When discussing engine longevity, most enthusiasts and mechanics eventually get to the topic of compression. Compression is one of the most critical factors in engine health because it directly affects power output, efficiency, and reliability. As engines age, it’s common for internal components to wear down.

This includes piston rings, valve seals, and cylinder walls. Over time, this wear can reduce compression, leading to poor performance, rough idling, increased oil consumption, and a general decline in the vehicle’s capabilities. However, not all engines suffer from this fate equally.

Some engines are known for retaining compression remarkably well, even after hundreds of thousands of miles. These engines are typically built with robust materials, precise engineering tolerances, and proven designs that withstand the stresses of long-term use.

In many cases, the engines that hold compression well are those found in vehicles designed for high mileage or commercial use. Think diesel engines in trucks, naturally aspirated engines in older Japanese sedans, and engines with conservative power tuning. What they all have in common is a focus on durability over outright performance.

That doesn’t mean high-performance engines can’t last, but they’re usually under more stress and require more maintenance to maintain healthy compression levels.

On the other hand, some engines have such a strong track record for durability that they’re almost legendary in car culture. These engines tend to hold up so well that compression loss is rarely a concern, even at mileage levels where most engines are being rebuilt or replaced.

They also tend to be relatively simple in design, often avoiding the complexity of modern turbocharging systems, direct injection, and cylinder deactivation. While some modern engines are built to be lighter and more efficient, they often sacrifice longevity to meet emissions and fuel economy targets. The engines in this list, however, prioritize staying power.

Their ability to maintain compression over time makes them ideal for long-term ownership and minimal mechanical headaches.

1. Toyota 2JZ-GE

The Toyota 2JZ-GE engine is a naturally aspirated inline-6 that gained a reputation not just for performance, but for its extraordinary longevity. This engine, found in cars like the Lexus SC300 and Toyota Supra (non-turbo), is widely respected for its build quality and ability to retain compression even after 200,000 miles or more.

Its cast-iron block, forged internals, and conservative power output mean that wear and tear are kept to a minimum, especially when owners stick to the factory maintenance schedule. The straight-six layout also contributes to inherent balance and reduced internal stress, both of which are beneficial for long-term engine health.

One of the key reasons this engine holds compression so well is the robust piston ring and cylinder wall design. Toyota engineered this engine with tighter tolerances and higher quality materials than were typical at the time.

The 2JZ-GE uses a relatively low compression ratio, which puts less stress on internal components, particularly when compared to high-compression or forced-induction engines.

This results in fewer issues related to blow-by or oil contamination, two problems that often lead to compression loss. Even in higher mileage examples, compression tests often reveal figures well within factory specifications.

Another factor that works in the 2JZ-GE’s favor is its relatively simple valve train. The engine features a double overhead camshaft design with hydraulic lifters, which means there’s no need for frequent valve lash adjustments. This not only reduces maintenance but also prevents improper valve sealing, a common contributor to compression loss.

With fewer moving parts to fail or fall out of adjustment, the engine retains good cylinder sealing over the long term. Enthusiasts who modify these engines often find that even turbocharged versions built from the GE block can handle significant boost without major loss of compression.

Maintenance is obviously still critical, but the 2JZ-GE rewards owners who keep up with oil changes, cooling system upkeep, and quality fuel. Many of these engines are still on the road today, quietly proving their durability one mile at a time.

The fact that they continue to deliver consistent compression across all cylinders, even after decades of use, is a testament to Toyota’s engineering in the 1990s. It’s no wonder that the 2JZ-GE remains one of the most trusted engines for long-term reliability.

