Keeping a Jeep Wrangler in top shape for the trail requires more than just filling up the gas tank and hitting the dirt. Whether you’re climbing rocky hills, splashing through mud pits, or crawling over logs, your Jeep needs to be ready for the unexpected at all times.

A Wrangler is built tough, but even the most rugged vehicles require consistent care and smart preparation to maintain performance and avoid issues far from civilization. For off-road enthusiasts, trail-readiness is about more than survival; it’s about maintaining confidence and ensuring a smooth experience every time the tires leave the pavement.

Many owners underestimate the small things that can ruin a trail day. A loose bolt, a worn-out tire, or a dead winch could turn a fun adventure into a frustrating or even dangerous situation. That’s why seasoned Jeep owners follow certain routines and habits to keep their rigs prepared.

These don’t always require advanced mechanical skills or high-end equipment, but they do call for consistency, attention to detail, and a willingness to inspect your vehicle regularly. By building a reliable checklist and learning to understand how your Wrangler behaves, you’re less likely to be caught off-guard.

Being trail-ready also means thinking ahead. That includes checking weather forecasts, understanding terrain, and keeping spare parts or recovery gear where they’re easily accessible. While spontaneous off-road trips are exciting, being prepared never kills the fun.

It’s what allows you to enjoy every bump and splash without constantly worrying about what could go wrong. By practicing a few simple tricks, you’ll avoid the preventable headaches that leave other drivers stuck, stranded, or calling for a tow.

Here are 10 tried-and-true tricks that help keep your Jeep Wrangler ready for the trail anytime. These tips combine routine maintenance, smart upgrades, and practical field habits that can make the difference between a great ride and a rough day.

Also Read: 5 Bikes That Love Long Rides and 5 That Hate Leaving Town

1. Regularly Inspect and Tighten All Bolts and Mounts

It’s easy to overlook bolts and mounts during regular maintenance, especially when everything seems to be running fine. But off-road conditions are known for shaking things loose. The constant vibration from trails, rocks, and uneven terrain gradually loosens bolts, particularly in suspension components, steering linkages, and skid plates.

This is not something you’ll notice until it’s too late. A single missing bolt can cause serious alignment problems or even lead to the failure of a major component mid-trip. Making it a habit to inspect and re-torque bolts before heading out can prevent a chain reaction of mechanical failures.

Start with the suspension system. Control arms, track bars, sway bars, and shocks should be thoroughly checked. Look for any signs of wear around the mounting points and use a torque wrench to confirm the bolts are within spec. Also, check under the Jeep, especially if you have installed aftermarket parts.

Aftermarket bumpers, armor, and skid plates often use multiple bolts, and if even one works itself loose, you might lose the part or cause damage while driving. These components take a lot of abuse, and without frequent checks, they might shift or rattle free.

