European automotive engineering has long been celebrated for its innovation, precision, and performance. While the continent is home to some of the most famous engines in history, such as the Ferrari V12s or the Porsche flat-sixes, there exists a quieter, yet equally fascinating, collection of powerplants that often go unnoticed.

These engines may not have the flashiest reputation, but they possess qualities that enthusiasts and mechanics alike can respect. From small displacement units with remarkable efficiency to mid-century designs that influenced future generations, Europe has a rich history of underappreciated engineering achievements.

Understanding these engines provides insight into the ingenuity and adaptability that European manufacturers have consistently demonstrated. Many of these units were built for longevity and reliability, yet they also offered surprising performance when properly tuned.

Their understated presence does not diminish their technical brilliance. The combination of innovative design, clever packaging, and practical performance means that these engines deserve more attention than they typically receive.

Overlooked European engines can also teach lessons about automotive evolution, highlighting how small changes in materials, layout, or timing mechanisms led to significant improvements in efficiency and power delivery.

Whether it is a compact four-cylinder that powered a city car or a robust inline-six that drove a luxury sedan, each engine reflects a particular approach to solving the challenges of automotive propulsion.

These engines were often ahead of their time, incorporating features such as lightweight alloys, advanced valve timing, or modular construction. Enthusiasts who seek to explore European engineering beyond the obvious icons will find these engines a source of fascination.

They illustrate that performance is not only measured in raw output but also in reliability, refinement, and adaptability. By examining these overlooked engines, one can appreciate the broader scope of European automotive culture, where clever engineering often overshadowed flashy marketing.

This article highlights ten engines that may have slipped under the radar but deserve recognition for their technical merits, historical significance, and enduring influence. These powerplants represent the quiet backbone of Europe’s automotive industry, showing that innovation was not limited to supercars or luxury models.

Each entry will provide a detailed look at the design philosophy, engineering features, and practical applications that made these engines remarkable.

From their mechanical layout to their impact on the vehicles they powered, these engines exemplify the depth and creativity of European engineering.

Enthusiasts, mechanics, and historians alike can gain a renewed appreciation for these machines and the minds that brought them to life. This list is not just a catalog of engines; it is a tribute to thoughtful design and the enduring legacy of European automotive ingenuity.