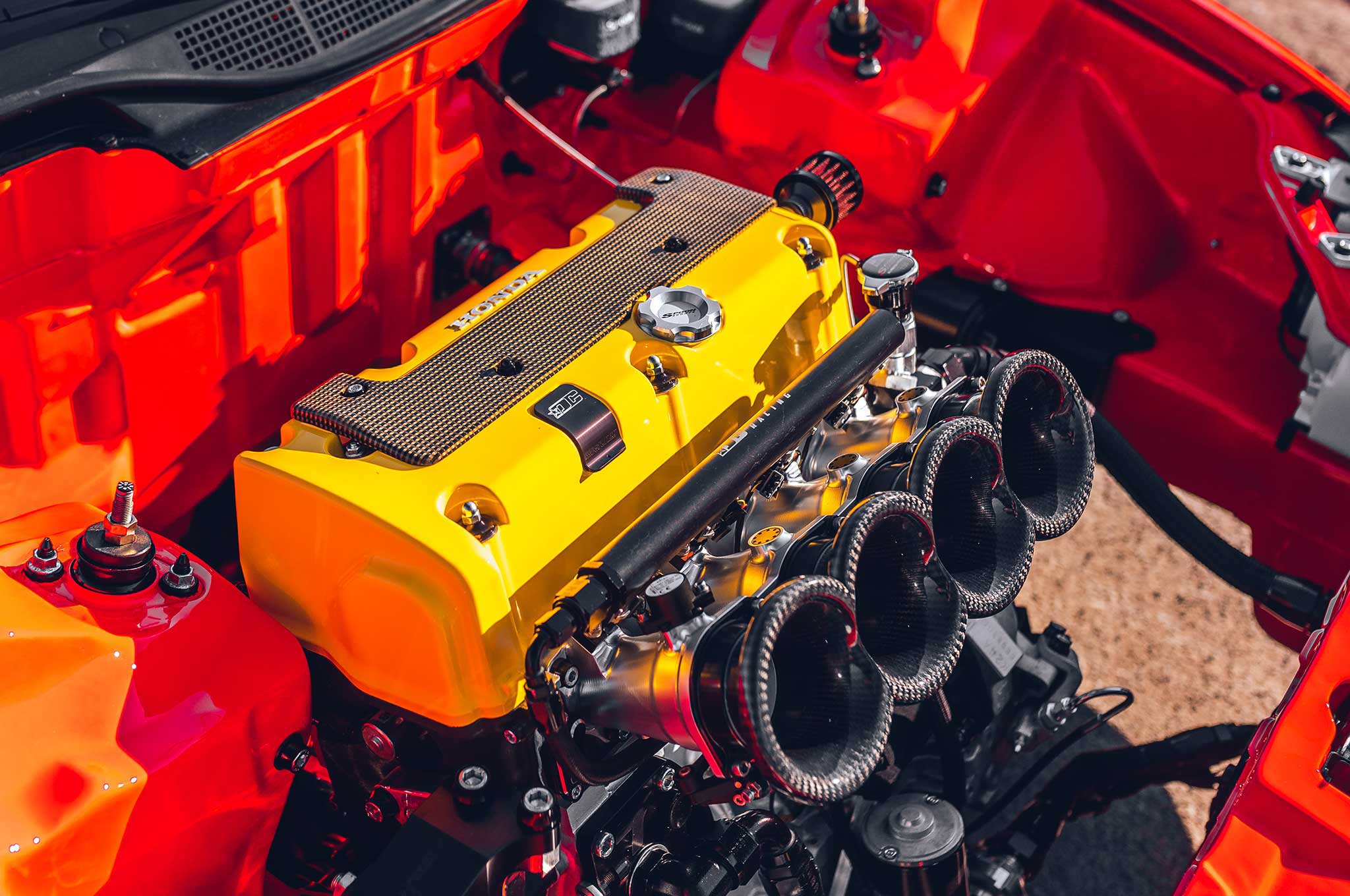

2. Honda K24

The Honda K24 is another engine widely regarded for its resilience and ability to retain compression throughout its lifespan. Found in a variety of Honda models including the Accord, CR-V, and Element, the K24 has become a favorite among mechanics and enthusiasts for its combination of power, efficiency, and simplicity.

It offers good performance while maintaining extremely low failure rates. The engine features a strong aluminum block with iron cylinder liners, which help maintain consistent sealing between the pistons and cylinder walls over time.

One standout feature of the K24 is its low-friction internal design. Honda engineered this engine with an emphasis on reducing wear over long periods. The use of molybdenum-coated piston skirts helps reduce friction, and the forged steel crankshaft adds another layer of durability.

These features contribute to the engine’s ability to hold compression, even after being subjected to years of daily driving. Many K24-equipped vehicles have been known to cross the 300,000-mile mark without any significant loss in performance or internal engine wear.

Additionally, the variable valve timing system (i-VTEC) used in the K24 doesn’t interfere with long-term reliability. Unlike some modern systems that introduce complexity and potential failure points, Honda’s implementation has proven to be robust and long-lasting. Valve sealing remains consistent thanks to good valve seat design and durable components.

This is important for maintaining compression, particularly in engines where valve seating can degrade over time due to high mileage or thermal cycling. With proper oil change intervals and good quality filters, the K24 remains clean inside, minimizing the risk of sludge or carbon deposits interfering with ring sealing or valve closure.

The K24 also benefits from having a strong aftermarket following. While some owners modify them aggressively, many K24s are left in stock form, used in commuter cars and SUVs. This combination of conservative use and excellent design makes the K24 one of the most reliable engines in terms of compression retention.

