Engine oil is the lifeblood of an internal combustion engine, serving to reduce friction, manage temperature, and prevent the accumulation of harmful deposits. Over time, oil breaks down due to heat, contaminants, and mechanical stress, making oil changes a critical part of any vehicle’s maintenance schedule.

However, not all engines demand the same frequency of oil replacement. Some power plants have been designed and engineered to handle longer periods between oil changes without suffering from excessive wear or degradation.

This endurance often comes from advanced metallurgy, precision machining, efficient combustion, and oil management systems that minimize contamination and oxidation.

Drivers who own such engines benefit from lower maintenance costs and reduced downtime, while manufacturers highlight these designs as examples of modern efficiency.

Extended oil intervals do not simply mean skipping regular maintenance. Instead, they represent a blend of engineering foresight and quality assurance. Factors such as tighter tolerances, superior piston ring sealing, improved PCV systems, and robust oil filtration all contribute to longer oil life.

Synthetic oils further complement these designs by resisting viscosity breakdown and maintaining stability under stress.

As emission standards and efficiency expectations rose over the decades, manufacturers refined engines that could operate reliably on extended maintenance cycles.

This trend has made engines more durable and easier to live with for owners who drive long distances or prefer fewer service appointments.

The following sections highlight 12 engines known for their tolerance to extended oil intervals. Each has earned a reputation for durability, clean operation, and internal stability. While every vehicle still requires routine checks, these engines stand out because they maintain performance and protection even as oil ages.

From dependable inline fours to robust diesels and smooth six-cylinders, these examples demonstrate what thoughtful engineering and proper maintenance can achieve.

1. Toyota 2GR-FE 3.5L V6

The Toyota 2GR-FE engine, found in models such as the Camry, Highlander, and Lexus RX, is known for its longevity and efficiency.

This aluminum-block V6 features dual overhead cams and variable valve timing that optimize combustion efficiency. One reason it tolerates extended oil intervals is its tight internal tolerances and clean-burning characteristics.

With proper maintenance and the use of high-quality synthetic oil, many owners report smooth performance even after several thousand miles beyond typical change intervals.

The 2GR-FE’s well-sealed crankcase and effective PCV design limit oil contamination, allowing the lubricant to retain its protective properties longer.

Another strength of this engine lies in its thermal stability. It runs relatively cool for a modern V6, thanks to its efficient cooling passages and oil control system. The piston rings and cylinder walls maintain consistent contact, which prevents blow-by and keeps combustion gases out of the oil.

Toyota’s engineering precision also reduces sludge buildup, a problem that plagued some earlier models. When paired with synthetic 0W-20 oil, the 2GR-FE can comfortably operate on maintenance intervals approaching ten thousand miles under ideal driving conditions.

Reliability studies have consistently ranked this engine among the most durable of its kind. Fleet vehicles equipped with the 2GR-FE often exceed two hundred thousand miles without major internal repairs, and oil analyses frequently show low metal content even after extended use.

That resilience speaks to the balance Toyota achieved between power and endurance. Owners who drive mainly on highways, where the engine maintains steady RPMs, experience the best results from longer oil intervals.

Still, Toyota’s recommendations should guide service schedules, as local conditions and driving style can alter oil degradation rates.

But it remains impressive that this engine, even in heavy midsize SUVs, continues to deliver dependable service with minimal oil-related issues. The 2GR-FE stands as a model of practical engineering where efficiency and durability meet in a single design.

2. Honda K24 Series 2.4L Inline-4

Honda’s K24 engine family earned its reputation for smoothness, efficiency, and resistance to wear. These engines feature chain-driven camshafts, strong bottom-end construction, and a well-balanced rotating assembly.

One major factor behind their tolerance for extended oil intervals is the precision of the piston ring design and the low oil consumption typical of these units.

Unlike earlier Honda engines that suffered from sludge buildup, the K24 keeps internal surfaces remarkably clean, aided by efficient crankcase ventilation and tight machining tolerances.

Synthetic oil performs especially well in the K24, as the engine’s moderate operating temperatures and efficient combustion reduce contamination. Many owners who conduct oil analysis report that the oil retains good viscosity and protective additives even after prolonged use.

