uncommon to hear about OM617 engines surpassing 400,000 or even 600,000 miles without ever needing a head gasket replacement. The key is simple maintenance: regular oil changes and keeping the cooling system clean and functional.

This is an engine built for endurance, and its resistance to head gasket failure is just one of many reasons it’s still revered by diesel enthusiasts and collectors alike.

Also Read: 5 Cars With Great Handling and 5 That Shake Apart

6. Toyota 1GR-FE

The Toyota 1GR-FE, a 4.0L V6 engine used in various Toyota trucks and SUVs, is often overlooked in performance circles but praised in the reliability department. Found in vehicles like the Toyota Tacoma, 4Runner, and FJ Cruiser, the 1GR-FE was built with longevity in mind.

With a cast aluminum block and aluminum DOHC heads, it might seem like a recipe for potential gasket issues, but Toyota addressed this through solid engineering. The head gasket design, in combination with high-grade head bolts and an efficient cooling system, results in one of the most dependable mid-sized V6s ever built.

Toyota’s design on this engine centered around minimizing thermal stress and preventing localized hot spots that typically lead to gasket failure. The cooling channels are well-mapped, and the thermostat and water pump systems are designed to keep the engine operating in a narrow temperature band.

This consistency reduces the expansion and contraction cycle that usually stresses head gaskets. Even under towing or off-road loads, the engine rarely suffers from overheating, and as a result, the gasket seal remains intact through years of operation.

The 1GR-FE also benefits from a simple and clean valvetrain design, which contributes to engine reliability. With fewer chances for oil leaks and overheating in the head area, there’s less opportunity for heat soak or detonation to compromise the gasket seal.

Another point of strength is the engine’s fairly low specific output. It doesn’t stress its components to produce power, which keeps cylinder pressures moderate and reduces the risk of head lifting or gasket failure under load.

Owners of Tacomas and 4Runners equipped with the 1GR-FE often report reaching 250,000 to 300,000 miles without any major engine work, and head gasket issues are almost unheard of unless the engine is severely overheated. It’s a testament to Toyota’s consistent commitment to practical reliability.

Even in rugged environments or poor maintenance situations, the 1GR-FE has proven to be one of the most trouble-free engines in its class when it comes to head gasket survival.

7. Subaru EE20

Subaru is often criticized for its head gasket issues in the older EJ series engines, but the EE20, a 2.0L turbo-diesel boxer engine, broke away from that stereotype. Designed primarily for markets outside the United States, the EE20 was used in models like the Subaru Outback and Forester.

Unlike its gasoline siblings, the EE20 features a modern, multi-layer steel head gasket and a design philosophy that corrects many of the weaknesses that plagued earlier Subaru engines. The result is a boxer engine that doesn’t carry the same head gasket curse.

One of the main improvements comes from the material and thermal design choices. The EE20 uses a robust aluminum head and block combination that was engineered with much tighter thermal tolerance considerations than the old EJ series.

Subaru spent considerable time refining the coolant flow and oil cooling systems, particularly because diesels inherently generate more heat and cylinder pressure. These changes drastically improved head gasket reliability, making the EE20 stand out within Subaru’s lineup for durability and long-term performance.

The head bolts in the EE20 are stronger and have a better clamping strategy compared to older Subaru engines. Subaru also revised the head casting to improve rigidity, reducing the flex and micro-movements that often led to gasket leaks in previous generations.

The symmetrical layout of the boxer engine helps balance temperature distribution, further lowering the chance of hot spots that can warp the heads or degrade the gasket seal. These engineering upgrades combined to create a system where head gasket failure became the exception, not the norm.

Even though the EE20 wasn’t designed for extreme performance, it was built to withstand long-distance driving, towing, and stop-and-go city traffic without failure. Reports from high-mileage users, especially in Europe and Australia, indicate consistent performance and extremely low failure rates in the gasket area.

While Subaru fans might still approach the brand with caution due to past issues, the EE20 proves that the company learned from its mistakes and built an engine that finally lived up to expectations in this crucial reliability category.

8. BMW M54

The BMW M54 inline-6 engine, used throughout the early 2000s in vehicles like the E46 3 Series and E39 5 Series, managed to strike a rare balance between performance, refinement, and long-term durability.

Despite BMW’s reputation for complex engineering and sometimes finicky reliability, the M54 stands out as one of their most dependable powerplants, especially when it comes to avoiding head gasket problems. Its robust design, balanced cylinder layout, and intelligent temperature management make it a surprisingly resilient engine even by today’s standards.

A big factor in the M54’s head gasket integrity is its inline-6 configuration. The straight-six layout offers inherent thermal balance and structural rigidity, which means the engine block and head experience very little flex during operation. Less mechanical distortion translates directly to less wear on the head gasket surface.

