Tesla edges closer to a breakthrough with its self-driving software, instilling confidence in Elon Musk regarding the company’s ability to achieve vehicle autonomy. The success of FSD Beta also bolsters Tesla’s robotaxi ambitions, with the electric vehicle (EV) manufacturer seeking partnerships to materialize the next-generation EVs.

On the battery front, CATL emerges as the leading contender for partnership, thanks to its high-performance, cost-effective LFP cells. Since Elon Musk introduced Master Plan Part Deux in 2016, Tesla has contemplated the idea of an affordable electric vehicle.

However, challenges such as the 2020 health crisis and subsequent supply chain disruptions inflated car prices significantly. By 2022, Tesla could have doubled the price of its electric vehicles and still struggled to meet demand, rendering the notion of an affordable EV impractical.

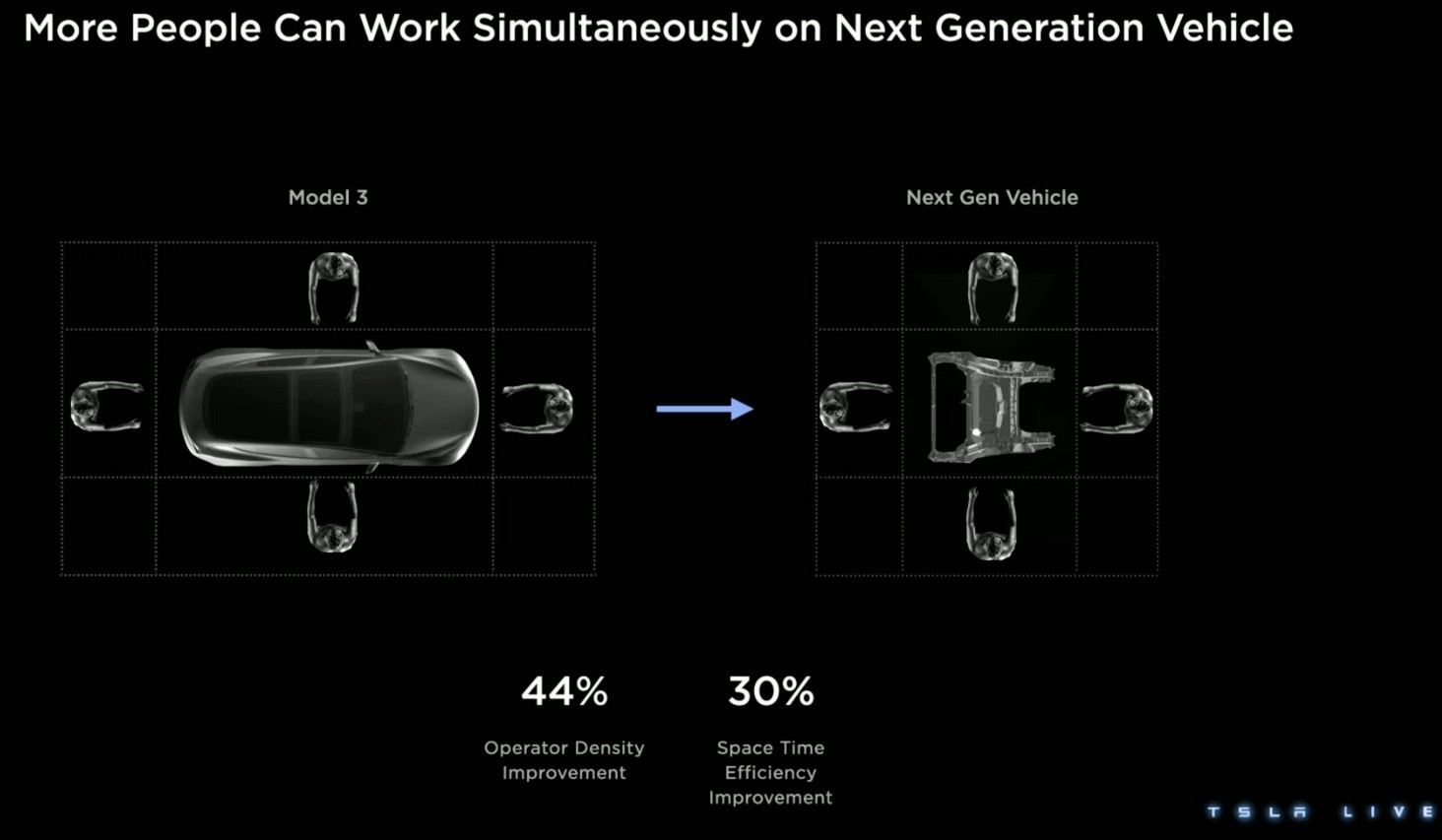

Nevertheless, recognizing the imperative of an affordable EV to Tesla’s ambitious goal of producing 20 million cars annually by 2030, Musk eventually acquiesced to the idea. The announcement made during Investor Day on March 1 revealed plans for a new gigafactory in Mexico and an innovative unboxed vehicle manufacturing process.

