Modern internal combustion engines have evolved significantly over the last century, with engineers constantly balancing power, efficiency, and emissions.

While most drivers expect engines to burn fuel efficiently and keep oil consumption minimal, there exists a unique category of engines designed to intentionally consume some oil during operation.

This phenomenon often surprises car enthusiasts who assume oil burning is always a sign of mechanical trouble. Understanding why certain engines burn oil by design requires a closer look at combustion processes, lubrication strategies, and emission requirements.

In these engines, controlled oil consumption helps maintain proper lubrication under extreme temperatures and pressures.

Some high-performance engines rely on a thin film of oil on cylinder walls to reduce friction and wear, ensuring longevity under racing conditions.

Turbocharged units often use oil for both cooling and sealing purposes, especially around the turbocharger’s bearings.

By allowing limited oil consumption, manufacturers can achieve higher performance outputs without compromising reliability, even if it slightly increases maintenance requirements.

Another factor influencing intentional oil burning is emission control. Some engines are engineered to consume oil to minimize particulate buildup or prevent carbon deposits in critical areas like intake valves.

Modern emission regulations have pushed engineers to balance hydrocarbon emissions with particulate matter, leading to carefully calibrated oil consumption patterns.

In some diesel engines, for example, small amounts of oil are burned to ensure proper operation of particulate filters and maintain emission standards.

This design choice, while counterintuitive to everyday expectations, is a necessary compromise between performance, efficiency, and environmental compliance.

Furthermore, oil-burning engines often appear in motorcycles, sports cars, and certain turbocharged vehicles where extreme thermal conditions demand advanced lubrication. These engines are typically built with tighter tolerances, high-revving characteristics, and advanced metallurgy.

As a result, the controlled burning of oil helps protect critical components such as piston rings, valve guides, and turbochargers. While this design can lead to increased oil consumption, it prevents catastrophic engine damage and ensures consistent performance over the long term.

Lastly, understanding these engines requires considering both the engineering rationale and practical ownership implications. Car owners may notice slightly higher oil consumption in such vehicles, but it is usually within manufacturer specifications.

Awareness of oil consumption patterns, regular maintenance, and using manufacturer-recommended oils are key factors in ensuring engine longevity. By appreciating the intentional role of oil consumption in these modern engines, drivers can better understand the balance between mechanical durability, performance, and regulatory requirements.