Compression tests on engines with 200,000+ miles often reveal numbers that are still well within spec, proving the strength of the platform and the wisdom behind Honda’s design philosophy.

3. Cummins 6BT (5.9L)

The Cummins 6BT, better known as the 5.9L, is one of the most durable diesel engines ever made. It has found its way into Dodge Ram trucks and various industrial equipment since the late 1980s. Known for its simple mechanical design and incredibly tough construction, the 6BT is a straight-six diesel that thrives in heavy-duty use.

One of the reasons it’s so revered is its ability to maintain compression levels even after prolonged periods of extreme use, often exceeding 500,000 miles in truck applications.

This engine utilizes a cast-iron block and a forged steel crankshaft, components that are designed to handle immense loads and high combustion pressures without flexing or degrading. The inline-six layout is inherently balanced, which reduces wear on the bearings and cylinders over time.

These characteristics ensure that piston rings maintain a proper seal against the cylinder walls, preventing blow-by and oil consumption, two of the main reasons for compression loss in diesel engines. The mechanical injection system, while older in design, is highly reliable and contributes to consistent combustion cycles that don’t stress the internals unnecessarily.

Another significant advantage of the Cummins 6BT is its relatively slow operating speed. Unlike modern high-revving gasoline engines, the 5.9L typically operates at lower RPMs, which extends the life of internal components. Lower piston speeds reduce friction, heat, and wea, three major contributors to compression loss over time.

Many of these engines are run for thousands of hours in generators and farm equipment, often idling for extended periods without issues. This slower pace of operation gives the engine a longer service life and helps retain tight sealing between pistons and cylinders.

The 6BT is also famously easy to rebuild, and when maintained properly, often doesn’t need it. Simple oil changes, fuel filter replacements, and proper cooling system maintenance are usually enough to keep the engine running like new.

Compression tests on high-mileage examples frequently show consistent results across all cylinders. For those looking for an engine that practically refuses to lose compression over time, the Cummins 6BT is one of the best choices available, whether it’s powering a work truck or a piece of construction equipment.

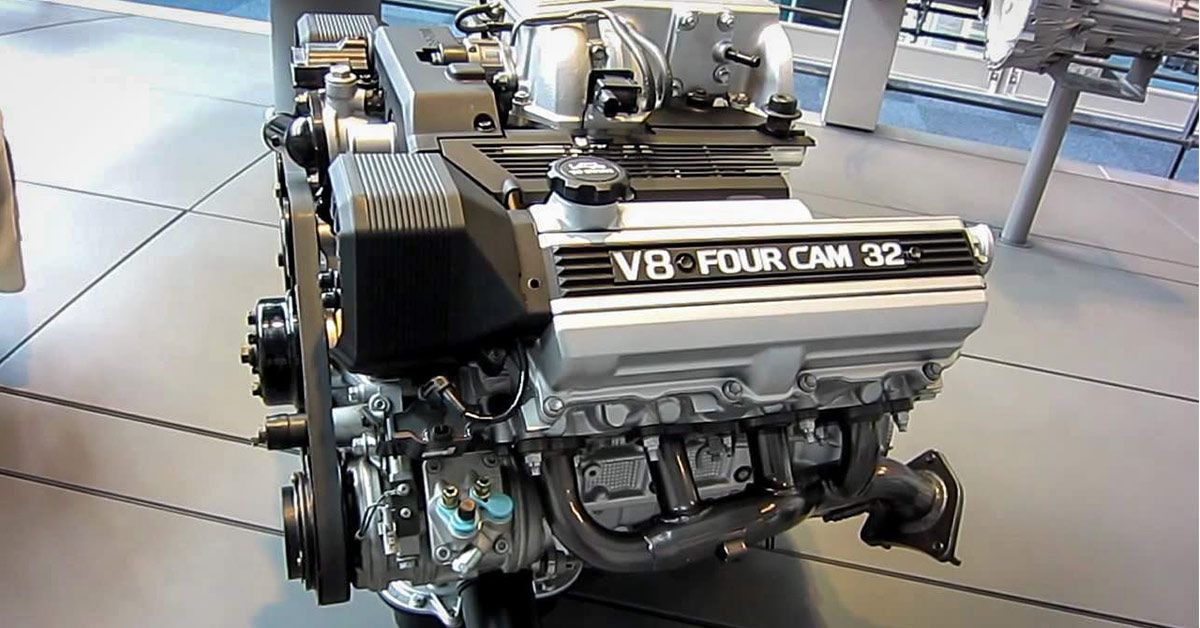

4. Toyota 1UZ-FE

The Toyota 1UZ-FE is often referred to as one of the most overengineered production V8 engines ever made. Introduced in the late 1980s and used prominently in the Lexus LS400, SC400, and other high-end Toyota vehicles, this 4.0L all-aluminum V8 was built during a time when Toyota aimed to demonstrate its engineering capabilities to the world.

