Diesel engines have earned a reputation for durability, power, and efficiency, especially in applications where longevity and toughness are paramount. For decades, these engines have been the workhorses behind trucks, industrial machines, agricultural equipment, and even passenger vehicles.

However, not all diesel engines are created equal. While some models are legendary for their ability to rack up hundreds of thousands of miles with minimal issues, others seem to suffer from frequent breakdowns, expensive repairs, and reliability concerns. Understanding which engines tend to stand the test of time and which ones tend to falter can be invaluable for buyers, mechanics, and enthusiasts alike.

The distinction between reliable and problematic diesel engines often boils down to design philosophy, manufacturing quality, and the conditions under which they are used. Certain engines have been refined over many years, benefitting from continuous improvements and a proven track record.

These engines tend to have robust components, straightforward designs, and a loyal following of parts availability and maintenance knowledge. On the other hand, some engines, despite being promising on paper, fall short in practice due to design flaws, poor materials, or complex engineering that increases the likelihood of failure.

This article presents a comparison between five diesel engines that have earned their reputation for lasting decades with minimal fuss and five others known for frequent mechanical troubles. The goal is not to dismiss any engine outright but to provide a clear perspective on which diesel powerplants tend to hold up and which ones demand extra caution.

From the classic big-blocks that powered decades of heavy-duty trucks to modern engines facing the challenges of emissions regulations and complex electronics, the range is broad and diverse. Both sides tell a story about engineering choices, maintenance realities, and how end-users have experienced these machines in the field.

In the following sections, you will find detailed descriptions and analysis of each engine’s characteristics, common strengths, and typical weaknesses. The reliable group highlights engines favored by fleets, farmers, and enthusiasts for their sheer toughness and ease of repair.

Conversely, the problematic group reflects engines with reputations for costly repairs, frequent failures, or design compromises that hinder their reliability. Understanding the differences can guide better decisions, whether you are buying a used diesel truck, managing a fleet, or simply curious about the nuances of diesel technology.

Also Read: 12 Cars Mechanics Say Are Overbuilt for Longevity

5 Diesel Engines That Refuse to Die

1. Cummins 5.9L 12-Valve (1989–1998)

The Cummins 5.9L 12-valve engine has become a legend in diesel circles, largely due to its reputation for incredible durability and mechanical simplicity.

This engine was introduced at a time when diesel technology was moving toward electronic controls, but Cummins held back from immediately adopting complex systems, instead opting for a mechanical fuel injection pump known for its reliability.

This meant the engine was easier to maintain, tune, and repair, even for those without access to advanced diagnostic equipment. The mechanical pump allowed mechanics to precisely adjust fuel delivery by hand, which contributed to the engine’s strong performance and longevity, particularly in heavy-duty use.

In terms of construction, the 5.9L 12-valve was built with a robust cast iron block and cylinder head, both designed to withstand high combustion pressures and extended periods of operation under load. Unlike many modern engines, which often use aluminum heads to reduce weight, the cast iron head on the 12-valve resisted warping and cracking even in harsh conditions.

The engine’s indirect injection system was less efficient than later direct injection designs, but it was far more forgiving of poor maintenance or lower-quality fuel. This balance helped many 12-valve engines reach incredible mileages without major overhaul.

What really set the 5.9L apart was its torque and power delivery, especially at low RPMs. It developed impressive torque figures that made it ideal for towing and hauling heavy loads, whether in pickup trucks or commercial vehicles.

Owners appreciated its steady, predictable power curve and the lack of turbo lag, which allowed for smoother operation under strain. The aftermarket scene for this engine grew rapidly, with parts and upgrade options flooding the market, enabling owners to maintain and enhance their engines with relative ease.

Owners who maintained their Cummins 5.9L 12-valves properly often report the engines lasting well beyond half a million miles. There are countless stories of these engines still running strong at 700,000 miles or more, with original components.

The simplicity, reliability, and strong community support around this engine have made it an enduring favorite for those seeking an engine that simply keeps going, no matter what.