This resilience is partly due to the even heat distribution across the block and head, preventing localized hot spots that can degrade oil quickly. Honda’s VTEC system, though performance-oriented, does not excessively strain the lubrication system under normal driving, which further extends the oil’s useful life.

Another noteworthy feature is the K24’s oil control ring system. The design prevents excessive oil burning, which keeps the lubricant cleaner for longer. The use of high-quality gaskets and seals minimizes the introduction of external contaminants.

Because of these characteristics, Honda’s maintenance minder system often allows drivers to go several thousand miles beyond traditional intervals before indicating service. This electronic monitoring supports the real-world evidence that the K24 can safely handle extended use between oil changes.

For enthusiasts, the K24 also represents a platform that rewards maintenance discipline. When serviced with good oil and filters, it remains mechanically quiet and efficient well beyond typical mileage milestones.

The engine’s combination of strong mechanical integrity and clean operation ensures that longer oil intervals do not compromise reliability. It remains a testament to Honda’s ability to balance performance and durability in a straightforward, naturally aspirated design.

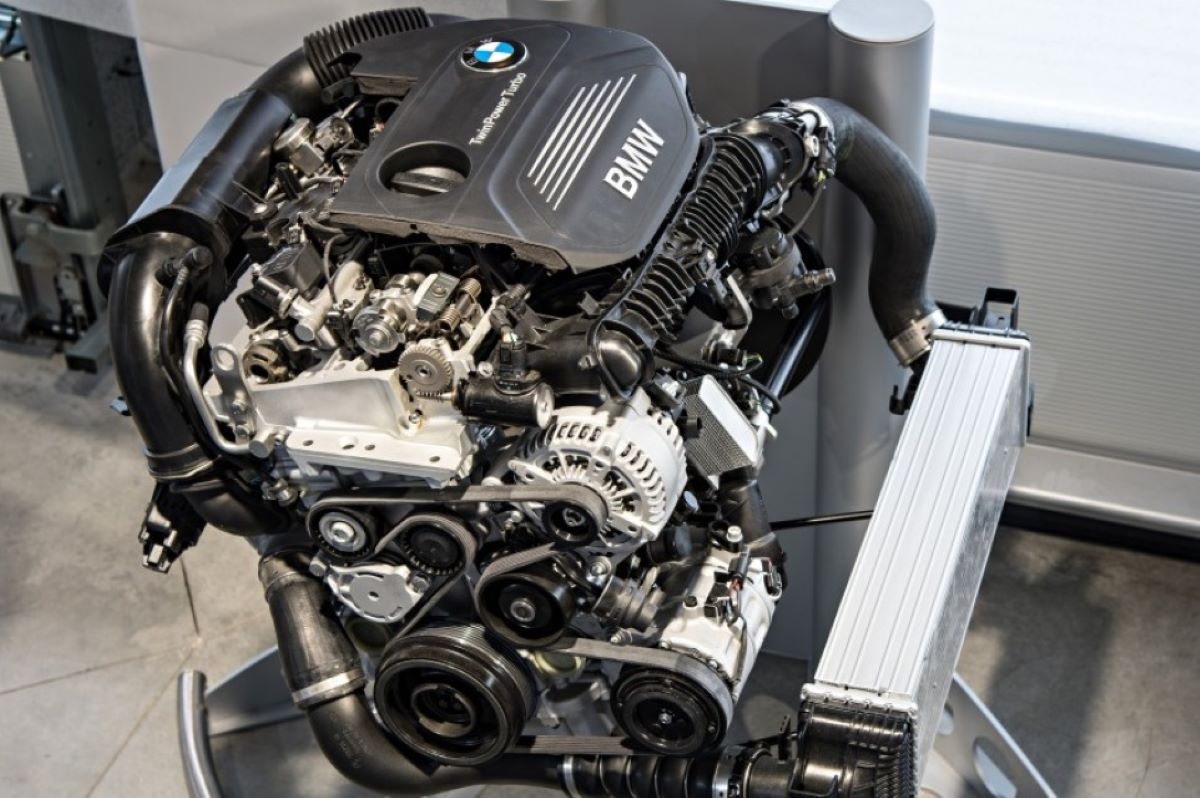

3. BMW B58 3.0L Turbocharged Inline-6

BMW’s B58 engine has become a benchmark for modern turbocharged six-cylinders. Found in vehicles like the 3-Series, 5-Series, and Toyota Supra, it was designed from the start to handle extended maintenance intervals without sacrificing performance.