The result was a powerplant designed for smoothness, quietness, and long-term durability. Unlike many V8s of the era, the 1UZ was not rushed into production to meet emission mandates or performance trends.

It was developed with meticulous attention to material quality and internal balance, which contributed directly to its long-term reliability and its strong ability to maintain compression over time.

One of the standout features of the 1UZ-FE is its use of a forged steel crankshaft, high-strength connecting rods, and forged pistons. These components were chosen to reduce wear and handle stress over hundreds of thousands of miles. The block and heads are made from aluminum, which helps with thermal efficiency, but Toyota reinforced key areas to prevent distortion.

The piston rings are of high quality and are supported by rigid cylinder walls that retain their shape under temperature fluctuations. This stability plays a major role in preserving compression. Engines that experience even slight distortion in cylinder shape under heat cycles tend to develop blow-by or oil burning problems, but the 1UZ is impressively stable in that regard.

Another factor in the 1UZ’s resilience is its oiling system. The engine uses a high-volume oil pump and well-designed oil passages that keep everything well-lubricated even under extended load or high-speed operation.

Clean oil flow prevents ring sticking, keeps hydraulic lifters functioning properly, and helps avoid excessive carbon buildup, all of which can contribute to compression loss over time. Valve seals and guides are also well-engineered, reducing the likelihood of valve-related sealing issues that plague many other high-mileage engines.

Many 1UZ engines with 250,000 or even 300,000 miles still pass compression and leak-down tests within factory spec, which is extremely rare for naturally aspirated V8s of its era.

What really cements the 1UZ’s reputation is its real-world track record. Fleet Lexus LS400s, often used for taxi services in places like the Middle East, have logged over 500,000 miles without major engine work.

Even abused examples tend to suffer from ancillary failures like alternators or gaskets long before the engine itself shows any signs of low compression or internal wear. For those looking for a powerful, quiet, and long-lasting engine that won’t gradually lose compression with time, the 1UZ-FE remains one of the most impressive and enduring V8s ever made.

5. GM LS3

The GM LS3 is part of General Motors’ third-generation small-block V8 family, and it has gained significant respect for combining modern performance with old-school durability. Displacing 6.2 liters and producing over 400 horsepower in its factory trim, the LS3 might seem like a performance-first engine.

However, beneath that power output is a design philosophy that emphasizes simplicity, robustness, and long-term use. Found in cars like the Corvette C6, Camaro SS, and later G8 GXP, the LS3 balances power and reliability in a way few modern V8s manage to achieve, and it does so while maintaining consistent compression across its lifespan when properly maintained.

A major part of the LS3’s durability comes from its cast aluminum block with iron cylinder liners and a forged steel crankshaft. The use of cathedral-port aluminum heads combined with durable valvetrain components means this engine doesn’t suffer the same valve-related compression issues seen in some other modern V8s.

The LS3’s hydraulic roller lifters and pushrod valvetrain, while considered old-fashioned by some, actually reduce complexity and potential failure points compared to overhead cam setups. This simpler system allows for easier maintenance and fewer timing-related issues, which indirectly contributes to consistent compression by maintaining proper valve timing and closure.

The piston ring design on the LS3 is also critical. GM uses low-tension rings for better efficiency, but they still maintain excellent cylinder sealing due to precision machining of the cylinder bores. The honing pattern on the cylinder walls promotes oil retention and prevents metal-to-metal contact that could lead to scoring or ring wear.

As long as owners change their oil on time and use high-quality lubricants, the LS3’s internal surfaces remain in excellent condition even with heavy use. It’s not unusual to see LS3 engines with 200,000 miles that still have even compression readings across all eight cylinders, especially in vehicles that were not heavily modified or abused.

Another key to the LS3’s longevity is its cooling and lubrication systems. GM designed the engine with effective oil flow, ample cooling passages, and a strong oil pump to ensure long-term durability even under spirited driving.

When LS3 engines are used in high-performance applications, they often see additional oil cooling and airflow enhancements, but even in stock form, the engine stays relatively cool and well-lubricated. For drivers who want both power and a long-lasting engine that retains its compression, the LS3 continues to be one of the best modern V8s available.