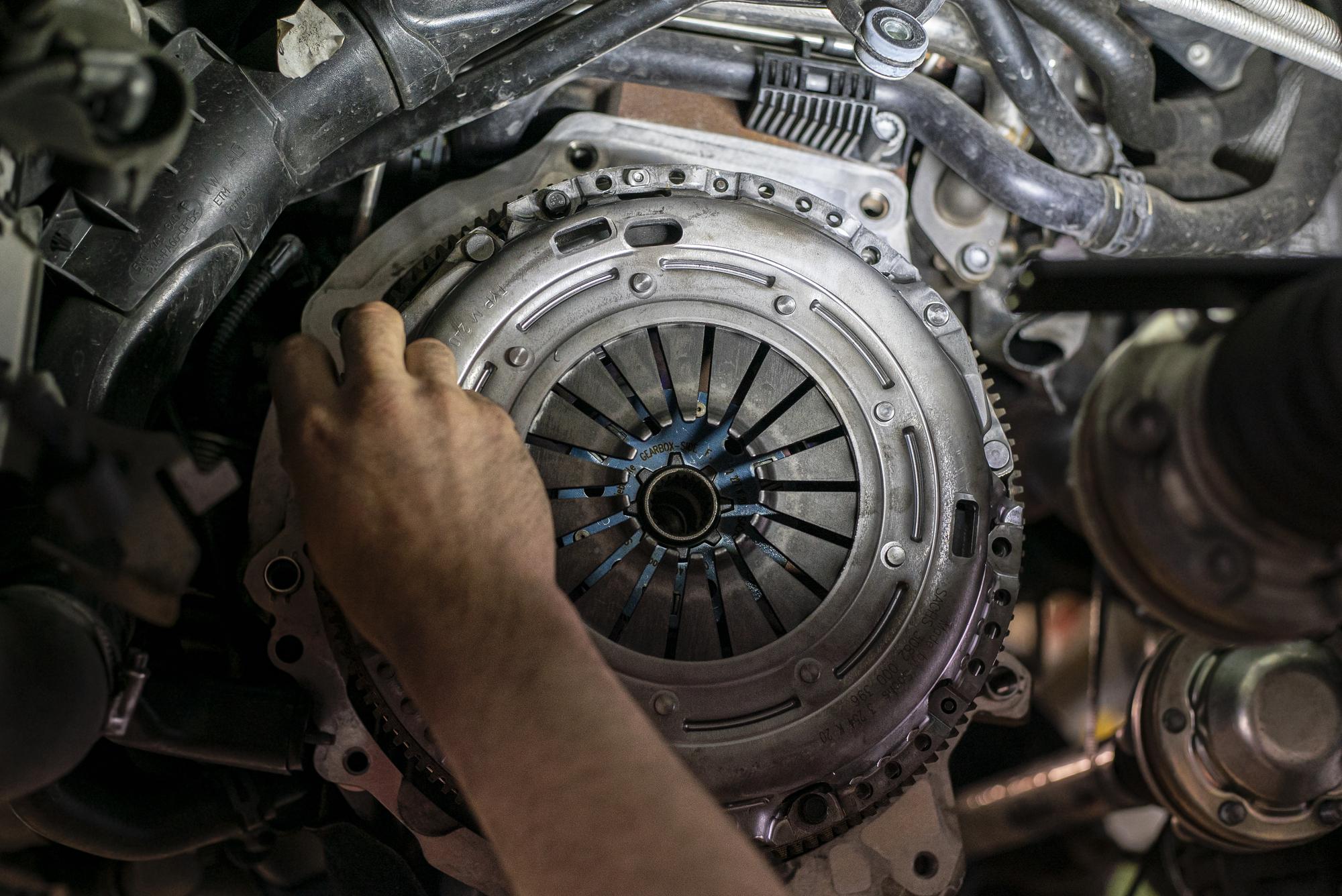

The drivetrain is another area that deserves attention. Driveshafts, transfer case mounts, and transmission cross members experience a lot of stress when crawling or climbing. If these bolts aren’t checked regularly, they could loosen and lead to a driveline vibration or worse, complete failure while on the trail. A few minutes spent underneath your Jeep after every ride will give you peace of mind and a clear understanding of your rig’s condition.

It helps to carry a tool kit with all the necessary sockets and wrenches in your Jeep. Many owners keep a torque chart specific to their setup so they can perform trail-side checks when necessary. Being proactive about bolt tightness doesn’t just preserve performance; it helps prevent costly repairs and dangerous situations. It’s a simple routine that pays off every time your tires hit the dirt.

2. Keep Your Tires Trail-Ready

Your tires are the only part of your Jeep that physically touch the trail, so keeping them in top shape is essential. It’s not just about having the right size or tread pattern, although those matter too, but also about monitoring their condition before and after every trail ride.

Worn or improperly inflated tires are among the most common reasons Jeeps get stuck or experience handling issues off-road. Whether you run mud-terrains or all-terrains, proper tire care is one of the easiest ways to maintain trail-readiness.

Start by checking air pressure. Off-roading often requires airing down for better traction, but that means you need to air up again afterward. Under-inflated tires on pavement can wear faster and hurt fuel efficiency.

Carrying a reliable air compressor ensures you’re always able to adjust pressure as needed. You should also invest in a good tire gauge, since inaccurate readings can throw off your pressure levels and make the Jeep harder to control in tough terrain.

