Fleet managers operate in an environment where durability, fuel economy, and service consistency mean everything. A truck or van that cannot reach 400,000 miles without extensive repair costs is more of a burden than a tool.

Across the logistics, construction, and public utility sectors, the conversation around engine reliability always comes back to the same principle: an engine that lasts must be built on proven engineering, responsible maintenance schedules, and balanced power output.

Every mile counts when the vehicle is part of a working fleet, and the ability to push well past 400,000 miles without catastrophic failure is a badge of honor for any powerplant.

Reaching that mark is not only about the components but also about the confidence a fleet manager has in knowing that downtime is minimized and operating costs are under control.

What defines an engine that truly lasts is not just horsepower or torque but a harmony between efficiency and resilience. Managers who have spent years dealing with fuel reports, maintenance sheets, and mechanical audits will often say that longevity is earned mile by mile.

Engines capable of passing 400,000 miles are not born from chance. They are the result of thoughtful design, rigorous testing, and real-world dependability under various load and temperature conditions. They tolerate both the idling of city deliveries and the sustained hauls of highway transport.

Another element that defines these long-lived engines is their serviceability. Fleet operations depend on quick maintenance procedures and the availability of replacement parts.

Engines that are complex or proprietary often cause delays when something goes wrong. The most respected models are designed with accessibility in mind. Components can be removed and replaced without extensive teardown, which means the vehicle returns to the road faster.

For this reason, fleet managers often form strong loyalties to certain engines. Whether built for medium-duty delivery vans, heavy-haul tractors, or utility trucks, these engines gain reputations that extend beyond brands.

Below are ten engines known throughout the fleet community as workhorses capable of achieving 400,000 miles of faithful service when treated with proper care and regular attention. Each one has earned its place through a mixture of engineering strength, endurance, and the ability to handle years of professional demand.

1. Cummax D14 Turbo Diesel

The Cummax D14 Turbo Diesel has been a cornerstone of many regional delivery fleets for years. Its design focuses on medium-duty trucks where consistent torque is more valuable than raw horsepower.

This engine’s cast-iron block and forged steel crankshaft allow it to withstand repetitive strain from heavy payloads while maintaining low vibration levels.

Fleet managers appreciate how predictable its maintenance intervals are. Oil changes, valve checks, and filter replacements are straightforward and can be handled by most in-house technicians without specialized tools.

One of the key reasons the D14 reaches the 400,000-mile mark is its conservative tuning. Rather than chasing extreme output figures, Cummax engineers balanced compression ratios and turbo boost levels to minimize stress on internal components. This makes the D14 forgiving when drivers are inconsistent with throttle use.

Many fleets that run local routes with constant stop-and-go traffic favor this engine because it maintains strong oil pressure and cool operating temperatures under load.

Another advantage of the D14 is its modular component design. The turbocharger, fuel injectors, and exhaust treatment systems can be replaced individually without affecting the rest of the engine’s assembly.

This keeps costs predictable and downtime short. Fleet managers also point out that rebuild kits are affordable and widely available, allowing these engines to go beyond their original 400,000-mile lifespan with a proper overhaul.

Even after years of service, the D14 retains smooth operation with minimal loss in compression. Many mechanics note that even after hundreds of thousands of miles, cylinder wear remains moderate when maintenance schedules are followed.

This engine represents the idea that reliability comes not from cutting-edge technology but from consistent, well-balanced engineering.

2. Detarq MX8 Heavy Torque Diesel

The Detarq MX8 is known for its strong torque curve and ability to pull heavy loads across long distances. Fleet managers in the freight sector often select it for regional and interstate hauling where the combination of power and longevity is critical.

The MX8’s large displacement and low-revving nature keep wear rates low. It is not uncommon for these engines to exceed 450,000 miles with only routine maintenance such as oil analysis and coolant checks.

The MX8 benefits from a dual-stage turbo setup that allows it to maintain efficiency at both low and high speeds. This system prevents lag during acceleration and stabilizes combustion pressure during long pulls.

Drivers appreciate the smooth delivery of power, while managers appreciate the reduced strain on drivetrain components. The ability to maintain consistent torque output across a wide RPM range reduces the likelihood of overloading the transmission or axles.

