In an automotive world increasingly dominated by turbochargers, superchargers, and hybrid systems, naturally aspirated engines represent a pinnacle of engineering simplicity and reliability.

Without forced induction components to generate heat and stress, these engines often deliver extraordinary longevity when properly maintained.

Their straightforward design minimizes points of failure, while their linear power delivery puts less strain on internal components compared to the sudden torque spikes of forced induction.

Throughout automotive history, certain naturally aspirated engines have earned legendary reputations not just for their performance characteristics, but for their ability to accumulate hundreds of thousands sometimes even millions of miles with minimal issues.

From economical four-cylinders that power family sedans across decades to high-performance V8s that endure punishing track days while remaining street-reliable, these engines demonstrate that sophisticated engineering doesn’t necessarily require complexity.

This collection celebrates twelve naturally aspirated engines that have consistently demonstrated exceptional durability, providing their owners with years of trouble-free operation while establishing themselves as benchmarks for reliability in the automotive world.

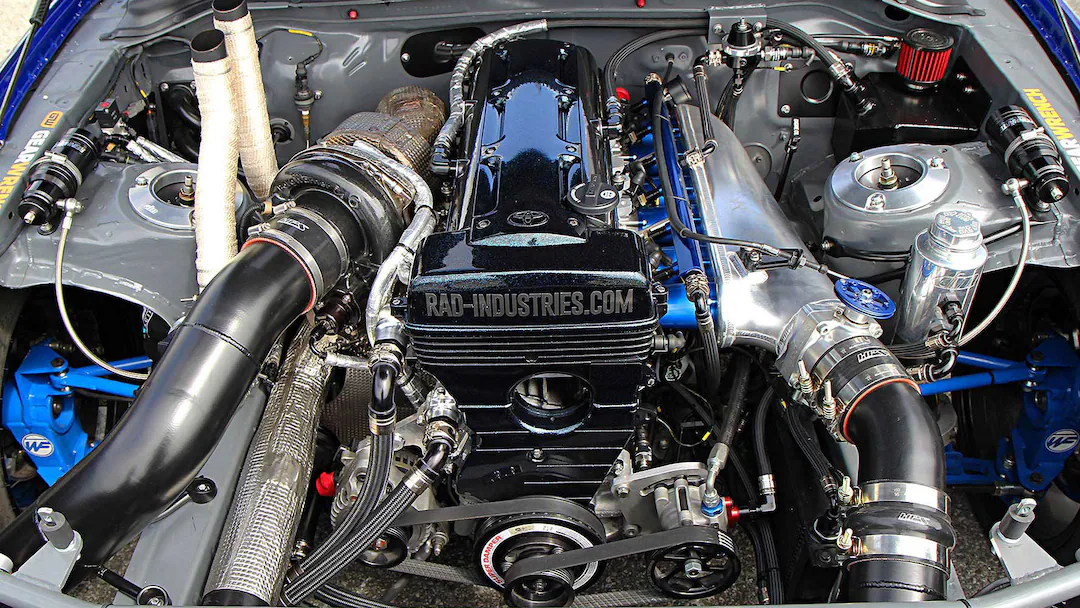

1. Toyota 2JZ-GE Inline-Six

The Toyota 2JZ-GE stands as one of the most overbuilt naturally aspirated engines ever mass-produced.

While its turbocharged sibling (the 2JZ-GTE) receives more attention from performance enthusiasts, the naturally aspirated GE variant deserves recognition for its extraordinary durability and smooth operation.

This 3.0-liter inline-six powered vehicles like the Lexus GS300, IS300, and naturally aspirated Supra models throughout the 1990s and early 2000s. What makes the 2JZ-GE special is its robust construction.

Like its turbocharged counterpart, it features a cast iron block with seven main bearings, a forged steel crankshaft, and an aluminum cylinder head designed to handle substantially more power than its factory rating of 215-227 horsepower.

This overbuilt nature means the engine rarely operates near its stress limits in normal use, contributing significantly to its longevity.

Toyota’s engineering philosophy during this era prioritized reliability above all else. The 2JZ-GE features a timing belt (rather than a chain) that, when replaced at recommended intervals, provides trouble-free operation for hundreds of thousands of miles.

The engine’s cooling system was conservatively designed with ample capacity, preventing the overheating issues that often plague high-mileage engines.

The inline-six configuration itself contributes to the engine’s durability. Inherently balanced and running with minimal vibration, this layout reduces wear on bearings and other critical components.

Toyota’s precision manufacturing ensured tight tolerances and excellent oil control, resulting in engines that maintain good compression and minimal oil consumption even after 200,000+ miles.

Perhaps most impressive is the 2JZ-GE’s versatility. While designed as a luxury car engine prioritizing smoothness and refinement, it has proven equally capable in performance applications, with many owners performing forced induction conversions that double or triple the factory output while maintaining reliability.