Next, inspect the tread depth and sidewalls. Cuts, bulges, or uneven wear patterns can hint at alignment issues or suspension problems. It’s common for tires to wear unevenly if your suspension isn’t balanced correctly or if you’ve been running low pressure on hard surfaces.

Catching these early helps you avoid blowouts or loss of grip when it matters most. You might not see a problem at first glance, so rotate your tires often and check inside tread grooves for debris like rocks or nails.

Lastly, carry a full-size spare and make sure it’s always aired up and accessible. Many off-roaders neglect their spare tire until they need it, only to discover it’s flat or worn down. A good tire repair kit and a plug kit should also be part of your regular trail gear. These tools take up little space but can save your entire trip. By maintaining your tires with care and checking them routinely, you’ll prevent a long list of issues and keep your Wrangler climbing confidently over whatever lies ahead.

3. Maintain and Upgrade Recovery Gear

Recovery gear isn’t just for the rare emergency. It’s a vital part of any Jeep Wrangler that goes off the beaten path. Even if you drive skillfully, there’s always a chance you’ll hit mud deeper than expected or get hung up on a rock you didn’t see.

Having reliable recovery equipment isn’t optional; it’s what allows you to get yourself out of trouble or help someone else when conditions take a turn. Simply throwing a tow strap in the trunk isn’t enough. Gear needs to be maintained, stored properly, and upgraded when necessary.

Start with the essentials. A high-quality recovery strap, soft shackles or D-rings, and gloves should be in your Jeep at all times. Over time, straps can wear out, fray, or become weakened by exposure to dirt and sun. Inspect them regularly and replace them if there’s any sign of damage. Shackles can corrode or get bent, especially if left attached all the time. It’s a good habit to take them off when you’re not on the trail and to lubricate the pins occasionally to prevent rust.

Winches are another area where maintenance can’t be overlooked. If you have a winch on your Wrangler, it should be tested periodically, not just assumed to work. Spool out the line completely, inspect for kinks or frays, and rewind it properly.

Keep the electrical connections clean and secure, and check that your remote works before heading into remote areas. A dead winch isn’t just a useless accessory; it’s a critical failure that could leave you stranded.

Storage matters, too. Keep your recovery gear in a clean, organized bag or case so you can access it quickly during a stressful situation. It should be located somewhere easy to reach, not buried under camping gear or tools.

Marking items with reflective tape or color-coded bags also helps during night recoveries. Treat your gear like the safety equipment it is. If you wouldn’t trust it to hold your weight in a dangerous moment, it shouldn’t be in your Jeep.

4. Check Fluids Often and Use the Right Types

Fluids are the lifeblood of your Jeep Wrangler. Whether it’s engine oil, transmission fluid, coolant, brake fluid, or differential oil, keeping these levels in check is one of the simplest yet most important tasks for trail-readiness. Off-road driving subjects your vehicle to extreme conditions, climbing steep hills, sitting in low gear for extended periods, and fording through water and mud.

These conditions accelerate the wear on internal components and increase the likelihood of fluid degradation or contamination. Neglecting fluid levels or using the wrong types can lead to performance issues or catastrophic failure when you’re miles away from a road.

Start with the basics: engine oil and coolant. Jeep Wranglers, especially those that spend a lot of time in low-range off-road conditions, tend to run hotter than usual. If your cooling system isn’t topped off or your radiator is clogged with mud, you risk overheating. Make it a habit to check coolant levels before every trip and ensure that the radiator fins are clean.

The same goes for engine oil. Off-roading stirs up more dust and dirt, which can sneak past filters and degrade oil faster. Stick to a tight oil change schedule and consider using synthetic oil for better heat resistance and lubrication under stress.

Then, there are the lesser-checked but equally vital fluids, differential and transfer case oil. These are often forgotten until a leak is spotted or strange noises appear. However, these components face intense pressure when off-roading, especially during water crossings. If water seeps into your differential or transfer case, it can cause immediate wear and eventual failure.

Checking and changing these fluids more frequently, especially after deep-water or muddy trails, can add years of life to your drivetrain. Look for milky discoloration in the oil; it’s a clear sign of contamination that requires attention.