The closed-deck block, high-quality aluminum construction, and precise fuel injection control all contribute to its endurance.

Unlike older BMW engines that suffered from carbon buildup or oil degradation, the B58 integrates a sophisticated oil management system that keeps contaminants at bay and maintains stable pressure under all conditions.

One of the main reasons for its oil longevity is the thermal efficiency of its cooling system. The B58 employs a heat management module that regulates temperature quickly after startup, keeping the oil from spending long periods at sub-optimal viscosity.

Stable oil temperature helps prevent sludge formation and preserves additive integrity. Furthermore, the use of advanced synthetic oils designed to meet BMW’s Longlife specifications allows service intervals that can stretch up to fifteen thousand miles under normal use.

The turbocharger’s water-cooled design and efficient bearing lubrication also reduce oil stress. Unlike older turbo setups that caused oil coking, the B58 maintains cleaner oil pathways, even after spirited driving.

The engine’s direct injection system burns fuel cleanly, minimizing soot and reducing the contamination that shortens oil life. BMW engineers optimized every component to work harmoniously, which helps maintain consistency in oil properties over time.

Owners of vehicles powered by the B58 often praise its combination of refinement and dependability. Despite its power output and complexity, the engine rarely suffers from oil-related failures when maintained properly. Regular analysis shows low wear metals, confirming that internal friction remains under control.

For drivers covering long distances or adhering to manufacturer maintenance schedules, the B58 demonstrates how modern engineering can reconcile high performance with long-term reliability and efficient servicing.

4. Ford 5.0L Coyote V8

Ford’s Coyote V8, introduced in the Mustang and F-150, has earned recognition for both power and resilience. This naturally aspirated engine uses dual overhead cams and variable valve timing to maximize efficiency.

What makes it tolerant of extended oil intervals is the combination of robust construction, precise machining, and efficient oil control. Its aluminum block and forged crankshaft reduce internal stress, while the piston and ring design limit blow-by gases that can degrade oil.

The Coyote’s lubrication system is one of its most significant strengths. A high-capacity oil pump and well-routed galleries ensure even distribution of oil under all conditions, from idle to high-RPM operation.

Because of this, the oil does not overheat or lose viscosity quickly, allowing it to maintain protective qualities for longer durations.

Many drivers report successful intervals approaching ten thousand miles when using premium synthetic oil. The system’s ability to keep internal temperatures even contributes to the stability of the oil over extended use.

Ford also developed the Coyote with longevity in mind, knowing that pickup owners often keep their trucks for years. The result is an engine that remains quiet and smooth even after extensive use. The crankcase ventilation system efficiently removes moisture and fuel vapors, two major causes of oil degradation.

This keeps the lubricant clean, extending both its life and the engine’s. Even under heavy loads, the Coyote maintains oil pressure and temperature within optimal ranges.

From daily driving to high-performance applications, the Coyote’s combination of durability and efficiency is well proven. It can handle modern low-viscosity oils without issue, and its internal coatings resist wear even when oil ages.

While Ford still recommends reasonable service intervals, the engine clearly demonstrates tolerance for longer periods between oil changes. It stands as a strong example of how performance and reliability can coexist through careful engineering and material quality.

5. General Motors 3.6L LGX V6

General Motors’ 3.6-liter LGX engine, part of the company’s modern V6 family, represents a significant step forward in efficiency and reliability.

It powers a wide range of vehicles, including the Chevrolet Camaro, Cadillac CT6, and GMC Acadia. What distinguishes the LGX is its ability to operate smoothly and cleanly even as oil ages.

GM designed the engine with lightweight materials, a stiffened block, and precision-machined internal components that limit mechanical friction. These factors help reduce the rate at which contaminants accumulate in the oil, allowing it to maintain its protective qualities for extended periods.

A major contributor to the LGX’s tolerance for longer oil intervals is its advanced direct fuel injection system. By delivering fuel directly into the combustion chamber, the system minimizes fuel dilution in the oil, a common problem that shortens oil life in older engines.