2. Ford Power Stroke 7.3L (1994–2003)

The Ford 7.3L Power Stroke engine is often celebrated as one of the last great “old-school” diesel engines before the wave of modern, emissions-focused designs introduced greater complexity. It combined the ruggedness of traditional diesel engineering with emerging electronic controls to strike a balance that many owners found ideal.

Its design was heavily influenced by Navistar, the company behind its mechanical heart, ensuring the engine was built with a focus on long-term durability and serviceability.

Featuring a cast iron block and cylinder heads, the 7.3L was engineered to resist wear and withstand demanding conditions such as heavy towing, off-road use, and long-haul driving.

The engine’s direct injection system provided better fuel efficiency and power than earlier indirect injection engines, while still maintaining a simple enough setup that mechanics could troubleshoot without overly complicated tools. The Bosch VP44 injection pump was a highlight, combining precision fuel delivery with manageable maintenance requirements.

The Power Stroke’s strength extended to its bottom end, which included forged steel crankshafts and robust connecting rods. This allowed the engine to tolerate significant power increases when modified, without sacrificing reliability.

The turbocharger system also earned praise for its efficiency and durability, producing strong boost pressures that enhanced torque while withstanding the stresses of hard work.

Users often praise the 7.3L for its forgiving nature, with many examples running well past 300,000 miles without major repairs. The availability of replacement parts and the widespread familiarity with the engine make it a favorite for fleets and individual owners who need a dependable diesel. Its reputation for reliability has even grown over time, with many referring to it as the “best Power Stroke Ford ever made.”

3. Detroit Diesel 6.5L (1982–1994)

The Detroit Diesel 6.5L engine is sometimes overlooked because of its smaller displacement compared to the big V8s common in diesel trucks. However, its reputation for toughness and longevity in light-duty and industrial applications remains strong.

It was introduced during an era when diesel engines were transitioning from large industrial units to more consumer-friendly powerplants, and the 6.5L managed to strike a balance between power and simplicity.

This turbocharged V8 uses an indirect injection system that contributed to its durability by reducing combustion pressures and engine stress. The mechanical fuel system design helped reduce complexity, which in turn minimized the potential for failures that can plague electronically controlled fuel systems.

Its cast iron construction provided a durable foundation, capable of withstanding rough treatment, extreme weather, and long hours of continuous operation.

One of the 6.5L’s biggest advantages was its ease of maintenance. Because it used relatively straightforward mechanical systems, owners could service it in the field with common tools and parts.

The engine became popular with government agencies, agricultural users, and off-road operators who valued its ruggedness over outright speed or refinement. This wide adoption contributed to a robust support network and ample parts availability.

While not known for high horsepower numbers, the 6.5L Detroit Diesel’s reliability was never in question. Many of these engines have been known to surpass 300,000 miles or more with consistent maintenance. Its reputation as a dependable, no-frills diesel powerplant continues to hold up decades after production ceased, making it a solid choice for those needing a durable engine without unnecessary complexity.

4. Mercedes-Benz OM617 (1974–1989)

The Mercedes-Benz OM617 engine has earned an almost mythical status among diesel enthusiasts due to its remarkable longevity and smooth operation. This inline-five diesel powered a wide range of Mercedes vehicles, from luxury sedans to utility wagons and light commercial trucks.

Its engineering emphasized durability, efficiency, and simplicity at a time when diesel engines were primarily seen as utilitarian machines. Built around a cast iron block and cylinder head, the OM617 was designed to resist the rigors of high-mileage use.

The mechanical fuel injection system, paired with precise timing and fuel delivery, helped the engine run efficiently while minimizing wear on internal components. Its indirect injection design, although less efficient than modern direct injection systems, provided reliable combustion that reduced stress and potential damage to the engine.

One key to the OM617’s durability was its conservative tuning and focus on smooth power delivery rather than peak performance. The engine operated at moderate RPMs and avoided extreme cylinder pressures, which helped extend its life. It also featured a robust cooling system and well-engineered lubrication, further preventing common failure modes associated with overheating or poor oil circulation.

Owners of vehicles powered by the OM617 often report engines running well past 500,000 miles, with many examples exceeding one million miles after careful maintenance.