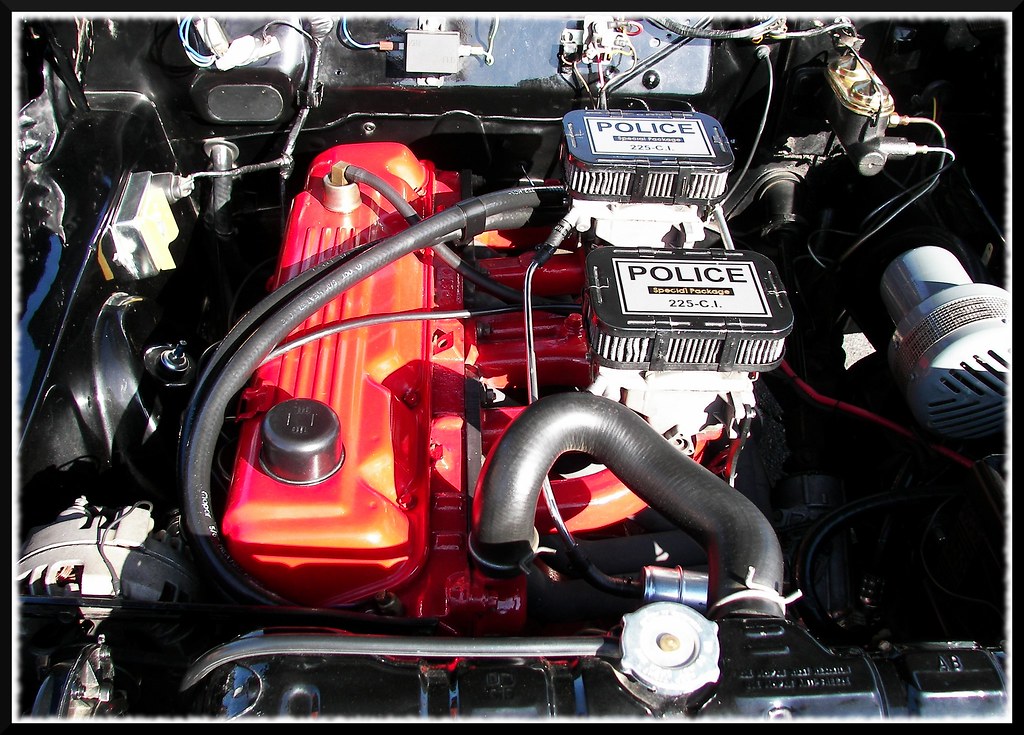

6. Mercedes-Benz OM617

The Mercedes-Benz OM617 is a 5-cylinder diesel engine that has earned a near-mythical reputation for longevity, simplicity, and exceptional durability. Originally introduced in the 1970s and used widely through the 1980s in models such as the W123 300D and 300SD, the OM617 was built during a period when Mercedes prioritized engineering excellence over cost-cutting or emissions compliance.

As a result, this engine was intentionally designed to operate under extreme conditions and for extraordinarily long lifespans. Its consistent ability to maintain compression over several hundred thousand miles is a direct result of its mechanical integrity and low-stress design.

The OM617 features a cast-iron block and cylinder head, contributing to its thermal stability and strength under load. While heavier than modern aluminum designs, this choice helped the engine maintain its cylinder shape and prevented warping or micro-fractures that can lead to compression loss.

The piston rings were designed to seat well and resist blow-by, even under high soot conditions common in diesel combustion. Mercedes also used sodium-filled exhaust valves in some versions of the OM617, which improved thermal management and prevented valve seat erosion. These components are part of the reason why compression remains strong even after 300,000 or 400,000 miles.

Another critical aspect of the OM617’s compression retention is its low-revving nature and indirect injection design. The engine typically redlines around 4,800 RPM, meaning the internals are never subjected to the same dynamic stresses that higher-revving gas engines face.

This conservative operating behavior drastically reduces wear on rings, bearings, and valve components. Also, the indirect injection system, though less efficient by today’s standards, was far more forgiving on fuel quality and less likely to cause carbon buildup in combustion chambers, another common reason modern diesel engines lose compression prematurely.

The OM617’s real-world track record is unmatched. There are countless stories of these engines surpassing 500,000 miles with minimal internal work. Compression tests on high-mileage examples routinely show cylinder pressures within spec, a testament to both the materials used and the precision of the design.

As long as the oil was changed regularly and valves adjusted every 15,000 miles, these engines would continue to run smoothly for decades. For anyone searching for an engine that resists compression loss over time with almost bulletproof consistency, the OM617 remains one of the most respected diesel platforms in automotive history.