The PCV system is also optimized to prevent excessive oil vapor from reentering the intake path, reducing sludge formation. These design elements ensure that the oil remains clear and stable longer, even under mixed driving conditions that include both city and highway travel.

The cooling system design also plays a role in oil durability. The LGX uses a variable cooling strategy that brings the engine to its ideal operating temperature quickly, preventing condensation and moisture buildup inside the crankcase.

Once warm, the engine maintains consistent thermal conditions, avoiding the high-heat cycles that can cause oil breakdown.

Owners using high-quality synthetic oils often see oil life monitor readings well beyond eight thousand miles before service is needed. These results reflect not just software calibration but the mechanical integrity of the engine itself.

Long-term fleet data and owner experiences confirm the LGX’s ability to handle extended intervals without sacrificing performance or longevity. Even in demanding conditions, such as towing or high-speed driving, the oil typically maintains its viscosity and chemical balance.

The engine’s precision and clean-running nature mean that maintenance schedules can be flexible without causing damage. This balance of performance, smoothness, and low maintenance requirements makes the LGX a solid representation of GM’s progress in modern engine durability.

6. Mercedes-Benz OM642 3.0L Turbo Diesel V6

The Mercedes-Benz OM642 diesel engine has built a reputation for endurance, smoothness, and remarkable oil life. Used across numerous Mercedes-Benz and Jeep models, this V6 diesel combines strength with efficiency.

The engine’s cast-iron block and aluminum heads contribute to durability and thermal balance, while its low-revving nature minimizes internal wear. Diesel engines inherently operate under higher pressures, yet the OM642 manages to maintain oil cleanliness for long periods thanks to its effective combustion and tight sealing.

A key aspect of its long oil intervals is its advanced fuel injection and emission control system. The common-rail injection ensures precise fuel delivery, which promotes cleaner combustion and fewer soot particles entering the oil.

The design of the EGR and crankcase ventilation systems further reduces the contamination that often shortens oil life in diesel engines. Combined with large oil capacity and high-quality filters, the OM642 can safely extend oil changes far beyond traditional expectations, often up to fifteen thousand miles or more under normal use.

The thermal management of this engine is equally sophisticated. The cooling system maintains stable temperatures across all cylinders, preventing localized hot spots that could accelerate oil degradation. Its turbocharger uses an efficient oiling system that minimizes heat soak after shutdown, a common cause of oil coking in other engines.

The result is an engine that runs cleanly and steadily, even under heavy loads or extended idling. Mercedes’ recommended service intervals are longer than most gasoline engines, reflecting their confidence in the design.

Owners of OM642-powered vehicles frequently note the engine’s ability to maintain quiet operation and performance over many years and hundreds of thousands of miles. Oil analysis often shows minimal wear particles even after long service intervals, a testament to the balance between engineering precision and diesel efficiency.

The OM642’s combination of durability and refinement makes it one of the most respected modern diesel engines, capable of extended operation with minimal maintenance disruption.

7. Subaru FB25 2.5L Boxer Engine

Subaru’s FB25 engine, a naturally aspirated 2.5-liter flat-four, offers a blend of balance, efficiency, and extended oil stability. Its horizontally opposed layout helps distribute heat evenly and minimizes vibration, which in turn contributes to consistent oil performance.

The FB25’s improved piston ring design and low-friction internals allow it to run cleanly for long intervals, particularly when paired with modern synthetic oil. Subaru’s engineers specifically addressed earlier issues of oil consumption found in previous generations, creating a more stable and durable powerplant.

The use of lightweight materials and optimized oil passages helps the FB25 maintain oil pressure across various operating conditions. Its oil pump is designed to deliver steady flow even at low RPMs, preventing dry starts and ensuring consistent lubrication.

The improved crankcase ventilation system also plays a critical role in extending oil life. By effectively removing moisture and vapors, it reduces contamination that could degrade the oil. Many owners report stable performance and low oil consumption even after exceeding conventional service intervals.

Temperature control is another advantage of the FB25 design. The flat layout allows air and coolant to circulate evenly around the cylinders, minimizing hot spots that can lead to oil oxidation. As a result, oil breakdown occurs more slowly, and protective additives remain active longer.