Examples with over 300,000 miles showing minimal wear during teardown are common, and properly maintained engines regularly exceed 400,000 miles without internal repairs.

This extraordinary lifespan has cemented the 2JZ-GE’s reputation as one of Toyota’s finest engineering achievements and a benchmark for durable engine design.

2. Honda F20C/F22C Inline-Four

Honda’s F20C and its later, torquier evolution, the F22C, represent perhaps the highest-revving naturally aspirated production engines ever to demonstrate exceptional longevity.

Powering the Honda S2000 sports car from 1999 to 2009, these engines combined seemingly contradictory characteristics: stratospheric redlines with bulletproof reliability.

What makes these engines remarkable is their ability to withstand extraordinary mechanical stresses.

The F20C revs to a motorcycle-like 9,000 RPM redline (8,800 RPM for later F22C versions), producing 240 horsepower from just 2.0 liters of displacement without forced induction a specific output that remained unsurpassed among naturally aspirated production engines until Ferrari’s 458 Italia more than a decade later.

This high-revving nature typically suggests compromised durability, but Honda’s engineering made no such concessions.

The engines feature forged connecting rods, forged pistons, fiber-reinforced metal cylinder liners, and a remarkably strong aluminum block.

The VTEC valvetrain, while complex, demonstrates outstanding reliability even when subjected to thousands of high-RPM engagements.

Honda’s fanatical attention to detail extends to critical oiling systems. The engines employ aggressive oil jets that spray the undersides of pistons for cooling, a sophisticated pressure relief system, and large-capacity baffled oil pans that prevent starvation during high-G cornering features typically found in racing engines rather than production cars.

What’s truly impressive about these engines is their durability despite abuse. Many S2000s see track use, where they endure sustained high-RPM operation and heat cycles that would quickly degrade lesser engines.

Yet documented examples with over 300,000 miles remain common in owner communities, often with no significant internal work performed.

Maintenance simplicity further enhances longevity. With a timing chain rather than a belt, conventional valve adjustment intervals, and accessible components, these engines reward owners who follow maintenance schedules with seemingly indefinite service lives.

The F20C/F22C engines demonstrate that extreme performance and exceptional durability need not be mutually exclusive.

Their continued functioning at high mileage, often despite hard use, establishes them as engineering masterpieces that showcase Honda’s capabilities at their zenith during what many consider the company’s golden era of naturally aspirated performance.

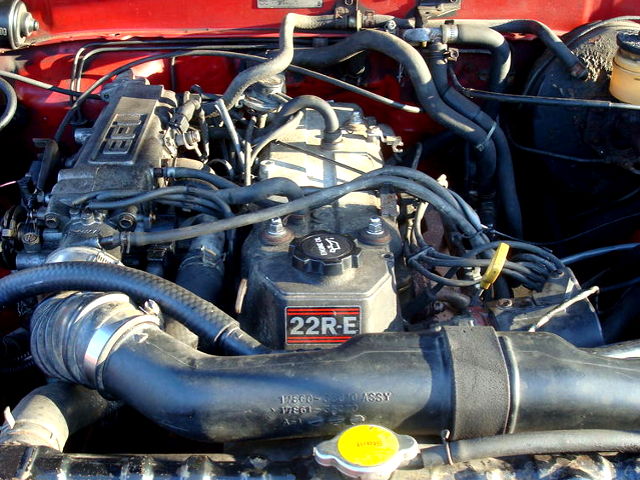

3. Toyota 22R/22RE Inline-Four

The Toyota 22R and its fuel-injected evolution, the 22RE, represent automotive legends not for their performance specifications but for their seemingly indestructible nature.

First introduced in 1981 and produced until 1997, these 2.4-liter inline-four engines powered Toyota’s trucks and 4Runners through an era when reliability expectations were redefined in the American market.

What makes these engines extraordinary is their fundamental simplicity combined with Toyota’s meticulous engineering.

The cast iron block features thick cylinder walls and seven main bearings supporting the crankshaft overkill for an engine producing a modest 105-120 horsepower but critical to its legendary durability.

The overhead camshaft design, driven by a timing chain with a reputation for lasting well beyond 200,000 miles, reduces complexity compared to dual-cam arrangements while maintaining adequate performance.

The 22R/22RE’s durability stems from conservative engineering throughout. The cooling system provides substantial overhead capacity, preventing the head gasket issues common in other engines of the era.

The oiling system delivers generous lubrication even under extreme angles during off-road use. Even the auxiliary components like the water pump and alternator were designed for extended service life rather than minimum production cost.

These engines’ tolerance for neglect borders on the supernatural. Tales of 22R-powered trucks running with minimal maintenance, incorrect oil weights, and even overheating events that would destroy most engines are common among owners.

The forgiving nature comes from loose manufacturing tolerances (by modern standards) that allow for thermal expansion without binding, along with simple mechanical fuel delivery systems that continue functioning when more sophisticated setups fail.