Lastly, use the correct fluid types recommended for your specific model and setup. Aftermarket upgrades, such as lockers or upgraded axles, may require different specifications. Mixing fluids or using the wrong grade can result in poor performance or internal damage.

Keeping a small stash of extra fluids in your Jeep, especially oil and coolant, can be a lifesaver on longer trips. Combine this with routine inspections, and you’ll significantly reduce the risk of breakdowns related to neglected fluids.

5. Clean and Protect Electrical Connections

Modern Jeep Wranglers rely on a variety of electrical systems, and while they’re rugged machines, electrical failures can cause serious problems off-road. From the ignition system to lockers, lighting, and winches, electrical connections need to be both clean and secure to function reliably.

Mud, water, and dust, the usual trail companions, can sneak into connectors, cause corrosion, and disrupt signals or power delivery. One weak connection could shut down an accessory, disable your lockers, or worse, prevent your Jeep from starting. Prevention begins with routine inspection and smart protection practices.

Start by identifying all major connectors in your Wrangler. Focus on the battery terminals, ground points, lighting harnesses, and any aftermarket accessory wiring you’ve installed. Check for signs of corrosion, usually white or greenish deposits, and clean them using a wire brush and terminal cleaner.

Apply dielectric grease to key connections to prevent future corrosion and improve conductivity. For battery terminals, an anti-corrosion spray is a cheap and effective way to guard against buildup, especially if your Jeep is exposed to rain, snow, or mud frequently.

Aftermarket wiring can be especially vulnerable. If you’ve added a light bar, additional fog lights, rock lights, a CB radio, or a winch, check the quality of the connectors and routing. Too often, owners rely on cheap crimp connectors or leave wiring exposed to the elements.

Over time, this leads to short circuits or system failures. Use marine-grade heat-shrink connectors and cover exposed wiring with loom or conduit. Secure wiring away from moving parts and ensure it won’t get pinched by suspension articulation or rub against the frame.

Finally, consider upgrading the factory ground wires and adding a dedicated power distribution panel if you run multiple accessories. This not only makes troubleshooting easier but also reduces the risk of overloaded circuits. Label all wiring and keep a multimeter in your toolkit to diagnose issues on the trail.

Electrical failures are notoriously frustrating, especially when you’re far from help, but with the right preparation and regular maintenance, they’re completely avoidable.

Also Read: 5 Bikes That Handle Touring Miles and 5 That Hate Distance

6. Lubricate Key Suspension and Steering Components

Suspension and steering components take a beating on the trail. The constant articulation, vibration, and exposure to dirt and moisture mean that these parts require frequent attention, especially when it comes to lubrication. If you’ve upgraded to an aftermarket suspension system, chances are it includes components with greaseable joints.

Failing to keep them lubricated can lead to squeaking, binding, premature wear, and eventually part failure. Even factory suspension parts benefit from occasional greasing and inspection, particularly if you regularly take your Jeep off the pavement.

Begin with your tie rod ends, ball joints, and control arms. These points are crucial for steering stability and suspension articulation. When they’re dry, they can bind or create noise during movement, which is not just annoying but also a sign of accelerated wear.

A basic grease gun can go a long way in keeping these parts moving smoothly. Use the recommended type of grease, usually synthetic or moly-based and apply it until you see the old grease purge from the joint. This helps push out contaminants and ensures a full grease cavity.

Next, look at sway bar links, track bars, and driveshaft slip yokes. Some of these may not have zerk fittings, but if yours do, take advantage of it. Off-roaders who frequently disconnect sway bars often forget to lubricate the mounting points, which can develop play or noise over time.

Driveshaft components, especially the slip yoke and universal joints, are also prone to wear when neglected. A well-lubricated driveshaft reduces vibration and prevents clunking noises, especially under load or on rocky trails.

Make it part of your routine to grease all necessary points after a weekend on the trail. Keep track of which components require attention and store a small grease gun with your tools. It’s a minor effort that pays off in smoother handling, quieter operation, and increased longevity of expensive suspension parts.

The more frequently you go off-road, the more often you should perform this maintenance. Suspension performance can make or break your trail experience, and keeping those parts greased helps ensure you’re never caught with a binding joint or steering issue halfway through a climb.

