Most car enthusiasts know that vehicles are built to wear out. Over time, frames rust, electronics fail, and interiors fall apart. Yet, amid all the decay, one part often survives long after the rest of the car is gone: the engine. Not every engine deserves this praise, of course.

Some are barely reliable enough to last a decade. But a few, through expert engineering and simple durability, keep going long after their original body has been crushed, sold for scrap, or retired from the road.

These engines don’t just outlive their cars; they often find a second, third, or even fourth life in new vehicles, race builds, or custom projects. Mechanics swear by them. Junkyard owners know to pull them first. And tuners search the globe for used examples, confident they still have plenty of life left in them.

First, it’s often about overengineering. Many manufacturers, particularly in the 80s, 90s, and early 2000s, built engines that could take far more punishment than their design required. Strong internals, low-stress designs, and proper material selection all contributed to engine blocks that refused to wear out.

Second, simplicity plays a role. The fewer moving parts or complicated systems, the fewer opportunities for something to go wrong. Naturally aspirated engines, for example, often last longer than turbocharged ones because they don’t run under constant pressure and heat.

Finally, the reputation of certain engines led owners to treat them better. When drivers know they’re sitting on something special, they tend to maintain it more carefully, whether that means frequent oil changes or avoiding unnecessary stress.

This list isn’t just about which engines lasted the longest mileage in one specific car. It’s about engines that consistently outlive the very cars they were built into. These engines are reused, rebuilt, and repurposed, sometimes running decades after the original car was retired.

Whether from Toyota, Honda, Mercedes, or even American brands like Ford and Chevy, these powerplants have become legends. Here are ten engines that have earned a reputation for durability so strong, the cars they came in often gave out first.

1. Toyota 2JZ-GTE

The Toyota 2JZ-GTE is often referred to with an almost reverent tone among performance enthusiasts and mechanics alike. Found famously in the Toyota Supra MK4, this inline-six engine has become one of the most iconic and reliable performance engines ever made.

Built between 1991 and 2002, the 2JZ-GTE was developed during a time when Toyota was less concerned with cost-cutting and more focused on bulletproof engineering. This engine came with a cast-iron block, forged steel internals, and a design that could withstand enormous amounts of pressure, making it popular for high-horsepower builds.

Part of what makes the 2JZ so is its tuning potential. Stock, it produced around 276–320 horsepower, depending on the market, but tuners have pushed it well beyond 1,000 horsepower with proper support. What’s even more impressive is how often these engines continue to run reliably, even under extreme power levels.

Many 2JZ engines have outlived multiple cars, pulled from wrecked Supras, IS300s, or GS300s, and transplanted into everything from drift cars to boats to off-road trucks. Some of them are running in builds decades after the original chassis has rusted or been totaled.

The engine’s design has a lot to do with this staying power. The block’s strength, the oiling system, and even the factory turbochargers were all engineered for long life and high performance. This made the 2JZ-GTE not just a tuner’s dream, but a mechanic’s favorite. Even poorly maintained 2JZs can sometimes be brought back to life with basic repairs. They can take abuse, heat, pressure, and high RPMs in ways most modern engines simply cannot.

While many cars from the 1990s have become scrap metal, the 2JZ-GTE continues to be pulled from junkyards, rebuilt, and thrown into new projects. It’s become common to see 2JZs powering cars far different from what Toyota ever imagined, a testament to how tough and adaptable this engine truly is.

2. Honda K20

The Honda K20 is a four-cylinder engine that has built a near-mythical reputation for longevity, efficiency, and performance. Introduced in the early 2000s in models like the Civic Type R, Accord Euro R, and Acura RSX, the K20 series has remained a favorite among Honda fans and engine swappers around the world. While many of the vehicles it originally came in have long since retired or been modified beyond recognition, the K20 itself continues to live on.

One reason the K20 survives so well is its balance between complexity and simplicity. It’s a dual overhead cam engine with VTEC, yet it’s designed with solid engineering and lightweight internals that allow it to spin to high RPMs without stress.

Honda’s reputation for tight manufacturing tolerances and quality control is particularly evident here. The engine’s ability to handle over 200 horsepower naturally aspirated, with a relatively small displacement, is rare even among newer engines.