Perhaps the most telling testament to these engines’ durability is their continued operation in developing countries with limited access to parts and specialized service.

From Latin America to Africa and beyond, 22R-powered Toyotas continue to serve as essential transportation decades after production, often accumulating mileages exceeding 500,000 miles.

While lacking the refinement, efficiency, or performance of modern powerplants, the 22R/22RE series established a benchmark for durability that few engines have matched.

Their legacy lives on in Toyota’s continued reputation for reliability and in the thousands of examples still providing daily service worldwide despite being built in an era when mobile phones were rare and the internet barely existed.

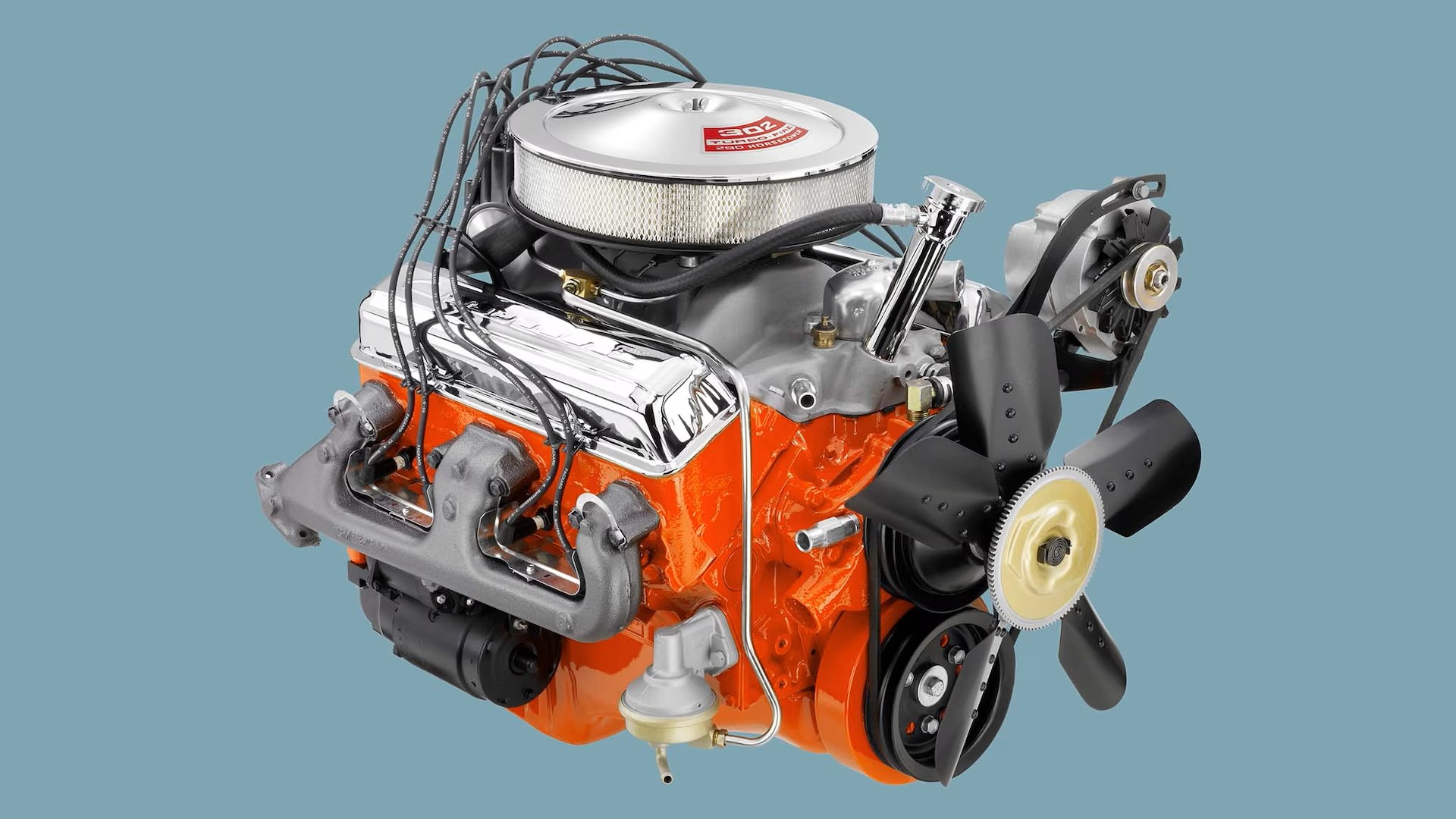

4. Chevrolet LS Small-Block V8

The Chevrolet LS series of small-block V8 engines represents perhaps the most successful marriage of performance potential and bulletproof reliability in modern automotive history.

Introduced in 1997 with the LS1 and developed through numerous iterations until being succeeded by the Gen V LT series, these pushrod V8s reset expectations for what a high-performance engine could endure.

