Diesel engines have built a reputation for durability, strength, and the ability to withstand punishing workloads over long periods. While gas engines often grab attention for speed and performance, diesel engines are chosen by those who care about long-term reliability and sheer operating hours.

For decades, industries like agriculture, freight, construction, and marine operations have depended on diesel power to get through long hauls and heavy lifting.

What separates diesel from gas, beyond fuel type, is the engine design itself, stronger blocks, lower RPMs, and higher torque output at lower speeds. That translates to less stress on moving parts and more mileage or engine hours before a rebuild or replacement is needed.

Among diesel engines, however, not all are created equal. Some have proven to go well beyond standard expectations, continuing to run reliably after hundreds of thousands of miles or tens of thousands of operating hours. They’re found in everything from semi-trucks and workhorse pickups to farm tractors and stationary generators.

Mechanics often talk about these engines in the same tone they’d use for old legends, models that seem to refuse to die, even after decades of heavy use. These are engines that often get passed from one vehicle to another, pulled out of wrecked trucks and installed in new frames, simply because the engine still runs like it did years ago.

The engines on this list stand out because of their longevity, simplicity, ease of maintenance, and design philosophy that prioritizes life span over high-rev excitement.

Many have earned almost mythological status, being used across continents in various conditions, from the scorching heat of desert oilfields to the icy stretches of northern logging roads.

Some are still being made today with only minor updates, a testament to how right the original engineering was. Others are no longer in production but continue to rack up hours in older equipment or restored machines.

Whether you’re a diesel enthusiast, a heavy equipment operator, or someone considering a long-term truck investment, understanding these engines gives insight into what truly lasts when all the bells and whistles are stripped away.

Also Read: 10 Mercedes Cars That Outast The Owners’ Expectations

1. Cummins 6BT (5.9L)

The Cummins 6BT, also known as the 5.9-liter 12-valve, is one of the most recognized and respected diesel engines ever produced. It first appeared in Dodge Ram trucks in the late 1980s and immediately stood out for its durability and torque.

With its cast-iron block and head, mechanical fuel injection system, and lack of electronics, the 6BT became a favorite among truck owners who valued simplicity and long-term reliability. Its design borrowed heavily from industrial engines, which means it was built to run under load for extended periods without breaking down.

One of the key reasons the 6BT lasts so long is its basic mechanical injection system. Unlike newer engines that rely on electronics and sensors, the 6BT uses a mechanical Bosch VE or P7100 injection pump.

These pumps are known to go hundreds of thousands of miles with minimal maintenance. With no computer to fail and fewer sensors to worry about, troubleshooting is simple and repairs are usually inexpensive. It also helps that the engine is non-interference, meaning even if a timing issue occurs, valves and pistons won’t collide.

In real-world use, the 6BT has often outlived the vehicles it was put into. Many Dodge Rams from the early 90s have long since rusted into the ground while their engines have been pulled and installed in other trucks, tractors, or even converted into generators.

The aftermarket support is enormous, which means parts are cheap and readily available. From simple rebuild kits to full performance upgrades, keeping a 6BT alive is not only possible but often economical compared to buying a new engine.

The legacy of the 6BT is still strong today. Even though it was eventually replaced by more modern engines in Dodge trucks, it remains a favorite in the swap community.

People continue to search junkyards and auctions for these engines, knowing that a properly maintained 6BT can easily surpass 500,000 miles and often hit a million with a rebuild or two along the way.

2. Detroit Diesel Series 60

When the Detroit Diesel Series 60 was introduced in the late 1980s, it broke the mold for heavy-duty diesel engines in long-haul trucking. It was one of the first computer-controlled engines to gain widespread acceptance in an industry that had always favored mechanical simplicity.

But what made the Series 60 special wasn’t just the new technology, it was the way it blended that technology with the same long-lasting design philosophy that powered older diesel platforms. Over the years, it proved itself as one of the most reliable engines in the freight world.