The engine’s reputation is bolstered by its widespread use in global markets, where ease of repair and parts availability helped keep it on the road for decades. It remains a favorite among collectors and those who appreciate engineering that prioritizes lasting reliability.

5. Isuzu 4BD1 (1985–2000)

The Isuzu 4BD1 diesel engine may not be as famous as some of the bigger American or European diesels, but it has built a solid reputation for reliability, especially in small trucks, pickups, and industrial machinery.

Its straightforward design and rugged construction made it popular in regions where simplicity and ease of repair were critical, such as rural or developing areas where advanced repair facilities might not be available.

This four-cylinder engine features a cast-iron block and cylinder head, giving it the durability needed to endure hard work and tough conditions. Its mechanical fuel injection pump offers predictable and reliable fuel delivery, avoiding some of the more delicate electronic systems that can plague modern diesels.

The relatively low compression ratio and indirect injection design help keep internal stresses manageable, contributing to a longer engine life. The 4BD1’s reputation is enhanced by its ability to operate in harsh environments and under continuous heavy loads without frequent failure.

Whether hauling heavy loads or powering industrial equipment, this engine has proven itself a dependable workhorse. The simplicity of its design also means that many operators can perform maintenance or minor repairs themselves, reducing downtime and repair costs.

Owners report that the Isuzu 4BD1 often exceeds 300,000 miles with proper care, making it a standout among small diesel engines for longevity. Its combination of durability, simplicity, and cost-effectiveness ensures that it remains a respected choice in markets where reliability is paramount.

5 Diesel Engines That Constantly Break

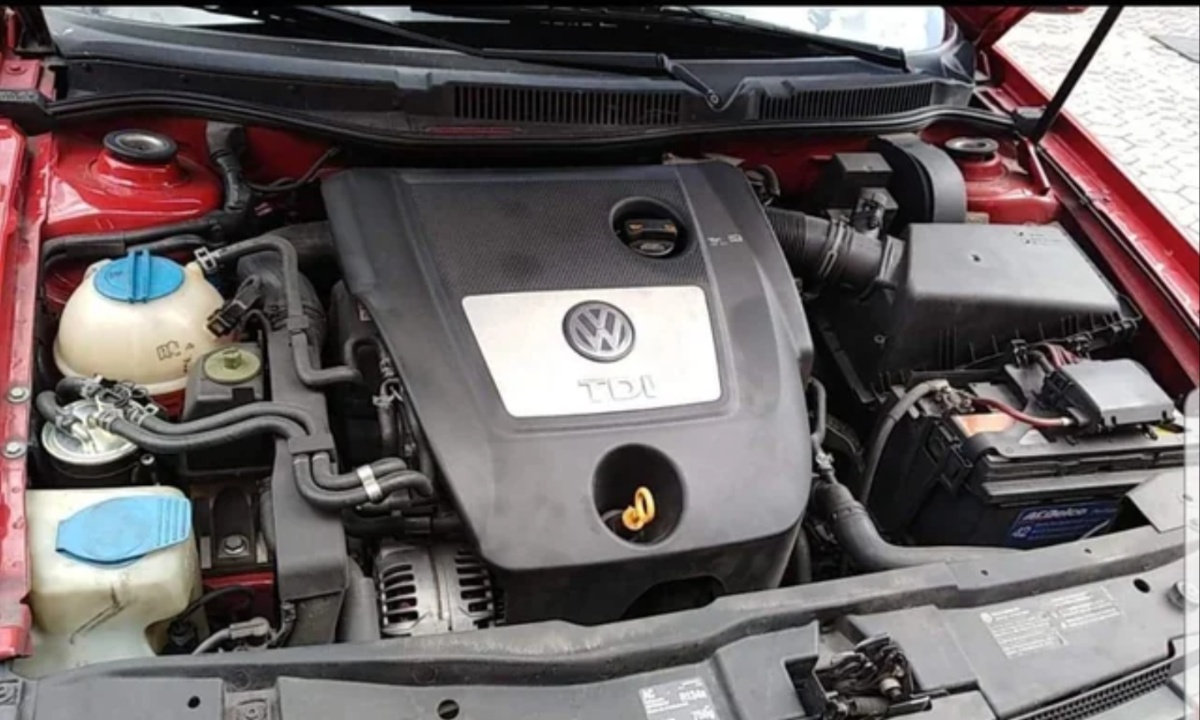

1. Volkswagen 1.9 TDI (Early Models, Late 1990s – Early 2000s)

The early Volkswagen 1.9 TDI engines gained popularity for their fuel efficiency and respectable performance, but they are also known for a variety of recurring mechanical problems that have frustrated many owners over time.