Another reason for the MX8’s reputation is its oil control system. Detarq designed this engine with improved piston ring geometry, which minimizes blow-by and oil consumption.

Over long service intervals, this reduces contamination of the aftertreatment system and extends the life of emission components.

Many fleets report that oil analysis results remain stable even after extended operation, which signals good internal health.

The MX8 is often found in vocational trucks and regional haulers that prioritize uptime over outright performance. When matched with a well-managed service program, this engine delivers excellent cost per mile results.

Mechanics often say that its simplicity is what makes it reliable: fewer electronic systems mean fewer failures and faster repairs. The MX8 is a classic example of how traditional engineering still wins the loyalty of experienced fleet managers.

3. Fordron 7.3L V8 PowerStroke

The Fordron 7.3L PowerStroke has achieved almost legendary status among fleet operators and independent contractors alike. Known for its durability, it powered many commercial vans and chassis cabs for over a decade.

Fleet managers appreciate its straightforward design and the availability of parts, which makes it ideal for long-term fleet service. With regular oil changes and proper cooling maintenance, it often runs past 400,000 miles without major internal repairs.

One of the strongest traits of this engine is its robust block and cylinder head design. The combination of cast-iron strength and balanced piston travel ensures even wear across all cylinders.

Its mechanical fuel injection system, though dated by modern standards, provides unmatched reliability in fleet applications that prioritize uptime over fuel economy. Even with heavy loads and extended idling periods, the PowerStroke maintains stable oil pressure and temperature.

The 7.3L’s longevity also comes from its ability to tolerate less-than-perfect maintenance. Many fleet vehicles see inconsistent service intervals due to busy schedules, yet this engine often continues performing well.

Mechanics note that the simple layout of the intake, exhaust, and turbo components makes troubleshooting fast and inexpensive. That accessibility contributes to lower lifetime costs and faster turnaround times during inspections or repairs.

Although newer engines feature more advanced emission systems and tighter tolerances, the 7.3L remains a trusted option for those who prioritize endurance.

Many used fleet vehicles with these engines are still working today, a testament to the engineering choices that emphasized durability over complexity. For many managers, this engine is synonymous with dependability.

4. Isamara JX12 Medium-Duty Diesel

The Isamara JX12 serves as a benchmark for medium-duty trucks that perform a combination of city and regional tasks.

This engine’s strength lies in its balanced approach: compact enough for maneuverable chassis but powerful enough to haul moderate loads consistently.

Fleet managers value its fuel economy and predictable maintenance pattern. The JX12 was designed to simplify access to critical service points, which means less downtime during oil and filter replacements.

Internally, the JX12 uses a reinforced crankcase and precision-forged connecting rods to manage high compression cycles without fatigue. Its electronically controlled common-rail system ensures even fuel distribution, keeping combustion smooth and efficient.

This not only improves performance but also prevents soot buildup that could otherwise shorten the engine’s life. Many fleet technicians find that after 400,000 miles, the JX12 still maintains excellent compression readings and minimal oil consumption.

Another strong feature is the engine’s advanced cooling circuit. The water pump, thermostat, and radiator layout are optimized for consistent temperature regulation even in stop-and-go conditions. This prevents heat soak, a common cause of premature engine wear.

Fleet managers often highlight that the JX12 can idle for long periods without overheating, which makes it perfect for delivery vehicles operating in urban traffic.

The JX12’s design philosophy focuses on operational balance rather than extremes. It doesn’t aim for record-breaking horsepower but instead delivers predictable performance for hundreds of thousands of miles. Its consistent reputation across various fleets demonstrates that a well-built medium-duty engine can be both economical and remarkably durable.

5. Catmar C9 Industrial Diesel

The Catmar C9 engine has a long history of serving in both construction equipment and heavy vocational trucks. Its heritage of ruggedness carries over into fleet vehicles that require both torque and endurance.

Fleet managers who handle mixed-use operations, such as dump trucks, flatbeds, and service rigs, often rely on the C9 for its resilience under heavy strain. The engine’s design emphasizes overbuilt components and conservative performance settings.

Inside the C9, the combination of a strong camshaft design and large bearing surfaces contributes to its longevity. It operates at relatively low RPMs, which significantly reduces frictional stress.