7. Ford 4.9L Inline-6 (300 I6)

The Ford 4.9L inline-6, also known as the 300 I6, is one of the most celebrated workhorse engines in American automotive history. Used primarily in F-Series trucks and Econoline vans from the 1960s through the mid-1990s, this engine is beloved by mechanics and truck owners for its incredible torque, simplicity, and ability to run seemingly forever without major issues.

One of the defining traits of the 4.9L is its ability to maintain good compression over very high mileages, even under rough use and minimal maintenance, a rare quality among gasoline engines of its era.

The 300 I6 features a cast-iron block and head, which are virtually indestructible when it comes to wear and thermal cycling. This heavy-duty construction helps maintain the integrity of the cylinder bores and combustion chambers over time. The long-stroke design produces excellent low-end torque, making it ideal for hauling and towing.

More importantly for compression retention, the engine runs at relatively low RPMs during normal driving, reducing stress on the piston rings and valve seals. Engines that are driven conservatively and don’t frequently see redline conditions tend to retain compression far longer, and the Ford 300 I6 fits that profile perfectly.

One reason the 4.9L holds up so well internally is its slow-wearing valvetrain and straightforward architecture. The cam-in-block pushrod design is simple and easy to service, with fewer components that can cause sealing problems or wear unevenly.

Valve seats are hardened, helping to prevent compression loss due to valve recession, a common issue in many older engines, especially those that predate unleaded fuel. The head gasket sealing is also robust, meaning compression loss due to gasket failure is rare, even in engines that have seen hard use.

Owners of high-mileage Ford trucks often report compression readings that are within spec even after 250,000 or 300,000 miles. That’s not just anecdotal; compression testing on old fleet vehicles, farm trucks, and even neglected junkyard finds consistently demonstrates the engine’s resilience.

As long as basic maintenance like oil changes and valve adjustments were carried out with some regularity, the 300 I6 simply keeps running, holding its compression like it was still in its prime. It’s an engine that earned its reputation not through flashy numbers, but through quiet, unyielding reliability.