What makes the LS engines extraordinary is their deceptive simplicity. While European and Japanese manufacturers pursued complex dual overhead cam designs, Chevrolet refined the classic pushrod V8 layout with modern materials and manufacturing techniques.

The result combines a compact, lightweight package with exceptional durability and almost unlimited performance potential.

Several key design elements contribute to the LS family’s legendary toughness. The deep-skirt aluminum block design (or iron in truck applications) provides superior rigidity compared to earlier small blocks.

The six-bolt main bearing caps resist crankshaft flex even under extreme power. The cam in block design reduces valvetrain complexity while improving structural rigidity.

Perhaps most importantly, the engineers designed these engines with generous safety margins even “base” LS engines can handle substantial power increases without internal modifications.

The cooling system deserves special mention for its contribution to longevity. The LS engines feature cooling passages that prioritize consistent cylinder temperature, preventing the hot spots that lead to detonation and premature wear.

This allows them to run cooler than many competitors despite often producing more power. What’s particularly impressive about the LS series is its durability across vastly different applications.

The same basic architecture powers everything from family sedans to Corvettes to heavy-duty trucks, often accumulating 250,000+ miles with minimal issues.

Even in performance applications where owners routinely double the factory horsepower through forced induction, the bottom end often remains untouched and reliable.

Maintenance simplicity further enhances long-term durability. With no timing belt to replace and widely spaced service intervals, these engines require minimal attention beyond regular oil changes.

This practicality, combined with extraordinary performance potential, explains why the LS has become the default engine swap choice for countless vehicle projects.

As internal combustion technology faces an uncertain future, the LS family stands as perhaps its most versatile and enduring ambassador proof that sophisticated engineering need not require complexity, and that performance and durability can coexist in harmonious balance.

Also Read: 10 Vintage Cars That Still Have a Loyal Fanbase

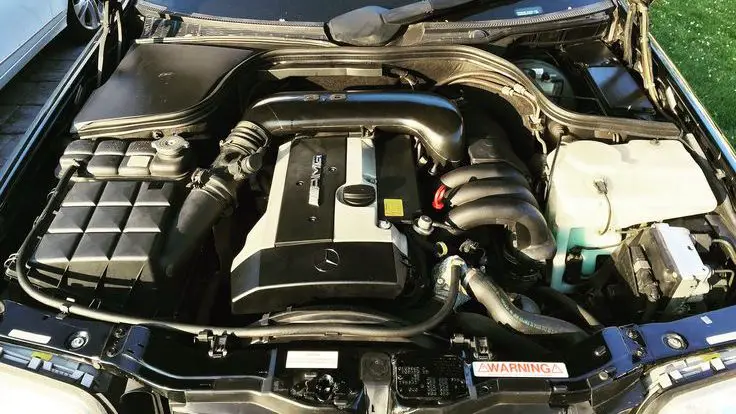

5. Mercedes-Benz M104 Inline-Six

The Mercedes-Benz M104 inline-six engine represents the pinnacle of over-engineered German powerplants from an era when durability trumped production cost considerations.

Produced from 1989 through 1999 in various displacements from 2.8 to 3.2 liters, this sophisticated naturally aspirated engine powered everything from executive sedans to the iconic 300SL/SL320 sports cars.

What makes the M104 extraordinary is its fundamentally robust design. The iron block provides exceptional rigidity and durability, while the aluminum dual overhead cam head houses four valves per cylinder for efficient breathing.

The seven main bearing crankshaft and fully counterweighted design ensure minimal vibration and bearing wear even after hundreds of thousands of miles.

Perhaps most impressively, Mercedes engineered this engine with a timing chain designed to last the life of the vehicle a claim substantiated by numerous examples exceeding 300,000 miles on their original timing components.

The M104’s durability stems partly from its conservative tuning. Even in its most powerful factory form, the 3.2-liter version produced 231 horsepower moderate output that ensured the engine rarely operated near its mechanical limits.

This headroom allowed the M104 to maintain consistent performance throughout its lifespan rather than degrading with age like more highly-stressed designs.

Mercedes’ fanatical attention to detail extended to the engine’s ancillary systems. The cooling system featured a large-capacity radiator, thermostat, and water pump assembly built to maintain consistent temperatures in any climate.

The oiling system was designed with ample capacity and excellent filtration, protecting critical components even during sustained high-speed autobahn running.

What truly distinguishes the M104 is its character as it ages. While many engines begin to show their wear through increased noise, vibration, and performance loss, properly maintained M104s retain their smooth, refined power delivery well beyond 200,000 miles.

This consistency explains why many Mercedes models powered by this engine command premium prices even with high mileage.

The M104 represents the end of an era in Mercedes engineering when longevity was prioritized above all else.

While modern engines may offer more power and efficiency, few can match the M104’s combination of smoothness, durability, and understated sophistication that continues to win devotees decades after production ended.