In performance circles, the K20 has become the go-to engine for lightweight swaps. Enthusiasts transplant these engines into older Civics, Integras, and even into non-Honda vehicles like Miatas, MR2s, and even Lotus Sevens. The engine’s compact size and modular nature make it ideal for swaps, and its durability ensures that it keeps running even after being pulled from a high-mileage donor car.

The cars the K20 came in weren’t always built to last forever. The bodies, especially in areas prone to rust, tend to wear out. Interiors fade, and electronics begin to fail over time. But even when the rest of the car is ready for the junkyard, the K20 is often still strong. Mechanics have seen these engines running smoothly well past 300,000 miles, provided they’re maintained with regular oil changes and not overly abused.

With aftermarket support continuing to grow, and with thousands of healthy K20s still being pulled from salvage yards, this engine shows no sign of disappearing. It’s one of the few modern engines that has built a reputation for outliving the very cars it came in.

3. Mercedes-Benz OM617 Diesel

The Mercedes-Benz OM617 is one of the most durable diesel engines ever created. Found in models like the W123 and early W126 during the 1970s and 1980s, this inline-five diesel was never fast, but it was nearly unkillable. These engines were designed during a time when Mercedes prioritized longevity and quality over all else, and that philosophy is baked into every part of the OM617.

The block and internals are heavy and overbuilt, with thick castings and strong components designed to handle the high compression of diesel operation. Many OM617 engines are known to last well over 500,000 miles with only basic maintenance.

Some have even crossed the million-mile mark with original internals. Stories of these engines running in extreme conditions, including third-world taxi services and desert environments, have only reinforced their legendary status.

Even after the W123 sedans and wagons have rusted into the ground or been retired due to outdated emissions or safety standards, the OM617 often gets pulled and reused. They’re found powering everything from homemade generators to custom-built trucks and off-grid vehicles. Some even repurpose them into boats or stationary engines.

What also makes this engine special is how forgiving it is. It can run on alternative fuels like biodiesel or even filtered waste oil with very little modification.

That level of versatility has given the OM617 a second life in sustainability projects and off-the-grid living setups. Mercedes may have stopped producing the engine decades ago, but its legacy continues, and its presence in the used market remains strong.

To this day, a running OM617 can be found in surprising places, often long after the original car has disappeared. It’s a monument to mechanical engineering done right, and one of the few engines in the world that seems almost immune to time.

4. Chevrolet Small-Block V8 (Gen I)

The Chevrolet small-block V8, particularly the original Gen I version produced from 1955 to the early 2000s, is arguably one of the most influential and long-lasting engines ever made. Used in countless GM vehicles, from Corvettes and Camaros to trucks, vans, and station wagons, this engine became the heart of American performance and utility for decades. It’s not just a powerful engine; it’s a symbol of simplicity and reliability.

With displacements ranging from 262 to 400 cubic inches, the small-block V8 was designed with a straightforward pushrod design, compact size, and excellent parts interchangeability. Mechanics loved it because parts were cheap and plentiful, and performance tuners loved it because it responded well to upgrades. But even in stock form, these engines were capable of lasting hundreds of thousands of miles, especially when properly maintained.

What sets the small-block apart is how often it lives on after the original vehicle is gone. These engines are pulled from wrecked or rusted-out cars and dropped into hot rods, rat rods, boats, and race cars. They’re also popular in engine-swapped off-road rigs and drag cars. Some people even build custom furniture and décor out of old small-block engines, knowing full well that they could be brought back to life if needed.

The aftermarket support for this engine is unmatched. You can rebuild a small-block entirely from scratch using nothing but brand-new off-the-shelf components. There are still entire industries built around modifying and supporting this engine, even though its original production run ended years ago.

The engine’s durability is more than just a happy accident, it was engineered with longevity in mind. The iron block and heads can handle high temperatures and stress without cracking or warping. The simple valvetrain design means fewer moving parts and less to go wrong.