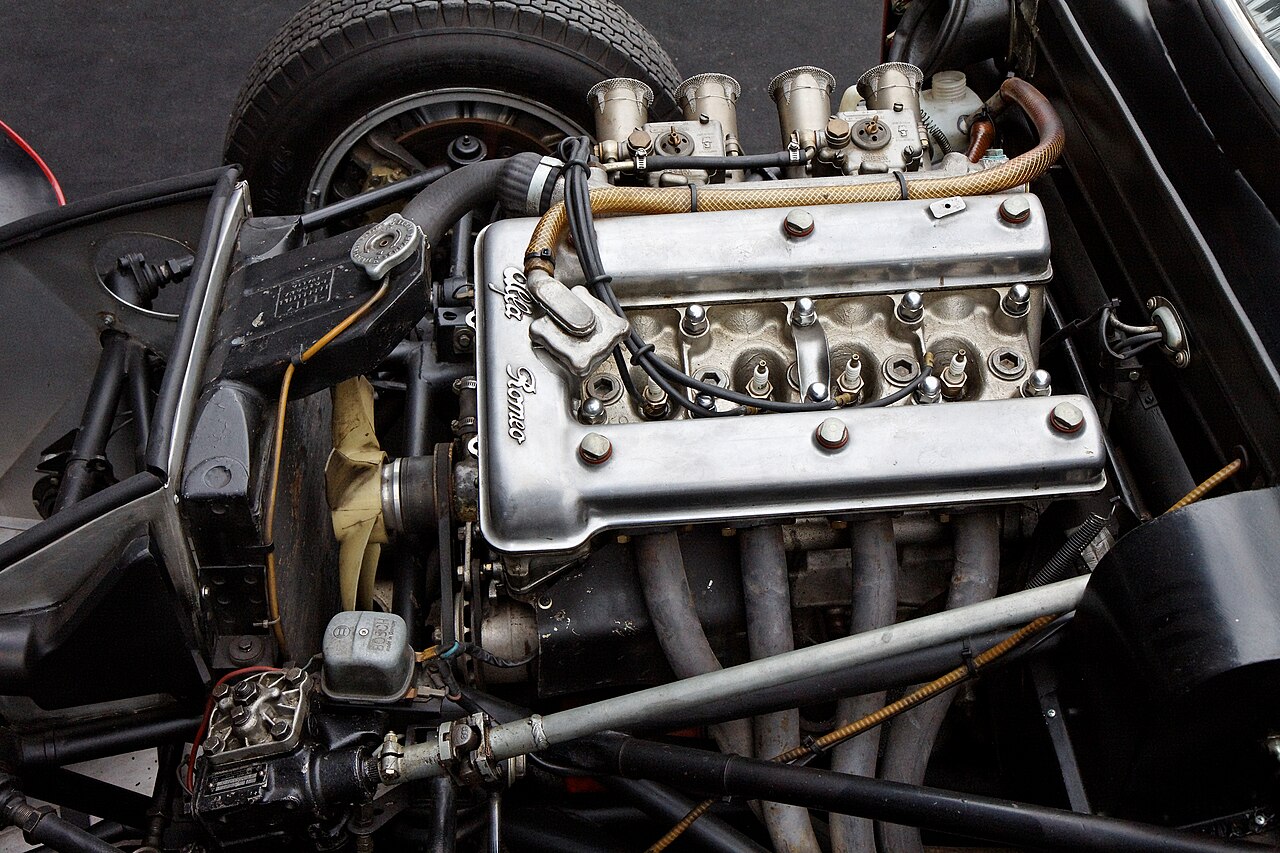

Alfa Romeo Twin Cam Engines

The Alfa Romeo Twin Cam engine was introduced in the late 1950s and quickly gained a reputation for its precision engineering. Its dual overhead camshaft layout was uncommon at the time, especially for production cars.

This design allowed for higher rev limits and better breathing, giving small engines impressive performance. Alfa Romeo used these engines in various models, from the Giulietta to the Spider, demonstrating versatility and reliability.

Lightweight construction was a hallmark of the Twin Cam series. Aluminum alloy cylinder heads reduced engine weight while improving heat dissipation. The engine also featured hemispherical combustion chambers, which optimized airflow and combustion efficiency.

Despite their small displacement, these engines could produce lively acceleration, making them popular among drivers seeking spirited performance. Alfa Romeo’s attention to detail extended to the use of high-quality bearings and precision-machined components.

This contributed to long engine life when properly maintained, further distinguishing the Twin Cam series from many contemporary competitors.

The Twin Cam engines underwent continuous refinement over the years. Variants included changes in bore, stroke, and carburetion setups to meet evolving performance demands. Some models incorporated fuel injection, enhancing efficiency and reliability.

These engines became a benchmark for small performance engines and influenced future Alfa Romeo designs. Enthusiasts often praise the sound produced by the Twin Cam, which was distinct and aggressive, highlighting the engineering care in valve timing and intake design.

Maintenance and tuning were straightforward for experienced mechanics, which contributed to the engine’s enduring popularity. Rebuild kits and performance upgrades remain widely available, allowing restoration or modification projects.

Owners could increase displacement, upgrade carburetors, or add camshaft modifications to extract additional power. The ease of tuning, combined with a robust foundation, ensured that the Twin Cam engines remained relevant for decades.

Even today, Alfa Romeo Twin Cam engines retain a loyal following. Classic car communities celebrate their performance potential and engineering elegance. They stand as a testament to a time when small engines were designed to be both spirited and mechanically robust.

Collectors and restorers appreciate these engines not only for their historical significance but also for the joy they deliver behind the wheel. The Twin Cam represents an overlooked European engine that deserves widespread respect.