While these engines brought diesel technology into the compact car segment with advanced features for their day, like direct injection and turbocharging, they were often plagued by issues related to their complex injection system and turbochargers. Many early models suffered from injector failures, which were costly and complicated to diagnose and repair.

Another chronic problem was with the dual-mass flywheel, a component designed to reduce engine vibrations. The flywheels were prone to premature failure, often requiring expensive replacements.

Additionally, the timing belt tensioners and water pumps were also known weak points that could fail unexpectedly if maintenance schedules were not meticulously followed. Neglecting these parts could lead to catastrophic engine damage, which contributed to the reputation of this engine as somewhat unreliable.

The 1.9 TDI’s high-pressure fuel pump and injection system demanded clean fuel and proper maintenance to function correctly. Problems such as clogged fuel filters, contaminated diesel, or low-quality fuel could cause injection pump failures, resulting in poor performance or engine stalling.

Repairs could be expensive and time-consuming because of the precise tolerances and advanced electronic controls involved, making this engine less user-friendly for those unfamiliar with modern diesel technology.

Although later versions of the 1.9 TDI were improved, early variants became infamous for these mechanical vulnerabilities. The combination of advanced engineering with some weak components and a reliance on exact maintenance created a scenario where many owners faced frequent, costly repairs. For those looking for a simple, trouble-free diesel, these early TDIs often fell short, despite their initial appeal.

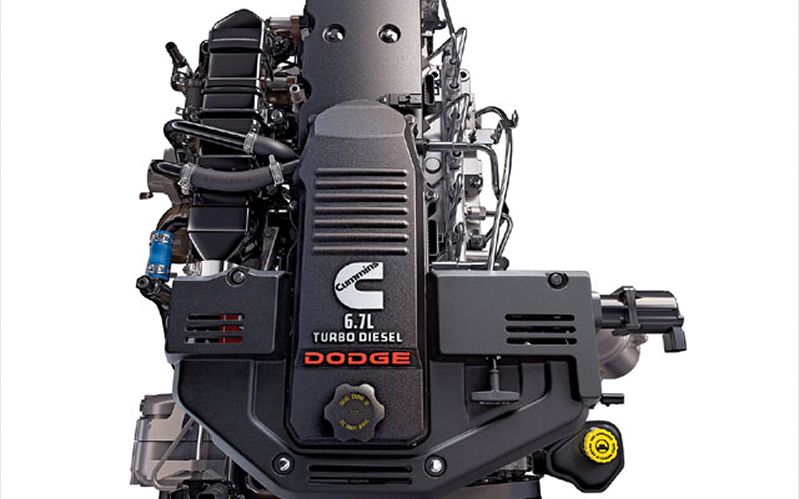

2. Dodge Cummins 6.7L (2013–Present)

The Dodge Cummins 6.7L, a modern high-performance diesel engine, has received mixed reviews regarding its reliability. While it offers impressive power and torque compared to older Cummins models, the 6.7L has been criticized for various mechanical and electronic issues that have led to frequent breakdowns and expensive repairs.

One of the major problems involves the high-pressure common rail fuel system, which is complex and sensitive to contaminants and maintenance lapses.

Many owners have reported issues with the fuel injectors, which can clog or fail prematurely, leading to misfires and poor engine performance. These injector problems often cause a ripple effect, damaging other parts like the fuel rails or pumps.

The 6.7L also features a turbocharger setup that, while powerful, is susceptible to failure under certain conditions. Turbocharger failures can result in costly repairs and significant downtime, particularly if oil changes and maintenance schedules are not rigorously followed.