7. Inspect Brakes for Trail-Ready Performance

Brakes are one of the most crucial safety components on your Jeep, and they work harder than usual during trail runs. Steep descents, muddy paths, and quick adjustments require a responsive braking system. Off-roading also exposes brakes to dirt, water, and extreme heat, all of which can wear down pads and rotors faster than normal driving.

Regular inspections can help you avoid situations where you lose braking power when it’s needed most. Trail-readiness means not just that your brakes stop you, but that they do so predictably and reliably under all conditions.

Start with your brake pads and rotors. Check for uneven wear, scoring, or any signs of contamination. Off-road trails can introduce grit into the calipers and cause premature pad degradation or warped rotors. If you drive through water crossings, your brakes can develop surface rust or reduced friction if they aren’t dried out afterward. Upgrading to slotted or drilled rotors and using high-performance brake pads can improve stopping power and heat resistance, especially on long downhill sections.

Don’t ignore the brake lines and fluid. Flexible rubber lines are vulnerable to punctures or cracking, especially if you’ve installed a lift kit and the lines are stretched. If you haven’t already, consider switching to stainless steel braided brake lines for durability and better pedal feel.

Brake fluid should be changed regularly, as it absorbs moisture over time, reducing effectiveness. On off-road trips, especially in humid or wet environments, this can happen even faster. Always check your reservoir and consider bleeding the brakes if the pedal starts to feel soft.

Lastly, test your parking brake frequently. On trails, especially when rock crawling, the parking brake is essential for keeping your Jeep stationary while you get out to spot or navigate obstacles. A poorly adjusted or worn-out parking brake can be a serious hazard.

Make sure it holds on an incline and doesn’t require excessive force to engage. A strong, reliable braking system doesn’t just protect your vehicle, it protects your confidence on the trail and helps keep you in control no matter what the terrain throws at you.

8. Keep the Undercarriage Clean and Protected

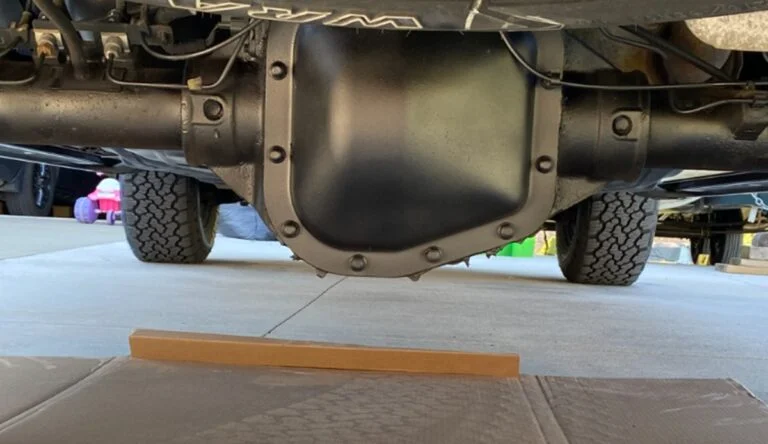

The undercarriage is one of the most abused areas of your Jeep Wrangler during trail rides, and it’s also one of the easiest to ignore. Dirt, rocks, sand, salt, and mud accumulate in hard-to-reach places under the vehicle and can gradually cause corrosion, clog ventilation points, or wear down critical components.

Even well-armored Wranglers are vulnerable to buildup around axles, brake lines, and suspension mounts. Keeping the underbody clean isn’t just about looks, it’s about long-term reliability and spotting damage before it turns into a serious issue.

After every off-road trip, especially one that involves water crossings or mud, wash the underside of your Jeep thoroughly. A high-pressure hose or undercarriage sprayer can help remove mud from skid plates, axle tubes, control arm mounts, and driveshafts. Letting that grime sit in place accelerates rust, particularly in areas where water gets trapped between metal parts or inside hollow frame sections. Many owners are surprised by how quickly rust can set in, even on newer vehicles, if regular cleaning is skipped.

Protection is just as important as cleaning. Consider applying a rust-preventive coating to high-risk areas. Frame rails, weld seams, and brackets are common corrosion points. You don’t need a professional application every time; there are many DIY options, like rubberized undercoatings and corrosion inhibitors, that you can spray yourself.