6. Nissan VQ35DE V6

Nissan’s VQ35DE 3.5-liter V6 established itself as one of the most versatile and durable naturally aspirated engines of the modern era.

Introduced in 2001 and produced in various iterations for over two decades, this engine powered everything from family sedans and crossovers to genuine sports cars like the 350Z and G35, demonstrating exceptional longevity across vastly different applications.

What makes the VQ35DE remarkable is its sophisticated yet robust design. The all-aluminum construction provides lightweight performance without compromising durability.

Variable valve timing, a high-flow exhaust manifold, and microfinished crankshaft and camshaft components deliver a remarkable (for its time) 260-300 horsepower depending on the application, yet the engine rarely suffers from the reliability issues typically associated with high-specific output naturally aspirated designs.

Several engineering details contribute to the VQ35’s legendary durability. The ladder-frame main bearing caps provide exceptional rigidity for the crankshaft, preventing the bearing wear that plagues lesser designs.

The timing chain system, while occasionally requiring replacement at very high mileages, generally proves more durable than belt-driven competitors.

Perhaps most importantly, the engine’s oiling system provides excellent lubrication even during aggressive driving, protecting critical components under stress.

What’s particularly impressive about the VQ35DE is how it maintains its performance characteristics over extremely high mileage.

While many engines lose compression and exhibit increasing oil consumption with age, properly maintained VQ35s often reach 250,000+ miles while maintaining factory power levels and minimal oil usage.

This durability translates across driving styles from Maximas driven gently by commuters to 350Zs subjected to frequent track days and aggressive street driving.

The engine’s reputation for durability is further enhanced by its relatively simple maintenance requirements.

With no timing belt to replace and conventional service intervals, the VQ35DE rewards basic maintenance with seemingly indefinite service life.

When issues do eventually develop, they’re typically related to ancillary components rather than internal engine failures.

The VQ35DE’s combination of performance, character, and extraordinary longevity earned it a place on Ward’s 10 Best Engines list for multiple years and cemented its status as one of Nissan’s finest engineering achievements.

Even as the automotive industry transitions toward electrification, this engine stands as a benchmark for naturally aspirated durability that future designs will be measured against.

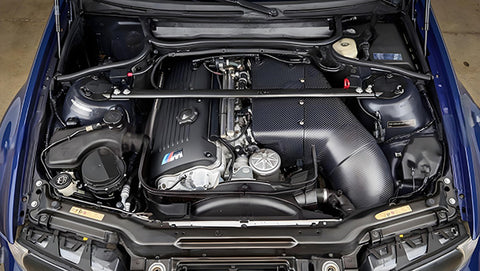

7. BMW M52/M54 Inline-Six

The BMW M52 and its evolution, the M54, represent the quintessential naturally aspirated inline-six engines that helped establish BMW’s reputation for combining performance, refinement, and remarkable durability.

Produced from 1994 through 2006 in various displacements from 2.0 to 3.0 liters, these engines powered everything from the 3-Series to the Z3/Z4 sports cars and 5-Series executive sedans.

What makes these engines special is their perfect balance of sophisticated engineering and bulletproof reliability.

The aluminum block (with cast iron liners in later M52TU and M54 versions) provides light weight without compromising strength, while the dual overhead cam arrangement with variable valve timing delivers both low-end torque and high-end power.

The inherent balance of the inline-six configuration eliminates the need for balance shafts, reducing complexity and potential failure points.

Several design elements contribute to these engines’ extraordinary longevity. The seven main bearings supporting the crankshaft ensure minimal flexing and bearing wear even after hundreds of thousands of miles.

The timing chain design, while occasionally requiring replacement at very high mileages, generally proves more durable than belt-driven counterparts.

The cooling system, when properly maintained with BMW’s specified coolant and preventative replacement of plastic components, provides consistent temperature control that prevents the head warping issues common in lesser designs.

What’s particularly impressive about the M52/M54 family is their tolerance for varied driving conditions.

Whether subjected to daily short trips, high-speed autobahn cruising, or occasional track use, these engines deliver consistent performance and reliability when maintained according to BMW’s specifications.

Documented examples exceeding 300,000 miles without internal repairs are common in enthusiast communities.

These engines’ character as they age also distinguishes them from competitors. Even high-mileage examples retain the smooth power delivery and distinctive inline-six sound that make BMW engines special.

Oil consumption typically remains minimal, and compression readings often stay within factory specifications even after 200,000+ miles.

While more powerful and efficient engines have succeeded them, the M52/M54 family represents a sweet spot in BMW’s engineering history sophisticated enough to deliver engaging performance but simple enough to provide exceptional reliability.

Their continued presence in collector-worthy BMWs decades after production speaks to their enduring quality and appeal.

8. Toyota 1UZ-FE V8

The Toyota 1UZ-FE 4.0-liter V8 stands as perhaps the most overbuilt production engine in automotive history.