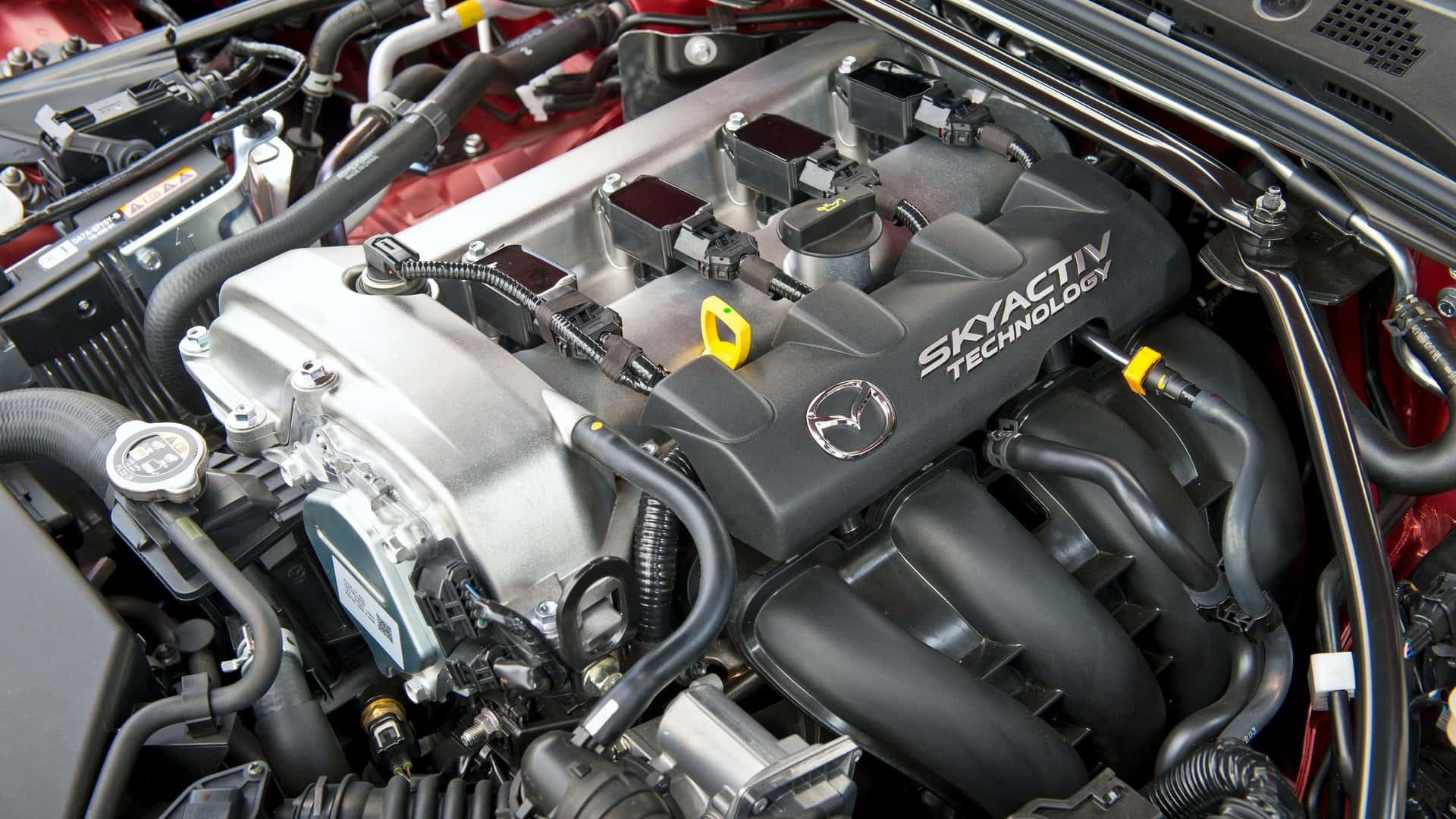

1. Mazda Skyactiv-G Engine

The Mazda Skyactiv-G engine is known for combining fuel efficiency with performance. While it burns very little oil compared to older engines, it is designed to allow controlled oil consumption under specific conditions.

The design helps maintain a thin lubrication film on the cylinder walls during high-compression operation. This prevents friction between the pistons and cylinder surfaces, which can extend the life of the engine considerably.

Mazda’s engineers achieved this balance through high compression ratios and advanced direct injection systems. The tight tolerances within the cylinder require careful lubrication to avoid scoring or wear.

By allowing a small amount of oil to enter the combustion chamber, the engine maintains an effective friction-reducing layer. Drivers may notice minor oil consumption, but it is part of the design rather than a mechanical fault.

Another benefit of controlled oil burning in this engine is improved thermal management. The combustion chamber can reach very high temperatures, and oil that enters the chamber helps cool critical components.

This controlled oil use ensures the pistons and valves operate within safe temperature limits. Without this mechanism, high-compression engines could develop premature wear or even catastrophic failures.

The Skyactiv-G’s valve system also benefits from intentional oil consumption. Oil reaching the valve guides ensures smooth operation, reducing the risk of sticking or excessive wear.

This contributes to both performance consistency and long-term durability. The design reflects a holistic approach to engine reliability and efficiency.

For Mazda owners, monitoring oil levels remains essential. While consumption is expected, maintaining proper oil levels ensures that the engine operates correctly and meets performance expectations. Using recommended oils and checking levels regularly prevents potential damage from low lubrication.