The Series 60 came in multiple displacements, most 11.1L, 12.7L, and later 14L variants. Trucking fleets loved it for its combination of fuel efficiency, long oil change intervals, and ability to keep running for over a million miles with proper maintenance.

Many owner-operators favored the 12.7L model for its balance of power and longevity. The engine’s inline-six configuration helped reduce vibration and wear, and it was known to handle poor-quality fuel better than some of its competition.

Beyond just durability, the Series 60 became famous for being relatively easy to work on for a heavy-duty engine. Routine service items were accessible, and parts were affordable due to the sheer number of these engines in use.

It also had a reputation for forgiving maintenance lapses better than other engines in its class. While neglect will eventually kill any engine, the Series 60 often gave owners a second chance before that point.

Today, despite newer engines offering more emissions control and modern tech, many older fleets still run Series 60-equipped trucks. The engine is often swapped into older chassis or used for glider kits, a legal loophole that allows truck owners to reuse older engines in new truck frames.

Its long-term presence on highways is a clear sign of how well this engine was engineered. Mechanics still speak highly of it, and used parts are found everywhere from scrap yards to dedicated rebuild shops.

3. International DT466

The International DT466 is the workhorse of medium-duty trucks and vocational equipment. It’s a legend in the world of school buses, delivery trucks, and construction equipment, and has earned a name for itself by consistently putting in the hours without much complaint.

The DT466 was first released in the 1970s and continued in various updated forms until the 2000s. Its robust, wet-sleeve inline-six design made it easy to rebuild and keep in service for decades.

One major feature that sets the DT466 apart is its use of replaceable wet sleeves in the cylinders. This design allows for easier and more cost-effective overhauls compared to engines that require complete machining or replacement. In many cases, a technician can rebuild a DT466 without pulling the engine from the frame.

That saves time and money and keeps trucks on the road rather than stuck in a shop. These engines were built with fleet maintenance in mind, and that shows in the way they’re put together.

The DT466 isn’t a powerhouse in terms of raw horsepower, but it’s not supposed to be. What it offers is consistent, usable torque and a long life at relatively low operating stress. Its performance in school buses is a testament to that.

Many of those buses rack up hundreds of thousands of miles without needing more than routine oil changes and maybe a turbo replacement along the way. The engines simply keep going, often outlasting the bodies of the vehicles they’re installed in.

Even after being phased out in favor of newer emission-compliant engines, the DT466 is still found in service all across North America.

Many municipalities and private fleets continue to rebuild and reuse these engines. Whether it’s being used in a water truck at a construction site or powering a backup generator in a rural town, the DT466 still proves that simplicity and solid design never go out of style.