Even when subjected to high-performance demands, such as in racing or towing applications, the small-block has a proven record of reliability. While the surrounding vehicle may give up the ghost due to rust, frame damage, or interior deterioration, the engine often just keeps going, willing to be transplanted into whatever chassis is ready to house it next.

Many of these engines are still alive in older pickup trucks that were built in the 70s, 80s, and 90s, even if the body panels are rusted or the suspension is sagging. Even in rough condition, the engine itself often fires up with little more than fresh gas and a charged battery.

This ease of maintenance and resistance to failure is part of what made the small-block such a reliable workhorse for farmers, hot rodders, and mechanics alike. It’s been passed from vehicle to vehicle, passed from generation to generation, and is often still running when the rest of the car is reduced to scrap.

5. Ford 300 Inline-Six

The Ford 300 cubic inch inline-six engine is perhaps the most underrated yet most indestructible engine ever made by Ford. Produced from the mid-1960s until the mid-1990s, it was used in everything from F-Series trucks to vans and industrial equipment.

This engine was never about speed or high horsepower, it was all about reliability, torque, and simplicity. And it delivered that in spades, often running long after the body of the vehicle had rusted through or been otherwise retired.

One of the main reasons the Ford 300 lives so long is its design. The engine block is heavy, overbuilt, and made to withstand abuse. With its long stroke and low-end torque, it didn’t need to rev high to get the job done, which also helped reduce internal wear.

It used a very straightforward pushrod valvetrain and simple carburetion or throttle-body fuel injection in later years, depending on the model. That simplicity meant there was very little to fail, and when something did go wrong, it could usually be fixed with basic tools and parts that were cheap and easy to find.

Farmers, construction workers, and tradesmen often swore by the 300 for its ability to keep going with minimal maintenance. Many trucks powered by this engine were used for heavy labor in rough environments, yet the engines just kept going.

Even when transmissions failed or frames cracked under heavy loads, the engine itself was usually the last thing to stop working. These engines often ended up being swapped into newer trucks, used in off-road projects, or repurposed for generators and sawmills. The engines lived on, even when the rest of the vehicle was long gone.

Even today, you’ll still find 300 inline-sixes quietly doing their job in old trucks, farm machinery, or backyard garages. They don’t get the same attention as high-revving performance engines, but among those who know reliability, the Ford 300 is legendary. It’s not glamorous, but it never quits.

That quality alone is enough to put it on this list of engines that outlive their cars. In many ways, it defines what a working-class, blue-collar engine should be: tough, dependable, and always ready for another job.