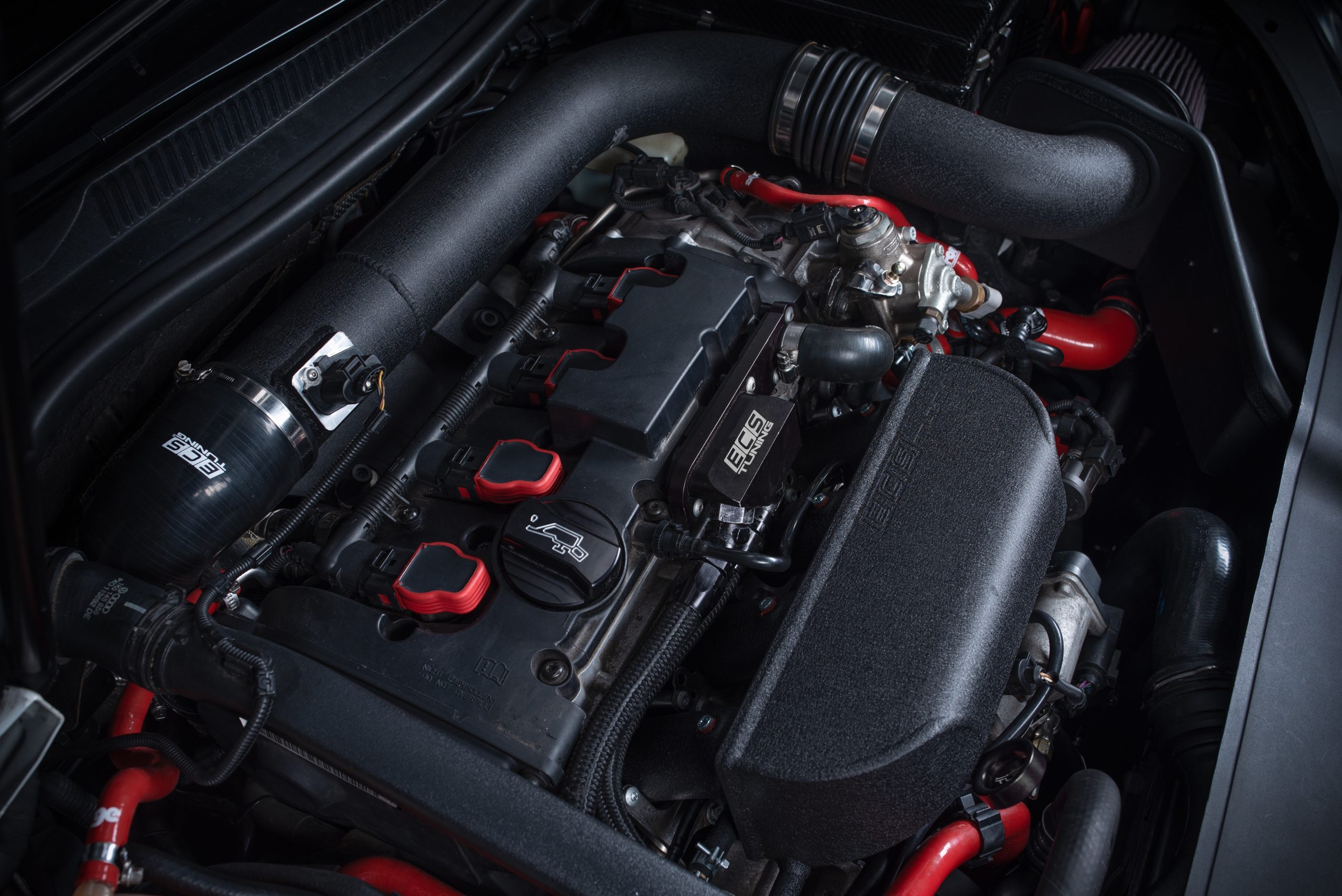

2. BMW N54 Engine

The BMW N54 is a twin-turbocharged engine that gained fame for its performance and tunability. One of its characteristic traits is slight oil consumption during operation.

This behavior results from its high-pressure turbochargers and direct injection system. By allowing controlled oil burning, the engine ensures adequate lubrication of the turbocharger bearings and piston rings under heavy loads.

BMW designed the N54 with precision machining and tight tolerances. These specifications necessitate a small amount of oil entering the combustion chamber to maintain lubrication consistency.

Oil helps seal the piston rings and reduce metal-to-metal contact, especially during hard acceleration or extended high-speed driving. Owners often notice minor oil loss, but it is an intentional design feature.

The engine’s turbochargers operate at extremely high temperatures, often exceeding 1,000 degrees Fahrenheit in their turbine sections. Controlled oil consumption helps cool and lubricate these components.

This strategy prevents premature wear and maintains the engine’s high-performance capabilities. Without it, the N54 could experience turbo failure or reduced lifespan under demanding conditions.

Carbon buildup is another factor addressed by oil consumption in the N54. Small amounts of oil entering the combustion chamber can reduce deposits on intake valves, helping maintain airflow and performance.

This design decision balances performance, efficiency, and maintenance requirements while conforming to emissions standards.

BMW owners should remain vigilant about oil levels and use manufacturer-recommended synthetic oils.

Regular monitoring ensures that oil consumption stays within normal design parameters and prevents potential engine damage. Understanding the purpose behind this controlled oil burn helps explain a feature that might otherwise seem like a defect.

3. Porsche 911 Turbo Engine

Porsche’s 911 Turbo engine exemplifies high-performance engineering where oil consumption is intentional. This flat-six, twin-turbo engine requires precise lubrication to function correctly at high RPMs.

Oil that enters the combustion chamber in small amounts protects cylinder walls and piston rings. The result is a longer-lasting engine capable of handling extreme performance demands.

Turbine efficiency and thermal control are essential for the 911 Turbo. Controlled oil burn helps prevent overheating in the turbos and ensures consistent lubrication even under heavy loads.