Subaru recommends longer intervals for vehicles running synthetic oil, and field data support this by showing minimal internal wear in engines with disciplined but extended maintenance routines.

The FB25 well supports Subaru’s reputation for long-lasting engines. Drivers often achieve high mileages without oil-related issues, provided they use recommended oil types and filters. The balance between mechanical simplicity and thoughtful refinement has made this engine an enduring favorite.

Its ability to operate quietly and efficiently over extended maintenance cycles reflects Subaru’s understanding of how consistent design improvements can lead to lasting reliability and convenience for owners.

8. Cummins 6.7L Turbo Diesel

Few engines command as much respect for endurance as the Cummins 6.7-liter turbo diesel found in heavy-duty Ram trucks. This inline-six engine was engineered for extreme conditions, including towing, hauling, and continuous high-load operation.

Its large oil capacity, efficient filtration, and robust internal components allow it to sustain extended oil intervals while maintaining reliability. Cummins designed this engine to perform under conditions that would quickly degrade oil in lesser designs.

A significant contributor to the 6.7L’s resilience is its low-revving nature and massive torque output. Because it produces peak torque at low RPMs, internal friction and heat generation remain relatively moderate. This helps preserve the oil’s viscosity and chemical balance over time.

The engine’s advanced high-pressure fuel system ensures clean combustion, minimizing soot and fuel dilution. Its crankcase ventilation and EGR systems are engineered to handle these byproducts effectively, keeping the oil cleaner and extending usable life.

Another factor in the 6.7L’s durability is its exceptional cooling and lubrication design. Large oil passages and a high-capacity pump ensure rapid circulation and temperature control even under heavy loads.

The engine’s materials and machining tolerances were chosen to handle enormous internal pressures, meaning less stress on bearings and cylinder walls. This precision contributes to reduced wear rates and slower oil contamination.

Owners often report oil analysis results showing strong additive retention and minimal metal presence even after long intervals. For commercial operators, the ability to extend service schedules without compromising engine health translates to lower downtime and reduced operating costs.

The Cummins 6.7L stands as one of the most oil-tolerant engines ever produced, balancing brute strength with thoughtful engineering that keeps it running clean and strong mile after mile.

9. Toyota 1NZ-FE 1.5L Inline-4

The Toyota 1NZ-FE, used widely in compact models such as the Yaris and Corolla, is known for reliability and efficiency. Despite its modest size, this engine has proven remarkably tolerant of extended oil intervals.

Its simple, lightweight design contributes to low friction, while its variable valve timing system optimizes efficiency without overworking the lubrication system. The result is an engine that keeps oil cleaner for longer periods, especially under steady driving conditions.

This engine’s internal design emphasizes durability over sheer performance. Its crankshaft and bearings are well matched, and the piston rings provide a secure seal that minimizes blow-by gases entering the oil.

The combustion process remains stable across a wide temperature range, limiting the production of contaminants that could degrade oil quality. Many owners have successfully operated their vehicles well past standard service intervals without negative effects when using good synthetic oils.

The 1NZ-FE’s PCV system and valve cover design also reduce oil vapor recycling, which helps the lubricant retain its original clarity and viscosity.

Because this engine is not heavily stressed, it avoids the high internal temperatures that often accelerate oil aging. Combined with Toyota’s consistent manufacturing standards, this simplicity has produced one of the most durable small engines ever built.

Even after years of operation, engines of this series often show minimal internal wear when properly maintained. Oil samples from high-mileage 1NZ-FE units reveal little metal residue, suggesting stable lubrication even during extended intervals.

This remarkable tolerance comes not from complexity but from precise engineering that focuses on balance, cleanliness, and consistent operation.