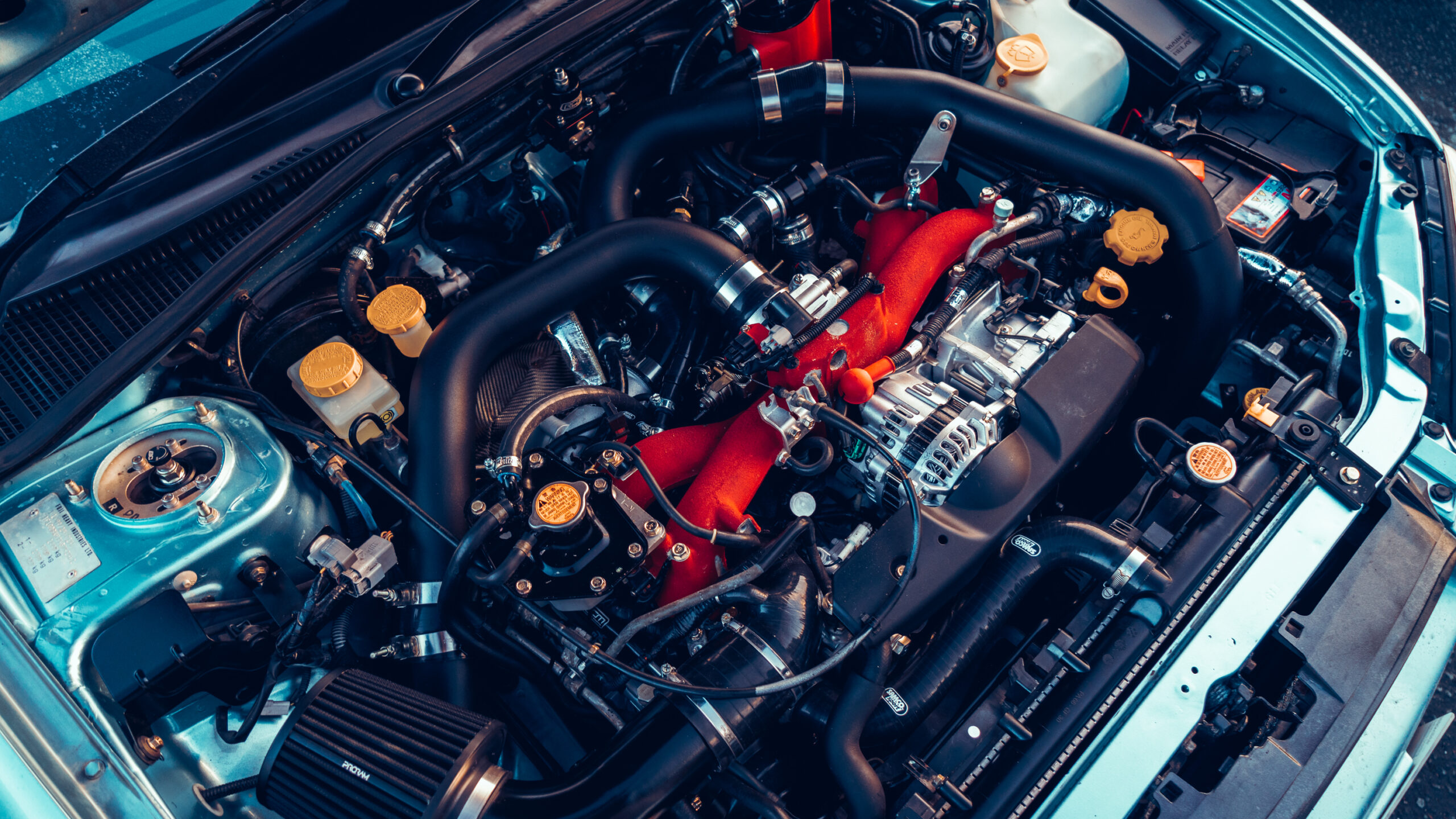

8. Subaru EJ22 (Phase 1)

The Subaru EJ22 engine, particularly the Phase 1 version produced from 1990 to 1996, is a naturally aspirated flat-four engine that became renowned for its unmatched durability and compression retention.

Found in models like the Subaru Legacy and Impreza during the early ’90s, the EJ22 was often overshadowed by its turbocharged siblings, but in terms of long-term health, it outperforms many of them.

This engine became known as the “bulletproof” Subaru motor, especially in comparison to later versions that were more complex and less reliable. When properly maintained, the EJ22 can surpass 300,000 miles without a drop in compression or any major internal issues.

One key advantage of the EJ22 is its simplicity. It lacks the complexity of turbocharging, variable valve timing, or direct injection, all features that can lead to premature engine wear or inconsistent combustion. The EJ22 used a cast-iron cylinder liner within an aluminum block, providing strong ring sealing and thermal stability.

Because of its naturally aspirated design and modest compression ratio, it wasn’t overstressed, allowing it to age gracefully without pushing internal components to their limit. The engine also benefited from symmetrical layout and balanced internals, which helped reduce vibrations and mechanical strain.

Another reason the EJ22 holds compression so well is due to its high-quality valve components and good combustion chamber sealing. Valve float, leakage, or recession is rare on this engine, thanks to hardened valve seats and well-matched cam profiles.

The timing belt system is also relatively reliable, and interference wasn’t a concern in early versions, which means even a snapped belt wouldn’t lead to piston-valve contact. This robust design minimized the chance of serious engine damage and helped maintain consistent compression in all cylinders well into high-mileage territory.

Subaru enthusiasts often point to the EJ22 Phase 1 as the gold standard for the brand’s engine reliability. Many owners of early ’90s Subarus report running the same engine for decades without needing a rebuild. Compression tests on EJ22s with over 200,000 miles regularly show healthy numbers.

In a world where many flat-four engines are associated with head gasket failure or uneven wear, the EJ22 stands apart for its toughness, simplicity, and long-term performance.

9. BMW M50

The BMW M50 inline-6 engine, produced from 1990 to 1996, is often cited as one of the most robust engines to come from BMW’s golden era of engineering. Used primarily in the E34 5 Series and E36 3 Series, the M50 is a 24-valve, dual overhead camshaft engine with a cast-iron block and aluminum head.

It was designed with a focus on durability, refinement, and smooth power delivery rather than high-strung performance. In terms of compression longevity, the M50 has consistently proven to be one of BMW’s most dependable engines, capable of running well into high-mileage territory without suffering from compression loss, provided it receives regular maintenance.

One of the most critical factors in the M50’s long-term reliability is its cast-iron block. Unlike modern BMW engines that shifted to aluminum construction for weight savings, the M50’s block retains its shape and integrity even after decades of heat cycling and use.

This contributes greatly to compression retention, as cylinder roundness remains consistent, reducing piston ring wear and ensuring a good seal. The engine’s internals, including the forged crankshaft and high-quality pistons, further add to its strength. The M50 is also non-interference, which means even in the event of a timing chain failure, the pistons and valves are unlikely to collide, a rare feature in a DOHC design.

Another reason for the M50’s longevity is its closed-deck block design, which provides extra rigidity around the cylinder walls and improves long-term sealing. The valve train is also highly reliable, with solid cam profiles and a strong timing chain system.