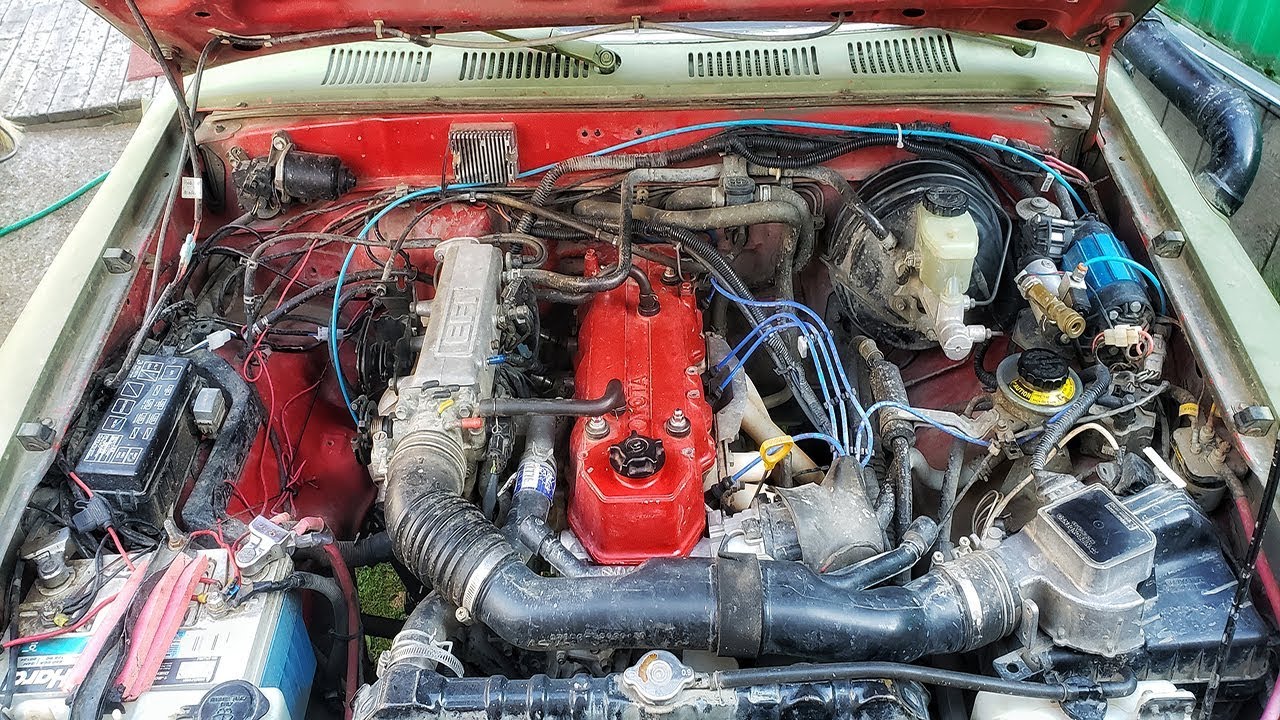

6. Toyota 22R / 22RE

The Toyota 22R and its fuel-injected sibling, the 22RE, are often held up as the gold standard of long-lasting four-cylinder engines. Built from the late 1970s through the mid-1990s, these engines powered vehicles like the Toyota Pickup, Celica, and 4Runner.

Known for their durability, they’re a favorite among Toyota truck enthusiasts, off-roaders, and DIY mechanics. What makes them exceptional isn’t just that they run well when new, it’s that they continue to run long after the rest of the vehicle has deteriorated beyond use.

With a cast-iron block and a simple overhead cam aluminum head, the 22R was designed to withstand rough use. Early carbureted versions were extremely basic, with fewer components to fail. The latter 22RE added fuel injection, which improved drivability and emissions without compromising reliability.

These engines were often used in harsh environments, from desert heat to snow-laden mountain regions, and developed a reputation for surviving it all. Many 22R and 22RE engines are known to last over 300,000 miles, and some have hit half a million with proper maintenance.

The vehicles these engines came in, however, were not always as resilient. The frames of early Toyota pickups, in particular, are prone to rust. The interiors of older 4Runners and Celicas often fall apart after decades in the sun.

Once these vehicles reach the point where repairs exceed their value, many owners simply pull the 22R or 22RE and use it elsewhere. These engines have ended up in all sorts of custom projects, from dune buggies to rock crawlers to farm equipment. Their simplicity and bulletproof nature make them a logical choice for reuse.

One of the most endearing qualities of the 22R series is how easy it is to work on. Parts are cheap, instructions are everywhere, and the design is straightforward enough for a first-time engine builder to understand. That’s led to thousands of these engines being rebuilt, reused, and repurposed over the decades. Even as modern trucks grow more complicated and fragile, the 22R continues to earn its keep as one of the most dependable four-cylinder engines ever produced.

7. Cummins 5.9L 12-Valve Diesel (6BT)

The Cummins 5.9L 12-valve diesel engine, also known by its engine code 6BT, is a powerhouse of reliability and longevity. Introduced in Dodge Ram trucks in 1989, it quickly developed a cult following for its industrial-level durability. Originally designed for commercial and agricultural machinery, this engine brought big-rig toughness to consumer pickup trucks. It didn’t take long for owners to notice that the Cummins engine often lasted far longer than the truck wrapped around it.

The 6BT is an inline-six design with a cast-iron block and head, direct injection, and mechanical fuel pump, no computers, no electronic sensors, and almost nothing to break. It produced respectable torque for its time and could tow heavy loads with ease.

Most importantly, it was capable of running for hundreds of thousands of miles with minimal maintenance. Stories of these engines passing the one-million-mile mark are not rare, especially among truckers and farmers who took care of them properly.