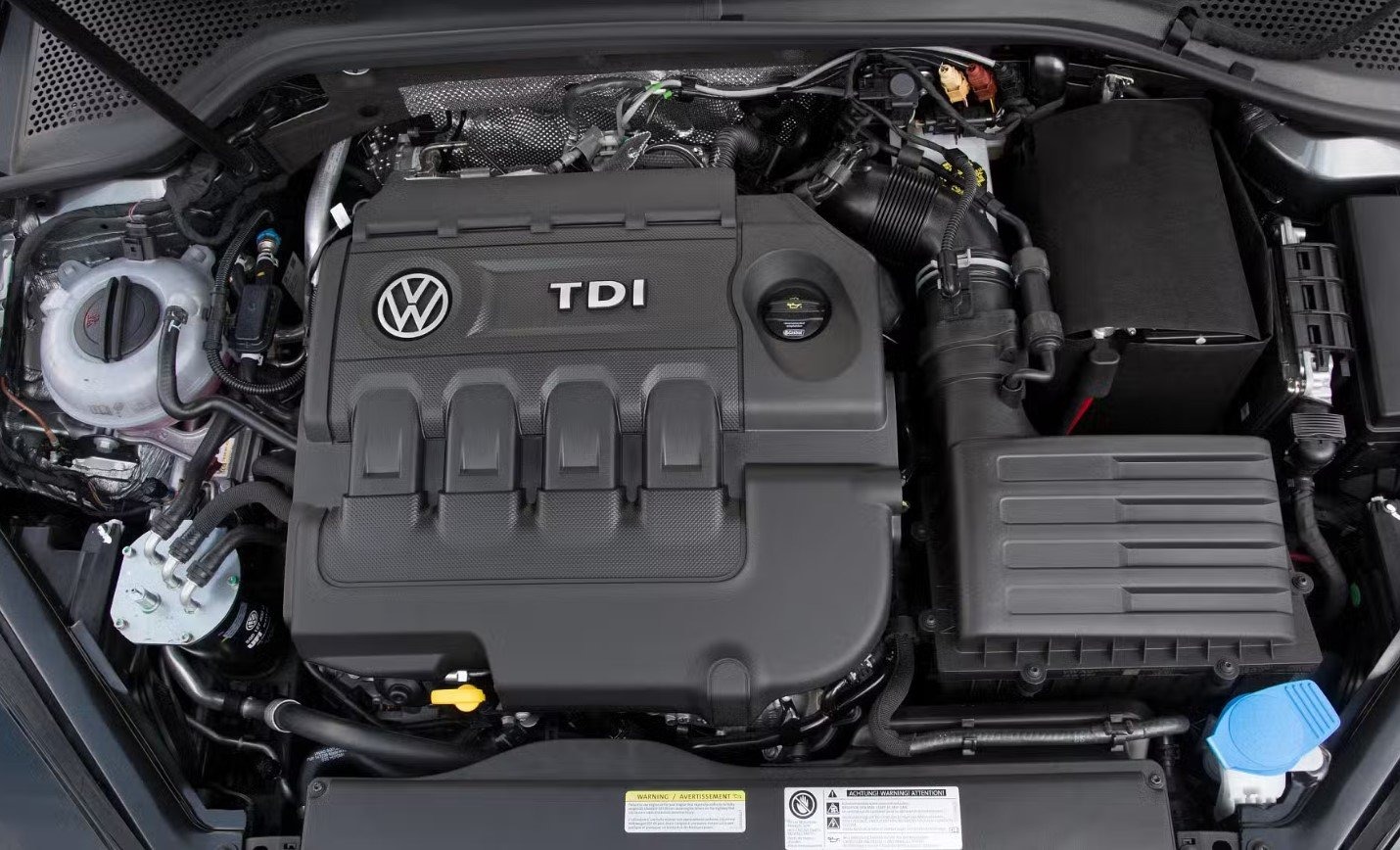

10. Volkswagen 2.0L TDI Diesel

Volkswagen’s 2.0-liter TDI diesel has long been recognized for efficiency and endurance. Although known for its emissions controversies, the engineering foundation of this engine remains sound, particularly regarding oil stability.

Its direct-injection design and relatively low operating RPMs help preserve oil integrity, while its strong cast-iron block provides excellent heat distribution. These characteristics make it well suited for extended oil intervals, especially when running long distances at steady speeds.

The 2.0L TDI’s turbocharger and intercooler systems operate efficiently, limiting the oil temperatures even during heavy load. Its large oil capacity, combined with advanced synthetic diesel oils, enables longer service cycles compared to typical gasoline engines.