Developed during Japan’s economic bubble era when cost was no object, this engine powered Lexus LS and GS models from 1989 through 2002, establishing new benchmarks for luxury car refinement and reliability that competitors struggled to match.

What makes the 1UZ-FE extraordinary is its no-compromise engineering. The all-aluminum block features six main bearing caps with 24 bolts securing the crankshaft design overkill that ensures minimal movement even under extreme loads.

The dual overhead cam design with four valves per cylinder was cutting-edge for its era, delivering 250-290 horsepower (depending on generation) with exceptional smoothness.

Perhaps most impressive was Toyota’s obsessive focus on durability testing: the engine was designed to run at redline for 24 hours without failure a standard that exceeded even aviation requirements.

Several engineering decisions contribute to the 1UZ-FE’s legendary toughness. The timing belt, despite being a worn item, was conservatively designed with replacement intervals double those of contemporary engines.

The cooling system features precise flow control that prevents hot spots and ensures consistent cylinder head temperatures.

The oiling system provides generous lubrication even under high G-forces, protecting critical bearings during aggressive driving.

What’s particularly remarkable about the 1UZ-FE is that its durability wasn’t achieved by detuning or simplifying the design.

Despite its sophisticated features including exotic materials, six-bolt connecting rods, and high-flow cylinder heads the engine delivers Mercedes-shaming reliability.

This combination explains why many examples exceed 300,000 miles without internal repairs, and some documented cases have surpassed 1,000,000 miles with original internals.

The engine’s versatility further demonstrates its robust design. Though originally engineered for luxury sedan duty, the 1UZ-FE has found its way into everything from drift cars to boats to experimental aircraft, often handling power increases of 50% or more without requiring internal strengthening.

This adaptability speaks to the massive engineering margins Toyota built into the original design.

As automotive manufacturers increasingly prioritize cost-efficiency over absolute quality, the 1UZ-FE represents a high-water mark for internal combustion engineering a reminder of what’s possible when durability and refinement take precedence over production economies.

Its legacy lives on in Toyota’s continued reputation for reliability and in the thousands of examples still providing smooth, trouble-free service decades after manufacture.

9. Honda K-Series Inline-Four

The Honda K-Series engines represent the evolution of Honda’s naturally aspirated expertise into a remarkably durable yet high-performance package.

Introduced in 2001 and still in production in various forms, these 2.0-2.4 liter inline-four engines power everything from humble Civics to the razor-sharp S2000 successor, the Civic Type R, combining surprising power with legendary Honda reliability.

What makes the K-Series special is how it delivers exceptional performance without sacrificing longevity.

The all-aluminum block features a die-cast construction with iron cylinder liners and extensive webbing for rigidity.

The cylinders are siamesed (sharing walls) for compact packaging but incorporate cooling passages designed to prevent the hot spots that typically plague such designs.

The crankshaft rides on five main bearings substantial support for a four-cylinder and connects to the pistons via strong connecting rods designed to handle far more than stock power levels.

Several innovations contribute to the K-Series’ durability. The timing chain (rather than a belt) design typically lasts the life of the engine when properly maintained.

The VTEC variable valve timing system, while complex on paper, demonstrates remarkable reliability even with hundreds of thousands of cycles.

Perhaps most importantly, Honda’s legendary manufacturing precision ensures consistent quality across production runs.

What’s particularly impressive about the K-Series is its adaptability across driving conditions. From daily commuters that see nothing but stop and go traffic to track-day weapons subjected to sustained high-RPM operation, these engines deliver consistent performance and reliability.

Many documented examples have exceeded 300,000 miles with nothing more than regular maintenance, often while maintaining their factory power output and minimal oil consumption.

The K-Series also demonstrates exceptional tolerance for modification a true test of inherent design strength.

Even when subjected to forced induction that doubles or triples the factory horsepower, the bottom end often remains reliable with minimal reinforcement.

This overbuilt nature explains why the K-Series has become a popular swap choice for numerous Honda platforms.

As the automotive industry transitions toward electrification, the K-Series represents one of the finest examples of naturally aspirated engineering proof that with proper design and manufacturing, an engine can deliver both thrilling performance and decade-spanning reliability.

Its continued production in an era of downsized turbocharged alternatives speaks to its enduring excellence.

10. Mazda BP/BP-ZE Inline-Four

The Mazda BP series engines, particularly the high-performance BP-ZE variant, represent an often overlooked engineering triumph that delivered exceptional durability despite sporting pretensions.

Powering the Mazda MX-3, Protegé, and most famously the first-generation Miata from 1989 through the early 2000s, these 1.8-liter naturally aspirated four-cylinders demonstrated that sports car reliability needn’t involve compromise.

What makes the BP-ZE remarkable is its fundamentally sound design combined with Mazda’s meticulous engineering.

The iron block provides exceptional rigidity and durability, while the aluminum 16-valve DOHC head offers efficient breathing and surprising power for its displacement, particularly in the 130-140 horsepower BP-ZE used in performance applications.