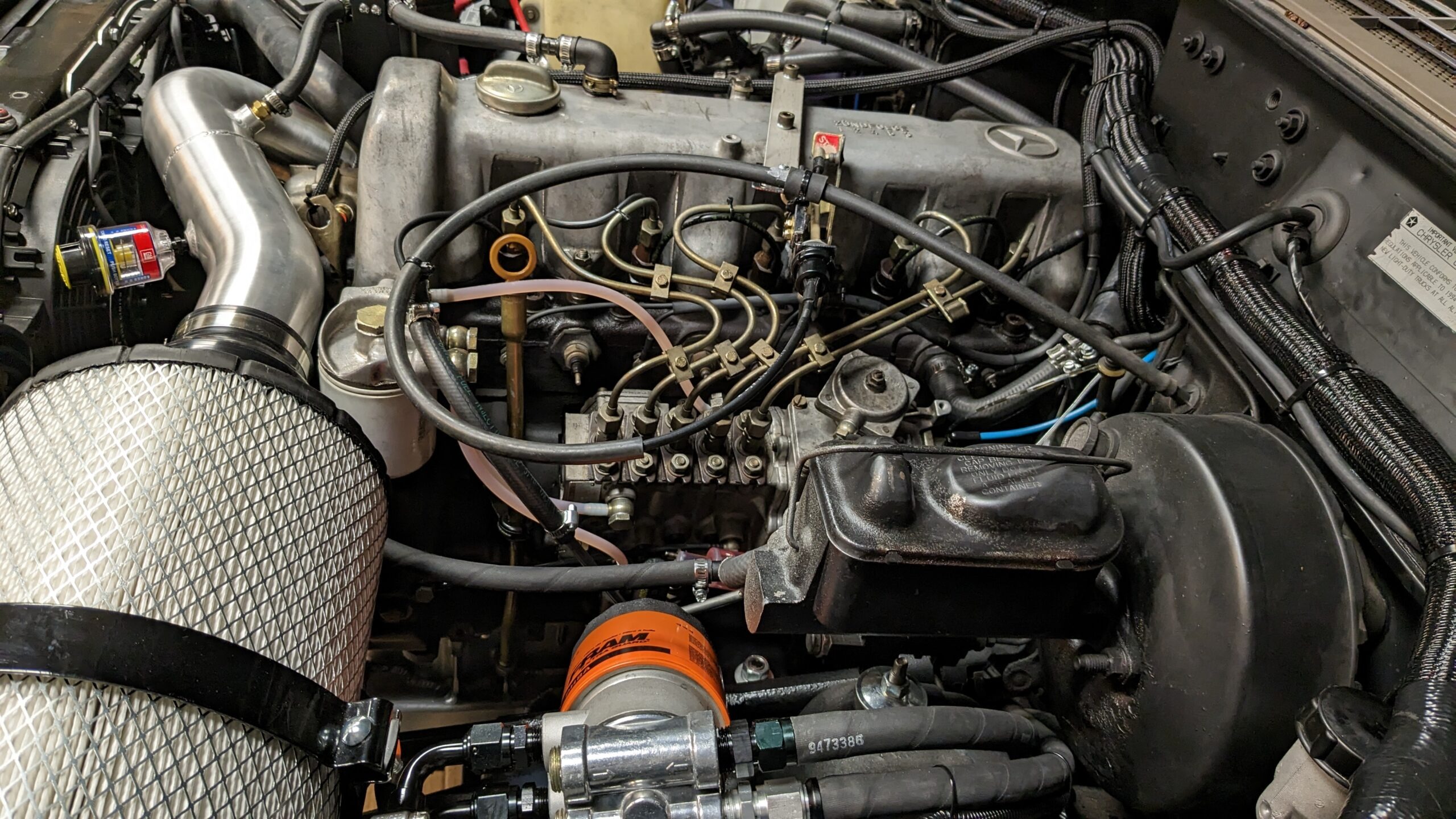

4. Mercedes-Benz OM617

The OM617 from Mercedes-Benz is often regarded as one of the most durable diesel car engines ever made. Found in the company’s sedans and wagons from the 1970s through the mid-1980s, this inline-five engine was never known for speed but became legendary for its longevity.

Thousands of these engines are still running today, especially in older 240D and 300D models. Many have surpassed 500,000 miles without needing a rebuild, and some have even crossed the million-mile mark with their original internals intact.

The OM617’s durability comes from its simple, overbuilt design. It uses indirect injection and a cast-iron block and head, with minimal electronics to fail over time. The engine was designed during a period when Mercedes was more concerned with quality than cost.

That philosophy resulted in a powerplant that could handle poor-quality fuel, extreme temperatures, and years of neglect while still firing up in the morning. It’s not uncommon for these engines to run even after sitting in a field for years.

Another factor in the OM617’s long life is its forgiving nature. Unlike modern engines that often go into limp mode or refuse to run when a single sensor fails, the OM617 doesn’t rely on much more than clean fuel, air, and oil to keep going. It’s also an easy engine to maintain for a DIY mechanic.

Valve adjustments, fuel filter changes, and even injector service can be done in a driveway with basic tools and some patience. This ease of maintenance contributes to the long-term viability of the engine.

Though no longer in production, the OM617 continues to maintain a cult following among Mercedes enthusiasts and diesel mechanics alike. It’s not just the engine’s lifespan that makes it impressive, but also its sheer reliability across a variety of driving conditions.