Peugeot XU Series Engines

Peugeot introduced the XU series in the early 1980s, and it quickly became a versatile powerplant across multiple models. This family of inline-four engines ranged from 1.6 to 2.0 liters, offering a balance of performance and reliability.

The XU engines were designed for efficiency, yet they could provide spirited driving dynamics when properly tuned. They were used in vehicles from the compact 205 to larger sedans, showcasing their adaptability.

The engineering behind the XU series focused on compactness and durability. Lightweight materials and optimized cooling pathways reduced thermal stress and improved fuel economy. Timing systems were precise, and later variants incorporated fuel injection for more consistent power delivery.

Many enthusiasts were surprised by the performance potential of the XU, especially in naturally aspirated form. Despite modest displacement, these engines could achieve competitive power output thanks to efficient airflow and combustion design.

Performance upgrades for the XU series were common in motorsports. Rally teams often relied on these engines for reliability and responsiveness in challenging conditions. Adjustable camshafts, improved exhaust manifolds, and lightweight internals allowed the XU to be competitive in lightweight racing applications.

The engine’s modular design made it easy to swap components or enhance performance without extensive modifications. This adaptability contributed to the series’ long production life and popularity among private teams.

Reliability was another strength of the XU series. With regular maintenance, these engines could last for hundreds of thousands of kilometers.

Parts availability remained strong due to widespread use, and the engines were known for handling both urban commuting and spirited driving without significant issues.

This balance of durability and performance made the XU series a quiet success story in European automotive engineering.

The Peugeot XU engines are now appreciated for their engineering foresight and versatility. While not as famous as Italian or German engines, they provided a strong foundation for everyday driving and motorsport alike.

Enthusiasts value them for ease of maintenance, potential for tuning, and historical significance. The XU series stands as a reminder that clever design and thoughtful engineering can produce an engine that outperforms its reputation.

Fiat FIRE Engine Family

The Fiat FIRE engine, which stands for Fully Integrated Robotized Engine, debuted in the mid-1980s and represented a leap forward in mass-production efficiency.

Designed for small cars, the FIRE engines prioritized simplicity, reliability, and ease of manufacture.

Despite being compact, these engines offered reasonable power output and excellent fuel economy. Over the years, they evolved with changes in valve timing, fuel injection, and emission control systems.

The engineering focus of the FIRE series was modularity. The engines shared a common architecture across multiple displacements, which simplified production and reduced costs. Aluminum construction reduced weight, and components were designed for longevity.

The balance of efficiency and durability made the FIRE series particularly well-suited for city cars, yet its performance capabilities allowed for sporty variants in small Fiat models.

Performance enthusiasts found ways to extract more power from FIRE engines through tuning. Lightweight internals, upgraded camshafts, and turbocharging were common modifications.

Despite being overlooked in favor of larger engines, the FIRE series offered impressive potential for compact performance applications.

Its small size and low weight contributed to handling dynamics in vehicles, making it a favorite among drivers seeking nimble performance without high fuel costs.

Many early examples remain in daily use, demonstrating the durability of the design. Ease of maintenance and the wide availability of spare parts have contributed to the FIRE’s reputation as a reliable engine. Owners often praise its robustness and adaptability, as the design could withstand modifications while maintaining reliability.

Today, the Fiat FIRE engine is recognized by enthusiasts for its blend of simplicity, performance potential, and longevity.

Its influence on compact car design remains significant, and it stands as a model for producing practical yet tunable engines. The FIRE series proves that thoughtful engineering in smaller engines can leave a lasting impact and earn the respect of drivers and mechanics alike.

Volvo Redblock Engines

Volvo’s Redblock series became a staple of the brand during the 1970s and 1980s, powering everything from sedans to wagons. These inline-four engines were named for their red-painted engine blocks and were renowned for reliability and durability.

Their simple design emphasized robustness over outright performance, but they offered steady torque delivery and surprisingly long life spans. The engines could handle high mileage with minimal issues, making them ideal for daily driving and long-distance travel.