BMW paired this with an aluminum block and head, both cast with high precision. The cylinder head gasket used in the M54 is a multi-layer steel type that seals tightly even under spirited driving, which many BMW owners are known to enjoy.

BMW also engineered the M54 with a high-quality cooling system that helps regulate temperature changes more effectively than in many competing engines. It uses an electronically controlled thermostat and well-routed coolant passages to maintain consistent temperatures under all conditions.

These systems prevent heat spikes that can lead to warping or micro-cracks around the combustion chambers. Combined with strong head bolts and a uniform torque pattern, the engine keeps combustion pressure from compromising the head gasket seal, even after many years of service.

While oil leaks from valve cover gaskets and cooling system failures are common complaints on aging M54s, head gasket failures remain rare. Owners who perform basic maintenance and keep the cooling system in good shape often drive these engines well past 200,000 miles without major internal issues.

It’s a testament to what BMW could accomplish when they focused on engineering strength rather than just novelty. In a time when many European engines became infamous for breakdowns and blown gaskets, the M54 quietly proved that dependability and sophistication could go hand in hand.

9. Chrysler 225 Slant-6

The Chrysler 225 Slant-6, affectionately nicknamed the “Leaning Tower of Power,” has earned its reputation as one of the most indestructible engines ever produced in North America. Introduced in the early 1960s, the Slant-6 was designed with ruggedness in mind, and that includes its strong resistance to head gasket failures.

The engine’s unique 30-degree slanted cylinder layout wasn’t just for style, it allowed for a lower hoodline, better intake manifold geometry, and improved engine bay fitment. But one of the unintended benefits was an even thermal load across the cylinder head, which helped maintain head gasket integrity.

The block and head of the 225 were both cast from thick iron, giving the engine incredible thermal stability. This meant that during long periods of operation, even under heavy loads, the head and block expanded at similar rates, avoiding the common warping issues found in mixed-material engines.

With head bolts that were long and evenly spaced, the cylinder head remained torqued securely to the block for the life of the engine. As a result, there were very few opportunities for the head gasket to fail unless the engine was severely overheated.

Another reason for the Slant-6’s longevity was its extremely conservative performance tuning. With modest compression ratios and low RPM operation, the engine wasn’t generating the kind of high-cylinder pressures that typically stress gaskets. The design encouraged durability over speed, making it ideal for taxis, delivery vehicles, and work trucks.

Even in high-mileage scenarios, the Slant-6 kept running with minimal internal wear. In fact, these engines often outlasted the vehicles they were installed in, which is a rare thing to say in today’s automotive industry.

Today, enthusiasts and restorers who find old Dodge Darts or Plymouth Valiants with Slant-6 engines are often surprised to discover that the original engine still runs smoothly with only basic upkeep. You can change the oil, maybe reseal the valve cover, and continue driving it for years.

Head gasket failure? Almost unheard of unless the cooling system has been totally neglected. The Chrysler 225 didn’t just resist blowing head gaskets; it laughed in the face of it.

10. GM 3800 Series II (Buick V6)

The GM 3800 Series II engine is often cited as one of the most reliable American engines ever built. Used in everything from the Buick LeSabre to the Pontiac Grand Prix and even some Chevrolet models, this 3.8L V6 became famous not just for its torque and smooth operation, but for how well it held up over hundreds of thousands of miles.

Unlike many V6 engines of the 1990s and early 2000s, the 3800 Series II rarely suffered from head gasket failures, thanks to a well-thought-out design that prioritized longevity over flash.

One of the core reasons for the engine’s durability lies in its cast iron block and iron heads. While this results in a heavier engine, the benefit is near-perfect thermal harmony between the block and head materials.

They expand and contract together as the engine heats and cools, which significantly reduces the chance of a compromised gasket seal. Many engines with aluminum heads on iron blocks suffer gasket failures due to different rates of thermal expansion, but the 3800 avoids this entirely by sticking with iron for both components.

In addition to the material choices, the 3800 was engineered for efficiency and smooth operation, not high-RPM performance. This kept cylinder pressures moderate and allowed GM to use conventional, proven gasket materials without concern.

The head gasket itself was of high quality and properly torqued using reliable bolt patterns that minimized any chance of warping or uneven clamping force. Combine that with a low-revving, long-stroke configuration, and you’ve got an engine that doesn’t put undue stress on the sealing surfaces between the head and block.

Despite being installed in millions of vehicles, it’s rare to hear of a 3800 engine blowing a head gasket unless it has been severely overheated or poorly maintained. In fact, the engine became somewhat of a meme in the automotive community for its ability to run even when neglected.

For families and daily commuters who just wanted a car that started every morning and didn’t leave a puddle of coolant in the driveway, the 3800 Series II proved to be a nearly unbeatable choice. It remains one of the best examples of bulletproof American engine design, and its resistance to head gasket failure is a big part of that legacy.