Porsche engineers designed the system to balance power output with engine longevity. Without this controlled consumption, sustained performance driving could lead to premature component failure.

Another critical aspect is carbon prevention. High-revving engines are prone to carbon deposits on valves and combustion surfaces.

By allowing minor oil consumption, the engine reduces the risk of buildup. This keeps the intake system clean and maintains optimal airflow. Consequently, performance remains consistent over time.

Piston ring sealing is improved by controlled oil use. The oil film reduces metal-to-metal contact, minimizing wear under extreme loads.

Porsche’s tight tolerances necessitate this feature to protect the engine during high-speed or aggressive driving. Controlled oil consumption is therefore part of the design rather than a flaw.

Owners of Porsche 911 Turbos must monitor oil levels regularly. Even though the engine is built to tolerate small oil loss, maintaining proper lubrication ensures reliability.

Using high-quality synthetic oils and following Porsche’s maintenance guidelines supports this advanced engine design.

4. Ford EcoBoost 2.3L Engine

The Ford EcoBoost 2.3L engine powers several modern performance vehicles while prioritizing efficiency. Its turbocharged design operates under high pressures and temperatures, making controlled oil consumption necessary.

The engine uses small amounts of oil to lubricate turbocharger bearings and protect cylinder walls during demanding driving. This design helps maintain performance without sacrificing reliability.

Direct injection and high boost levels increase thermal loads within the combustion chamber. Oil entering in minor quantities ensures components remain properly lubricated, reducing wear and friction.

The result is an engine capable of handling spirited driving while meeting modern efficiency standards. Controlled oil burning is a built-in feature, not a mechanical defect.

Turbocharger longevity depends on proper oil management. The EcoBoost engine’s turbos spin at high speeds and temperatures, requiring a consistent supply of oil for cooling and lubrication.

This controlled oil use protects the bearings from excessive heat and ensures a longer service life. It also supports consistent performance under heavy loads.

Piston and valve health also benefit from minor oil consumption. A thin oil layer reduces friction and helps prevent carbon deposits in the combustion chamber. This contributes to the engine’s efficiency and durability. By design, the engine balances power, efficiency, and longevity.

Drivers should follow Ford’s recommended maintenance schedule and monitor oil levels regularly. While the EcoBoost engine burns oil by design, staying within specified limits ensures reliability. Using the correct synthetic oils supports the engineered lubrication strategy.

5. Audi 2.5 TFSI Engine

Audi’s 2.5 TFSI inline-five engine powers sports-oriented vehicles and features controlled oil consumption. Its turbocharged design produces significant power from a compact layout.

Small oil quantities entering the combustion chamber lubricate piston rings and cylinder walls. This reduces wear while supporting the high-performance characteristics of the engine.

The engine’s tight tolerances and high pressures necessitate controlled oil burn. Oil ensures that friction between moving components is minimized under high load conditions.

This design preserves engine life while maintaining responsiveness and performance for drivers seeking aggressive acceleration.

Turbocharger and bearing longevity are enhanced through minor oil consumption. The high rotational speeds of the turbo require continuous lubrication and cooling.

By allowing a small amount of oil to enter the combustion chamber, Audi ensures that these critical components remain protected and functional during extreme driving scenarios.

Carbon buildup is reduced through controlled oil use. Small quantities of oil help keep valves and combustion surfaces clean, supporting performance consistency.

This is particularly important in engines using direct injection, where carbon accumulation can impact airflow and efficiency.

Audi owners should remain aware of oil levels and use manufacturer-approved synthetic oils. Regular checks and maintenance ensure that oil consumption remains within the intended range. This proactive approach prevents issues and maintains engine performance and reliability.