By contrast, the Dodge trucks these engines came in during the 1990s were not always built to the same standard. Interior plastics cracked, bodies rusted, and suspensions wore out under the stress of towing and hauling. As a result, many of these trucks were eventually scrapped or stripped down.

But in most cases, the Cummins engine was pulled first and either sold or swapped into another vehicle. The engine became so popular for engine swaps that full kits were developed to drop them into everything from older Fords to custom-built 4x4s.

Today, the 6BT is still widely used in off-road builds, heavy-duty work trucks, and even converted RVs and buses. It’s not uncommon to see these engines still working hard more than 30 years after they were built. Their ability to run on alternative fuels, including biodiesel, adds to their appeal.

The 6BT may not be flashy, but its durability is the stuff of legend. Few engines in history have proven themselves to be such long-term survivors, making it a worthy place on any list of engines that outlast their original vehicles.

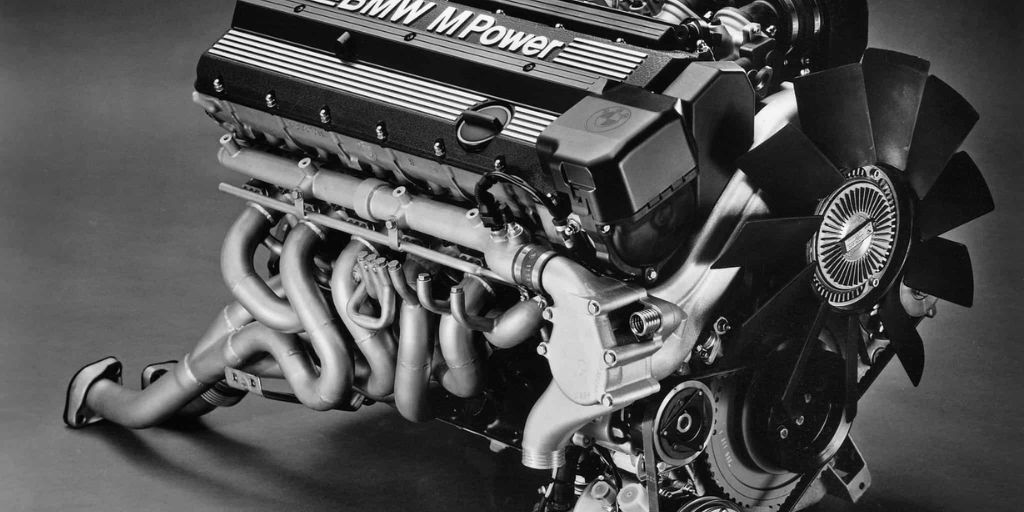

8. BMW M50 Inline-Six

The BMW M50 engine, particularly the versions found in the early 1990s 3-Series (E36) and 5-Series (E34), represents a time when BMW prioritized engineering precision over cost-saving measures.

Launched in 1990, this inline-six engine replaced the M20 series and introduced a number of advancements, including an aluminum head, dual overhead cams, and in later versions, BMW’s VANOS variable valve timing system. Though not as powerful as modern BMW engines, the M50 offered a near-perfect balance of smoothness, reliability, and serviceability that made it stand out, not just for performance, but for how long it could last.

What makes the M50 remarkable is how well it holds up over time. Unlike some of BMW’s later engines, which gained a reputation for oil consumption and complex failure points, the M50 is relatively simple and overbuilt. The iron block is incredibly tough, and the head gasket issues that plagued earlier designs were resolved in this series.

These engines regularly hit 250,000 to 300,000 miles without needing internal rebuilds, and even those that have suffered neglect can often be revived with basic maintenance. Their resilience under abuse has made them popular with budget drifters and weekend racers, who have proven time and again that these engines can be revved hard and still keep ticking.

By contrast, the BMWs that housed the M50s have not always aged as well. The E36, for instance, is known for structural issues, interior wear, and fragile electronics, especially in higher-mileage examples. As a result, many of the cars ended up in salvage yards or were stripped for parts.

But the M50 engines themselves are frequently pulled, cleaned up, and used in engine swaps. They’ve become common in E30 conversions, older BMW restomods, and even in non-BMW builds like Volvos and kit cars due to their reliability and availability.