Whether operating in frigid northern climates or under the scorching sun of the Southwest, the engine rarely complains.

Its indirect injection system may not be the most efficient by today’s standards, but it enables smooth starts in cold weather and allows the engine to tolerate a broader range of diesel fuel types, including older blends and even some biofuel variants when properly filtered.

What also separates the OM617 from many modern engines is its mechanical purity. There is no ECU (engine control unit), no complex sensor network, and no proprietary software locking out the owner or mechanic from basic diagnostics.

Everything from throttle response to fuel injection is purely mechanical, making the engine not just durable, but also incredibly serviceable.

That mechanical simplicity makes the OM617 especially attractive for remote travel or off-grid builds. It has become a popular engine choice in overlanding vehicles and even some military and humanitarian aid vehicles that require reliability without dependence on modern parts or diagnostics equipment.

A big part of the engine’s longevity also comes from its conservative tuning. The OM617 was never pushed to its performance limits.

In most configurations, it produced only around 77 to 125 horsepower, depending on whether it was turbocharged. This low-stress setup meant that internal components like pistons, rods, and bearings experienced much less wear over time.

While performance enthusiasts might scoff at the idea of a 3.0-liter diesel barely cracking 100 horsepower, the payoff is an engine that seems almost immune to failure. Many owners note that the turbocharged versions are just as reliable, provided the turbo is well-maintained and the oil changes are done on time.

5. Caterpillar 3406E

The Caterpillar 3406E is a heavy-duty diesel engine built for endurance and power in equal measure. It gained popularity in the 1990s and early 2000s, especially among long-haul truckers and heavy equipment operators.

Known for its massive displacement, high torque output, and rebuildable structure, the 3406E carved out a strong reputation in the world of Class 8 trucks and industrial machinery.

What really set it apart was how consistently it could run under full load for hours on end without succumbing to heat, wear, or component failure. That resilience is exactly why so many trucking fleets relied on it for their most demanding routes.

One of the defining traits of the 3406E is its design philosophy, which focused on maintainability and operational lifespan.

The engine uses wet cylinder sleeves, much like the International DT466, allowing for easier overhauls and rebuilds without needing to machine the block. With an engine like the 3406E, rebuilds aren’t just a repair option, they’re an expected part of the maintenance cycle.

Many operators have taken these engines through two or three full rebuilds, often crossing the million-mile mark multiple times. Rebuild kits are readily available and well-documented, making it possible for experienced diesel mechanics to keep these engines alive for decades.

The 3406E also offered something that not all heavy-duty engines could at the time: electronic engine management combined with traditional mechanical robustness.

The ACERT (Advanced Combustion Emissions Reduction Technology) version introduced later attempted to reduce emissions, but it was the pre-ACERT versions of the 3406E that many still swear by.

These earlier versions were considered the “sweet spot” between old-school durability and modern efficiency. They maintained strong performance without being overburdened by the complexity of modern emissions systems, which can sometimes introduce more failure points.

To this day, the 3406E is a favorite for engine swaps and glider kit builds. Enthusiasts and professionals alike seek out these engines because they know what to expect: a long life of reliable performance with the ability to control nearly every aspect of the engine’s behavior.

Many old-school truckers believe the 3406E was the last great Caterpillar on-highway engine before emissions regulations led the company to exit that market.

It may not be the most fuel-efficient or environmentally friendly engine by modern standards, but when it comes to toughness and long-term reliability, few can argue with what the 3406E has achieved.