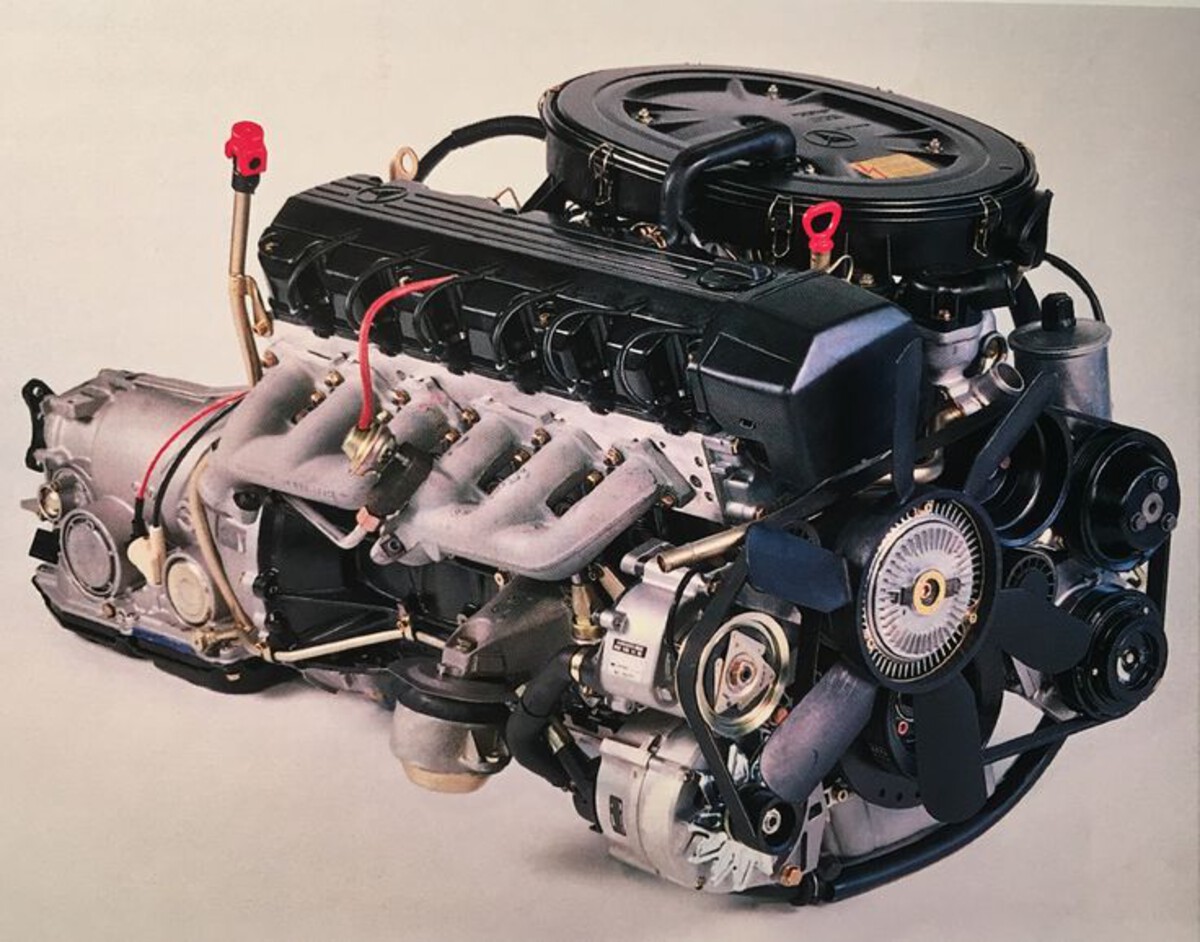

6. Mercedes-AMG M133 Engine

The Mercedes-AMG M133 engine delivers impressive power from a compact turbocharged four-cylinder configuration. This engine is engineered to consume small amounts of oil deliberately to maintain lubrication under high stress.

By allowing controlled oil burn, AMG ensures the turbocharger bearings, pistons, and cylinder walls remain protected even under extreme driving conditions. The small oil consumption contributes to the engine’s durability while supporting peak performance.

High boost pressures and direct injection make precise lubrication essential for the M133. The turbocharger spins at extremely high RPMs, generating significant heat.

A thin film of oil helps maintain bearing integrity and prevent metal-to-metal contact. Without this carefully designed oil consumption, the engine could face accelerated wear or component failure during heavy loads, especially in track or spirited driving scenarios.

Piston rings benefit from controlled oil consumption as well. The oil film reduces friction between the rings and cylinder walls, minimizing wear over time.

This is particularly important in an engine that revs aggressively and maintains high power output across a wide RPM range. Mercedes-AMG engineers designed the M133 to balance performance, reliability, and longevity without sacrificing drivability.

Carbon prevention is another reason for this design choice. Minor oil burning helps keep valves and combustion chambers clean, which is crucial for engines with direct fuel injection.

Maintaining airflow and preventing deposit buildup ensures consistent performance and helps the engine comply with emission standards. Controlled oil consumption is therefore part of a holistic approach to engine longevity and operational efficiency.

Owners of AMG vehicles must monitor oil levels regularly, even though the engine is built to tolerate slight consumption. Using high-quality synthetic oils recommended by the manufacturer supports the engineered lubrication strategy. Regular maintenance ensures the M133 engine continues delivering reliable performance while meeting Mercedes-AMG’s high standards.