Another point of concern is the engine’s emission control system, which uses diesel particulate filters (DPFs) and selective catalytic reduction (SCR) technology. These systems are known to be sensitive, sometimes clogging or malfunctioning if the vehicle is primarily used for short trips or idling, which prevents proper regeneration cycles.

When these emission components fail, repairs are costly and complicated, often involving expensive sensors, controllers, and cleaning procedures.

Despite its advanced engineering and performance capabilities, the 6.7L Cummins has faced criticism for being less durable and more expensive to maintain compared to older, simpler Cummins engines.

The complexity of modern emissions and fuel systems means that even small maintenance oversights can lead to cascading failures, which is why this engine often ends up in the “constantly breaking” category for some owners.

3. General Motors Duramax LB7 (2001–2004)

The LB7 Duramax engine, introduced by General Motors in the early 2000s, was highly anticipated for its power and efficiency. However, it quickly earned a reputation for several recurring mechanical issues that affected many vehicles.

One of the most problems was the alarmingly high injector failure rate, which was significantly higher than that of other diesel engines at the time. These injectors would often leak or clog, leading to rough idling, loss of power, and even engine misfires.

The fuel injection system on the LB7 used electronically controlled injectors that were sensitive to fuel quality and contamination. Many owners found themselves needing injector replacements as frequently as every 100,000 miles or less, which became a costly maintenance burden. The injector issue also led to secondary problems such as damaged cylinder heads and turbochargers, which further escalated repair expenses.

Another frequent problem was the head gasket failures, often caused by the increased combustion pressures from the powerful engine combined with some design weaknesses in the cylinder head and gasket materials.

These head gasket issues caused coolant leaks and overheating, which, if not addressed promptly, could lead to complete engine failure. Additionally, the turbochargers on the LB7 sometimes suffered from premature wear or boost leaks, which reduced performance and engine efficiency.

While the Duramax LB7 engine was revolutionary in many ways and formed the foundation for later Duramax models, its early production problems meant that many owners experienced frequent repairs and high maintenance costs. Despite these setbacks, it remains popular in the used market, though prospective buyers are advised to be cautious and prepared for potential issues.

4. Ford Power Stroke 6.0L (2003–2007)

The Ford 6.0L Power Stroke engine is widely considered one of the most problematic diesel engines in modern history. Released with high expectations as a successor to the reliable 7.3L, the 6.0L quickly became infamous for a wide array of mechanical failures.

Many issues stem from design flaws, poor quality control, and the addition of complex emissions systems that introduced new failure points.

One of the most common problems was with the EGR (Exhaust Gas Recirculation) system, which often clogged and restricted airflow, leading to overheating and reduced engine performance.

The cooling system itself was prone to failure, with coolant leaks, warped heads, and radiator problems frequently reported. Additionally, the high-pressure oil system responsible for operating the fuel injectors was notorious for failures, resulting in hard starts, rough running, and sometimes catastrophic engine damage.

Fuel injector failures on the 6.0L were also a persistent issue. The injectors were sensitive to oil contamination and poor fuel quality, and once they began to fail, they often damaged the cylinder heads.

The turbochargers on these engines were similarly unreliable, with many owners experiencing premature failures caused by soot buildup and oil coking. The complexity of the engine’s electronics further complicated diagnostics and repairs, making the 6.0L a maintenance nightmare for many.

Despite numerous aftermarket fixes and technical service bulletins issued by Ford, the 6.0L Power Stroke still carries a reputation for being unreliable and costly to maintain. Many owners either avoid it altogether or invest heavily in preventative maintenance and upgrades to try and keep these engines running smoothly.

The 6.0L is often cited as an example of how increasing emissions regulations and complexity can negatively impact diesel engine reliability.