Mechanics appreciate the accessibility of the timing components and injectors, as they can be serviced without removing major assemblies. This keeps maintenance quick and costs predictable, two essential concerns in fleet operations.

Another area where the C9 shines is its ability to handle varying fuel qualities. In many fleet environments, diesel storage and distribution conditions are not always ideal.

The C9’s robust filtration and injection systems tolerate minor impurities without long-term harm. That adaptability is part of why it maintains a strong reputation for crossing the 400,000-mile threshold with minimal downtime.

The C9 embodies the philosophy of strength through simplicity. Its straightforward layout and proven construction make it one of the most trusted engines for fleets operating in demanding environments. For fleet managers, the C9 represents peace of mind: an engine that can take abuse and keep working day after day.

6. Naviron XH13 Long-Haul Diesel

The Naviron XH13 has become a favorite among long-haul operators who demand both stamina and efficiency.

Fleet managers respect it for its ability to sustain strong pulling power while keeping fuel consumption within manageable limits. Designed for Class 8 tractors, the XH13 thrives on consistency rather than extremes.

It’s not an engine that boasts the highest output figures on paper, yet in real-world service, it proves itself year after year by completing extended runs without complaint.

Many fleets that focus on coast-to-coast routes trust this engine to deliver on-time performance under heavy loads. Its large displacement combined with refined combustion control provides a stable, predictable driving experience that minimizes driver fatigue.

The XH13’s design philosophy centers around steady thermal management. By optimizing coolant flow and integrating a multi-stage oil filtration system, Naviron engineers ensured that every major component stays protected under continuous load.

Even after days of uninterrupted operation, the engine maintains stable temperatures, preventing heat-related wear that can shorten lifespan.

Mechanics appreciate the smart layout of sensors and service ports, which allows for quick diagnostics. Fleet managers often note that this engine’s self-monitoring systems can alert operators early to small issues, allowing preventive maintenance before costly breakdowns occur.

Another strength of the XH13 lies in its gear-driven accessories and reinforced timing mechanism. This configuration reduces dependency on belts and minimizes slippage, improving reliability.

Fleet technicians frequently report that after 400,000 miles, internal inspections reveal little scoring on cylinder walls and consistent compression across all cylinders.

The turbocharger’s efficiency remains strong when serviced correctly, maintaining boost levels that promote both fuel economy and responsive acceleration.

The XH13’s components are also designed to be replaced individually, avoiding the need for large assembly swaps and saving fleets substantial money.

In fleet circles, the Naviron XH13 has earned a reputation as an engine that simply refuses to quit. It combines old-fashioned toughness with modern electronic control precision, resulting in a powerplant that performs well under demanding conditions.

With disciplined maintenance and the use of high-quality lubricants, it routinely surpasses its rated service life.

For many fleet managers, it represents a fine balance between cost, reliability, and total mileage capability, making it a cornerstone for long-haul operations that aim to keep trucks on the road for decades.

7. Hinoza HD10 Straight-Six Diesel

The Hinoza HD10 Straight-Six engine represents the kind of mechanical reliability that earns quiet respect rather than flashy headlines.

It is popular among fleets running box trucks, municipal vehicles, and regional haulers. The HD10’s inline-six configuration gives it natural balance, resulting in smooth operation and reduced vibration throughout the driveline.

Fleet managers appreciate this smoothness because it translates into less stress on mounts, transmissions, and accessories.

Vehicles equipped with this engine are known to maintain tight tolerances and minimal component fatigue even after years of daily operation.

One reason the HD10 consistently reaches and surpasses the 400,000-mile mark lies in its oiling system. The engine uses a high-capacity pump and deep-sump design that keeps oil pressure stable during steep climbs or extended idling. Even under heavy payloads, oil starvation is virtually nonexistent.

This consistent lubrication is key to long-term reliability. Many fleet technicians also praise the HD10 for its accessibility.

Routine service points such as filters, injectors, and coolant lines can be reached without major disassembly. That reduces service time and ensures that trucks spend more hours working rather than waiting for parts.

The HD10 is also known for its fuel efficiency, which helps offset its initial purchase cost. Its electronically managed injection system maintains optimal combustion across different load conditions. This consistency not only improves fuel economy but also limits carbon buildup inside the combustion chambers.