The Redblock engines incorporated a cast-iron block with aluminum heads, balancing strength and heat dissipation. Timing belts were used for camshaft operation, which required routine maintenance but were easy to service.

These engines were designed to withstand harsh conditions, including cold climates and frequent stop-and-go driving. This ruggedness contributed to Volvo’s reputation for practical, dependable engineering that prioritized safety and longevity.

Fuel injection was added to later versions of the Redblock, improving efficiency and throttle response. The engines were naturally aspirated or turbocharged in some models, with the turbo variants offering spirited performance in the 700 and 900 series.

These engines demonstrated that a conservative approach to design could still produce enjoyable driving characteristics, particularly in long, comfortable European sedans.

Enthusiasts appreciate the Redblock for its tuning potential. Turbocharged versions can be modified to extract significantly more power, while naturally aspirated variants respond well to head and cam upgrades.

Their straightforward design means that even complex modifications are manageable, and the engines maintain their reliability if upgrades are done sensibly. Redblock engines have often been the choice of DIY mechanics and tuners seeking robust performance.

Today, Volvo Redblock engines are celebrated as some of the most durable European powerplants. Cars equipped with these engines can exceed 300,000 kilometers with routine maintenance, a testament to their over-engineered design.

While they lack the glamour of exotic European engines, their consistent performance, reliability, and tuning potential earn them enduring respect among enthusiasts and collectors.

Renault Cléon-Fonte Engine

The Renault Cléon-Fonte engine, introduced in 1962, was a foundational engine for the French manufacturer, powering cars for decades. Its inline-four layout was simple and reliable, yet it offered opportunities for modification and performance improvements.

Small displacement variants were efficient, while larger versions delivered adequate power for family vehicles. The engine’s longevity made it a mainstay of Renault’s production, appearing in models ranging from the R8 to the early R19.

Design simplicity was key to the Cléon-Fonte’s success. Cast-iron blocks ensured strength and durability, while overhead valves allowed for straightforward maintenance. The engine was designed to be inexpensive to manufacture and repair, making it accessible to a wide range of drivers.

Despite its utilitarian nature, clever engineering allowed it to deliver smooth and consistent power. This balance between cost-efficiency and mechanical reliability was characteristic of Renault’s approach during the mid-20th century.

Over the years, the Cléon-Fonte was adapted for various performance applications. Motorsport versions featured higher compression ratios, improved carburetion, and lightweight components to maximize output.

Rally teams occasionally favored this engine for small competition cars, highlighting its adaptability. Its compact size and low weight contributed to agile handling in small vehicles, showing that even modest engines could deliver engaging driving experiences.

Reliability remained a defining feature of the Cléon-Fonte. With proper lubrication and timing adjustments, these engines could last well over 200,000 kilometers. Replacement parts were abundant, and the engine’s simple construction made it accessible for amateur mechanics.

This combination of longevity, efficiency, and ease of repair contributed to its reputation as a workhorse of European motoring.

The Cléon-Fonte engine’s influence extended beyond its production life. Its engineering principles informed later Renault designs, including overhead cam units that benefited from lessons learned in durability and efficiency.

Today, enthusiasts recognize the Cléon-Fonte not only for its historical importance but also for its surprising performance potential when upgraded. Its understated reliability earns it a quiet place among Europe’s respected engines.

BMW M20 Engines

BMW’s M20 engine family, introduced in 1977, became a benchmark for smooth and reliable inline-six powerplants. These engines were used in a variety of sedans and coupes, delivering a balance of performance and refinement.

With a focus on even torque delivery and responsive throttle behavior, the M20 proved that inline-six engines could excel in both everyday driving and spirited situations. Lightweight construction and precise engineering helped BMW maintain a reputation for driving enjoyment.

The M20 employed an aluminum head over a cast-iron block, allowing for durability without excessive weight. Single overhead camshaft designs were used in early versions, with subsequent models adding fuel injection for efficiency and emissions compliance.