The undersquare design (longer stroke than bore) creates excellent torque characteristics while keeping piston speeds manageable, reducing mechanical stress during high-RPM operation.

Several design elements contribute to the BP’s legendary toughness. The timing belt, while a maintenance item, is conservatively designed with reasonable replacement intervals.

The oiling system provides excellent lubrication even during sustained high-RPM driving and high lateral G-forces common in Miata track use.

The cooling system features precisely engineered flow that prevents hot spots and ensures consistent cylinder head temperatures even during demanding driving.

What’s particularly impressive about the BP-ZE is its durability despite enthusiastic use. Miatas are frequently subjected to aggressive driving, track days, and even amateur racing, yet the engines routinely exceed 200,000 miles without internal repairs.

Oil consumption typically remains minimal, and compression readings often stay consistent even in high-mileage examples.

The BP’s serviceability further enhances its longevity. With accessible components, straightforward maintenance procedures, and excellent parts availability, these engines reward attentive owners with seemingly indefinite service lives.

This combination of durability and repairability has made the first-generation Miata one of the most popular entry-level race cars worldwide.

While not as powerful as modern alternatives, the BP series engines represent a sweet spot in naturally aspirated design sophisticated enough to deliver engaging performance but simple enough to provide exceptional reliability.

Their continued presence in grassroots motorsport decades after production speaks to their enduring quality and the sound engineering principles that guided their development.

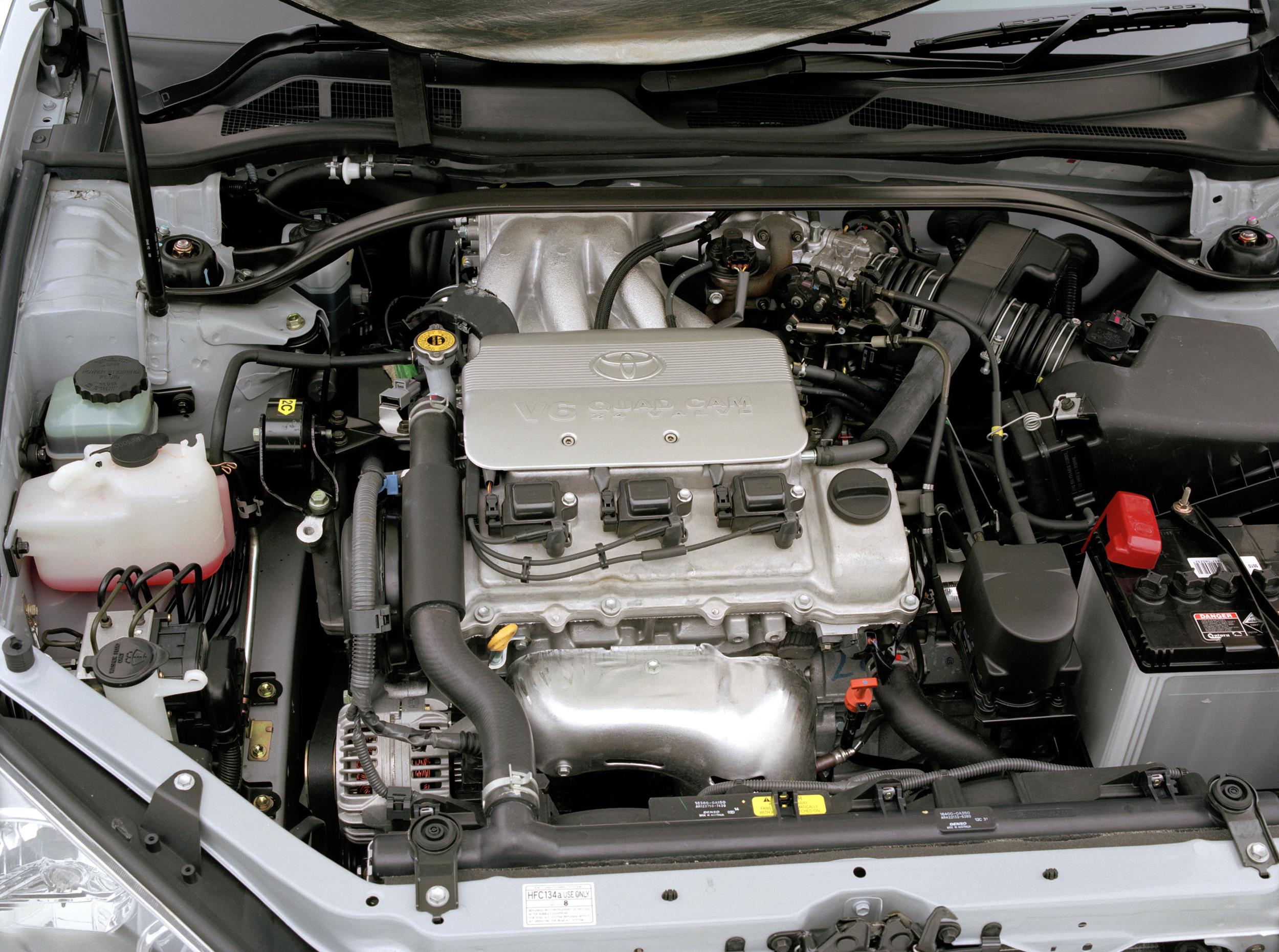

11. Toyota 1MZ-FE V6

The Toyota 1MZ-FE 3.0-liter V6 represents one of the most versatile and dependable naturally aspirated engines of the modern era.