Cleaner combustion leads to fewer mechanical problems and keeps the exhaust system functioning effectively. Managers who oversee large fleets often mention that this engine’s predictable fuel and maintenance records simplify budget forecasting over multi-year contracts.

Another valuable trait of the HD10 is its resilience to varied environments. Whether operating in hot urban conditions or cold mountain climates, it maintains steady output.

The cooling and intake systems are designed to adapt quickly to changes in ambient temperature and air density.

This adaptability helps prevent performance dips and excessive wear. Over time, that translates to an engine that can endure diverse routes and operating styles without premature aging.

The Hinoza HD10 earns its place among fleet favorites not by bold marketing but by quietly performing its job mile after mile.

8. Paccor PX9 Integrated Diesel

For fleets that value balance between power and emissions compliance, the Paccor PX9 has become a practical choice. It powers a variety of vocational trucks, buses, and delivery vehicles.

Fleet managers often describe it as an engine that bridges the gap between traditional toughness and modern environmental standards.

The PX9’s success is largely due to its combination of compact design and robust output. Despite its moderate size, it consistently delivers enough torque to manage demanding duty cycles, while maintaining the efficiency that modern fleets demand.

When maintained properly, the PX9 commonly passes 400,000 miles without requiring major component replacement.

Internally, the PX9 utilizes a precision-machined cylinder head and high-strength pistons designed to handle higher injection pressures.

This allows complete combustion, reducing soot formation and lowering wear on internal surfaces. The cooling system includes dual thermostatic control, ensuring rapid warm-up in cold climates and steady cooling under high loads.

Fleet technicians note that the engine’s coolant channels are easy to flush, preventing sediment buildup that often shortens the life of competing engines.

Maintenance procedures are streamlined with digital diagnostic tools, making it easier for shop technicians to identify issues before they become serious.

The PX9’s integration with automated transmissions has further boosted its reputation among fleet managers. The communication between the engine’s control module and transmission system ensures smooth gear transitions, which reduces shock loads.

Over the lifespan of a vehicle, this integration can prevent transmission wear and extend clutch life. The result is a drivetrain that feels cohesive and minimizes mechanical stress across multiple systems.

Fleets that operate in mixed-duty cycles appreciate this harmony because it supports both stop-and-go urban driving and long, steady highway cruising.

The PX9’s long-term dependability is supported by strong manufacturer backing and the wide availability of service parts.

Fleet operators can source components without extended wait times, which is vital for maintaining uptime. Because of this, many fleet managers standardize their trucks around the PX9 to simplify maintenance logistics and inventory.

This engine demonstrates that modern design, when combined with robust build quality, can meet stringent performance expectations and still deliver the mileage endurance that professional fleets require.

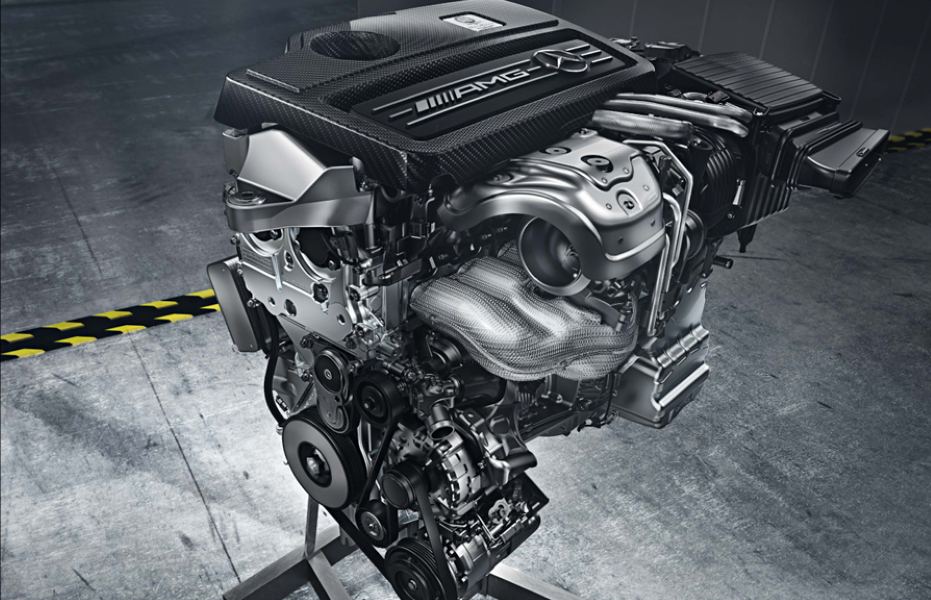

9. Mercedes-Omech 470 BlueTorque Diesel

Among imported heavy-duty options, the Mercedes-Omech 470 BlueTorque engine has earned admiration for its sophisticated engineering and impressive service life. Known for powering both European and North American trucks, it combines refined technology with robust mechanical architecture.