The engine layout prioritized smoothness, with evenly spaced firing intervals and minimal vibration. This refinement made the M20 a preferred choice for executive and sports sedans, blending comfort with a sporty feel.

Tuning potential for the M20 was significant, especially in naturally aspirated models. Performance enthusiasts could increase displacement, upgrade camshafts, or install performance exhausts to extract more power.

Turbocharging conversions were also possible, turning a reliable daily driver engine into a spirited track-capable unit. Its mechanical simplicity made it easier to modify without sacrificing long-term reliability.

Maintenance of the M20 was straightforward for skilled mechanics. Timing belts, valve adjustments, and cooling system upkeep were essential but manageable, allowing engines to survive hundreds of thousands of kilometers with proper care. This reliability, combined with smooth performance, contributed to the M20’s reputation as one of BMW’s most enduring engines.

Today, the BMW M20 is respected for its balance of refinement, reliability, and tuning potential. Classic BMW enthusiasts often seek these engines for restoration projects or performance builds, appreciating their engineering sophistication. The M20 proves that understated design and smooth execution can create a powerplant worthy of admiration alongside more famous European engines.

Mercedes-Benz M102 and M103 Engines

Mercedes-Benz produced the M102 and M103 engines during the 1980s and early 1990s as part of its inline-four and inline-six family. These engines were engineered for reliability, smooth operation, and consistent performance, aligning with Mercedes’ reputation for solid construction.

While not as celebrated as high-performance AMG variants, they powered sedans and coupes with competence, offering dependable torque and minimal maintenance issues.

The M102 and M103 featured cast-iron blocks with aluminum heads, a common design choice for balance between durability and weight. Overhead camshafts allowed for improved efficiency and smooth airflow.

Early carbureted versions gave way to fuel-injected models, enhancing emissions performance and reliability. These engines were designed to deliver refinement rather than outright power, making them ideal for luxury sedans that required quiet and consistent operation.

Durability was a hallmark of the Mercedes engines. They could reach extremely high mileage when properly maintained, with many examples still running today.

Components were engineered to handle sustained stress, and maintenance procedures were accessible for skilled owners. Even under heavy urban or highway use, the engines retained their integrity and performance, emphasizing Mercedes’ conservative yet effective engineering philosophy.

Performance tuning was not common, but the M102 and M103 offered potential for enthusiasts who understood the engines.

Head and cam modifications could slightly increase output, and naturally aspirated variants could handle mild forced induction upgrades. While not extreme performers, these engines provided a stable platform for modest performance enhancements without compromising reliability.

Today, the M102 and M103 engines are appreciated by collectors and restorers who value engineering consistency and longevity.

Their understated strength and smooth performance have earned them respect as some of the most reliable European engines of their era. Enthusiasts admire these engines not for fame but for their quiet contribution to Mercedes’ reputation for durable, dependable cars.

Audi Five-Cylinder Engines

Audi’s five-cylinder engines first appeared in the late 1970s and quickly gained a reputation for smooth power delivery and distinctive sound. The unusual layout offered a compromise between the compactness of a four-cylinder and the smoothness of a six-cylinder.

These engines powered a variety of vehicles, including sedans, coupes, and early Quattro models, demonstrating their versatility. Despite their unique configuration, they proved reliable and capable of spirited driving.

Engineering these engines required careful balancing due to the inherent asymmetry of five cylinders. Audi used precise crankshaft and counterweight designs to minimize vibration while maximizing torque output.

The engines combined aluminum heads with cast-iron blocks, optimizing durability and weight. Fuel injection was gradually adopted, improving efficiency and reducing emissions without compromising performance. This combination of reliability and innovation made the five-cylinder a technical success.

Turbocharged variants of the five-cylinder engine became legendary in motorsports. Rally teams exploited their torque and responsiveness, particularly in the Quattro system, where all-wheel drive enhanced traction.

Enthusiasts could also modify naturally aspirated versions, installing higher-performance camshafts or intake systems to improve breathing. The engines’ adaptability in both street and competition applications demonstrated their engineering sophistication.