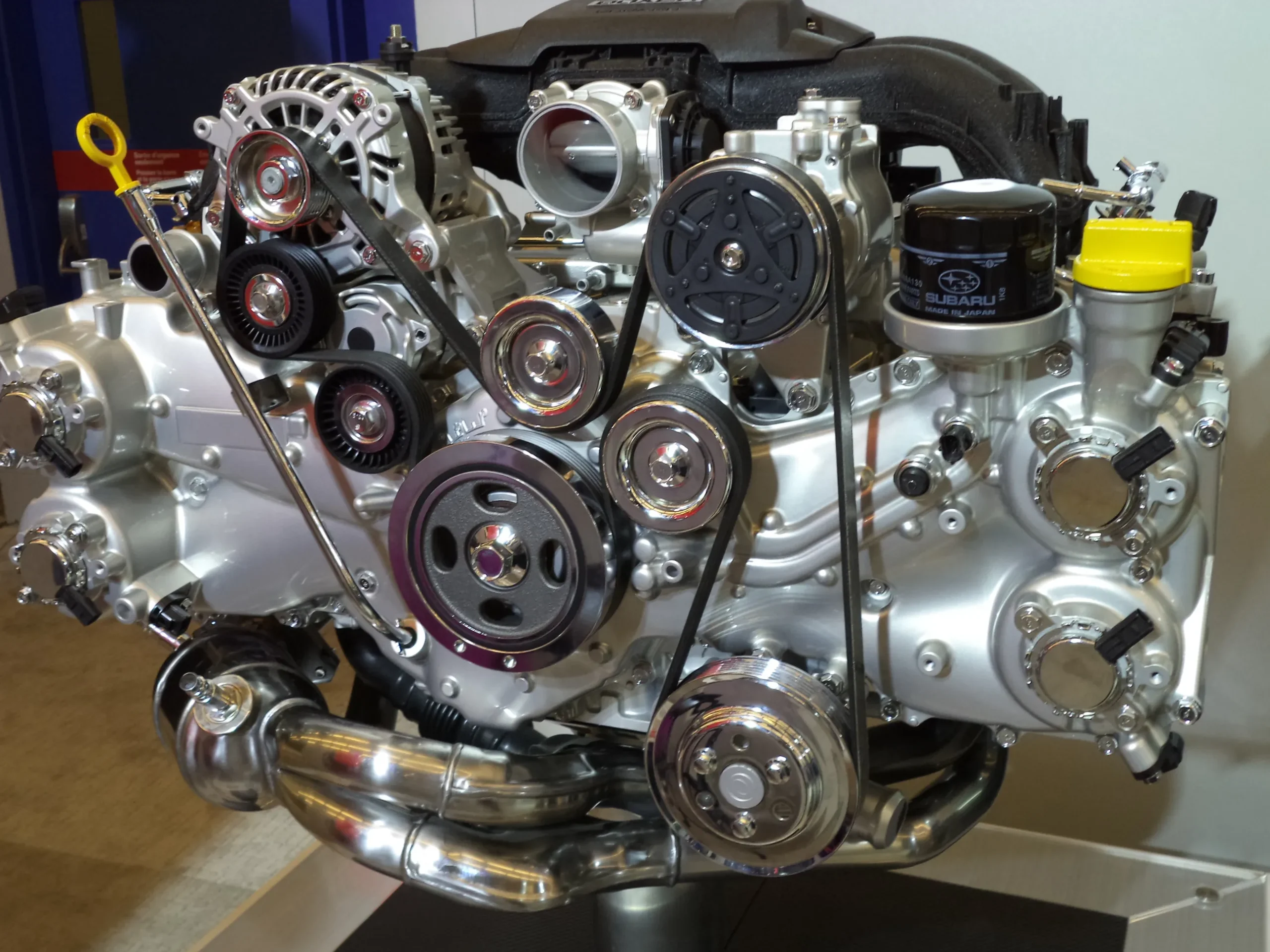

7. Subaru EJ25 Turbo Engine

The Subaru EJ25 turbocharged engine is well-known in performance car communities, particularly among rally enthusiasts. This engine was designed with controlled oil consumption in mind, especially under high RPM and boost conditions.

Minor oil burning ensures proper lubrication for the pistons, cylinder walls, and turbocharger bearings, all of which experience high stress during performance driving. Without this feature, the EJ25 would be more prone to overheating and premature wear.

The horizontally opposed boxer layout of the EJ25 requires precise oil distribution to all moving components. Controlled oil consumption allows a thin film to coat cylinder walls evenly, reducing friction and enhancing component longevity.

Turbocharged models particularly benefit from this feature, as oil reaching the turbocharger helps maintain bearing health under extreme rotational speeds.