In today’s world of turbocharged, plastic-laden engines filled with complicated emissions systems, the M50 stands out as a reminder of a different approach. It’s smooth, dependable, and made to last.

Even though the BMWs it powered may have moved on or fallen apart, the M50 continues to live on in garages, race cars, and project builds around the world. It’s an engine that outlasts its era, and often, its entire chassis.

9. Nissan SR20DET

The SR20DET is one of Nissan’s most respected four-cylinder engines, especially in performance and tuning circles. Found in various vehicles, including the Nissan Silvia, 180SX, and some models of the Pulsar GTI-R, the SR20DET combined a turbocharged design with strong internals and a high-revving nature.

Built during the 1990s, a golden era for Japanese engineering,this engine gained fame not only for its impressive power potential but also for how long it could survive hard use. Even when the cars around it aged, rusted, or were destroyed by aggressive driving or drifting, the SR20DET often kept going.

The engine is based on a robust iron block and features aluminum heads, dual overhead cams, and variable cam timing in some versions. It was built with longevity in mind, despite being a performance engine. Internals like forged pistons and a strong crankshaft made it capable of handling power increases without falling apart.

As a result, the SR20DET became a favorite for tuners who wanted reliable turbo performance without sacrificing reliability. Many of these engines have seen multiple vehicles in their lifetime, often being swapped from wrecked drift cars into new builds or repurposed into track cars, rally builds, or time-attack machines.

Unfortunately, the Nissan chassis the SR20DET came in wasn’t always built to the same standard. The S13 and S14 bodies in particular have become notorious for rust and chassis fatigue, especially in colder climates. Many were also driven hard, crashed, or parted out due to age and wear.

But the engine was almost always the one component that could be salvaged. It became common practice to remove the SR20DET and save it for future use, often stored in garages or tuning shops awaiting its next life. It’s a testament to how tough the engine is that so many still exist today despite the dwindling supply of clean original cars.

Even now, the SR20DET is in demand, especially in motorsport. It’s a compact, capable engine that can still be found pulling impressive lap times or drifting sideways at events.

Whether it’s running with factory internals or fully built for boost, the SR20DET continues to prove that it’s far more durable than the cars it was born in. That resilience is what has kept it alive long after many Nissan shells have met the crusher.

10. Jeep 4.0L Inline-Six

The Jeep 4.0L inline-six, often simply referred to as the “4.0,” is widely regarded as one of the most dependable and enduring American engines ever built. Introduced in the late 1980s and used through the early 2000s in models like the Jeep Cherokee (XJ), Grand Cherokee (ZJ/WJ), and Wrangler (YJ/TJ), this engine has gained a legendary status for its toughness and refusal to quit.

Designed as an evolution of AMC’s older straight-six engines, the 4.0 kept the rugged design philosophy alive while improving power and reliability. It wasn’t the most fuel-efficient or advanced engine on the market, but it outlasted just about everything else.

What set the 4.0 apart was its incredibly stout construction. The cast-iron block and head were heavy, but that heaviness came with strength. It had a very conservative redline and operated well within its mechanical limits, which meant less internal wear over time.

The vehicles that housed the 4.0, particularly the XJ Cherokee, have not always stood the test of time. The unibody construction could rust out, and suspensions and electronics often failed after years of abuse. Yet even when the frame was beyond repair or the interior was falling apart, the engine was usually still healthy.

Mechanics would often pull these engines before sending the vehicle to the crusher. From there, they ended up in engine-swapped Wranglers, off-road buggies, or as spares in case someone’s Jeep blew its original motor. In many cases, these engines outlive multiple bodies, a true mark of long-term durability.

Even now, you’ll find the 4.0 being kept alive by off-roaders, Jeep enthusiasts, and rural mechanics who know that sometimes, older really is better. While newer engines offer more power or better emissions, few match the 4.0’s track record of dependability.

It’s the kind of engine you can depend on when you’re 50 miles into the woods with no cell service, and for that reason, it continues to outlive the cars that carried it off the lot decades ago.