First introduced in 1994 and produced until 2007, this powerplant became Toyota’s workhorse across numerous platforms, from the Camry and Avalon sedans to the Sienna minivan and Lexus ES/RX models, combining smooth performance with extraordinary longevity.

What makes the 1MZ-FE special is its perfect balance of sophistication and durability. The all-aluminum construction provides lightweight performance without compromising strength, while the 60-degree V configuration delivers inherent balance that contributes to the engine’s legendary smoothness.

The dual overhead cam, 24-valve design created respectable power for its era (around 200 horsepower) while maintaining exceptional reliability.

Several engineering details contribute to the 1MZ-FE’s remarkable durability. The timing belt, while a maintenance item, was designed with conservative service intervals and rarely causes issues when replaced as scheduled.

The cooling system features precise flow management that prevents hot spots and ensures consistent cylinder head temperatures.

The oiling system provides generous lubrication to critical components, preventing premature wear even in high-mileage examples.

What’s particularly impressive about the 1MZ-FE is its indifference to driving conditions. From taxi fleets accumulating massive mileage in punishing stop and go traffic to family vehicles subjected to long highway trips, these engines deliver consistent performance and reliability across vastly different use cases.

Documented examples exceeding 300,000 miles with original internals are common, and some have surpassed 500,000 miles with basic maintenance.

The 1MZ-FE’s refinement also distinguishes it from many durable counterparts. Unlike some long-lasting engines that sacrifice smoothness or quietness for longevity, this V6 maintains its silky power delivery and hushed operation throughout its lifespan.

This combination made it particularly suitable for Lexus luxury applications, where NVH (noise, vibration, harshness) standards were exceptionally high.

Though it lacks the performance pedigree of some engines on this list, the 1MZ-FE represents Toyota engineering at its most balanced delivering sufficient power, exceptional smoothness, and remarkable durability in equal measure.

Its legacy lives on in the millions of vehicles still providing reliable transportation decades after manufacture, often with their original engines performing flawlessly despite astronomical mileages.

12. Ford 4.0L SOHC “Cologne” V6

The Ford 4.0-liter SOHC “Cologne” V6 stands as one of the most rugged naturally aspirated engines ever fitted to mass-market vehicles.

Evolved from a design dating back to the 1960s but thoroughly modernized in the 1990s with single overhead cam heads, this engine powered Ford Rangers, Explorers, Mustangs, and other vehicles from 1990 through 2010, earning a reputation for exceptional longevity in punishing conditions.

What makes the 4.0 SOHC special is its no-nonsense, overbuilt design. The iron block and substantial internal components prioritize durability over weight savings, while the relatively low output (around 205-210 horsepower) ensures the engine rarely operates near its mechanical limits.

The single overhead cam conversion of the older pushrod design created a unique hybrid of traditional ruggedness with improved breathing and efficiency.

Several engineering details contribute to the engine’s legendary toughness. The massive iron block provides exceptional rigidity and superior heat dissipation compared to aluminum alternatives.

The timing chains, while occasionally requiring replacement at high mileage, generally outlast timing belts used in competing designs.

The cooling system features a large-capacity radiator and water pump that prevent the overheating issues common in lesser engines.

What’s particularly impressive about the 4.0 SOHC is its tolerance for less-than-ideal operating conditions.

From off-road use in Rangers and Explorers to towing applications exceeding recommended limits, these engines demonstrate remarkable resilience when faced with challenges that would quickly destroy less robust designs.

This forgiving nature makes them particularly well-suited to work vehicles and applications where maintenance might be delayed or performed under less than ideal circumstances.

The 4.0 SOHC’s serviceability further enhances its longevity. With accessible components, straightforward repair procedures, and excellent parts availability, these engines can be economically maintained almost indefinitely.

Even when issues do develop, they typically affect peripheral components rather than the basic engine structure, allowing for cost-effective repairs rather than complete replacements.

While lacking the refinement, efficiency, or specific output of more modern designs, the 4.0 SOHC represents an engineering philosophy increasingly rare in today’s automotive landscape one that prioritizes decade-spanning durability over cutting-edge performance or efficiency.

The engine’s continued prevalence in high-mileage work vehicles speaks to its success in delivering on this mission.

Also Read: 10 SUVs That Retain Their Value Better Than Any Other Vehicles