Maintenance was straightforward for the mechanically inclined. Valve adjustments, timing belt changes, and turbo upgrades were well-documented, making these engines accessible for restoration or tuning projects.

The balance of durability and performance meant the engines could survive long-term ownership while remaining enjoyable to drive. Their distinctive growl and smooth midrange torque remain a highlight for classic Audi fans.

Audi’s five-cylinder engines continue to inspire admiration among enthusiasts. Their combination of engineering innovation, motorsport heritage, and everyday reliability makes them deserving of respect.

Even today, these engines are celebrated for their character, longevity, and the clever approach to solving the challenge of combining power and smoothness in a compact package.

Lancia Lampredi Engines

Lancia’s Lampredi engines were developed in the post-war era and became a cornerstone of Italian engineering for decades.

Designed primarily for racing and performance applications, they featured innovative layouts for their time, including large bore-to-stroke ratios and advanced combustion chamber design. While not widely recognized outside Italy, these engines contributed significantly to motorsport success and technical development within Lancia’s lineup.

The Lampredi design emphasized airflow and high-revving potential. Aluminum components and precise machining allowed the engines to operate efficiently at high speeds.

Overhead valve and dual overhead camshaft versions offered flexibility for both road and racing applications. These engines were robust despite their performance focus, demonstrating Lancia’s ability to balance competition demands with reliability.

In motorsports, Lampredi engines powered various Lancia rally and sports cars to success. Engineers continually refined port shapes, valve timing, and ignition systems to extract maximum power. Small-displacement variants could achieve surprisingly high outputs, proving that careful design could compensate for limited capacity. Their reputation for performance extended into road-going models, where enthusiasts appreciated spirited driving dynamics.

Maintenance and tuning were feasible for knowledgeable mechanics. While precision was required for racing variants, road engines could be serviced with standard tools. Rebuilds and performance upgrades remained practical due to modular design, making these engines popular among private racers and classic car restorers. Their reliability combined with tunability added to their enduring appeal.

Today, Lancia Lampredi engines are valued for their historical importance and technical innovation. Their contributions to rallying and sports car engineering have earned them recognition among enthusiasts who appreciate engineering excellence beyond mainstream fame. These engines exemplify how focused design can achieve remarkable results even in overlooked European powerplants.

Volkswagen VR Engines

Volkswagen’s VR engines represent one of the most innovative solutions to packaging constraints in the automotive world. First appearing in the late 1990s, the VR6 design allowed six cylinders to be fitted into a narrow engine bay with minimal width.

This compact arrangement combined aspects of inline and V configurations, providing smooth performance while maintaining space efficiency. These engines powered sedans, hatchbacks, and performance models, demonstrating practical versatility.

Engineering the VR6 required ingenuity. The narrow-angle V layout allowed a single cylinder head to cover both banks, reducing complexity and weight. Overhead camshafts and optimized intake and exhaust pathways improved airflow and combustion efficiency. Despite the unconventional configuration, the VR6 delivered linear torque and surprisingly refined performance for its size. This innovation made it a favorite for enthusiasts seeking power without a traditional large six-cylinder footprint.

Turbocharged versions of the VR engines offered significant performance improvements. These variants could deliver rapid acceleration and spirited driving dynamics, while naturally aspirated versions remained smooth and reliable. The combination of compact design, high output, and ease of installation in existing models demonstrated Volkswagen’s clever approach to balancing performance and practicality.

Maintenance of VR engines was manageable for skilled mechanics. Their long service life, coupled with enthusiastic aftermarket support, made them attractive for both street and tuning applications. Owners appreciated the balance between reliability and the distinctive VR6 sound and character.

Today, VR engines are respected for their engineering ingenuity. Their combination of space-efficient design, performance potential, and reliability ensures a lasting legacy. Volkswagen proved that unconventional thinking could produce engines that excel in real-world use while appealing to enthusiasts who value both practicality and performance.