Fleet managers who run long-distance transport operations praise it for its smoothness and predictable torque delivery.

The BlueTorque 470’s design emphasizes efficiency without sacrificing strength, allowing it to meet tough emission standards while still achieving 400,000 miles and beyond with disciplined maintenance routines.

The BlueTorque 470 features a lightweight yet durable aluminum head paired with a cast-iron block for optimal heat management.

This design minimizes stress on the gasket surfaces and keeps combustion chambers evenly cooled. The result is reduced risk of warping and gasket failure, even under continuous load.

Mechanics often remark on how little sludge or carbon residue builds up inside the intake system after extended operation, thanks to the precision fuel delivery and controlled burn cycle. This clean operation helps maintain consistent power output throughout the engine’s life.

A standout characteristic of the BlueTorque 470 is its advanced turbocharging system. It employs a variable-geometry setup that adjusts boost pressure based on demand, improving both fuel efficiency and throttle response.

This system not only enhances driving comfort but also reduces strain on pistons and rods by maintaining steady pressure levels.

Fleet technicians appreciate that this turbo system is easily accessible for service, avoiding the complex disassembly that plagues some other models. The combination of advanced technology and service-friendly design makes this engine a practical choice for demanding fleets.

Beyond its mechanical reliability, the BlueTorque 470 also stands out for its long oil change intervals. With proper synthetic lubricants, some fleets extend service cycles up to 40,000 miles without compromising internal health. That kind of maintenance flexibility greatly improves operational efficiency.

Drivers also report lower vibration levels, which reduce fatigue during long hauls. Taken together, these characteristics explain why many fleets choose the Mercedes-Omech 470 when the goal is a balance of refinement, endurance, and total cost efficiency over hundreds of thousands of miles.

10. VolvoMax D13 Efficiency Diesel

Rounding out the list is the VolvoMax D13 Efficiency Diesel, an engine that has earned recognition for combining durability with cutting-edge technology. It is a mainstay among large fleets that prioritize total operating cost control and long-range dependability.

The D13’s architecture was designed from the start with 400,000-mile service in mind. Everything from its cooling system layout to its piston coating materials was engineered for endurance.

Fleet managers appreciate how this engine pairs efficiency with mechanical simplicity, providing the kind of reliability that builds trust between operators and their equipment.

The D13 employs a high-pressure common-rail fuel system that ensures complete and consistent combustion across all cylinders. This precision fuel control minimizes soot buildup, leading to cleaner exhaust flow and longer-lasting emission components.

The cooling system uses a cross-flow design that evenly distributes temperature across the head and block, reducing hotspots that often cause cracking in lesser engines.

Mechanics who work with the D13 often remark that even after extensive use, internal wear is remarkably uniform, showing that the engine maintains balance and stability deep into its service life.

Another key advantage of the D13 is its integrated engine brake, which reduces dependence on service brakes during downhill operation. This feature not only enhances safety but also reduces wear on braking systems, saving fleets thousands in replacement costs over the years.

The D13’s strong torque at low RPM allows trucks to climb steep grades without frequent gear changes, easing strain on the transmission and differential.

This synergy between engine and drivetrain helps vehicles maintain peak mechanical condition over extended periods.

Fleet managers also favor the D13 for its diagnostic support. The engine’s control software records detailed performance data that can be analyzed to detect early signs of trouble.

Predictive maintenance programs built around these data points help fleets plan service schedules with precision.

This proactive approach minimizes downtime and prevents unexpected failures. Many fleets running D13-powered trucks report vehicles reaching 500,000 miles with only routine servicing.

It stands as a clear example of how thoughtful engineering and real-world practicality can coexist in a long-lasting engine.