Also Read: 10 Best Trucks That Hold Value Decades Later

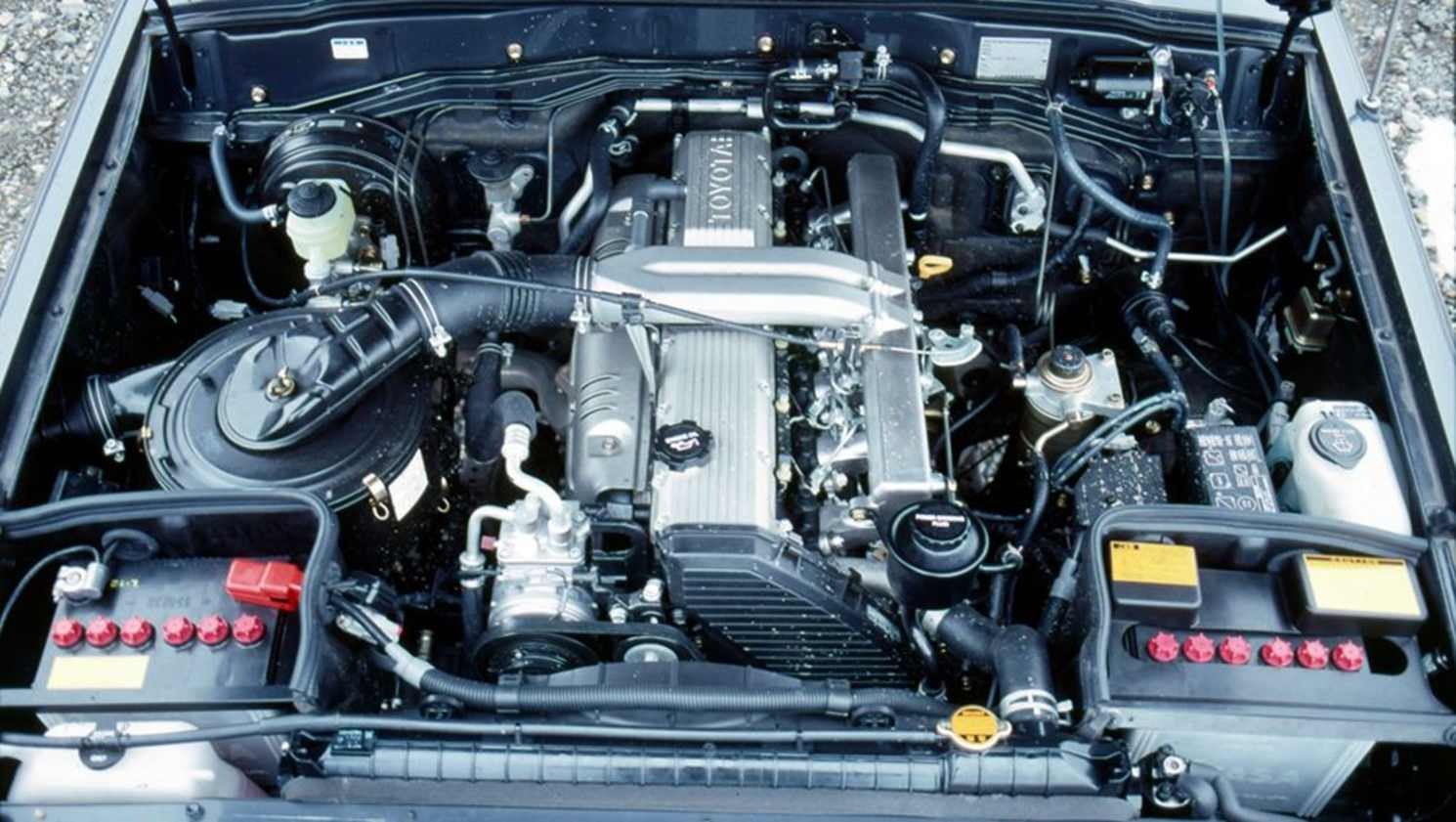

6. Toyota 1HZ

The Toyota 1HZ is a naturally aspirated inline-six diesel engine that has earned a strong reputation worldwide, especially in remote and rugged environments where reliability is more important than power.

First introduced in the late 1980s and still found in various Toyota Land Cruiser models, the 1HZ has become synonymous with dependability in countries like Australia, parts of Africa, and the Middle East.