Valve seat erosion, a common cause of compression loss in high-mileage engines, is rarely seen in the M50. Even the VANOS variable valve timing system introduced in the later M50TU versions is relatively straightforward compared to later BMW systems, and when maintained, does not negatively affect long-term valve sealing or compression integrity.

Perhaps most telling is how these engines have aged. Many M50-powered vehicles have surpassed 200,000 or even 300,000 miles without a rebuild. Mechanics frequently note that compression tests on these high-mileage engines show minimal variance between cylinders and numbers close to factory specs.

This is a testament not just to the materials used, but to the conservative tuning and balance of the engine’s design. In the used BMW market, vehicles with M50 engines are often considered more desirable precisely because of their legendary durability and their tendency to maintain compression, even after a long, hard life.

10. Toyota 1HD-T

The Toyota 1HD-T is a 4.2L inline-6 turbocharged diesel engine that was built for some of the most demanding environments in the world. Found in the Land Cruiser 80 Series and various commercial vehicles during the 1990s, the 1HD-T is known for its remarkable strength, reliability, and ability to handle abuse while keeping internal integrity intact.

Built to power vehicles in remote locations with little to no infrastructure, the 1HD-T was engineered to operate under extreme temperatures, poor fuel conditions, and long intervals between service. One of its most impressive features is its ability to maintain high compression levels over hundreds of thousands of kilometers.

The engine features a cast-iron block and head, along with a forged crankshaft and heavy-duty internals built to endure high boost and load without fatigue. The turbocharging system is relatively simple and designed to operate within safe limits, avoiding the stress associated with more aggressive forced induction setups.

With its robust bottom end and moderate RPM range, the 1HD-T puts minimal stress on piston rings and cylinder walls. Unlike many modern turbo diesels that rely on high-pressure fuel injection and complex electronics, the 1HD-T uses a mechanical injection pump, which is not only more reliable but also helps ensure even and consistent combustion across all cylinders,v a key factor in preserving compression.

Another area where the 1HD-T excels is in thermal management. Its cooling system is designed to handle long climbs, heavy loads, and intense heat without allowing engine temperatures to spike. This stability in operating temperature helps prevent warping or expansion in critical areas like the head gasket, valve seats, and piston ring lands.

The result is an engine that, even under sustained stress, maintains the tight internal tolerances necessary to retain compression over the long term. Valve wear, a common issue in high-mileage diesels, is rarely a concern here due to hardened components and a well-designed valve train that resists fatigue.

This reputation for compression stability, even in hostile environments, makes the 1HD-T one of the most respected diesel engines ever produced. It’s no exaggeration to say that if you need an engine that simply won’t quit, the 1HD-T should be at the top of your list.

11. Volkswagen 1.9 TDI (ALH)

Volkswagen’s 1.9L TDI engine with the ALH code is another shining example of engineering focused on long-term durability. Introduced in the late 1990s and used in cars like the Golf, Jetta, and Beetle, the ALH version of the 1.9 TDI is widely praised for its ability to maintain strong compression numbers well into high mileage.

The ALH TDI uses a cast-iron block, an aluminum head, and indirect injection via a mechanical injection pump (Bosch VE). This design prioritizes simplicity and reliability over cutting-edge performance, which works in its favor.

The compression ratio is high, typical of diesel engines, but internal stresses are well managed thanks to a conservative tuning approach and a small turbocharger that doesn’t produce overwhelming boost pressures.

This balance ensures that the piston rings, valves, and head gasket remain in good condition over time, avoiding the kind of gradual wear that leads to compression loss in more aggressively tuned engines.

Another reason for the ALH engine’s longevity is its efficient cooling and lubrication systems. The engine is known to run cool and maintain stable temperatures, which helps preserve the shape and sealing surface of the cylinder walls and valves. The use of full-synthetic diesel oil by most owners contributes significantly to the internal cleanliness of the engine.

Sludge buildup, ring sticking, and valve deposits, all of which can cause a loss of compression, are uncommon in well-maintained ALH TDIs. Additionally, the engine is relatively easy to work on, and the availability of quality parts has encouraged owners to maintain them properly for years.

Compression testing on these engines after hundreds of thousands of miles often shows impressively consistent numbers. It’s not unusual to see all four cylinders testing well above 400 psi even at 300,000 miles, as long as basic maintenance like timing belt changes, fuel filter replacements, and oil services were done regularly.

These results are a testament to Volkswagen’s commitment to longevity in this particular engine. For diesel fans who want an efficient, long-lasting engine that resists compression loss even after years of daily use, the 1.9 TDI ALH is one of the best options ever offered in a passenger car.