Subsequent revisions saw the production of the next-generation EV shifted to Giga Texas from Giga Mexico, aimed at expediting development. Rumors now suggest trial production commencing in June 2025. Codenamed Project Redwood internally, details on the mass-market electric car remain scarce, but its sustainability hinges on cost-effectiveness, necessitating careful consideration of production locations.

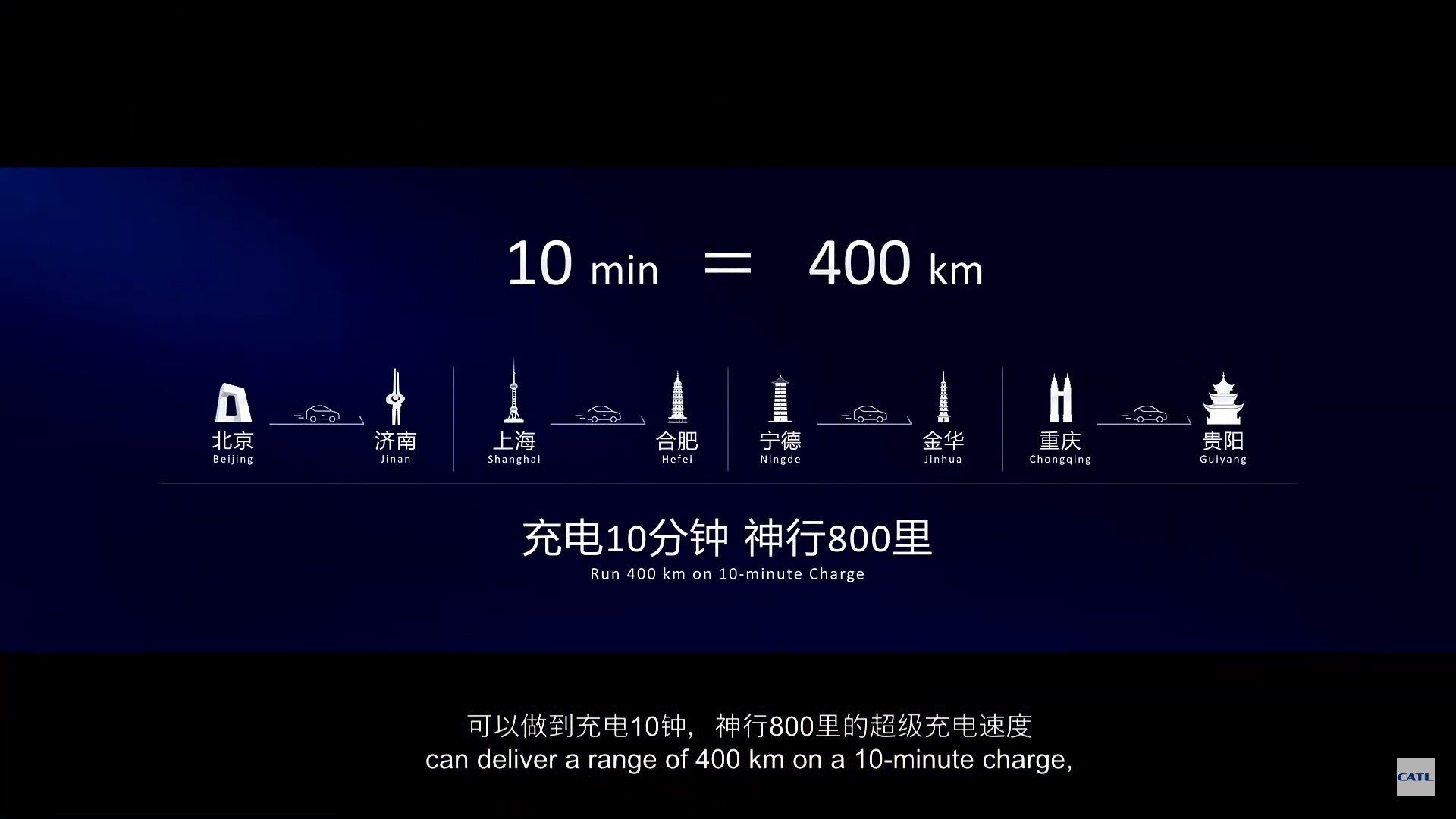

Central to cost efficiency is the selection of suppliers and components, with the battery pack representing a critical component. Tesla contemplates employing lithium-iron-phosphate (LFP) cells for its Gen-3 vehicles, leveraging their cost advantage over NMC cells. Notably, advancements in LFP technology have enhanced competitiveness, with CATL emerging as Tesla’s preferred LFP cell supplier for the $25,000 model.

Reports indicate Tesla’s plans to expand battery production in Sparks, Nevada, using idle equipment from CATL, albeit primarily for research purposes given its limited capacity. Collaborative efforts between CATL and Tesla aim to further enhance LFP chemistry, facilitating faster charging and higher energy density, underscoring the strategic partnership’s significance.