It was never designed to be flashy or high-performing, but rather to last under conditions that would destroy lesser engines. That includes long-distance desert travel, deep river crossings, and long idle times in intense heat.

Part of the 1HZ’s success comes from its overbuilt nature. It features a cast-iron block and head, a gear-driven timing system, and simple indirect fuel injection. These components are chosen not just for strength but for long-term serviceability.

The engine doesn’t require specialized tools to repair, and many common issues can be diagnosed visually or through mechanical checks. In the developing world, where access to modern diagnostic equipment can be limited, the 1HZ is prized for its ability to be fixed with basic hand tools and a bit of mechanical know-how.

The 1HZ is also well-known for its smooth operation and consistent power delivery, despite its low horsepower output. Producing around 129 horsepower and 210 lb-ft of torque, it was never intended to win races. However, it delivers that power in a very usable manner, especially at low RPMs.

This makes it ideal for climbing, towing, and slow-speed maneuvering through rough terrain. The engine’s natural aspiration, while limiting top-end performance, eliminates the complexity and heat management issues associated with turbochargers. Fewer parts mean fewer potential failures, especially in areas where replacements may be hard to come by.

Because of its proven track record, the 1HZ continues to be highly sought after, even in secondhand markets. Many off-roaders and expedition builders prefer the 1HZ to more modern diesel engines because of its simplicity, reliability, and ease of repair.

Vehicles equipped with the 1HZ often have odometers that read half a million kilometers or more and are still in daily service. For those venturing far off the beaten path, the 1HZ represents peace of mind that the engine will keep running long after others have quit.

7. Perkins 4.236

The Perkins 4.236 is one of the most prolific small diesel engines in agricultural and industrial history. Introduced in the 1960s, it powered a wide range of machinery, including tractors, forklifts, generators, and small trucks.

Built in the UK and used globally, this 4-cylinder engine became a staple in places where simplicity and long life were essential. It’s often referred to as a “million-mile engine” not in terms of road mileage, but in hours of operation. Many units are still running today in fields and workshops, some having accumulated well over 30,000 hours of operation without major issues.

One of the main reasons for the 4.236’s longevity is its minimalistic and rugged design. The engine was made to run in harsh environments, often with poor fuel quality and minimal maintenance. It features a gear-driven camshaft, simple inline injection pump, and mechanical everything.

There are no complicated electronics, no sensors, and no digital modules to fail. This kind of mechanical simplicity means that it can run in conditions that would cripple modern engines. It’s also forgiving of poor maintenance practices, with many engines having run on dirty fuel or extended oil intervals with little consequence.

Another advantage of the Perkins 4.236 is its flexibility. The engine was used in dozens of different applications and configurations, from stationary power units to marine engines. That broad usage has kept parts availability strong even decades after its peak production.

Rebuild kits, replacement pumps, and even entire remanufactured engines can still be found. This allows owners to continue using equipment powered by the 4.236 rather than scrapping it, which is a major benefit in areas where capital investment in new machinery is cost-prohibitive.

Mechanics who work with the 4.236 often speak of it with admiration. They know what it takes to keep one going and appreciate how rarely major problems arise. While it may not be the most powerful or advanced engine on this list, the Perkins 4.236 stands out for being nearly indestructible in the hands of someone with even basic mechanical skills.

Its ability to keep running decade after decade, often in the harshest working environments, puts it in a class of its own among small diesel engines.

8. Ford 7.3L Power Stroke (International T444E)

The Ford 7.3L Power Stroke, also known internally by International as the T444E, is often seen as one of the most reliable diesel engines ever put into a consumer-grade pickup truck. Produced from 1994 to 2003 in Ford trucks and vans, the 7.3L became the gold standard for diesel pickups across the United States.

It wasn’t just the power or the fuel economy that earned it this status, it was the fact that this engine simply kept going, often for hundreds of thousands of miles with nothing more than regular maintenance.

For contractors, farmers, and everyday truck owners, the 7.3L earned a reputation for being the kind of engine you could depend on year after year, regardless of how you used it.