Many owners observe that oil life monitors and lab tests support intervals approaching fifteen thousand miles under normal conditions.

One reason for its oil longevity is the engine’s effective separation of fuel and lubricant systems. The high-pressure pump design and precise injection timing prevent fuel from seeping into the oil, which would otherwise dilute it and shorten its usable life.

Additionally, the particulate filter and EGR systems maintain combustion cleanliness, further slowing the accumulation of soot in the lubricant.

The 2.0L TDI’s legacy continues to influence modern diesel engineering. Its combination of smooth torque delivery, efficiency, and long-lasting oil stability demonstrates the effectiveness of proper design and high-quality components. Even after many years, well-maintained examples show how extended oil intervals can be achieved without compromising dependability or performance.

11. Nissan VQ35DE 3.5L V6

Nissan’s VQ35DE is one of the most respected engines ever produced by the brand, powering vehicles such as the Altima, Maxima, 350Z, and Infiniti G35. This V6 is celebrated for its balance of performance and durability, and it has consistently proven capable of running extended oil intervals without ill effects.

Its all-aluminum construction, forged crankshaft, and well-balanced rotating assembly create a platform that manages heat and friction efficiently. These features prevent premature oil breakdown and make the VQ35DE an engine that remains smooth and clean even after long service cycles.

One of the primary reasons this engine tolerates extended intervals is its well-designed oil control system. The combination of a high-capacity oil pump and well-sized passages ensures consistent lubrication across the valvetrain and crankshaft bearings.

The engine’s piston ring design also minimizes oil consumption and keeps blow-by gases under control, which helps maintain cleaner oil for longer periods.

Many owners who use high-quality synthetic oils report smooth performance well beyond the manufacturer’s recommended intervals, often confirmed by used oil analyses showing stable viscosity and low metal content.

The VQ35DE’s efficient combustion process contributes to oil stability as well. Its variable valve timing system adjusts cam timing to achieve complete fuel burn, reducing carbon buildup and keeping the oil from becoming contaminated with unburned hydrocarbons.

This clean-running nature also limits sludge formation and oxidation, two common causes of oil degradation. Because of its balance between temperature management and fuel efficiency, the engine can handle extended use in both city and highway conditions.

Even in performance settings such as the Nissan 350Z, where the VQ35DE often operates at higher RPMs, it maintains excellent internal cleanliness when maintained with the right oil. Its durability is evident in the many examples still running smoothly after hundreds of thousands of miles.

The VQ35DE stands as proof that high-output engines, when engineered with precision and balance, can comfortably handle long oil intervals without sacrificing reliability or performance.

12. Lexus 2UR-GSE 5.0L V8

The Lexus 2UR-GSE engine, found in high-performance models like the RC F, GS F, and LC 500, combines advanced engineering with a focus on longevity. Despite being a high-revving, naturally aspirated V8, it demonstrates an impressive ability to sustain oil performance over extended intervals.

Built with meticulous precision and assembled under tight quality control, the 2UR-GSE features a lightweight aluminum block, titanium valves, and forged connecting rods.

These materials not only enhance performance but also maintain structural integrity under stress, reducing the strain placed on engine oil during high-speed operation.

This minimizes soot and fuel dilution, two major contributors to oil contamination. The piston design also reduces blow-by, meaning the oil remains cleaner for longer.

Lexus engineered this engine to operate reliably under both high load and extended cruising conditions, resulting in an unusually long oil life for such a powerful unit.

The lubrication system uses a variable displacement oil pump that adjusts flow based on engine demand, ensuring optimal pressure without overworking the oil.

This feature helps prevent aeration and maintains consistent lubrication at all times. High-quality synthetic oils designed for high-temperature stability perform exceptionally well in this environment, often allowing safe operation beyond ten thousand miles between oil changes.

What makes the 2UR-GSE remarkable is its balance of refinement and toughness. It produces over 450 horsepower, yet it retains the quiet, smooth character Lexus engines are known for.

Owners who adhere to proper maintenance schedules and use recommended lubricants often find that their engines show little wear even after prolonged use.

This V8 serves as a model of how modern performance engineering can still achieve the reliability standards that Lexus has long been recognized for.