These form a protective layer that repels water and mud and can be reapplied throughout the season. Pay attention to areas around drain holes and make sure they’re not blocked, as trapped water can accelerate decay from the inside out.

Finally, inspecting the undercarriage while you clean it gives you a chance to catch other issues early. You might spot a leaking differential, a cracked bushing, or a bent bracket that would have gone unnoticed.

Skid plates and control arm mounts, in particular, can take serious hits off-road, so make sure they’re not loose or dented to the point of affecting performance. A clean and protected underbody is the foundation for off-road durability, and it pays off every time you hit a rough trail without worrying about hidden damage or corrosion spreading out of sight.

9. Organize Tools, Spare Parts, and Emergency Supplies

A trail-ready Jeep isn’t just about the machine; it’s also about what you carry with you. Tools, spare parts, and emergency supplies often make the difference between a minor inconvenience and a trail-ending problem. Keeping these items well-organized and properly stocked ensures that when something does go wrong, you’re prepared to fix it without wasting time or energy.

Off-roading takes you far from help, and waiting for recovery can be frustrating, dangerous, or even impossible depending on your location. With the right gear onboard, you can solve most problems yourself and keep the trip going.

Start with the basics: tools. You don’t need to carry your whole garage, but a quality set of sockets, wrenches, pliers, screwdrivers, and hex keys is essential. Make sure you have the sizes specific to your aftermarket parts, especially if you’ve installed custom suspension, bumpers, or winches. Include tire tools like a lug wrench, breaker bar, and valve core remover.

Organize everything in a roll-up bag or sturdy toolbox that fits neatly in your cargo area. Foam inserts or pouches help prevent rattling and keep tools easy to locate when you need them quickly.

Spare parts can be equally important. Consider carrying extra fuses, serpentine belts, U-joints, valve stems, hose clamps, and fluids. These are lightweight, inexpensive items that are commonly needed on the trail and difficult to replace once you’re off-grid.

A spare axle shaft or tie rod may sound excessive, but in remote locations, even a cracked part can strand you if you’re not equipped. Whether you’re solo or part of a group, being the one with the right part can turn you into the trail hero when something breaks.

Emergency supplies round out your setup. Include a fire extinguisher, first aid kit, flashlight, tow strap, jumper cables, and a multi-tool. If you travel in remote areas, consider a satellite communicator or radio. Make sure everything is easy to reach, especially the first aid and fire gear.

Regularly check expiration dates, battery levels, and storage conditions. A well-organized Wrangler is a safer Wrangler, and knowing that everything has a place and is ready to go lets you focus on the trail, not on what’s missing from your gear bag.

10. Practice Regular Trail Simulations and Pre-Trip Walkarounds

Trail-readiness isn’t just about parts; it’s about knowing your Jeep and how it performs in real conditions. Too many owners install upgrades or do maintenance work, then wait until they’re on the trail to test it all out.

Practicing trial simulations and doing thorough pre-trip walkarounds helps catch issues early and gives you confidence that everything is working correctly. These habits are often overlooked, but they make a huge difference in how well your Jeep handles real-world conditions when it matters most.

Trail simulations can be done anywhere, even in your driveway or a local dirt lot. After installing new parts, check how they respond to articulation, flex, and vibration. Test your lockers, check how your steering feels, and listen for new noises. If you’ve added new wiring, lights, or a winch, make sure they operate correctly under load.

These small tests help catch loose bolts, wiring issues, or misalignments that might not show up during a normal street drive. Simulating recovery scenarios is also useful, practice using your winch or setting up a snatch strap before you’re in an emergency.

The pre-trip walkaround is your last line of defense. Before every off-road outing, walk around your entire Jeep and visually inspect the tires, suspension, steering, undercarriage, fluids, lights, and recovery gear. Look for leaks, sagging, worn bushings, or anything that just seems “off.”

Open the hood and check belts, hoses, and fluid levels. Turn on all electrical accessories to make sure they function properly. This process takes less than ten minutes but can save you hours of downtime or prevent a breakdown entirely.