One of the core reasons for the 7.3L’s longevity is its engineering philosophy. Built with a cast-iron block and heads, forged-steel internals, and a relatively conservative factory tune, the engine was designed to operate well within its mechanical limits.

The HEUI (Hydraulically actuated Electronically controlled Unit Injector) fuel system, while more complex than traditional mechanical systems, was highly reliable when maintained properly.

With regular oil changes and clean fuel, the injectors would last a long time, and even when they did begin to wear out, the symptoms were usually gradual rather than catastrophic. This gradual nature of wear allowed truck owners to plan repairs rather than being caught off guard by sudden failures.

The 7.3L Power Stroke also earned praise for its real-world performance. It produced up to 275 horsepower and 525 lb-ft of torque in its later years, enough to tow large trailers, haul heavy loads, and handle commercial work without feeling underpowered.

And it delivered that performance without the emissions systems that burden many newer engines. There was no exhaust gas recirculation (EGR), diesel particulate filter (DPF), or diesel exhaust fluid (DEF) required.

The result was an engine that had fewer components likely to fail and one that ran cleaner and more efficiently in the long term when properly maintained. It also didn’t suffer from the turbo lag or heat-related issues found in some of its modern counterparts.

Even today, nearly two decades after production ended, the 7.3L Power Stroke remains one of the most sought-after diesel engines on the used market. Trucks equipped with this engine often retain high resale value, especially if service records show consistent oil changes and injector maintenance.

Some owners have logged over 500,000 miles on a single engine with only minor repairs. There’s also a massive support community online, with resources, repair guides, and aftermarket upgrades that help extend the life of the engine even further.

Whether in an old F-250, a van doing cross-country deliveries, or a modified tow rig, the 7.3L continues to prove that reliable diesel power isn’t just a thing of the past, it’s a standard others are still trying to match.

9. Kubota D1105

The Kubota D1105 is a compact, three-cylinder diesel engine that has gained a solid reputation for reliability in the world of compact construction equipment, small tractors, generators, and utility vehicles. Though small in displacement at just 1.123 liters, the D1105 punches far above its weight in terms of dependability.

Kubota designed this engine to be a long-running, low-maintenance solution for equipment that often sees extreme duty cycles, irregular servicing, and exposure to dusty or dirty environments. It’s not flashy, and it’s not designed for speed or hauling massive loads, but what it lacks in brute power it makes up for in staying power.

A key reason the D1105 lasts so long is its incredibly simple, rugged construction. It features a cast-iron block and head, gear-driven camshaft, and mechanical injection, all proven, time-tested technologies that minimize points of failure.

Because it lacks the complex electronics found in modern emissions-compliant engines, the D1105 is easy to troubleshoot and repair.

Owners can typically do basic maintenance themselves, including oil changes, injector swaps, and valve adjustments. This ease of service is critical in remote job sites or agricultural settings where access to a repair shop isn’t always practical.

Despite its size, the D1105 has been used in a wide variety of applications across many industries. You’ll find it in skid steers, small tractors, water pumps, concrete saws, and even marine applications. In most of these cases, the engine is run hard, often at high load for hours on end, yet continues to operate without complaint.

It’s common to hear stories of these engines surpassing 10,000 operating hours with only minor repairs. For a small engine, that’s a level of endurance usually reserved for much larger, industrial-grade powerplants.

Part of this can be credited to Kubota’s precise manufacturing standards, which have remained consistent across decades.

Because of its proven durability, the D1105 continues to be widely used in new equipment today. Even as emissions regulations have forced many manufacturers to adopt complex aftertreatment systems, Kubota has managed to keep the D1105 relevant by offering cleaner-burning variants without compromising reliability.

It’s a favorite among rental companies, municipal fleets, and contractors who need machines that just work, day after day.

Quiet, compact, and easy to maintain, the D1105 proves that you don’t need size or complexity to build an engine that lasts a lifetime. It may be small, but in terms of real-world performance and dependability, the D1105 deserves a place among the diesel greats.