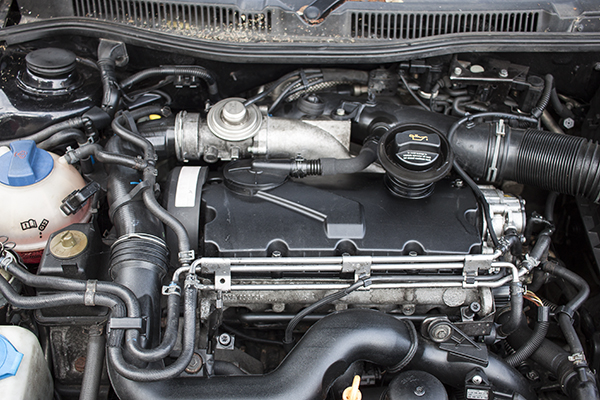

5. Volkswagen TDI PD (Pumpe-Düse) Engines (Mid-2000s to Early 2010s)

Volkswagen’s TDI engines using the Pumpe-Düse (unit injector) system were praised for their power and efficiency, but they also developed a reputation for being prone to frequent mechanical issues. The PD system was an advanced form of direct injection that allowed high injection pressures and better combustion, but it came with its own set of challenges that affected long-term reliability.

One major problem was with the injectors themselves, which were subject to premature wear and clogging due to the extremely high pressures and delicate components involved. Injector failure could lead to rough running, loss of power, and increased emissions. Repairs were often expensive because replacing injectors required significant labor and specialized tools.

The PD engines were also known for timing chain tensioner failures. If the tensioners failed, the timing chain could slip or jump teeth, causing serious engine damage including valve and piston collisions. These timing chain issues were a significant concern because they could occur relatively early in the engine’s life, leading to expensive repairs or even complete engine replacement.

Another issue involved the dual-mass flywheel, which was a weak point similar to the early 1.9 TDI engines. Failure of this component resulted in vibrations and drivability problems and was costly to replace. Furthermore, the emissions equipment on these engines, including diesel particulate filters and EGR systems, were prone to clogging and failure if not properly maintained or if the vehicle was used primarily for short trips.

While the Volkswagen PD engines delivered excellent performance and fuel economy, their complex mechanical systems and sensitive components contributed to a high maintenance burden. Owners needed to stay vigilant with maintenance and fuel quality to avoid frequent breakdowns, making these engines a challenge for those seeking simple, trouble-free diesel power.

Also Read: 12 Cars That Refuse to Quit Even After Collisions

Diesel engines have long been prized for their durability, torque, and fuel efficiency, making them the powerplants of choice in heavy-duty trucks, commercial vehicles, and many industrial applications. However, as with any technology, not all diesel engines are created equal.

The contrast between engines that “refuse to die” and those known for frequent breakdowns underscores the importance of design simplicity, robust construction, and maintenance-friendly engineering in achieving long-term reliability.

Engines like the Cummins 5.9L 12-valve, Ford’s 7.3L Power Stroke, and Mercedes-Benz’s OM617 have earned their reputations by combining sturdy materials, straightforward mechanical fuel systems, and a focus on reliability over complexity.

These engines were built during eras when diesel technology was less dependent on intricate electronics and emissions controls, which often translates into fewer failure points and easier repairs.

Their success stories are often backed by owner testimonials of hundreds of thousands of miles with minimal major repairs, demonstrating how thoughtful engineering and simplicity can contribute to longevity.

In contrast, modern diesel engines, such as the Dodge Cummins 6.7L, Ford 6.0L Power Stroke, and Volkswagen’s Pumpe-Düse engines, often struggle with the challenges brought on by stricter emissions regulations and the push for greater power and efficiency.

The introduction of complex fuel injection systems, high-pressure common rail technology, and advanced emissions equipment has increased the potential for component failures. While these technological advancements improve performance and reduce environmental impact, they have also made these engines more sensitive to maintenance lapses, fuel quality, and driving conditions.

Common themes among the diesel engines that frequently break include intricate electronic controls, sensitive fuel systems, and emission components that require precise operating conditions to function properly.

Issues like injector failures, turbocharger problems, timing chain wear, and clogged emission systems are often costly and time-consuming to repair. These factors highlight the trade-offs between cutting-edge technology and long-term durability.

Choosing a diesel engine depends on the intended use, willingness to maintain, and priorities around reliability versus performance. Those seeking engines that “refuse to die” often favor older designs that are simpler to maintain and repair, while owners who prioritize power and emissions compliance may accept the increased risk of breakdowns.

Understanding the strengths and weaknesses of each engine type can help users make informed decisions and maximize the lifespan and performance of their diesel-powered vehicles.