Temperature management is critical for Subaru’s EJ25. Controlled oil burning helps dissipate heat from the combustion chamber and turbo components.

High-performance driving generates significant thermal stress, and this small oil consumption ensures that the engine maintains safe operating temperatures. This design choice contributes to Subaru’s reputation for durable performance engines.

Piston rings and valves also benefit from this mechanism. The thin oil layer reduces wear and prevents carbon buildup, keeping the engine performing optimally over time.

Direct injection systems in later EJ25 variants increase the risk of deposits, making this controlled oil consumption a necessary part of design rather than a defect.

Owners should monitor oil consumption closely and follow Subaru’s recommended maintenance intervals.

While slight oil burning is normal, staying within manufacturer-specified limits ensures the EJ25 engine remains reliable, even under demanding driving conditions. Using high-quality synthetic oils further supports performance and longevity.

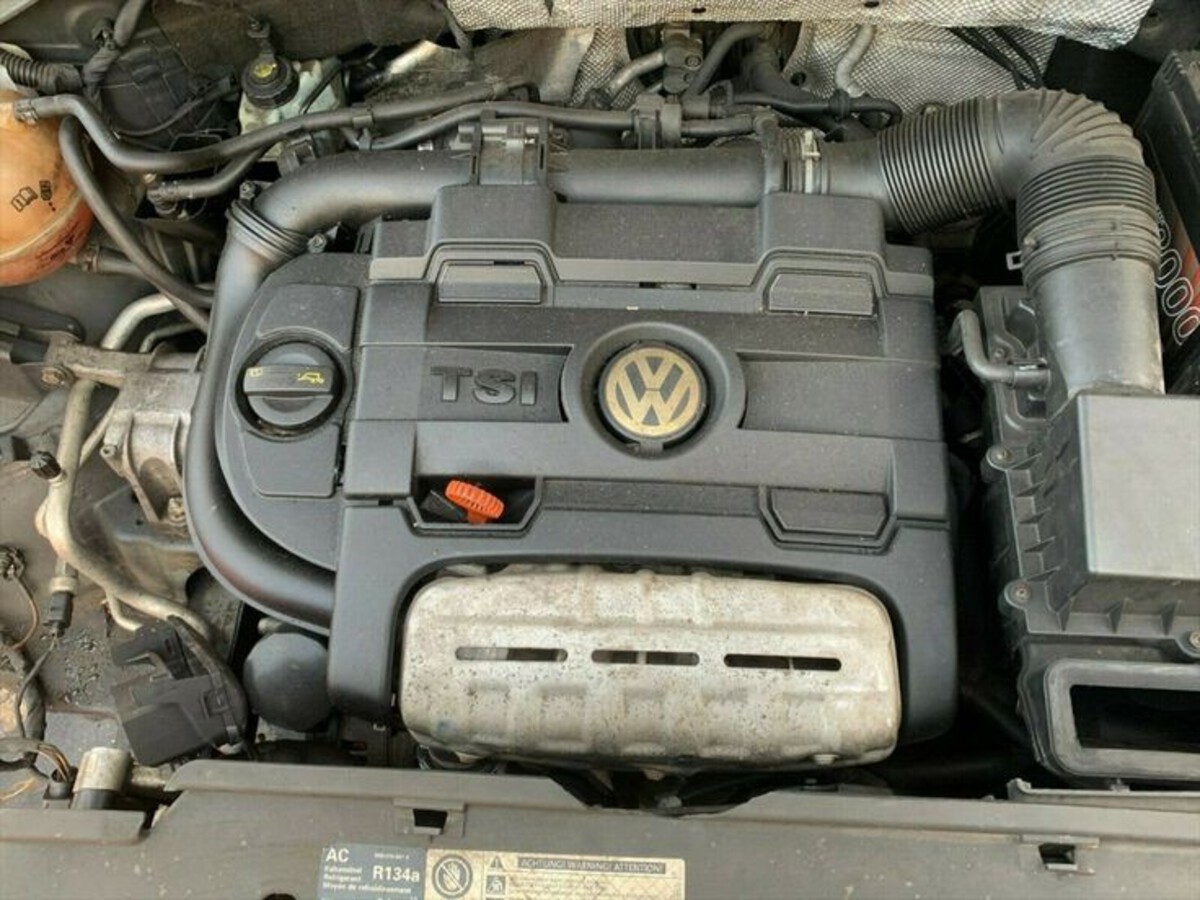

8. Volkswagen 2.0 TSI EA888 Engine

The Volkswagen 2.0 TSI EA888 engine is widely used across multiple VW and Audi models, blending efficiency with high output. This engine was designed to allow controlled oil consumption, particularly in its turbocharged variants.

A small amount of oil entering the combustion chamber lubricates piston rings, cylinder walls, and turbo bearings, helping the engine maintain performance under heavy load and high temperatures.

Direct injection combined with high boost pressures requires precise lubrication to avoid accelerated wear. Oil provides a thin protective layer between moving components, reducing friction and extending engine life.

VW engineers intentionally allowed this design to balance performance demands with engine longevity and efficiency, especially in smaller displacement turbo engines.

The turbocharger depends heavily on proper oil supply. Controlled oil consumption helps maintain bearing health and cooling in the high-speed turbo.

Without this mechanism, the engine could experience premature turbo failure, especially under sustained highway speeds or aggressive acceleration. Oil burning also aids in reducing heat-related stress on pistons and cylinder heads, preserving structural integrity.

Carbon accumulation on intake valves is another issue addressed by minor oil burning. The oil helps prevent deposits from forming in direct injection engines, maintaining airflow and consistent performance. This ensures that the EA888 remains both responsive and reliable over long-term operation.

Regular maintenance and oil checks are essential for owners of vehicles with the EA888 engine. Slight oil consumption is normal, but exceeding manufacturer specifications can indicate other mechanical issues. Using high-quality synthetic oils helps preserve the designed lubrication balance and ensures continued reliability.

9. Ferrari F154 Turbo V8 Engine

The Ferrari F154 engine is a twin-turbocharged V8 that powers modern Ferrari sports cars. It is designed for controlled oil consumption to optimize performance and protect high-stress components.

Small amounts of oil entering the combustion chamber reduce friction on piston rings, lubricate turbo bearings, and prevent wear under extreme RPM and high temperature conditions. Ferrari’s engineers carefully calibrated this system to balance power and longevity.

Turbocharger operation in the F154 produces intense heat. Controlled oil consumption allows a steady supply of lubrication and cooling to the high-speed turbo bearings.

This prevents overheating and ensures that the engine maintains consistent performance during track or spirited driving. Without this intentional design, turbo failure or reduced engine life could occur quickly.

Piston and valve components benefit from this system as well. The oil film prevents direct metal-to-metal contact and reduces wear during high RPM operation.

Ferrari engines are known for their tight tolerances, and controlled oil consumption ensures that these tolerances remain effective over the engine’s life. This protects the engine while enabling the high-performance output Ferrari is famous for.

Carbon buildup in the combustion chamber is minimized with this method. Direct injection systems, which improve efficiency, are prone to valve deposits.

Minor oil consumption keeps combustion surfaces clean, maintaining optimal airflow and performance. This contributes to the reliability and longevity of the F154 V8 despite its extreme performance capabilities.

Owners must monitor oil levels carefully and adhere to Ferrari’s maintenance guidelines. While slight oil burning is part of the engine’s design, staying within specified limits ensures optimal operation. Using Ferrari-approved oils supports the engine’s engineered lubrication and cooling strategy.

10. Honda K20C1 Engine

The Honda K20C1 engine powers modern Honda performance vehicles with a turbocharged inline-four configuration. This engine allows controlled oil consumption to maintain lubrication at high boost pressures.

Minor oil entering the combustion chamber reduces friction on pistons, cylinder walls, and turbo bearings, ensuring long-term reliability while achieving impressive performance levels. The design is intentional, reflecting Honda’s engineering priorities.

Turbocharger bearings in the K20C1 operate at extremely high speeds and temperatures. Controlled oil burn helps prevent premature wear and maintains cooling for these components.

By allowing a thin layer of oil in the combustion process, Honda engineers ensured that the engine could handle high-stress conditions without sacrificing durability. This is especially important for vehicles driven aggressively or on race tracks.

Piston rings and cylinder walls are protected through this method as well. The thin oil layer reduces wear under high RPM operation, extending engine life. Tight manufacturing tolerances necessitate precise lubrication, and minor oil consumption is a solution designed to keep the engine performing optimally while avoiding damage.

Carbon buildup is minimized in the K20C1 thanks to controlled oil consumption. Direct injection engines can experience deposits on valves and combustion surfaces.

By intentionally allowing small amounts of oil into the chamber, Honda maintains airflow and performance consistency over the life of the engine. This ensures a balance between efficiency and reliability.

Owners should monitor oil levels closely and follow Honda’s recommended maintenance schedule. While slight oil burning is normal, using manufacturer-approved synthetic oils ensures proper lubrication and cooling. This approach maintains the K20C1 engine’s high performance and long-term reliability.